Print Preview for the Fabrication of Physical Objects David Carr

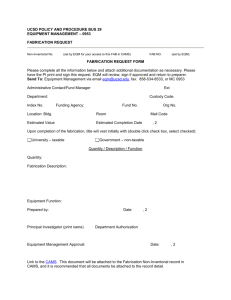

advertisement