Instrumentation, Controls & Electrical

High-Speed Busbar Transfer System

Compact Solution

Using SIPROTEC 7SJ647

SPPA-E3000 Unit Protection & Synchronization

Compact High-Speed Busbar Transfer System

Using SIPROTEC 7SJ647

enables interruption-free transfer between the

independent incoming feeders of medium

voltage switchgear. This ensures a continuous

energy supply for the auxiliary section of power

plants and important industrial plants and

thereby safe functioning of the plant.

Functions

Three different configurations are possible:

■ Two incoming feeders on a Busbar

(principle 1 of 2)

■ Two incoming feeders and a sectionalizer

(principle 2 of 3)

■ Three incoming feeders on a Busbar

(principle 1 of 3)

The following transfer modes are possible:

■ Parallel transfer (sequential switching)

Benefits at a Glance

■ Low investment and operating costs

■ Compact dimensions – can be installed

directly in the medium-voltage switchgear

■ Simple wiring and engineering –

no additional components required

■ Fast installation and commissioning –

can be installed, wired and supplied with

the switchgear

■ Easy parameterization and operation –

using the same philosophy and software

as other SIPROTEC protection devices in

the switchgear

■ Wide variety of communication interfaces

for connection to the control system

(modules can also be retrofitted)

■ Time synchronization with the plant

control system (plant central clock)

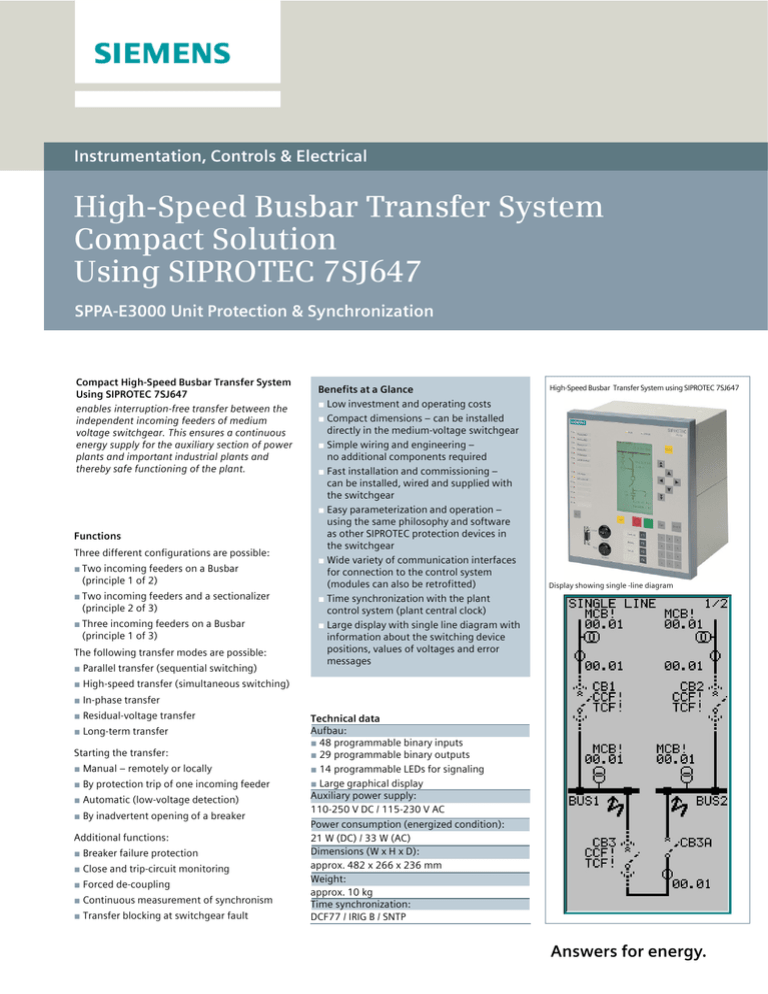

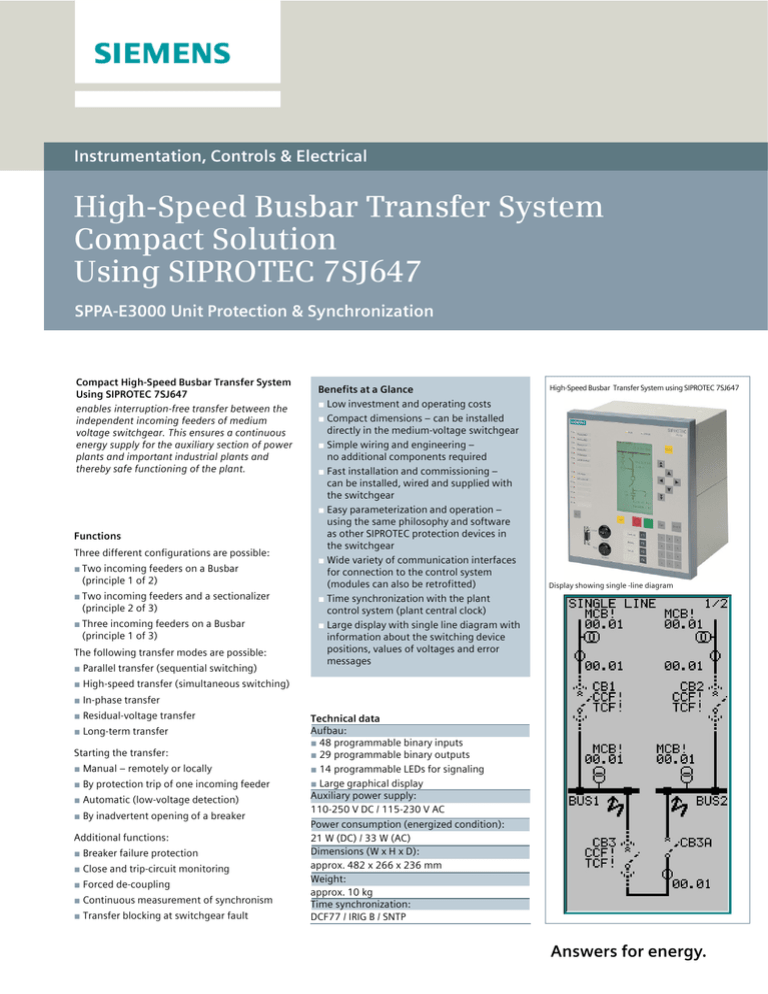

■ Large display with single line diagram with

information about the switching device

positions, values of voltages and error

messages

High-Speed Busbar Transfer System using SIPROTEC 7SJ647

Display showing single -line diagram

■ High-speed transfer (simultaneous switching)

■ In-phase transfer

■ Residual-voltage transfer

■ Long-term transfer

Starting the transfer:

■ Manual – remotely or locally

■ By protection trip of one incoming feeder

■ Automatic (low-voltage detection)

■ By inadvertent opening of a breaker

Additional functions:

■ Breaker failure protection

■ Close and trip-circuit monitoring

■ Forced de-coupling

■ Continuous measurement of synchronism

■ Transfer blocking at switchgear fault

Technical data

Aufbau:

■ 48 programmable binary inputs

■ 29 programmable binary outputs

■ 14 programmable LEDs for signaling

■ Large graphical display

Auxiliary power supply:

110-250 V DC / 115-230 V AC

Power consumption (energized condition):

21 W (DC) / 33 W (AC)

Dimensions (W x H x D):

approx. 482 x 266 x 236 mm

Weight:

approx. 10 kg

Time synchronization:

DCF77 / IRIG B / SNTP

Answers for energy.

Technical details

Construction

The compact high-speed busbar transfer system from the

SPPA-E3000 portfolio is based on the established Siemens SIPROTEC

7SJ647 multi-functional protection device and can be used for

interruption-free transfer between two or three circuit-breakers.

Up to four voltage sources as well as position contacts of

the individual switching devices are connected to the device.

The implemented logic ensures that the correct two voltage sources

are compared with each other at any time.

As this selection is an integral part of the transfer device, no

additional auxiliary relays are needed. This simplifies the

interconnection which in turn increases the reliability.

This transfer system can be used for three different switchgear

configurations.

Communication with the plant control system

Communication with the other feeder protection relays within the

switchgear and with the plant control system can be established by

using one of the many selectable communication interfaces. The

most common are IEC 61850, PROFIBUS DP or PROFIBUS FMS,

MODBUS, DNP 3, IEC 60870-5-103.

In addition, the device is equipped with a time synchronization

interface and can be synchronized with the plant‘s central clock.

Parametrization

The DIGSI software and the CFC programming language are used to

create the transfer logic and interlocking conditions for each individual

application and network configuration. The internal programmable

logic controller of the device provides a fast and reliable medium to

implement the specific customer requirements for each project.

Programming example

Possible Configurations

Incoming 1

Incoming 2

7SJ647

Incoming 2

Incoming 1

7SJ647

Oscillographic Recorder

For each changeover operation the data of full voltage waves,

command signals and circuit-breaker positions are stored in the

internal memory of the device. The capacity enables the storing of

up to 8 subsequent events each with a duration of 5 seconds. The

data and the graphical figures can be exported from the device and

can be analyzed by using the SIGRA software.

Analysis in SIGRA (example)

Sectionalizer

Incoming 1

Incoming 2

Incoming 3

7SJ647

Published by and copyright © 2013:

Siemens AG, Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Energy, Inc.

Instrumentation, Controls, & Electrical

1345 Ridgeland Parkway, Suite 116

Alpharetta, GA 30004, USA

For more information contact

sppa-er3000.energy@siemens.com

www.siemens.com/energy/sppa-e3000

E305_FP_HSBTS_e_V1-0

Order no. E50001-G230-A371-X-4A00

Printed in Germany

Dispo 05401, c4bs-Nr. 7465

Printed on elementary chlorine-free

bleached paper.

Unrestricted

AL:N ECCN:N

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should

therefore be specified in the contract.