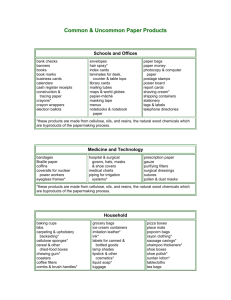

Wood and Cellulose: Building Blocks for Chemicals, Fuels and Advanced Materials

advertisement