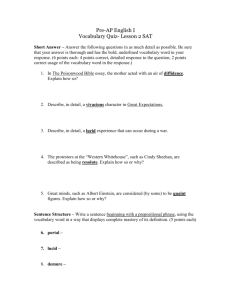

Resolute Linear Columns Automated chromatography columns for pilot and process scale

advertisement

USD 3001 Resolute® Linear Columns Automated chromatography columns for pilot and process scale The Resolute Linear column range offers a unique combination of active multi-axis piston control, precision linear actuation and fully automated unit operations that delivers the following benefits to the end-user: ` Fully scalable technology ` Quiet, clean operation ` Reduced operator involvement and error ` Predictable time efficient packing Overview Software Resolute Linear chromatography columns are designed for largescale pilot and production use. The range is available from 400 to 1200mm internal diameter, in all common sizes. The columns utilize the proven Resolute wetted flowpath providing low pressure drop and high-resolution chromatography over a wide range of normal operating flow rates. The typical flow range is from 30 - 800 cm/hr. In a departure from more traditional HMI and control cabinet configurations, control of a Resolute Linear column is performed using a handheld touch screen remote control, from which the operator can initiate all the inbuilt Resolute functionality; including fully automated packing, unpacking, CIP and hoist-free maintenance. The patented Resolute nozzle system is used, with identical remote controlled three position nozzles at the top and bottom of the column. This technology allows packing and unpacking without opening the column. The remote control is universal and can be used on all Resolute Linear columns. The software is purpose coded for the remote control and is designed to be intuitive. For example, all operator actions and commands are a maximum of four clicks away from the home screen, making navigation and operation as easy as possible. Integrated into the remote control is a safety enable system that prevents operation while the operator is absent; this can be disabled on request. Resolute Linear columns support both fixed and variable geometry pack in place methodology, however the platform has been specifically designed to fully exploit the capabilities of Resolute AutoPak; a one touch system for the fully automated packing, unpacking and CIP of the Resolute range of actuated columns. Where AutoPak is specified a packing skid is not required. A standard Resolute Linear column comes with the Resolute AutoPak system, 20µm polyethylene sinters, an acrylic tube, 3 bar operating pressure and 100-400mm packed bed capability (100-500mm packed bed capability for non-AutoPak columns). A range of material options and accessories is available to configure Resolute Linear to your requirements. Multi-Axis Control Precision control of the piston is delivered by three linear actuators, which operate in unison through the control software to deliver class-leading piston movement stability. This technology is fully scalable across the entire range of columns. The software actively monitors and controls the position of the actuators to ensure that the piston is always kept level. This provides a distinct advantage over central single actuator designs, where the piston is held level solely by passive seal action and design stiffness. Figure 2: Resolute Linear Remote Control Resolute Linear Feature Benefit Active multi-axis levelling control of piston, delivering class leading stability Fully scalable column design, reduced risk of column damage over single axis designs Small footprint, no cooling liquid required, no risk of oil leakage Safe operator environment, small cleanroom footprint Easier operator training, reduced risk of operator error Electric only control unit and linear actuators In built maintenance, enabling consumable change out from ground level Intuitive software Figure 1: Cut through of a linear actuator 2 Resolute Linear with AutoPak The AutoPak system was developed in direct response to an industry need for fully automated operations. Often key column preparation operations, particularly packing, are regarded as high risk clean room events. These risks include human error, packing failure, and absence of experienced operators; they can result in plant downtime, loss of product or sorbent and inefficient use of resources. By adopting a fully automated approach, the AutoPak system greatly simplifies operation, effectively eliminates operator error and reduces the burden on key operators. The automated sequences assure that reproducible and consistent operation is the norm. Figure 3: Typical Configuration Of A Resolute Linear Column With Integrated AutoPak The scope of the installation above shows a Resolute Linear column with the AutoPak system, remote control and column mounted valve control accessory. The illustration should not be interpreted as a process and instrumentation diagram. AutoPak System Feature Benefit Fully automated packing unpacking and CIP Greatly simplified operator interaction Ability to use all the sorbent in the tank Simplified pipework over pump pack methods Multiple fully configurable packing methods Reproducible results, reduced time for column packing Risk of operator error reduced, fewer operators required Reduction in media costs Quicker, error free set-up Future-proofed ability to easily adjust to changing plant requirements, ability to pack a wide range of sorbents www.pall.com/biopharm 3 Maintenance Wetted Pathway Options Hoist-Free Maintenance Mode The following wetted pathway options are available. All Resolute Linear columns have a patented maintenance function inbuilt, allowing access to major consumable spare parts from ground level, without the need for an external crane or hoist. The maintenance function provides: ` assured operator safety ` foot print efficiency Wetted Stainless Steel Component Options* Can be applied to column tubes, bed supports, nozzle tubes and pipework kits. As standard, columns are supplied with 1.4404 components. Stainless Steel (1.4404, 316L) Entry into maintenance mode is made through easily followed instructions on the handheld remote control. The column is disassembled using the Linear drives without increasing the column footprint. The list of key consumables and part numbers for the standard Linear column range is provided in the list below. Maintenance schedules are advised in the operating manuals. Stainless Steel (1.4435, 316L) - not available for meshes Stainless Steel (1.4539, 904L) Stainless Steel (C22, Hastelloy) Increasing chloride resistance * Stainless steel options are quoted on request. Bed Support Pore Size Options Bed supports are available in 10 micron and 20 micron pore sizes. The mesh should be selected based on the sorbent average particle size; generally a bed support size < 1/3 of the average particle size is sufficient to prevent particle flow through. For example, for a 90µm sorbent, 20µm bed supports would be specified, for a 34µm media 10µm bed supports would be specified. Note that the difference between a 10 and 20 micron bed support pore size makes a negligible difference in overall column pressure drop. Key Accessories Linear Remote Control The remote control is the master controller for Resolute Linear column and allows the full scope of operations to be initiated and monitored. At least one remote control must be purchased for each set of columns. If packing, unpacking or CIP is to take place simultaneously on more than one column, then additional remote control(s) should be purchased as required. Model Number Description Columns Applicable LD-HMI Resolute Linear Remote Control All Figure 4: Resolute Linear 1000 in Maintenance Mode Figure 5: Resolute Linear Remote Control 4 Column Mounted Valve Control The touch screen device is fitted permanently to the column, and allows the process valving and nozzles to be controlled when the remote control unit is not connected. This permits the remote control unit to be used with other columns. This option should be obtained when multiple columns are purchased and only one column is packed at a time. Model Number Description Columns Applicable LD-VC Resolute Linear Column Mounted Valve Control Kit All Figure 7: AutoPak Tank Valve Block Resolute Drive Station The Resolute Linear Drive Station supplies the power and drive control for the three linear actuators. One Drive Station can operate all columns sizes, therefore, at least one drive station must be purchased for each set of columns. If packing, unpacking or CIP is to take place simultaneously on more than one column, then additional drive stations are required as necessary. The drive station is not required when the column is in process mode. However a separate 24V power supply will be required to operate valves and nozzles using the Resolute Linear Remote Control or Column Mounted Valve Control. Figure 6: Column Mounted Valve Control AutoPak Tank Valve Block The AutoPak tank valve block provides the ability to switch between buffer and slurry while controlling the agitation in the tank. Included with the column is the valve block, mounting, hoses to connect to the column tanks and associated clamps and EPDM gaskets. As standard, pipework and GEMU block valves are included in 316L (1.4404) stainless steel. If an alternative stainless steel is selected then the material change must be stated at the point of order. The external material of the cabinet is stainless steel, suitable for wipedown, and use in a clean environment. The cabinet is rated to the requirements IP65. The drive station is a discrete unit which occupies minimal floor space and requires only an electrical supply to operate. Model Number Description Columns Applicable EPU Resolute Linear Drive Station All At least one AutoPak tank valve block must be purchased for each set of AutoPak columns. If packing, unpacking or CIP is to take place simultaneously on more than one column, then additional valve blocks should be purchased as necessary. Model Number Description Columns Applicable TVB-1 TVB-2 AutoPak Tank Valve Block AutoPak Tank Valve Block <800 >800 Figure 8: Resolute Drive Station www.pall.com/biopharm 5 Non-AutoPak Valve Kits For Resolute Linear columns that are selected without the AutoPak system, a valve kit is available to facilitate process and packing connections. This kit enables manual selection of column online and bypass modes and provides the required burst disk* pressure relief. It is recommended for both chromatography skid connection and packing operations. As standard, pipework and GEMU block valves are included in 316L (1.4404) stainless steel with all necessary EPDM gaskets, clamps and mounting brackets. If an alternative stainless steel is selected then the material must be stated at the point of order. This kit is factory fitted, and shipped with the column. Model Number Description Columns Applicable LD-PFK-XXXX** Resolute Linear Pipe and Manual Valving Kit All * Pressure relief valves can be quoted on request. ** XXXX = column diameter in mm Additional Accessories Other accessories such as column transport options, slurry tanks, packing skids, bed support transporters and media handling solutions are available upon request. Please contact your local Pall representative or www.pall.com for more information. The picture below shows a Resolute Linear column being moved by an operator using a MasterMover. This makes moving the columns a safe and operator friendly activity. Figure 9: Resolute Linear with a MasterMover◆ 6 Consumables Name ADJ PE bed support 20µm kit ADJ 316L bed support 20µm kit FIXED PE bed support 20µm kit FIXED 316L bed support 20µm kit Snap ring for PE sinters Snap ring for SS meshes Wiper ring for PE sinters Wiper ring for SS meshes Major seal kit (adjuster main seals and fixed end main seals) Intermediate fixing screw kit Nozzle tip kit Nozzle valve seal kit Name ADJ PE bed support 20µm kit ADJ 316L bed support 20µm kit FIXED PE bed support 20µm kit FIXED 316L bed support 20µm kit Snap ring for PE sinters Snap ring for SS meshes Wiper ring for PE sinters Wiper ring for SS meshes Major seal kit (adjuster main seals and fixed end main seals) Intermediate fixing screw kit Nozzle tip kit Nozzle valve seal kit 400 Part No 450 Part No 500 Part No 600 Part No 630 Part No EEA14A136A13 EEA14A139A13 EEA14A142A13 EEA14A145A13 K400-3033 K400-3012 EEA12A181A129 EEA12A181A129 EEA14A136A27 EEA14A139A27 EEA14A142A27 EEA14A145A27 Contact Pall K450-4058 EEA12A181A252 EEA12A181A252 EEA14A136A37 EEA14A139A37 EEA14A142A37 EEA14A145A37 Contact Pall K500-3011-03 EEA12A181A253 EEA12A181A253 EEA14A136A14 EEA14A139A14 EEA14A142A14 EEA14A145A14 K600-3013 K600-3012 EEA12A181A130 EEA12A181A130 EEA14A136A189 EEA14A139A189 EEA14A142A189 EEA14A145A189 Contact Pall K630-3025 EEA12A181A254 EEA12A181A254 EEA12A155A129 N/A EEA13A159A20 EEA12A152A20 EEA12A155A252 N/A EEA13A159A20 EEA12A152A20 EEA12A155A253 N/A EEA13A159A21 EEA12A152A21 EEA12A155A130 N/A EEA13A159A21 EEA12A152A21 EEA12A155A254 N/A EEA13A159A21 EEA12A152A21 700 Part No 800 Part No 1000 Part No 1200 Part No EEA14A136A227 EEA14A139A227 EEA14A142A227 EEA14A145A227 Contact Pall K700-3073-01 EEA12A181A255 EEA12A181A255 EEA14A136A15 EEA14A139A15 EEA14A142A15 EEA14A145A15 K800-3075-01 K800-3249 EEA12A181A131 EEA12A181A131 EEA14A136A16 EEA14A139A16 EEA14A142A16 EEA14A145A16 K1000-3023-02 K1000-3023 EEA12A181A132 EEA12A181A132 EEA14A136A17 EEA14A139A17 EEA14A142A17 EEA14A145A17 K1200-3067 K1200-3039 EEA12A181A133 EEA12A181A133 EEA12A155A255 EEA13A220A15 EEA13A159A21 EEA12A152A21 EEA12A155A131 EEA13A220A15 EEA13A159A22 EEA12A152A22 EEA12A155A132 EEA13A220A16 EEA13A159A24 EEA12A152A24 EEA12A155A133 EEA13A220A17 EEA13A159A23 EEA12A152A23 www.pall.com/biopharm 7 Specifications Table 1: Weights and Dimensions The table below provides indicative dimensions and weights for the standard range. For additional diameters and bed heights, please contact your Pall representative for an engineered solution. Weight Empty Footprint Smallest Dimension Not Inc. Valves Heights Length Depth At Minimum Height Type kg mm mm mm Drive station 90 510 600 850 400 400 with AutoPak 450 450 with AutoPak 500 500 with AutoPak 600 600 with AutoPak 630 630 with AutoPak 700 700 with AutoPak 800 800 with AutoPak 900 900 with AutoPak 1000 1000 with AutoPak 1200 1200 with AutoPak 580 700 650 780 720 860 860 1030 1060 1270 1270 1520 1680 2010 1970 2370 2270 2730 3550 4250 840 840 880 880 920 920 1010 1010 1100 1100 1180 1180 1360 1360 1440 1440 1510 1510 1800 1800 1050 1050 1050 1050 1050 1050 1060 1060 1150 1150 1250 1250 1450 1450 1480 1480 1510 1510 1780 1780 1700 2000 1700 2000 1700 2000 1700 2000 1760 2040 1820 2070 1930 2140 1940 2150 1950 2160 2180 2410 At Maximum Packed bed Height Maximum Height During Maintenance mm mm 2200 2750 2200 2750 2200 2750 2200 2750 2260 2790 2320 2820 2430 2890 2440 2900 2450 2910 2680 3160 2200 2550 2200 2540 2200 2530 2200 2510 2270 2560 2340 2600 2470 2700 2540 2700 2620 2700 2870 2960 Table 2: Materials of Construction Table 3: Standard Surface Finishes Process Wetted Fixed Components Material Stainless Steel* Column tube Distribution cell Nozzle body Non-wetted Wetted Mobile phase termination Slurry nozzle tip Slurry inlet port Main seals Nozzle tip seals Wiper ring Acrylic (PMMA) / Stainless Steel* Polypropylene 480 – 1000 mm Ø Column: PVDF 1200 mm Ø Column: Polypropylene 480 – 1000 mm Ø Column: PEEK 1200 mm Ø Column: Stainless Steel 316L PEEK 400 – 1200 mm Ø Column: Stainless Steel 316L* EPDM (Peroxide Cured) / FEP FEP Encapsulated Silicone PTFE All non-wetted materials are suitable for wipe down and clean room use. * Different grades of stainless steel are available. See Wetted Pathway Options. 1.5 micron Ra 0.5 micron Ra Plastics Acrylic (PMMA) All others Polished smooth Not applicable *Improved surface finishes quoted on request. Certification & Technical Construction File Resolute Linear columns can be designed to meet either of the following pressure vessel codes. ASME Boiler & Pressure Vessel Code 2013 addition. PD 5500: 2012 + A2: 2013 All columns and accessories come with a full technical documentation file. Examples are available on request. 8 Table 4: Operating Temperature Ambient Temperature Ranges Operating Temperature Static* Operating Temperature Dynamic** 2 - 30ºC 15 - 25ºC * The static temperature range refers to when the column is in process mode and no piston movement will take place. ** The dynamic temperature range refers indicates the acceptable temperature range when the column piston is moving. Temperature ranges outside of these values above are quoted upon request. Columns can be designed for operational ranges up to 60 degrees C. Visit us on the Web at www.pall.com/biopharm E-mail us at biopharm@pall.com Corporate Headquarters Port Washington, NY, USA +1.800.717.7255 toll free (USA) +1.516.484.5400 phone biopharm@pall.com e-mail European Headquarters Fribourg, Switzerland +41 (0)26 350 53 00 phone LifeSciences.EU@pall.com e-mail Asia-Pacific Headquarters Singapore +65 6389 6500 phone sgcustomerservice@pall.com e-mail International Offices Pall Corporation has offices and plants throughout the world in locations such as: Argentina, Australia, Austria, Belgium, Brazil, Canada, China, France, Germany, India, Indonesia, Ireland, Italy, Japan, Korea, Malaysia, Mexico, the Netherlands, New Zealand, Norway, Poland, Puerto Rico, Russia, Singapore, South Africa, Spain, Sweden, Switzerland, Taiwan, Thailand, the United Kingdom, the United States, and Venezuela. Distributors in all major industrial areas of the world. To locate the Pall office or distributor nearest you, visit www.pall.com/contact. The information provided in this literature was reviewed for accuracy at the time of publication. Product data may be subject to change without notice. For current information consult your local Pall distributor or contact Pall directly. , Pall and Resolute are trademarks of Pall Corporation, Filtration.Separation.Solution. is a service mark of Pall Corporation, ® indicates a trademark registered in the USA, © 2014 Pall Corporation, MasterMover is a Registered Trade Name of MasterMover. 09/14, PDF, GN14.9516 USD 3001