-WOSUB- A SUBCHANNEL CODE FOR STEADY-STATE AND TRANSIENT THERMAL-HYDRAULIC ANALYSIS OF

advertisement

WO

· S

JU

-WOSUBA SUBCHANNEL CODE FOR STEADY-STATE AND

TRANSIENT THERMAL-HYDRAULIC ANALYSIS OF

BWR FUEL PIN BUNDLES

VOLUME III

ASSESSMENT AND COMPARISON

by

L. Wolf, A. Faya, A. Levine,

W. Boyd, L. Guillebaud

Energy Laboratory Report No. MIT-EL 78-025

October 1977

__I

_

___

I_

·

_I_

t

-WOSUBA SUBCHANNEL CODE FOR STEADY-STATE AND

TRANSIENT THERMAL-HYDRAULIC ANALYSIS OF

BWR FUEL PIN BUNDLES

VOLUME III

ASSESSMENT AND COMPARISON

by

L. Wolf, A. Faya, A. Levine,

W. Boyd, L. Guillebaud

Energy Laboratory Report No. MIT-EL-78-025

October 1977

Topical Report for Task 3 of the

Nuclear Power Reactor Safety Research Program

Sponsored by

New England Electric System

Northeast Utilities Service Co.

under the

M.I.T. Energy Laboratory Electric Power Program

-------

__

ii

ABSTRACT

The WOSUB-codes are spin-offs and extensions of the

MATTEO-code [1]. The series of three reports describe WOSUB-I

and WOSUB-II in their respective status as of July 31, 1977.

This report is the third in a series of three, the

first of which [2] contains all the information about the

models, solution methods and constitutive equations and the

second

[3] being the user's manual of the code.

This report summarizes the assessment of the WOSUBcode against experiments and compares its results with the

results of other subchannel codes.

The following experiments

are used for the purpose of the assessment

of the code under

steady-state conditions:

1) 9-rod GE-tests with radially uniform and nonuniform peaking factor patterns.

2)

16-rod Columbia

tests with slight power tilts.

3) Planned 9-rod Swedish tests with very strong

power tilts.

4)

Actually performed 9-rod Swedish tests with

power tilt.

5)

9-rod GE-CHF experiments.

The comparison with these data shows that WOSUB is capable of

predicting the lower-than-average behavior of the corner subchannel and the higher-than-average behavior of the center

subchannel for both quality and mass flux. None of the other

well-known subchannel codes is indeed capable of specifically

predicting the correct corner subchannel behavior.

These codes

seem to inherently suffer from major deficiencies associated

with their incorporated mixing models. Therefore, it is concluded that only improved models for the description

of two-

phase flow phenomena are capable of handling these situations

and that the vapor drift flux model together with the vador

diffusion model as incorporated into WOSUB is doing a good job.

The fact that WOSUB does not perfectly match the experimental

results over the whole spectrum of experimental evidence can

be attributed to the vapor diffusion model which was originally

fitted to air-water test results in a geometry consisting of

two subchannels only.

Obviously, this geometry leads to overemphasizing the importance of the vapor diffusion as compared

to what actually happens in a multi-rod geometry.

WOSUB gives the user the option of calculating

the

critical power as a function of the boiling length - a concept

which is especially useful to easily account for axially

___

_____

__

· ___

_

1_

1

iii

nonuniform power profiles and which closely resembles the

procedure now used by GE. Furthermore, the code determines

four heat transfer coefficients around the circumference of the

fuel pin, thus giving the user the possibility of selecting

the minimal one for the purpose of hot spot calculations.

Overall, the assessment and comparison presented in

this volume show that the WOSUB-code

has to be considered

a

valuable tool for BWR bundle and PWR test bundle analysis with

a potential for further improvements.

The commonly used concept of power-to-flow ratio

fails to explain most of the test data used for comparison

this report.

in

The WOSUB-code is still in the stage of evolutionary

development.

In this context, the results presented in this

present report have to be considered preliminary.

reflect the development

as of July 1977.

They

iv

ACKNOWLEDGEMENTS

The assessment

and comparison of the WOSUB-subchannel

code results was started in the Fall of 1976, when Louis

Guillebaud worked on his N.E. Thesis.

His preliminary results

were updated by Alan Levin who provided the additional subroutines for calculating the heat transfer coefficient and

the critical heat flux.

By his efforts the spectrum of the

assessment and the comparison was greatly enlarged.

He was succeeded by William Boyd in January 1977, who

largely concentrated his work on a parametric sensitivity study

of the drift flux parameters and their effects upon the overall

results.

When he left M.I.T., Artur Faya started working on

His first achievement,

his Ph.D. Thesis.

was to fully inte-

grate the fuel pin model into WOSUB thus making it possible

calculate pointwise

the first time.

assessment

temperatures

in fuel and clad regions for

Again, this step enlarged

of the code.

to

Furthermore,

the spectrum of the

he provided

all the

left

necessary help to collect all the pieces of information

from the others to put this report together.

To all these gentlemen I owe a great deal of gratitude for their devotion

as well as their tireless efforts in

accomplishing all these achievements.

would like to acknowledge the financial

Finally,

support as well as the fruitful discussions

by the New England

Electric System and Northeast Utilities Service Company as part

of the Nuclear

·--- ·---- I----_

-- -

I--

__

___

Eactor Safety Research

__

__

I

Pro-ram under the M.I.T.

_

v

Energy Laboratory's Electric Power Program.

Lothar Wolf

Principal Investigator

Associate Professor of

Nuclear Engineering

--111111··-···-LI

_1

_

__

I·

vi

TABLE OF CONTENTS

Page

Chapter 1

1.

Comparison of WOSUBResults with Steady-State Experiments

1.1

9-Rod GE Test Bundle Experiments

1.1.1

1.1.2

Introduction

Bundle and Test Description

1.1.3 Results for Isothermal Test Data

1.1.3.1 Comparison with Experiments

1.1.3.2 Comparison with Analytical Results and

Other Subchannel Codes

1.1.3.3 Conclusions

1.1.4 Results for Radially Uniform Peaking Factor Patterns

1.1.4.1 Overall Comparison

1.1.4.2 Detailed Subchannel Behavior and Comparison

1.1.4.2.1 Corner Subehannel

1.1.4.2.2 Side Subchannel

1.1.4.2.3

1.1.4.3

Center Subchar.nel

1

1

2

10

10

10

17

18

18

23

23

26

26

Comparison with Results of Other Subchannel

Codes

1.1.4.4 Conclusions

1.1.5 Results for Radially

30

35

Nonuniform Peaking Factor

Patterns

1.1.5.1

1.1.5.2

1

Comparison of WOSUB Results with the Experiment

Comparison with Other Subchannel Codes

1.2 16-Rod Columbia Test Bundle Experiment

1.2.1 Introduction

1.2.2 Description of the Bundle and Test Conditions

41

44

50

57

57

57

1.2.3

1.2.4

Results of the Experiment

Comparison of Columbia Tests with GE Tests

59

61

1.2.5

1.2.6

Comparison of COBRA-II with the Experiments

Comparison of WOSUB withthe Columbia Eeiments

and COBRA-IIIC/MIT

61

1.2.7

Conclusions

72

65

1.3

*

Planned 9-Rod Studsvik Test Bundle Experiments with

Strong Power Tilt

1.3.1 Introduction

73

73

1.3.2

1.3.3

1.3.4

76

76

88

Description of the Geometry and the Test Conditions

Comparison of WOSUB with Other Subchannel Codes

Conclusion

vii

Table of Contents continued

Page

1.4

Performed 9-Rod Studsvik Test Bundle Experiments with

Power Tilt

96

1.4.1

Introduction

1.4.2

Description

96

of the Geometry

and the Test Conditions

Comparison of WOSUB with the Experiment and the

Other Subchannel Codes

1.4.3.1 Comparison of the Quality Predictions

1.4.3.2 Comparison of Mass Flux Predictions

1.4.3.3 Comparison of Predicted Individual Subchannel

97

1.4.3

Qualities

1.4.3.4

1.4.4

1.5

113

Comparison with Predicted Individual Subchannel

Mass Fluxes

120

Conclusion

123

Hitachi 7 x 7 BWR Fuel Pin Bundle with 3-D Power

Profile

1.5.1 Introduction

1.5.2 Description of the Bundle and Physical

1.5.3 Results and Comparison

1.5.4 Conclusions

1.6

Input Data

GE-CHF Tests

1.6.1

1.6.2

1.6.3

1.6.4

1.7

103

103

110

125

125

126

129

136

139

Introduction

Bundle and Test Descriptions

Results and Comparison

Conclusions

Sample Cases for the Prediction

139

139

140

150

of the Heat Transfer

Coefficient and the Pin Temperature Distribution

1.7.1 Introduction

153

153

1.7.2

155

Results and Discussion

1.8

Sensitivity Study of the Void Concentration Parameters

and Relaxation Length

1.8.1 Introduction

1.8.2 Results and Discussion

162

162

162

1.8.3

166

1.9

Conclusions

Other Supporting Evidence

for the GE Findings

and the

Drift-Flux, Vapor-Diffusion Model

1.9.1 Introduction

1.9.2 Results and Discussion

168

168

168

1.9.3

174

Conclusions

____

___

·

viii

Table of Contents continued

Pag,

Chapter

178

2

Tests of WOSUB-I in Transient

2.

Situations

178

2.1

Introduction

2.2

Mass Flow Reduction Transients

2.3

2.4

Depressurization

Power Transient

2.5

Discussion and Conclusions

Transient

Chapter 3

3.

Steady-State Calculations

Transient Calculations

187

191

194

196

Recommendations

196

Calculations

4.1

Steady-State

4.2

Transient Calculations

Refeernces

184

184

191

Chapter 4

4.

178

191

Conclusions

3.1

3.2

178

196

198

200

ix

LIST OF FIGURES

Page

Figure

1

9-Rod GE Bundle Geometry

Figure

2

Radial Power Peaking Pattern for the 9-Rod

3

GE Bundle

Figure

Figure

Figure

3

4

5

8

THINCII',THINC-IV [9], and WOSUB Results for

Nine Rod Bundle Isothermal Flow Tests

15

Comparison of Measured Versus Calculated

Subchannel Exit Mass Velocities for the SinglePhase Isothermal Data (COBRA-IV-I, WOSUB)

16

Comparison of WOSUB with GE Experiments 2D

for Subchannel

Figure

6

Figure 7

Exit Qualities

as a Function

of

Bundle Averaged Exit Quality

20

Comparison of WOSUB with GE Experiments 2E for

Subchannel Exit Qualities as a Function of

Bundle Averaged Exit Qualities

21

Comparison

of WOSUB with GE Test 2D for the

Subchannel Mass Flux in the Corner Subchannel

as a Function of Subchannel Exit Quality

Figure

8

Comparison of WOSUB with GE Test 2D for the

Subchannel Mass Flux in the Side Subchannel

as a Function

Figure 9

25

Comparison

of Subchannel

Exit Quality

27

of WOSUB with GE Test 2D for the

Subchannel Mass Flux in the Center Subchannel

as a Function

of Subchannel

Exit Quality

Figure 10 Comparison Between Experimental Data and

Predictions by Various Subchannel Codes for

the Individual Subchannel Mass Flux Deviations

from Bundle Average Behavior

28

36

Figure 11 Nine Rod Bundle Uniform Radial Power Distribution

Tests, Mass Velocity Comparion

THINC-IV, and WOSUB

Figure

THINC-II,

37

12 Nine Rod Bundle Uniform Radial Power Distribution

Tests, Quality Comparison THINC-II, THINC-IV, and

WOSUB

38

x

List of Figures continued

Page

Figure

13

Figure 14

Figure 15

Figure 16

Comparison of Measured Versus Calculated

Subchannel Exit Mass Velocities for the

Two-Phase Data (COBRA - IV - I, WOSUB)

39

Radial Power Peaking Pattern and Subchannel

Numbering Scheme

42

Nine Rod Bundle Non-Uniform Radial Power

Distribution Tests, Quality, Comparison

THINC-II, THINC-IV and WOSUB

55

Nine Rod Bundle Non-Uniform Radial Power

Distribution Tests, Mass Velocity Comparison

THINC-II, THINC-IV and WOSUB

56

58

Figure

17

Columbia University 16-Rod Test Geometry

Figure

18

Mass Flux Deviation from Bundle Average for

the Hot Center Subchannel

Figure

19

Figure 20

of

66

Mass Flux Deviation from Bundle Average for

the Cold Center Subchannel as a Function of

Bundle Average Exit Quality

67

Mass Flux Deviation from Bundle Average for

the Hot Center Subchannel

the Exit Quality

Figure 21

as a Function

the Bundle Average Quality

as a Function

of

68

Mass Flux Deviation from Bundle Average for

the Cold Center Subchannel

its Exit Quality

as a Function

of

Figure 22

Layout of Planned 9-Rod Studsvik Text Bundle

Figure

Numbering

23

Figure 24

Figure

25

69

74

Scheme for the Subchannel of the

Studsvik Test Bundle

77

Comparison of Various Subchannel Codes for

the Deviation of Exit Subchannel Qualities

from Bundle Average as a Function of Subchannel

Number and Bundle Power a Parameter

91

Comparison

Deviations

of Various Subchannel Codes for the

of Exit Subchannel 2 and 8 Mass

Fluxes from Bundle Average as a Function of

Bundle Power

92

xi

List of Figures continued

Page

Figure

26

Comparison of Various Subchannel Codes for the

Deviation of Subchannel Exit Qualities Versus

Subchannel Exit Mass Fluxes from Bundle Average

for Subchannels

2 and 8

93

Figure 27a Geometry of the 9-Rod Studsvik Test Bundle

98

Figure 27b Spaces Locations in the 9-Rod Studsvik Test

Bundle

99

Figure 28

Flow Split Device in the 9-Rod Studsvik Test

Bundle for Sampling Two Neighboring Subchannels

102

Figure 29

Layout of the 7x7 Hitachi Pin Bundle

127

Figure 30

Axial Heat Flux Profiles at the Corners a and

b of Bundle 3 and Control Rod Positions of

Rods A and B

128

Heat Flux Distribution Across the Bundle

Diagonal at Four Axial Elevations

130

Comparison of Void Fraction Distributions Across

the Bundle Diagonal at Three Axial Elevations as

Determined by COBRA-IIIC/MIT, FASMO and WOSUB

132

Schematic View of Test Channels, Showing Axial

Positions of Heated Length and Grid-Type Spacers

141

Comparison of Three CHF Correlations with

Measurements

144

Figure 31

Figure 32

Figure

Figure

Figure

33

34

35

Critical Heat Flux Versus Quality, Test

Channel No. 1

Figure

Figure

Figure

36

37

38

Comparison

of Measured

145

and Calculated

CHF as a

Function of Bundle Average Quality

147

Comparison of Measured and Calculated CHF Versus

Bundle Average Quality for the 9-Rod GE Bundle

at High Mass Flux

148

Comparison of Measured and Calculated CHF Versus

Bundle Average Quality for the 9-Rod E Bundle

at Low Mass Flux

149

xii

List of Figures continued

Page

Figure

39

Figure 40

Comparison Between Measured and Calculated

Critical Bundle Power Versus Subcooling

Logic for the Evaluation

fo the Heat Tansfer

Coefficient

Figure 41

42

154

Heat Transfer Coefficients and Clad Surface

Temperatures

Figure

151

Around a Corner Pin in a 3x3

Pin Bundle

156

Temperature Distribution in a Fuel Rod During

a Power Transient - Comparison Between the

Finite Difference Method and the Collocation

Method

160

43

Steady-State Temperature Profiles in the Fuel

as Obtained by the Collocation Method Using

Hermite Cubic Spline Functions

Figure 44

Effect of the Variation in Ze Upon Subchannel

Quality and Mass Flux

164

Effect of the Variation in Ze Upon Subchannel

Quality and Mass Flux

165

Subchannel Mass Flux Deviations from Bundle

Average Versus Bundle Average Quality [191

169

Subchannel Mass Flux Deviations from Bundle

Average Versus Bundle Average Quality [19]

170

Subchannel Exit Quality Deviation from Bundle

Average Versus Bundle Average Quality [19]

172

Subchannel Exit Quality Deviation from Bundle

Average Versus Bundle Average Qualtiy [19]

173

Figure

Figure

Figure

45

46

Figure 47

Figure 48

Figure 49

Figure 50

Cross Flow Enthalpy Between Side and Corner

Channels

Figure 51

Figure 53

175

Cross Flow Enthalpy Between Center and Side

Channels

Figure 52

[19]

[19]

176

Center and Corner Subchannel Exit Qualities

Versus Time for a Mass Flux Reduction Transient

Transient Subchannel Mass Fluxes for a Severe

Mass Flux Reduction

of 50% in ls

179

xiii

List of Figures continued

Page

Figure

54

Deviation of Subchannel Exit Quality from Bundle

Average Exit Quality as Function

Figure 55

Figure 56

Figure 57

Figure 58

of Time for the

Mass Flux Reduction Transient Shown in Figure 53

183

Subchannel Mass Fluxes Versus Time for a

Depressurization Transient

185

Subchannel Exit Qualities versus Time for a

Power Transient

i86

Boiling Length and Clad Surface Temperature

Versus Time for the Power Transient

188

Calculated

CHF as Function

Power Transient

--

-1

of Time for the

189

xiv

LIST OF TABLES

Page

Table 1

Table 2

Table 3

Geometric

and Hydraulic

Parameters

of the

9-Rod GE Bundle

4

Experimental Test Conditions for the 9-Rod

GE Isothermal Tests

6

Test Conditions for Uniform Radial Peaking

7

Runs

Table 4

Test Conditions for Non-Uniform Radial Peaking

Runs

Table 5

Table 6

Table 7

9

Comparison of Experiments and Calculations for

Single-Phase Subchannel FlowSplits

11

Comparison of WOSUB with Vapor Diffusion Model

and GE-Test Data for Radially Uniform Peaking

Factor Pattern in a 9-Rod Bundle

19

Comparison of the Results of Different Subchannel

Codes with the Experimental Results for Test

33

Run 2E2

Table 8

Comparison of the Results of Different Subchannel

Codes with the Experimental Results for Test

34

Run 2E3

Table 9

Comparison Between GE Data and WOSUB Results

for

Table 10

Channels

1, 16,

2, 15 and

45

6

WOSUB Predictions for the Individual Subchannels

for Test 3E1 with X = 0.0304 and G = 1.097 x 106

2

lb/ft-hr

Table 11

48

WOSUB Predictions for the Individual Subchannels

for Test 3E2 with

= 0.096 and

= 1.077 x 106

lb/ft2-hr

49

Table 12a Comparison Between Test Results and Subchannel

Code Results

51

for 3D!

Table 12b Comparison Between Test Results and Subchannel

52

Code Results for 3E1

ii

I

xv

List'of Tables continued

Page

Table 13

Comparison Between Test Results and Subchannel

Code Results

Table 14

Table 15

Table 16

for 3E2

53

Test Conditions for the Columbia 16-Rod Bundle

Tests

60

Test Conditions for the 9-Rod Bundle with

Tilted Power Distribution

78

Comparison

of Results for Subchannel

1 and 2

Qualities from Various Subchannel Codes with

WOSUB (Vapor Diffusion) and (No Vapor Diffusion)

Table 17

Comparison

of Results

for Subchannel

1 and 2

Mass Fluxes from Various Subchannel Codes with

WOSUB (Vapor Diffusion and (No Vapor Diffusion)

Table 18

Comparison

of Results for Subchannel

Comparison

of Results

for Subchannel

Comparison

of Results

for Subchannel

Comparison

of Results

for Subchannel

Trends in Quality for the WOSUB Options When the

Total Bundle Power is Raised from 346KW to 870KW

for the Studsvik BWR Bundle

Table 23

Test Conditions

Table 24

Steam Quality (%) in Each Split Channel Comparison Between Experiment and Various

Subchannel

Table 25

83

7 and 8

Mass Fluxes from Various Subchannel Codes with

WOSUB (Vapor Diffusion) and (No Vapor Diffusion)

Table 22

82

7 and 8

Qualities from Various Subchannel Codes with

WOSUB (Vapor Diffusion) and (No Vapor Diffusion)

Table 21

81

5 and 6

Mass Fluxes from Various Subchannel Codes with

WOSUB (Vapor Diffusion) and (No Vapor Diffusion)

Table 20

80

5 and 6

Qualities from Various Subchannel Codes with

WOSUB (Vapor Diffusion) and (No Vapor Diffusion)

Table 19

79

Codes (Case 1)

[91

84

94 95

101

104

Mass Flux in Each Split Channel - Comparison

Between Experiment and Various Subchannel

Codes

(Case 1 continued)

105

xvi

List of Tables continued

Page

Table

26

Steam Quality in Each Split Channel - Comparison

Between Experiment and Various Subchannel Codes

(Case 4)

Table

27

106

Mass Flux in Each Split Channel - Comparison

Between Experiment and Various Subchannel

Codes

Table

Table

Table

28

29

30

Table 31

(Case 4 continued)

107

Steam Quality in Each Subchannel - Comparison

Between Various Subchannel Codes (Case 1)

114

Mass Flux in Each Subchannel - Comparison

Between Various Subchannel Codes (Case 1

continued)

115

Steam Quality in Each Subchannel - Comparison

Between Various Subchannel Codes (Case 4)

116

Mass Flux in Each Subchannel - Comparison

Between Various

Subchannel

Codes (Case 4

continued)

Table 32

117

Comparison of CHF Results Between Experiments

and Predictions

Table 33

for Test Channel No. 2

142

Comparison of a Finite-Difference Method with

the Collocation

158 -

Method at Time = 2 seconds

and 4 seconds

I

-

-

I

--

159

-

-- ---

-- ---

-

----.-- -- -

--

CHAPTER

I

COMPARISON OF WOSUB RESULTS WITH STEADY-STATE EXPERIMENTS

In this chapter a comparison between the WOSUB results

and a number of experimental

discussed.

test data will be performed

and

These efforts are mainly focused on the following

test data which are available in the open literature:

1)

9-Rod

2)

10-Rod Columbia Test Bundle

3)

9-Rod Swedish Test Bundle

4)

GE-CHF Data [5]

GE

Experiment

4,

5,

6,

7]

[8]

[9, 10, 11. 12]

It should be noticed at this point that although

larger bundles were tested, no detailed information concerning

subchannel

quantities

are available

for those.

Thus, this

study has to be limited to bundles of comparatively

size,

Fortunately,

a lot of computer

small

codes have been tested

against the aforementioned experimental evidence.

Therefore,

it is possible not only to show how WOSUB compares

to the ex-

periment but at the same time to indicate

commonly

used codes for the analysis

its superiority

over

of encapsulated bundles.

All

of these comparisons are performed for steady-state conditions

because no information is available for subchannel quantities

in transient situations.

1. Comparison of WOSUB Results with Steady-State

Experiments

1.1

1.1.1

9-Rod GE Test Bundle Experiments

Introduction

Test conditions typical of operating BWR situations

2

have been investigated at GE with electrically heated (3 x 3)

rod bundles for both uniform and nonuniform radial power distributions.

The experimental

have been widely published

findings of the various tests

[3, 4, 5, 6] but the reports

GEAP-13049 and GEAP-10347 have to be considered the main documents.

It should be noticed that the GE-data were the first

published for square-array arrangements.

ticularly

important

for the development

It is therefore par-

of the WOSUB code to

assess its analytical predictions against these findings.

The

data were the first to indicate deficiencies inherent to

commonly used subchannel models.

Although this was already

explicitly stated in 1971 [6, 7] by comparing the data with

COBRA--i nothing was really done about it.

Therefore,

deficiencies

including the most

were carried through up to and

recently developed codes as will be shown

the same

n Section l..4.3.by

comparison.

The assessment of WOSUB consists in comparing the

data against results obtained for both vapor and no-vapor

diffusion options.

ocal qualities and mass fluxes are the

relevant physical quantities for the following series of comparisons.

1.1.2 Bundle and Test Description

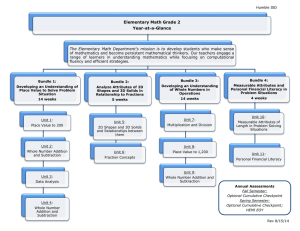

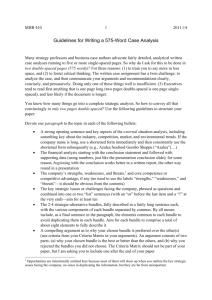

The 9-rod bundle test section is shown in Figure 1

and its geometrical and hydraulic data relevant for the comparison are summarized

in Table 1.

Reference

[4] describes

in

great detail the set-up of this experiment as well as the

3

I 1l

An

CORNER SUBCHASNNEL

0

_"

0.40

ADIUS(TYPICAL)3'

O o~i

0.7 38

(TYPICAL)

FIGURE 1:

9-Rod GE Bundle

0. 420

(TYPICAL)

eometry

-

-- --------

-L-*-

Number of Rods

9

Rod Diameter

.570 inch

Radius of Corner Subchannel

.400 inch

Rod Rod Clearance

.168 inch

Rod Wall Clearance

.135 inch

Hydraulic Diameter

.474 inch

Heated Length

-

-----

..

Table 1:

72 inches

___

__

__

________

Geometric and Hydraulic

Parameters of the 9-Rod GE-Bundle

measurement techniques.

this reference

The interested reader should consult

for a complete review.

Three types of experiments were performed:

1)

Unheated, isothermal tests in order to determine

the flow split between

subchannels.

The corresponding

test conditions are summarized in Table 2.

2)

Tests where all rods were uniformly heated in

the radial direction as well as in the axial direction.

The corresponding test conditions used for the

purpose of comparison are reported in Table 3.

3)

Tests where the rods were non-uniformly

radially but uniform in axial direction.

heated

The radial

peaking pattern is shown in Figure 2 whereas the

corresponding

test conditions

used for the purpose

of comparison

in this study are reported

in Table 4.

6

Test Point

Bundle

Average

Corner

Subchannel

Side

Subchannel

Center

Subchannel

G x 10 - 6

G 1 x 10 6

G2 x 10 6

G3 x 10

lb/hr-ft

i

lb/

lbft

/hr-ft2

lb/hr-ft 2

1B

0.480

0.311

0.462

0.526

1C

0.990

0.701

0.939

1.150

1D

1.510

1.095

1.441

1.690

1E

1.97

1.62

1.91

2.190

_

i

Table 2:

Experimental

._

6

i

Test Cond'itions for the 9-Rod

GE Isothermal Tests

_i

7

>~

-o

i

Z C

Ii

C

3

-

oU

-o

i

C

C

C

z

t

C

Ln-

I

O

·

PO

m

CD

coJ

JD

H

1

C4

co

U2

r-~

X

0

H

tu

H

h

o

o

C

a))

C

H

H

H

rl

0

-_

C

IM

Co

C

C

C

i m

on oInC\ oO

n Cn

I in I L

¢rs \7

i i,i

ii

fzc I .

....

H

rl

1

H

E--

C

X

*

H

ZOM

C-O

C

C

H

H

- CM

CM

A

CM

CM

x

H

C

_

8

FIGURE

RADIAL

POWER PEAKING

PATTERI

2

FOR THE 9-ROD

GE BUNDLE

9

E-e

H

x

H

[

iii

I

ICO

I

C

i

i

i

oO

i

i

rU

r.

.r

P,:

=..

)E.

,o

C',O

G

oC

o

b

rn

a,

0

Q

H

EcK

0

Ov

r

-i

ZC ,I

X

COH

oI

iI

H

o

_o

4Q,

_

i

0

zHC

10

1.1.3

1.1.3.1

Results for Isothermal Test Data

Comparison with Experiments

GE performed several unheated tests with the bundle

described in the foregoing section.

results are given in Table

and 1E.

5

The test conditions and

for the test points

The purpose of these single-phase

B, 1C, 1D

flow tests was to

establish the flow splits between the subchannels and at the

same time to check the validity of the turbulent mixing models.

The comparison

of the WOSUB-results

mental test data shows excellent agreement;

being not larger than ±5%.

with the experi-

the differences

The only data point which falls out

of this range is that of the center subchannel at the highest

lbm/ft 2-hr.

flow rate of G = 1.97 x 106

Unfortunately,

error bands are given by GE for these measurements

no

but it can

be safely assumed that it is finite and may even increase with

an increase in flow rate.

The agreement between experiment and

WOSUB results is best for the side subchannels.

for test point

measurements.

D show the overall best agreement with the

It can be safely concluded that the single-phase

mixing model built into the WOSUB-code

1.1.3.2

The results

[31 is working just fine.

Comparison with Analytical Results and Other Subchannel Codes

A first estimate

for the flow split between

sub-

channels

can be obtained by assuming that no mixing takes place

at all.

With this assumption

from [

4

].

ui

=

2/3

hi

u3

Gi(i = 1,2,3) can be determined

11

1B

1E

2

G3 x10- 6

lbm/

0.311

0.322

0.352

0.462

0.447

0.456

0.526

0.562

0.565

COBRA-IB = 0.01

0.352

0.451

0.551

COBRA-IB = 0.005

0.336

0.447

0.560

Data

0.701

0.939

1.150

0.664

0.922

1.159

WOSUB

0.730

0.942

1.160

COBRA-IB = 0.01

0.740

0.934

1.128

COBRA-IB = 0.005

0.704

0.925

1.149

Data

1.095

1.441

1.690

1.013

1.406

1.768

WOSUB

1.120

1.440

1.767

COBRA-IB= 0.01

1.143

1.427

1. 713

COBRA-IB = 0.005

1.085

1.414

1.746

Data

1.62

1.91

2.19

Dh2 /3 -Prediction

1.321

1.834

2.306

WOSUB

1.54

1.937

2.37

COBRA-IB= 0.01

1.502

1.865

2.229

COBRA-IB = 0.005

1.424

1.847

2.273

3-Prediction

[

II

I

I

Table 5:

III

I

I

I I I I

Gx1O6

lm/

hr ft-hr

Data

Dh2 / 3 -Prediction

WOSUB

h2 / 3 -Prediction

1D

lbm/

ft

Dh

1C

6

Gxx10-6

ibm/

TEST

POINT

I~~~~~~~~~~~~~

Comparisonof Experirents

and Calculations

for Single-Phase SubchamnelFlow Splits

0.48

0.99

1.51

1.97

12

Results according to this formula are listed in Table 5.

The

comparison with the experimental data indicates that this simple

model gives fairly good results especially for side and center

subchannels

at low average mass fluxes.

This suggests

that un-

der these conditions the flow split is indeed fully developed.

In order to cope with the other data the concepts

of

mixing and crossflows have been introduced into subchannel

codes.

Various processes are known to generate crossflows

among them pressure gradients and turbulence effects.

Under

the assumption of a totally ventilated bundle cross section the

contribution

due to diversion

crossflow is zero and only tur-

bulent mixing remains to be considered. This approach has

been taken by all the subchannel codes of the first generation

and is accepted

to be valid for the encapsuled

Therefore,

Lahey et al

subchannel

mass fluxes.

specified

4,7] used COBRA-I [131 to compute the

One of the variables

as input to the commonly

the mixing parameter

W'

=

BWR bundles.

that has to be

used subchannel

codes is

which is indirectly defined by

sG

where W' = mass flux per unit length

s

= rod-rod or rod-wall

gap spacing

= dimensionless mixing parameter

G

= average mass flux of adjacent

The mixing parameter may be redefined

subchannels.

in terms of an eddy

diffusivity of momentum as:

G1

where

1 is the mixing

length or the effective mixing

13

distance between subchannels.

The latter approach

is used in WOSUB as described

in

as a result the supply of a appropriate

necessitates

tutive equation

2] and

consti-

For COBRA-I, Rowe [ 7 ] recommends

for E.

for

B the following equation:

Dh

=

(0.0062)

-h

0

(Re) -

.1

which for the geometry under consideration gives a value for

B of the order of 0.005.

Lahey et al [4 ] used this value and

= 0.01 to obtain the results as listed in Table 5.

The

comparison with the experimental data indicates that the best

overall agreement is achieved by taking 3 = 0.005.

for the highest

flow rate it seems that B >0.01

However,

would result

in better agreement with the data.

By comparing the WOSUB results with those obtained

from COBRA-I it can be concluded that the former present a

trend which resembles data obtained for

>0.01.

Therefore,

the high flow rate results are indeed in better agreement with

the test data than the COBRA-results

In the underlying

are.

concept of turbulent mixing

in

single-phase flow nothing has changed until now since the

generation of COBRA-I with the exception that due to more

experimental data slightly different coefficients and exponents

for

are recommended now.

However, the functional dependancy

remained essentially unchanged.

Due to the fact that most publicly

available

sub-

channel codes today are applied for both PWR and BWR core design

modern versions

of COBRA, such as COBRA-II,

COBRA-III-C

and

14

COBRA-IV-I [14] contain a diversion crossflow model which is

essential to deal with semi-open cores.

Therefore, the whole

solution procedures of these codes are even oriented towards

this phenomenon.

In order to examine the question of whether

diversion crossflow and/or improved correlations for

changes

the computational results it seems prudent to compare WOSUB

with more recent versions of subchannel codes.

Fortunately,

two sources of information are available for this purpose.

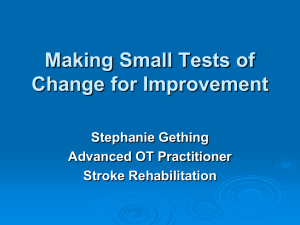

Figure 3 shows the comparison of THINC-II and THINC-IV results

[15

with the GE test data.

are added into this graph.

The most deviating WOSUB-results

Overall, the indications

are that

WOSUB generates more reliable data than either of these codes.

In most cases the WOSUB results fall just in between those

obtained by THTNC-II and THINC-IV.

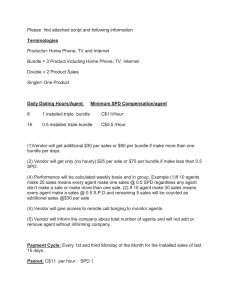

Figure 4 shows the same comparison

tained by COBRA-IV-I [l14.

with results ob-

WOSUB results are added for test

lE because there the largest deviations were observed.

Again, overall WOSUB shows closer agreement.

No outlier,

i.e. where differences are larger than ±10% are produced by

WOSUB, rather all data are within ±5% as shown in Figure 4

with one exception.

Finally, it can be concluded that obviously diversion

crossflow does not play a role for the tests considered here.

The assumption of zero pressure gradient between subchannels

seems therefore justified

at least for the single-phase

tests.

I

__

flow

15

i

6035-17

t

[

(

2.6

W

.... D:

LEGEND:

TH I C-l

2.2

i

I

IsIjITH

5h

h/WOSUTH

I C-'

L"

X

,..

A

SUBCHASNEL

CORNER

S1DE

El

CENTER

-

to

x

1.8

0

0

I-I

cZ3

I.4

-

.i=

-;

ui

1 .0

0.6

0.2

0.2

I

I

0.6

1.0

GPREDIOTED

FIGURE 3:

(L

l

!

1'. 4

"I

I.

IIF

THINC-II; THIINC-IV [9];

Results for Nine Rod Bundle

Isothermal Flow Tests

I

(

i

!o. ~),

and WOSUB

2.2

2.G

2.6

, 2.4

22

= 2.0

=LS

xL2

b-

Z LO

I

Q 0.8

C 0.6

, 0.4

U

0.2

0

0

02

0.4

06

8

LO u1

L4

L6

L8

2.0 2.2

2.4

2)

- (106Iblhr - ft

EXITMASSVELOCITY

SUBCHANNEL

MEASURED

FIGURE

__

4:

-Comparison of Measured Versus Calculated Subchannel Exit Mass Velocities for the SinglePhase Isothermal Data (COBRA-IV-I,WOSUB)

17

1.1.3.3

Conclusions

The comparisons of WOSUB results with single-phase

flow test data and results obtained by various subchannel

codes indicate the code generates results which are equal if

not even superior in accuracy.

The fully ventilated-bundle

assumption is valid for single-phase flow conditions.

.____

18

1.1.4

Results for Radially Uniform Peaking Factor Patterns

1.1.4.1

Overall Comparison

The comparison with the experimental data from GE

concentrates

upon the 2D and 2E series as summarized

Table 6. Figures 5 and 6 illustrate

in

the trends in the subchannel

qualities with respect to the bundle average quality.

are taken at the exit of the bundle.

quantities

All

The subchannel

qualities increase with the average quality, the center subchannel

(#3) being the "hottest" and the corner subchannel

the "coolest".

The side subchannel

(#1)

(#2) behaves about the same

The center subchannel quality is seen

as the bundle average.

to be consistently higher than the average whereas the quality

of the corner subchannel is lower than the average.

There

appears to be a trend such that subchannel qualities

tend to

converge to the average at approximately 5-15% bundle average

quality.

This can be attributed to enhanced mixing in the

slug-annular

transition

flow-transition

regime.

Due to the fact that this

occurs in different subchannels at different values

this effect may not occur simultaneously

of the average quality,

in all subchannels.

As Figures 5

and 6 depict, WOSUB overpredicts

the

quality in the corner channel at low values of x but underpredicts

it at high values of x.

For the 2D series the qualities

of side and center subchannels are predicted well within the

experimental

error band.

For the 2E series the center sub-

channel quality is slightly overpredicted

for x > 5%.

The

deficiency in calculating the corner subchannel quality becomes

T ___

__

___

19

H

C-1

ONE

* -

mo

-

U\

L\

*

H

O

oo

b-~~

L~

-

O

CY

O

C

cO

H f Ln

CX

z,9 ~~D

Cn'

mf

LL rH

oC

0

o1

CJ

Cc-q

r

C\

O

C

H

H

I c

0

0D0 0

C)

0

0

ro

r-4

CD

0

11

a:

4o

O4

0H

11

CM H-C \QO

O

C.D

'l I0

_

'

=

E4H

E-o

4

I

C)

0- 0

0N

C

cO

OL EIO

1

M

i

I

o1

.a

0

CC

H

0C

0

. O

Cm.. rcoCD

O

O

o

m

J

0

I

o

n

O

H

C

zI P:

OS '

Cl

Q1CC

LC

,-

Il

OL\

o

XP

- a

oX

0

0LD

I

0

O9

0

IKOO

0

t Co

cIc

H

..0

CO

0.

L

00 h0

I

0-i

i

d

H

Z

)

O

H

0C

U2

H

CM

C

O~

Or~

rC

O

0

o

C

El

)

0

E-0)

0

I

C)LC\

OX CM

0rt

O

0C

1

0CM

C

0CM

,

-.

_

-~

'

--

u)

I)

0

CCd

-

-

20

L")

4,1

d

O

4

':

C,

ce

O

"l

o

H

x2

C

c

0

0

4*4

S-,

£ c

O

IS)

o

O~rO

C

=C

''.;

U

..

0

O

lO

O

O

0r

O

r0

o d

q X ' AlInflO

____I_

O

0

O

0

0

2NVHDGnflS

O

0

C

21

I

I

I

I

/

THI

0.24

-

SUBCHANEL

3

0.20

0.16

x

Es

" 0.12

03

al

a

-~~~~---

ct

0.04

0

J

-0.04

I

0.05

0

I

I

I

0.10

0.15

0.20

AVERAGE

,IrTJIT

65:

Comparison

Qualities as a

ofe

QUALITY,

WTOSUB wiith GE

unction

0.25

X

Exneriments

2E

of Bundle Averaged Exit

for Subchannel Exit

ualities

.

.

22

more apparent for this series especially for high bundle average

quality

(x =20%).

However,

this deficiency

has to be seen in

the light of the results obtained from THINC-IV

corner subchannel

[ 15 ] for the

as shown in Figure 6 for 2E2 and 2E3 as

taken from Tables 7 and

8 . As the dotted line indicates,

THINC-IV predicts the corner subchannel always "hotter" than

the bundle average,

i.e., it gives a completely wrong picture.

As the tables show, the failure of predicting

the correct corner

behavior is representative for all the other known subchannel

codes, too.

It should be kept in mind that although

the WOSUB

results are not perfect as compared to the experiments. it

still has the potential

for corrective actions.

it is hoped to increase

the gradient of the line xl

at the same time decrease

qualitatively

In this context,

=

f(x) and

that of the line x 3 = f(x) as shown

by the directions

of the arrows in the figure

below.

XCh

Xx

No

equivalent

correction

seems to work for the other subchannel

codes, because even with high mixing factors they cannot predict the substantially

lower-than-average

qualities

in the

corner subchannel, and higher-than-average qualities

23

in the center subchannel.

In fact, if mixing were made even

infinitely

large the three subchannels

would all be at average

conditions

and thus the data cannot be explained

in terms of

mixing.

The most reasonable explanations for the trends of

the data are the tendancy of the steam to move preferentially

to the center of the rod bundle and/or the presence of thick

liquid "cold" film on the unheated channel wall.

1.1.4.2

1.1.4.2.1

Detailed Subchannel Behavior and Comparison

Corner Subchannel

For the 2D seriesWOSUB with vapor diffusion model

included overpredicts the quality at low bundle average qualities,

x, and underpredicts

The same behavior

Figure 6.

it for x > 20% as can be seen from Figure 5.

shows up for the 2E-series as depicted

in

If WOSUB is run without the vapor diffusion option

it generates qualities comparable to those of the other subchannel codes such as COBRA-IV and THINC-IV.

qualities are determined

This means that

far too high in the corner subchannel.

There is no way to correct this wrong trend by changing

coefficients in the mixing models of these subchannel codes.

However, the vapor diffusion model in WOSUB can be changed such

that the corner subchannel does not lose too much vapor at

high x and gives up more at lower x.

The reason that the

built-in vapor diffusion model overemphasizes the vapor transport at higher bundle average qualitites has to be attributed

to the fact that this model as described

in [2] was fitted to

results of air-water

consisting

tests in a geometry

_II____I___·I1_IIII_1_111^1111111-sl-1

--IYDII·---

-Il_--_t--ll

I

-

of two

-

_

·

24

sized subchannels.

differently

As Lahey et al [ 7] pointed out,

mixing data stemming from these types of test sections tend to

the transport

overpredict

Thus, it must be concluded

effects.

that multi-rod bundles show a damping effect as compared

to

the data obtained from simplified test section set-ups.

Corrective actions will be made during the next round of model

improvements

in the future.

In terms of the mass flux behavior,

Figure

7 shows

for the 2D-series that WOSUB predicts overall the characteristic

behavior

lower-than-average

gradient

over the range of x.

of the computational

However,

the

It is hoped

results is too high.

though that the aforementioned corrective actions with respect

to the vapor diffusion model will cure this problem,

same behavior

as for the 2D-series is experienced

too.

The

for the 2E-

series where for x > 15% WOSUB is giving a slightly higher-

than-average result.

Again, it is thought that the correction

in the vapor diffusion model will help to move the curve back

into the lower-than-average region.

It should be noticed that both test series were

calculated

model.

taking the same parameters

in the vapor drift flux

As explained in Section 11.8.

something can be gained

by individually fitting these parameters according to test

conditions.

However,

this margin

is not very large and it

must be concluded that WOSUB's deficiencies are with the

vapor diffusion model as outlined above.

fusion WOSUB predicts

subchannel

_

__

far too low mass fluxes in the corner

as do THINC-IV

___

____

11____

Without vapor dif-

and COBRA-IV as shown in Figure

___I_·

25

_

I

__

I

I

-1

0

'A

uI

O

wl

er

-

>1

-C

s

'L

C

-a

cd

kO- z

0

V)

n

o

VI

c~

ci, 0

Q11

N r-a,

cC

Cd

;0

4a)

cIt

rQ

.0

oa) rl)

C

;m

ok

Ce

C X

0 .Orci,

-J4

mI

LU

x

'2

r-

2

$L40.f-4

o o

d

C.

cd

0

O11

UZ rr

t

V]

Q

V4

O a

,)

2

z

su

.0

z

m

Qt

4-

ed

0

.- C

U

Cr

W:

H

Fx-

0

C~

C,

W

r=

Cd

I

I

a

6

6

i

e4

c0

!

0

1e

=

oC)

26

Finally,

it must be pointed out that the well known

concept of power-to-flow

ratio which is mostly used to get a

first estimate for the thermal-hydraulic subchannel behavior

totally fails in predicting

the GE test results.

be kept in mind in interpreting

This should

the other test results in the

following sections.

1.1.4.2.2

Side Subchannel

In general,

which

the side subchannel shows a behavior

closely follows that of the bundle average.

series the side subchannel

shows a very slightly higher-than-

average quality at high x whereas in the 2E-series

the lower-than-average

In the 2D-

region for all x.

it stays in

WOSUB with vapor

diffusion model included does an excellent job in predicting

the qualitites

for both series as can be seen from Figures

5

and 6 by comparison.

In terms of the behavior

underpredicts

of the mass flux, WOSUB

the mass flux for both test series at lower x

(O - 10%), whereas it predicts

tained by the experiment

fr

It is interesting

very closely the data as ob-

x > 10%.

(Compare with Fig.

8.)

to notice that the option without

vapor diffusion gives reasonable results for the side subchannel.

1.1.4.2.3

Center Subchannel

The GE test data show that the center subchannel runs at a

higher-than-average quality and mass flux. The WOSUB results (see

Fig. 9 ) are in excellent

quantities

__

agreement with the test data for both

in the case of the 2D-series.

However,

the code

27

rt

a)

_I

v~

.I

6

I

az

s(U ri

C

,.

4:

C

;n

od

a

-J

w

Cd

t.

c

H

4

U PCd)

a:

Em

ILl

O-

o

C3

c'

G3Cd

OA

C5

LU

1d

U

0

0-

CIA

%A

a

%LL

O

Cd

:

D

oa)

a

CQ

C

U

H

a

F S

U

X

..

.

I

·

I

0

I-

I

III

I

i)

rU

3o E

H

rr

Cd

>t

Cd

x

w~3

28

I

I

I

I

II

X

I

I

6

-I

0

..

H

C

Q)

0

C

Cd

Co

I.I

2

d

VI

w

to

UI

~1

(.J

UL

tU

vW

C

o

czl

a)

H(

D

PI

C

0

-ri

4-)

0

-I

t~L

CO

4--

.

0

Z0)

E.

H

Cd

Q)

C;

ai

IC

__

He

o

_

__

a·

1!

41

H

1

.

rC')

E1

Cd

.

U]V

-H

x

29

30

slightly overpredicts

predicts

especially

the quality of the 2E-series and under-

the mass flux for x > 5%.

It is hoped that

this trend can be reversed, once the vapor diffusion model has

been corrected.

distribution

This correction should indeed lead to a re-

of flows.

It is interesting

to note that WOSUB without the

vapor diffusion model gives closer results

the center subchannel

or the quality in

for higher values of x than does the

vapor diffusion option as compared with the experiment. This

finding supports the aforementioned reasoning, namely that too

much vapor is transferred from the corner into the center subchannel thus making it too "hot".

1.1.4.3

Comparison with Results of Other Subchannel Codes

Due to the complete documentation

of the GE-test

series, these data have been widely used by various researchers

and institutions

in order to check the validity

of their sub-

channel codes against local exit subchannel quantities.

This

is very fortunate indeed because it makes it possible to compare the results obtained by WOSUB with those generated by a

whole variety of well-known

codes.

Although

the results of the

latter show widespread differences between them, no explanations

are given for these phenomena in what follows.

considered

behind

as one group as compared to WOSUB.

this approach

ticated two-phase

Rather they are

The reasoning

is that whereas WOSUB uses a more sophis-

flow model as well as a vapor generation and

transport model, the other subchannel codes are mainly characterized by the fact that they all use the homogeneous

__

flow

31

model as the basic underlying flow model.

As a result, dif-

ferences between these codes are mainly attributable to

differences in the mixing model and their associated input

data.

What is of interest here, instead,

answer to the question

is to find an

of whether or not the introduction

of

a more sophisticated flow model results in improvements in

the interpretation

is worth mentioning

of experimental

data.

Inthis context, it

that inherent deficiencies

in the sub-

channel codes were discovered and pinpointed as early as

1971 [ 6 ].

However, until then nothing had been actually

done in the area of subchannel code development

this situation,

was introduced.

to improve

up to the point where the MATTEO-code

Despite of its appearance

new code developments.

[1]

it did not spark

Instead, as most recent developments

such as THINC-IV and COBRA-IV show, most institutions stayed

within the concepts and models already being used about a

decade ago.

This has to be considered very unfortunate

be-

cause on the other hand side trends in the thermal-hydraulic

reactor safety analysis clearly indicate the need for improved

two-phase flow models.

Indeed, these developments are well

underway and first results

ustify the efforts.

As a result,

the gap in the model sophistication between design and safety

codes widens, although

it is not clear where and how to draw

the line between these two classes,

felt that the application

yet.

Therefore,

it is

of the drift flux model is indeed

needed to bridge this gap and thereby to enlarge the range of

applicability of design codes.

.______

32

By inspection

of Tables 7 and

that the common subchannel

8

it becomes obvious

codes using the homogeneous

flow

model together with common state-of-the-art mixing models

strongly overpredict the quality of the corner subchannel. At

the same time they underpredict

by a substantial margin.

difference.

the mass flux in this subchannel

Especially COBRA-IV shows a large

In the context of the applied mixing models there

seems to be no way to reverse the trend in quality by pushing

it into the lower-than-average

region by an appropriate

choice

of input parameters to the mixing model because even infinitely

large mixing coefficients would only result in a corner subchannel quality which equals just the bundle average one.

a result,

if one accepts the experimental

As

findings - and there

is more evidence to support them today (see Section 1.9)- it

must be concluded that the flow model together with the transverse transport mechanisms employed by those codes show inherent dificiencies which are obviously unrepairable in the

context of the theory used by the codes.

This is to say,

that as long as these subchannel codes are used to analyze

encapsuled bundles where diversion crossflows are less likely,

their results are of limited value.

With respect to the side and center subchannels

the

following conclusions can be drawn from the calculational

results by these codes.

They all cverpredict the side sub-

channel quality and underpredict that of the center subchannel

to some extent.

are equally wrong

With respect to the mass fluxes the trends

especially

for the side subchannel as shown

33

r'd

-p

u

E

>

o-i

II

O

o

o

o

-'

r"rd

H

"- O'

O'

O

,,.

.. r

H

H

o

o

ooO

0 ,4 CCO .O

rl

r

r

H

rH H

Cx

CM

rH

O

0

0

C'

a

C

I ,4 oc

-I

o "- O'C

UM

CD CO

r4 O

rl

H

H

o

O

e

O

0

ml

t

O

>C4

OC

U1

z

ao

al

*,

2:

EH

o\

Ir0'

E

0

0o

'-

O

O

r-

X

6

Cl)

O

O

'

O

0k.

,0O

r

O

01

O

O

O

O"

O

0..c

o-

c

.o\

O

0

CO

O

j

01 Z

r

O,

C-H

.- " .

.

"I .-

O

X,..

r.. rlfE

8i

P

H

- l0

O

t. .- ~

03

E-

0

H

'-

C

: -

OO

r

rH

It '

C

t-

L

cO

H 0

.

o

.-

0

O

o

0

0

4-

H

:

ZD

o

O

O

O

oII

11

oII

EH

E

o

11

V

o

HC

I

0

H=

E

U)

I

'

O

*

ri

a

II

0

Q

Z

II

V

o0

40

Z

H

H

E

E

oV

oV.)

(%1

CM

4-p

U)

E

II

i~~~~~~~~~

Cl)

0>/)C/

00

C-

::

o

r-

E-

o

o

c0

rd

co

i

3

.o

0I

C,!

324

C

i

Ch

CO

-

0 .-

r

r-l

CO

rl

=

O

O0

C'

rn

¢o

Cdx

H

r4

4U

i\

-C

kD

L:E

r

rl

-r i

r(

M

U)

H(d

Ic

IIb'

Icz)

zPr;

w

E-

z

01

Hd

C

S

CO

ri

rt

d

O

r-

C

C

C1

oC

I

C

,

c

rH

r

O

-P

U) 0

I HC

rH

-P

H

.CO

CO

co

0O

0OO

H H

LC

H

Cr

0

-0

H

H

C>

H

CM

Z

H

H

M

H

0O

0O

CM

O

CO

-

i

,

H

I

co

CM

0

o 0O

O

r;-

0

Z

cn

'.D

rU

. 0

C

II

-

0

CU

CM

CM

CM

CM

-X

CD

O

Cd

fr

-' ,CMH

H

'3

.r-i

I01.

H

Q

3

0

.0

F--

w

P-4

Io

O

o

01

QN,

5f

X

-;

i

LN

Cr)

O

O

CM

0

r

H

C

c

-J

O

J

0

J

r-4

0>

0

JJ

0

J

O

J~~~~~~(;

O

COj

0

9-

-c

0

r'

.l

H

S

0

H

z

0

4-

O, 0

r-.

O

CC

0

>

0

a0

c

r

0u

C

0

O

O

o3 0i

i

o

1

U

0

0

U0

CIv

o

O

I

cH

I

·

U

;:L

!x

EP

1I

0

ri

z

H

3e

C

rd

QU

E- 0

o

35

in Figure 10 for THINC-IV.

If at that point in time one

worries about the wrong trend given by WOSUB for the mass flux

in the center subchannel as a function

Section

of x as discussed

in

one should realize that all the other subchannel

codes are not doing better basically in all the subchannels.

This fact has been obviously overlooked

if error bands of ±10% are assigned

trends of side and center

thus far.

the details of values and

subchannel quantities

good example for this approach

Indeed,

get lost. A

is given in Figures

for the mass flux and quality results,

11 and 12

respectively,

as obtained

by THINC-II and THINC-IV, as well as in Figure 13 for the mass

flux calculated by COBRA-IV-I.

For the purpose of comparison

There is

the WOSUB results have been added into these graphs.

no doubt that they compare more favorably

to the measurements.

1.1.4.4. Conclusions

From the foregoing comparison of the results with

experiments and other widely used subchannel codes the

following

conclusions

1)

can be drawn:

The drift flux model together with the vapor

diffusion model produces data which are in good

agreement with the experimental data.

2)

The drift flux model without the vapor diffusion

model generates results which are close to those

obtained by the common subchannel codes.

3)

The widely used subchannel codes such as COBRA

and the like are unable to predict the lower-thanaverage behavior of the corner subchannel quality

_..__·__I____·

__

36

__

0.1Z

0.0

0. 4

I

I

I

I

I

I

1

I

__

I

I

I

I

O.IS'

0.20

0.25

-

_

0

I 1

x

- 0.04

:3

- 0.08

_

/

U

A

z

Ca

;

- o.12

_

A

cn

-0.

-O.l.

2E SERICS trSTS

i

CORNERSUSCANNEt.

.

SDE

. .....

--

1I

!

_

1Q

i J El

i V·

W

SCAHANNNEL

fR SU8CHA N(L

C,

GE-EXP.

-. -. -_ WOSUB

O.24

m

O

-

THING IV

COBRA IV

,

0.O

0.0o

SUBCHANNEL QUALITY,

I7JURE 10:

Compariscn. Between

X

xperimental Data and

Predictions by Various Subchannel Codes for the

Individual Subchannel M-'assDeviations

Average

..-. c.

---

---.._I.

1.._

from Bundle

ehavior

.L

__ __

0,30

I

37

I

3

6035-16

=:I,

i

I

I

C

cc,

C"

0

_

O

_

XL

C:

.2

II

c

*0

H

L

o

.

i

)

cC

-C

-

C

I

)

i

t

I

i

Z>

i

I

A

-'.o

r

I,

4

--

-

(;

i

~~~~~~~(

_0I zij

-}'/,I 8 )

3 LO 'S,V 2 N

09

y9

t

_I

----

· I__L-l--(---·--·III-

-

-

_-

*

i~~~~~

~rlr

ilI

6035-1

38

I

I

Ij

_W

I

eo

__

,.

=.

C,,

O

01

111,

N

sO

Q_

LA

Z

LL

ak:

C.

z

C)

*

-)

C

4)

'of

1

,:o

iuJ

LO

,

-. o

I

.0

I

0

"

0 ..

4

W .J

o O- G

C.J

LI

.t:

,j

_

--

__-

r .)

L--~~~~~~~~~~~~

R~~~

,

0

.

r--H

0 -.Z

c

r

!

J~

-'1

I

v

.Ik

I

L

.

i

I

o

0

C)

i

36)

\Jn~~

I~iSV.

£

----

;,

---

-.-

'iH

i

r

!

-

!

o

k--

H

H

r_

..

L.

39

'-

I-

I-

I

=C

w

c

0.1 02

0.3 04

0.5 0.6 07

0.

0.9

1

L1

1.2

MEASURED

SUBCHANNEL

EXITMASSVELOCITY106Iblhr - ft2 )

FIGURE 13: Comparison of Measured Versus Calculated Subchannel Exit Mass Velocities for the Two-Phase

Data (COBRA-IV-I, WOSUB)

111111111

-

40

and mass flux as well as the higher-than-average

behavior

of the two quantities

in the center sub-

channel.

4)

There is no hope of effectively

inherent deficiency

correcting the

of these codes in the framework

of the mixing models used thus far.

5)

A model like the vapor diffusion model seems to

be necessary

to predict the trends observed

in the

data.

6)

Still existing

differences

which show up in the

comparison between the data and the WOSUB results

are consistent

in themselves,

that is to say, they

follow a logical pattern which can be attributable

to a too strong vapor diffusion transport coming

mainly out of the corner channel.

7)

The vapor diffusion model is simple in its

structure and without changing the underlying theory

can be improved very easily in order to fit the

multi-rod test data more closely.

8)

Empirical transport correlations stemming from

simplified

geometries

should be carefully

such as two-subchannel

tests

checked for their applicability

to

multi-rod geometries. The latter introduce a damping

effect upon the transverse transport.

9)

The widely used power-to-flow

to interpret

_

the experimental

_I

_·

ratio concept fails

data.

41

1.1.5

Results for Radially Nonuniform Peaking Factor Patterns

For this test series, GE ran subchannel

sampling tests

with different power on the nine rods in order to obtain a

radial peaking factor distribution, whereas the heat flux was

kept uniform in the axial direction.

The radial peaking factor

pattern is shown in Figure 14 together with the numbering

scheme of the subchannels.

As can be seen the pattern is nearly

diagonally symmetrical with the hot corner rod power being approximately

twice the cold rod power.

The test conditions

for

the three out of four runs performed by GE which are considered

in this report are summarized in Table 4.

The experimental

findings by GE [5-7] can be summarized

as follows:

1)

The hot center subchannel runs at the highest

quality in all cases.

2)

The cold side subchannel

is the lowest in quality

and generally has the highest mass flux.

For tests

3D1 and 3E1 this channel is even substantially

sub-

cooled at the exit.

3)

The hot corner subchannel runs at higher-than-

average quality and has generally the lowest mass

flux.

4)

The quality of the hot corner subchannel runs

much higher than that of the corner subchannel for

uniform local peaking conditions discussed in the

preceeding section.

It also runs higher than the

bundle average.

.___. _·__11_______1_111_Y___···LII·^.·_

I__

_

_

_

_

42

FIGURE 14

RADIAL

POWER PEAKING

PATTERN

I

AND SUBCHANNEL

NUT4BER SCHEME

_

5)

The quality of the cold corner subchannel is not

very much affected and behaves close to the corner

subchannel under radially uniform heating conditions.

Some data indicate even that the quality is slightly

higher than that in the uniform case.

6)

The quality of the hot side subchannel

than in the uniform

is higher

case and higher than the bundle

average quality.

7)

The hot center subchannel quality is higher than

that obtained without local peaking which as was

shown in the preceeding section was already the hottest

subchannel for uniform heating.

8)

The trends in mass flux are not as clearly defined

as those for the quality.

9)

With one exception the hot corner subchannel has

the least flow when compared to the uniform case and

cold corner subchannel flows.

10) The cold side subchannel has a greater mass flux

than the uniform case except at low flow and quality.

11) The hot side subchannel flow is lower than the

side subchannel

flow in the uniform case.

12) The hot center subchannel has a lower flow rate

than the center subchannel in the uniform case except

at low average flow rate and quality.

Altogether,

these findings

give a fairly complex picture of

what happens in this more realistic case.

Unfortunately, the

results obtained by GE suffer from the fact that no mass and

__1__1_1_

_

44

and energy balances were performed because not all subchannels

were sampled.

1L1.5.1. Comparison of WOSUB Results with the'Experiment

Table 9

summarizes the comparison for the three test

cases 3D1, 3E1, 3E2 for the hot and cold corner subchannels,

hot and cold side subchannels

It should be recalled

the

and the hot center subchannel.

that with the exception of the local

peaking factor pattern the test conditions for 3D1 are identical

to those of 2D1, 3E1 is identical to 2E1 and 3E2 is identical

to 2E2.

This makes it easy to refer back to the radially

uniform heated tests discussed in the preceeding section.

The following conclusions can be drawn from Table

with respect to the WOSUB results (if not

therwise stated

"WOSUB results" means with vapor diffusion):

1)

The hot center subchannel has the highest quality

only for 3E2 whereas for 3D1 and 3E! the hot side

channel shows the highest quality.

2)

The cold side subchannel is the lowest in quality

and has the highest mass flux.

The exit qualities

for tests 3D1 and 3E1 are subcooled.

3)

The hot corner subchannel runs with the exception

of that in test 3E2 at higher-than-average

quality.

In general it has the lowest mass flux.

4)

The quality of the hot corner subchannel is pre-

dicted higher for local peaking than for uniform

heating condition.

It is higher than the bundle

average with the exception

· ____

_

I_ _·_1_ 1__1__1___

_

_

of test 3E2 where it is

______ _ __ _ L___

45

-0

k\o

Ct

'

-

c_) ~

~~

o

Il

~

tD S 9-01 X S

r-

Ii

ooo

ooo

CC

C kD

r i

i~ ilii

CD C(_ Cz/Ul

O0

~

~

~

~

~

~

c

oLC- o04- o('Xo00os -o 0oo

C

ZTMn Z C0 _Cm

0\ !cC00

000

oL¢S

o,md\c

rlH g (R79_0l