Eskom Brackenfell Complex Lesson’s Learnt

advertisement

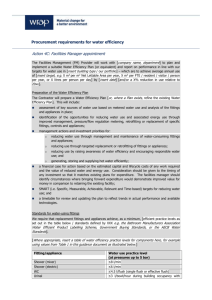

Eskom Brackenfell Complex Lesson’s Learnt Presented by : Riyaad Omer Senior Energy Advisor DSM Eskom 2011/08/01 1 Implementation Process – For Internal Efficiency Projects 1. Divisions to undertake audits to determine potential energy savings on a project by project basis (cost recovery for audits to be addressed as part of the project costs) including potential savings, technologies to be implemented and projected costs. 2. Prepare project proposal highlighting the business case for the proposed intervention including comparison with the existing DSM benchmarks 3. Register project proposal with M&V and obtain their input. 4. Measurement & Verification (M&V) must be addressed for all projects (costs need to be included in project budgets) in order for savings to be counted and reported. 5. Engage with the relevant energy efficiency experts (DSM, ERID etc.) to obtain technical approval in writing 5. Present to relevant divisional committees including investment committees to confirm the economic viability of the project 6. Funding to be released after divisional investment committee for approval 7. Divisions to procure equipment in line with procurement practices and implement projects 8. Monthly reporting to the EEC on the status of projects ESCO – Complete Audit and prepare a proposal Important to take Lux measurements M&V prepare baseline report Technology Overview 1. Lighting retrofitting • Replacement of old magnetic ballast to new more energy efficient electronic ballast 2. Install efficient lamps • The downlights was replaced with new generation low voltage lamps (IRC) provide 30% savings without a reduction in light output. The 50W dichroics was replaced with 35W low voltage lamps (IRC). • Energy saving fluorescent tubes called “Eco tubes”. These tubes were a direct replacement for the 1.2m (36W) to (32W) and 1.5m (58W) tubes to (51W) New Electronic Ballasts Technology Overview cont.. 3. Install efficient fittings • 400W Hi-Bay fittings with Mercury Vapour lamps will replaced with energy efficient “T-Bay fittings”. T-Bay fittings uses the latest T5 lamp technology and one fitting consists of 4 x 54W T5 linear fluorescent lamps and electronic control gear. • 1.8m and 2.4m fittings with T12 tubes are being phased out internationally due to the low energy efficiency. These fittings will be replaced with single or double 1.5 meter fittings with electronic control gear. Hi Bay Lights Removed Hi Bay Lamps Scissor Jack and Cherrie picker used in hard to get places Technology Overview cont.. 4. Active Lighting Control • The installation of occupancy sensors in strategic areas ensured that the lights were switched off when not used. 5. Active HVAC Control • Occupancy sensors will be installed in the circuit feeding an air conditioner in an office or area in order to switch it off when nobody is present. Import that each AC had it’s own motion sensor with contactor SHE Specification Planning important – Scaffolding, Cherrie picker crane Storage of Old Stock – Try to prevent stealing Counting of removed equipment Ensure save removal and crushing off site Scrapping of Magnetic Ballasts CFL’s and Flourescents Final M&V report Thank you http://www.eskomidm.co.za/