Use of Boolean Logic and Probabilistic Analysis in work

advertisement

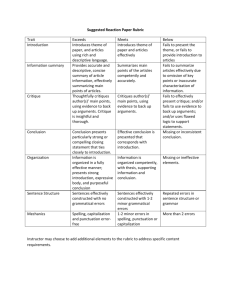

Use of Boolean Logic and Probabilistic Analysis in work During my YINI placement I have been working in the Safety Case Team for Hinkley Point B and Hunterston B nuclear power stations at British Energy – part of EDF Energy, the owner and operator of eight nuclear power stations in the UK. When designing and operating a nuclear power station, safety is a top priority. Modern power stations operate with the help of Probabilistic Safety Analysis (PSA). This enables the frequency of radiological releases to be calculated, and helps the Company keep the frequency of these events as low as reasonably practicable (ALARP), with a target of less than a 1 in a million chance of a significant release per year. The frequency of radiological releases is calculated using a PSA model on a computer. This program enables us to create fault trees using Boolean Logic. Once completed, a model will have hundreds of fault trees and event trees, and the probability of every conceivable hazard and its consequence can be calculated in minutes. The diagram below illustrates a simple fault tree with arbitrary values assigned. Probability of Emergency feed system failing = 0.1702 Emergency feed system fails OR 0.01 0.0602 Basic Event (e.g. a pipe leak or electrical failure) 0.1 No feed from pumps Valve 2 Fails OR Common Cause fault 0.0102 0.05 Probabilities multiply at AND gates Both pump trains fail Valve 1 Fails to open AND 0.101 0.101 Probabilities add at OR gates No feed from train A No feed from train B OR OR 0.1 0.001 0.1 0.001 Probability of event occurring (ie. probability of plant item failing) Pump A fails Valve A fails Pump B fails Valve B fails (Note that real probability values are much lower) This is a simple example of one fault tree. This fault tree would then connect to other fault trees and event trees in the model relating to different parts of the plant. Fault trees are particularly useful when planning maintenance. Suppose Pump B had to be taken offline for maintenance. One could use the PSA model to work out the probability of the emergency feed system failing if pump B is unavailable - see diagram below. Benjamin Brocklehurst MEI Mathematics at work competition 2010 Probability of Emergency feed system failing = 0.261 Emergency feed system fails OR 0.151 0.01 0.1 Increase ratio = 0.261/0.1702 = 1.533 No feed from pumps Valve 2 Fails OR Common Cause fault 0.101 0.05 Both pump trains fail Valve 1 fails to open AND FAILED 0.101 No feed from train A No feed from train B OR OR 0.1 Pump A fails 0.001 UNAV Valve A fails Pump B fails 0.001 Valve B fails By repeating this process on the full PSA model, it is possible to test the contribution each plant item has in reducing the frequency of events. The graph shows the % increase in events caused by unavailability of combinations of plant items. As shown in the graph, the frequency of events increases by over 2000% if plant items in case number 21 are made unavailable. Therefore the operating rules would forbid the operators from entering this condition as the frequency of events is no longer ALARP. Benjamin Brocklehurst % in c re a s e in e v e n t fre q u e n c y Making pump B unavailable does not fail the whole system because pump A is still functioning normally. However, the probability of the system failing has increased by a factor of 1.533 as only one pump is now available to feed the system. Therefore the operators would wish to carry out the maintenance of pump B as quickly as possible in order to keep the probability of the system failing ALARP. 2000.0% 1500.0% 1000.0% 500.0% 0.0% 1 4 8 11 14 17 20 23 26 29 32 35 38 41 44 47 50 53 56 59 62 Case No. MEI Mathematics at work competition 2010