NORTH NEVADA EVENTS CENTER November 17, 2010 MECHANICAL DESIGN NARRATIVE

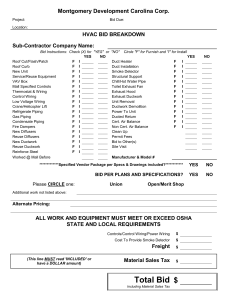

advertisement

NORTH NEVADA EVENTS CENTER November 17, 2010 MECHANICAL DESIGN NARRATIVE The existing North portion of the TRW building is being considered for use as an exposition hall. The space originally had sections for office functions with the larger portion being utilized for electronic manufacturing. Area considered is approximately 64,000 square feet; 46,700 square feet of the area will be dedicated to the actual exposition area. This narrative will be referring to various documents, included in the submittal. The architectural drawings will indicate the existing/demo plans, and the new proposed area plan. Also included are PDF documents dated 1981, indicating existing HVAC and plumbing plans. These are assumed to be fairly accurate with only minor changes that may have been occurred since originally constructed. New schematic plans currently dated are included to help visualize scope of the two design considerations. Also included is information for the major equipment described in the narrative and associated documents. The renovation will require modifications to the existing spaces, and the following mechanical design criteria will provide information needed for developing the requested budgets. Two separate HVAC design approaches are to be considered and evaluated for costs. Plumbing modifications will be required due to the increased occupancy loads and code requirements. The existing kitchen has had all equipment and fixtures removed except for one hood. No work is anticipated in this area at this time. The first design consideration will be to utilize the existing air handler systems and most of the ductwork. The second system design would remove existing ductwork and abandon the associated air handlers and replace with new packaged rooftop units. Fire and smoke venting, if required by the Fire Department, will differ depending on the design consideration. The utilization of the existing HVAC system will have two options to consider one nd utilizing roof vents, and the 2 will be mechanical exhaust, while the new HVAC system utilizing package RTU units will utilize only mechanical exhaust. In either case a method for introducing make up air will need to be considered (through doors, or other new openings). The costs associated with the smoke vent/exhaust shall be an add alternate. UTILIZATION OF EXISTING HVAC SYSTEMS Intent: Reuse existing air handler systems for heating and ventilation only. Cooling for the main Exposition area to be provided by adding new evaporative coolers on roof. The original design appears to have the been designed to accommodate economization using roof top exhaust fans to relieve building pressure and will be reused in the air handler economizer mode and for the evaporative cooling mode. November 17, 2010 Page 2 NORTH NEVADA EVENTS CENTER MECHANICAL NARRATIVE The existing 30-year-old air handler systems serving the proposed area for renovation consist of three constant volume air handlers (AHU-1, 2, 3), one multi-zone air handler (AHU-4) and one VAV air handler (AHU-5). These air handlers are configured for chilled water and hydronic heating. The units have been checked by owners and have found that all units can be operated, but condition of all components has not been determined. The system chiller is not functional, but the boiler is operational. The existing air handlers, noted above, will be used for heating and ventilation only, and will need to be reconditioned. The cooling coil and heating coils, along with associated piping and controls for each air handler will be removed. New heating coils are to be installed in each of the air handlers. The heating coil piping will require new control valve. New blower shaft bearings are to be installed. AHU -5 will need to have the inlet guide vanes locked open or removed. The interior of the air handlers will need to be thoroughly cleaned and checked for air leaks and resealed. Each of the AHU blower motors will need to be tested for proper continuity, rpm, amps and bearing noise. New sheaves and belts will be installed on each unit. The filter racks in each unit will be inspected and resealed to insure air stream is properly filtered. The existing exhaust fans will remain and be utilized. Only duct that extends down from ceiling space to floor from exhaust fans will be removed. All fans will need to be checked for proper operation, and have new belts installed. There are two heating circulation pumps in the lower mechanical room. One has been removed; the second has had a new motor installed. Provide new replacement heating pump (P-1a) Ductwork modifications will be as described – please refer to the accompanying 1981 mechanical drawings, and proposed HVAC drawings M-1 and M-2. On 1981 sheets M-1 and M-2, the duct work associated with AHU -1, 2, and 3 will require the removal of all of the duct branch drops to diffusers, and the opening patched. A new round duct drop will be installed in the bottom of the duct at the previous diffuser take-offs. This diffuser replacement will typically be 2 for 1, with the new diffuser type being a round end of duct adjustable diffuser mounted at 14” AFF. Typical diffuser will have 16” round neck with balance damper at diffuser. Again referring to 1981 sheet M-1, the duct work associated with AHU-5 will have all VAV boxes and connections to slot diffusers removed, except where duct serves existing offices, and bathrooms at existing entry. The supply duct will be separated at the transition in supply duct from 36 x 24 to 30 x 20. The 30 x 20 duct, VAV boxes, and diffusers will require some modification to accommodate the new entry vestibule, and will be connected to a new package VAV roof top unit. The remaining duct from AHU-5 serving the event area will be modified similar to AHU 1, 2, 3 ductwork as noted above, but will require some new branch duct to feed the new diffusers. The existing hydronic baseboard on the East exposures will remain except for where the entry is renovated. In the vestibule, new hydronic fan powered cabinet heaters will be utilized, and fed from the baseboard heating piping. New gas piping will need to be installed from the meter location to the new packaged RTU. November 17, 2010 Page 3 NORTH NEVADA EVENTS CENTER MECHANICAL NARRATIVE The duct work from AHU-4 supplying the old kitchen and support areas will remain as is. This will provide ventilation and heating only at this point. A new DX coil and remote condenser can be added in the future to this air handler if the area is finished out such that it requires mechanical cooling. Provide a line item cost to clean existing duct that will be reused. Inspect duct when work begins and report to owner conditions found. 10 evaporative coolers supplying approximately 19,000 CFM each will provide cooing in the main expo area. Each location will require a new roof opening, and curb installed. The curb will have to be flashed back in to existing roofing (or into new roofing if installed). Each unit will require motorized damper in the supply duct. A fill and drain kit shall be included and piped below the roof. The make-up water supply will be from a new tap in the existing cold water service near the central bathrooms. This single new connection will be provided with a backflow preventer and will serve all the new coolers. The drain lines(s) will be piped to the janitor rooms and discharged to janitor sinks. (Drain flow rate regulated by pipe size). The existing exhaust fan system (scheduled for approximately 79,000 CFM) will be utilized in the evaporative cooling mode. (A new 6500-CFM fan will be added). Additional barometric relief will be required and installed to keep building from over pressurizing. 4 new relief openings will be provided with back draft dampers. These will need to accommodate an additional 100,000 CFM of air. Additional bathroom exhaust ductwork will be needed, and fans will need to be replaced (1981 plans EF-8 and EF-11) with larger fans to accommodate new bathroom fixtures. The HVAC systems shall be retrofitted using new Set Point DDC controls, and will be able to communicate with main UCCS campus facilities. See 2010 plan sheet M-1 for basic control sequences. The smoke vent requirement per IBC 910, 2009 allows for automatically operated smoke vents in a fully sprinklered building. These could be an approved combination vent/skylight vent. These must be placed evenly throughout the ceiling space and may be difficult to do and coordinate with the existing mechanical duct and equipment. The requirement will be for a minimum of 467 square feet of venting. (3’ x 6’ units would require approximately 26 placements, etc; and coordinating with existing duct and other ceiling systems could be difficult and may not end up with much symmetry). The alternate is to provide mechanical smoke exhaust. The exhaust requirement will be a minimum of 140,100 CFM. The existing exhaust fans on the roof (79,000-CFM) will not meet this requirement alone. (These fans are probably not listed for smoke exhaust, and will need to be discussed with the fire department to verify if they can be used). Additional exhaust fans would need to be installed to provide an additional 61,100-CFM. The code mandates a maximum of 30,000 CFM per fan. Adding one additional 6500 CFM building exhaust fan and two dedicated 27,000-CFM exhaust fans is recommended. The existing fans and the new 6500 CFM fan will be used for HVAC economizer operation, and would have to be overridden by the Fire Control Panel to operate in conjunction with the 2 new dedicated smoke exhaust fans. November 17, 2010 Page 4 NORTH NEVADA EVENTS CENTER MECHANICAL NARRATIVE NEW HVAC SYSTEMS FOR EXPO AREA Intent: Provide new packaged rooftop units to serve the main Exposition area and separate units for the existing offices, and bathrooms near the existing entry, and in the future, possibly add a dedicated unit for the kitchen and support areas. Refer to existing mechanical drawings dated 1981, demo all supply ductwork associated with AHU-1, 2 and 3 beginning at the penetration from the mechanical room. These air handlers along with AHU-5 will be abandoned in place. Remove all supply ducts from AHU-5 to the transition (36 x 24 to 30 x 20). Remaining duct will be reused. .Ductwork from AHU-4 to kitchen area will remain. Referring to proposed HVAC plans M-3 and M-4, six new 50-ton packaged gas/DX rooftop units with power exhaust will be installed for the main Exposition area. The unit’s discharge will be a single supply drop with minimal ductwork, and a separate return back to the unit. A smaller 10 ton VAV packaged roof top will be installed and connected to existing 30 x 20 duct serving the main entry and offices. VAV boxes and diffusers will require some modification to accommodate the new entry vestibule. The existing hydronic baseboard on the East exposures will be replaced with electric baseboard except for where the entry is renovated. In the vestibule, new electric fan powered cabinet heaters will be utilized. Each RTU location will require a new roof opening, and a factory curb installed. The curb will have to be flashed back in to existing roofing (or into new roofing if installed). The new 50 ton units weigh approximately 6,500 lb each, requiring a structural review, units may require reoriented to accommodate the structural limitations. Bathroom exhaust fans will need to be replaced (1981 plans EF-8 and EF-11) with larger fans for additional bathroom fixtures being added. New gas piping will need to be installed from the meter location to the new rooftops at 7 locations. All new systems will have new Set Point DDC controls, and will be able to communicate with main UCCS campus facilities. See 2010 plan sheet M-2 for basic sequence of control. The smoke vent requirement per IBC 910, 2009 allows for mechanical smoke exhaust. The exhaust requirement will be a minimum of 140,100 CFM. The new RTU units have a powered exhaust that will be used for the smoke exhaust. Each RTU will have a capacity of approximately 18-19,000 CFM and when combined with the existing exhaust fans, (resheaved to about 2500 CFM each). The existing fans would not be used for any other purpose except smoke exhaust and would operate when the Fire Control signals RTU’s to change to smoke exhaust mode. (These fans are probably not listed for smoke exhaust, and will need to be discussed with the fire department to verify if they can be used). Standard skylights could easily be coordinated with this mechanical system and added if budget allows. November 17, 2010 Page 5 NORTH NEVADA EVENTS CENTER MECHANICAL NARRATIVE Plumbing System Modifications The existing acid waste drainage indicated on 1981 plans will be abandoned and grouted closed at floor drain locations. Bathrooms will be modified to accommodate the occupancy requirements. This will include additional fixtures at the two main bathroom groups. For the North (central location) the existing water closets are wall hung back outlet and for the intent of this budget, assume new fixtures can be connected to existing waste line in plumbing chase. In the other main bathroom to the south the slab will need to be cut and new waste lines added to accommodate the additional fixtures, specifically for 2 new lavs and 5 new water closets where there is not a possibility of connection to existing plumbing chase. This would be true foe the new unisex bathroom adjacent to the main bathroom area. Water for new flush valves will require new supply from main. The existing domestic hot water was supplied from a central water heater in the mechanical room. The water heater is not functional and has been abandoned. New water heaters are to be installed to serve each bathroom group. At each location, abandon existing mixing valve and pipe cold water to new electric water heater. Resupply existing fixtures and new fixtures from new water heaters. At each location, provide a small recirc pump to minim Mize the wait time and water use. The bathroom group at the main entry will also need to have the hot water supplied from a new electric water heater. Insure that all janitor closets remain connected to revised water supply. All existing flush valves for urinals and water closets need to be checked for proper operation, and have new repair kits installed where needed. Faucets needing repair will be replaced. Fire Protection System The building is currently fully sprinkled protecting spaces with lay-in ceilings. These ceilings will be removed. The sprinkler system will require modification to provide coverage for the open exposed ceiling. Variations will be needed to accommodate the ductwork indicated in the two HVAC design considerations described above. The entire system will require new Hydraulic calculations. Refer to above narrative for discussion regarding smoke exhaust systems. The installation shall conform to the 2009 International Mechanical Code, International Plumbing Code, NFPA, National Electrical Codes and all Colorado Springs code requirements. The budget shall include permit fees and drawings necessary for permits.