GEOTECHNICAL INVESTIGATION STUDENT HOUSING BUILDINGS UCCS SUMMIT VILLAGE COLORADO SPRINGS, COLORADO

advertisement

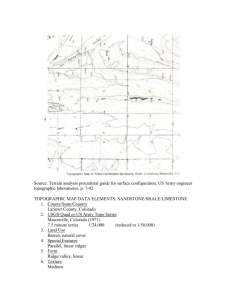

GEOTECHNICAL INVESTIGATION STUDENT HOUSING BUILDINGS UCCS SUMMIT VILLAGE COLORADO SPRINGS, COLORADO Prepared for: UNIVERSITY OF COLORADO AT COLORADO SPRINGS Facilities Services 1420 Austin Bluffs Parkway Colorado Springs, Colorado 80918 Attention: Mr. Gary Reynolds CTL|T Project No. CS17805-125 July 29, 2011 5240 Mark Dabling Blvd | Colorado Springs, Colorado 80918 | Telephone: 719-528-8300 Fax: 719-528-5362 TABLE OF CONTENTS SCOPE..................................................................................................................................... 1 SUMMARY............................................................................................................................... 1 SITE CONDITIONS.................................................................................................................. 2 PROPOSED CONSTRUCTION .............................................................................................. 3 SITE GEOLOGY ...................................................................................................................... 4 PREVIOUS INVESTIGATIONS ............................................................................................... 4 FIELD INVESTIGATION.......................................................................................................... 4 SUBSURFACE CONDITIONS ................................................................................................ 5 Existing Fill ....................................................................................................................... 5 Natural Soils ..................................................................................................................... 6 Bedrock ............................................................................................................................. 6 Ground Water ................................................................................................................... 6 Seismicity.......................................................................................................................... 7 SITE GRADING AND UTILITIES ............................................................................................ 7 FOUNDATIONS ....................................................................................................................... 8 Drilled Piers ...................................................................................................................... 9 Laterally-Loaded Piers .................................................................................................. 10 Closely-Spaced Pier Reduction Factors ..................................................................... 11 FLOOR SYSTEMS ................................................................................................................ 12 BELOW-GRADE CONSTRUCTION ..................................................................................... 15 PAVEMENTS ......................................................................................................................... 15 CONCRETE ........................................................................................................................... 16 SURFACE DRAINAGE.......................................................................................................... 17 CONSTRUCTION OBSERVATIONS .................................................................................... 18 GEOTECHNICAL RISK......................................................................................................... 18 LIMITATIONS ........................................................................................................................ 18 FIG. 1 – LOCATION OF EXPLORATORY BORINGS FIG. 2 – CONTOURS OF ESTIMATED BEDROCK SURFACE ELEVATION FIGS. 3 & 4 – SUMMARY LOGS OF EXPLORATORY BORINGS FIG. 5 – EXTERIOR FOUNDATION WALL DRAIN APPENDIX A – SWELL CONSOLIDATION TEST RESULTS TABLE A-1 – SUMMARY OF LABORATORY TESTING UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc SCOPE This report presents the results of our Geotechnical Investigation for two proposed student housing buildings to be constructed at Summit Village on the campus of The University of Colorado at Colorado Springs. The purpose of our investigation was to evaluate subsurface conditions at the site in order to develop geotechnical design criteria for the proposed structures. This report summarizes the results of our field and laboratory investigations and presents our design and construction recommendations for building foundations, floor system alternatives, pavement sections, and below-grade construction, as well as other details influenced by subsurface conditions. We believe the investigation was completed in general accordance with our proposal (CTL|T Proposal No. CS-11-0112) dated June 2, 2011. Evaluation of the project site for the possible presence of potentially hazardous materials (environmental site assessment) was beyond the scope of this investigation. This report was prepared based on conditions disclosed by our exploratory borings, results of laboratory tests, engineering analyses, and our experience with the campus and adjacent housing buildings. The design criteria presented in the report were based on our understanding of the planned construction and site improvements. If changes occur, we should review the revised plans to determine their effect on our recommendations. The following section summarizes the report. More detailed descriptions of subsurface conditions, as well as our design and construction recommendations, are presented in the report. SUMMARY 1. Subsurface conditions encountered in our exploratory borings drilled in the vicinity of the planned buildings consisted of about 2 to 7 feet of existing fill (all but one of the borings) underlain predominantly by natural sands. Sandstone and claystone bedrock were found in each of the borings underlying the existing fill or natural soils at depths of 2 to 34 feet below the existing ground surface. The sandstone was generally poorly to moderately cemented. However, refusal to practical auger drilling occurred in one boring (TH-1) at a depth of 27.5 feet below the existing ground surface. Samples of the sandstone and claystone exhibited a variety of swell-consolidation characteristics, ranging from low to very high measured swell values when wetted. UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 1 2. At the time of drilling, ground water was encountered in one of the borings at a depth of 28 feet. When ground water levels were checked again 22 days after the completion of drilling and sampling operations, water was measured at depths of 31 and 36 feet below the existing ground surface in two of the borings. 3. We anticipate the soils encountered at the lower level in each of the buildings will include grading fill, natural sands, and sandstone and/or claystone bedrock. To reduce the risk of excessive differential settlement of shallow foundations underlain by a widely varying combination of soil and bedrock materials, we recommend the proposed student housing buildings be constructed with drilled pier foundations bottomed in the underlying bedrock. Design criteria and construction recommendations for the drilled pier foundation are presented in the report. 4. We expect conventional slab-on-grade floors are considered an attractive floor system alternative for at-grade areas and we believe a low risk of poor slab performance will exist for slabs-on-grade underlain by at least 5 feet of the natural sand and/or new, densely compacted granular fill. We estimate floor slab movements of about 1 inch or less for this subgrade condition. Where sandstone and/or claystone bedrock is encountered at floor slab elevation or within 5 feet of the bottom of the floor slab, we recommend the bedrock materials be removed to a depth of at least 5 feet. The excavation should be backfilled with the on-site sand or a similar, non-expansive material that has been moisture conditioned and densely compacted. Floor slab movements on the order of about 1 inch can be expected for this condition. If the owner wishes to further reduce the risk of floor movements in the lower level of each building, structurally supported floors should be installed. 5. The proposed access driveways and parking areas can be paved with 5 inches of asphalt concrete. Alternative pavement sections are included in the report. 6. Surface drainage should be designed for rapid runoff of water away from the proposed buildings. Conservative irrigation practices should be followed to avoid excessive wetting. Water should not be allowed to pond adjacent to the structures, or over exterior slabs and pavements. SITE CONDITIONS The proposed student housing buildings will be located to the southwest of the existing Summit Village complex. Columbine Hall is situated to the east of the planned location for the east proposed building. Parking Lot 7 occupies the ground to the south of the planned structures. Regent Drive forms the western boundary of the project site. The location of the site and the surrounding features are presented in Fig. 1. UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 2 The ground surface in the area of the east building (borings TH-1 through TH-3) is comparatively flat in the northern half of the site where an existing basketball slab is located. The southern half of the anticipated east building footprint slopes downward to the southwest toward Parking Lot 7 at a grade estimated to be about 15 percent. A small rock outcrop is present to the south of the southern edge of the basketball slab. The anticipated area of the west building footprint (borings TH-4 through TH-8) comprises a shallow storm detention basin with its low point directly west of Parking Lot 7, near boring TH-8. The ground surface to the north of the bottom of the basin slopes downward to the south and southwest at grades estimated to be about 8 to 12 percent. No storm water was present in the basin at the time of our investigation. Vegetation in the area of the two proposed buildings consists of a thick stand of grasses, weeds, and deciduous bushes and trees. PROPOSED CONSTRUCTION We understand two additional student housing buildings are to be constructed to the southwest of the existing Summit Village and west of Columbine Hall. Plans for the buildings are in the very early conceptual stages. It is our understanding the east building will be similar to the smaller housing buildings that were previously constructed to the north. The west building may be somewhat larger. We anticipate the new structures will be similar in style to the existing housing buildings. Current development concepts call for the proposed buildings to have the first level cut into the existing hillside so that the northern end of the structure is below-exterior grades and entry will be at the second floor elevation. The first level of both buildings will “walkout” at the southern end of the structure. The first level of the west building might be used as a drive-under automobile parking area. The basement levels of the buildings could also include dorm rooms and storage areas. Three or possibly four stories are reportedly planned above the basement level in both buildings. Paved driveways will provide access to the buildings. We anticipate the proposed buildings will be concrete-frame structures with twin tee floors and roofs or steel-frame structures with concrete topping slabs over steel decking. Foundation column loads are expected to be in the range of 400 to 500 kips with exterior foundation wall loads possibly as high as 3 to 5 kips per lineal foot. UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 3 No grading plans were available for our review during the preparation of this study. Based on our understanding of the planned construction and observations of the existing site topography, we anticipate maximum cuts on the order of about 12 to 14 feet will be necessary in the northern end of the site and maximum fills of about 5 to 10 feet will be needed in the southern end of the building footprints to achieve the desired building pad elevations. SITE GEOLOGY Published geologic mapping (“Geologic Map of the Pikeview Quadrangle, El Paso County, Colorado,” Jon P. Thorson, Christopher J. Carroll and Mathew L. Morgan, Colorado Geological Survey, 2001) indicates the site is underlain locally by alluvial deposits (Qfo). The upper member of the Laramie Formation (Klu) comprises the underlying bedrock found beneath the near-surface soils. Conditions encountered in our borings generally confirm the mapping, although our borings suggest some man-made fill has been placed to adjust site grades. PREVIOUS INVESTIGATIONS CTL|Thompson, Inc. (CTL) prepared a Geotechnical Investigation (Job No. CS5371; report dated May 10, 1995) for the Summit Village student housing buildings (Phases I and II). CTL also prepared a Geotechnical Investigation (Job No. CS-6002; report dated December 13, 1995) for Columbine Hall. Drilled pier foundations bottomed in the bedrock were recommended in the 1995 soils investigations for both projects. Subsurface conditions encountered in the borings drilled during these previous studies were similar to the conditions found in the borings drilled during this investigation. FIELD INVESTIGATION The field investigation included drilling eight exploratory borings within the anticipated building footprints. Borings TH-1 through TH-3 were located in the general vicinity of the proposed east building. Borings TH-4 through TH-8 were intended to evaluate the subsurface conditions in the area of the west building. The borings were advanced to depths of 25 to 40 feet using 4-inch diameter, continuous-flight auger and a UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 4 truck-mounted drill rig. Drilling was observed by our field representative who logged the conditions found in the borings and obtained samples. Graphical logs of the conditions encountered in the borings, the results of field penetration resistance tests, and laboratory test data are presented in Figs. 3 and 4. Swell-consolidation test results are presented in Appendix A. Laboratory test data is summarized in Table A-1. Soil and bedrock samples obtained during drilling were returned to our laboratory and visually classified, and laboratory testing was assigned to representative samples. Testing included moisture content and dry density, swell-consolidation, sieve analysis, and water-soluble sulfate content tests. SUBSURFACE CONDITIONS Subsurface conditions encountered in our exploratory borings drilled in the vicinity of the planned buildings consisted of a layer of existing fill (all but one of the borings) underlain predominantly by natural sands. Sandstone and claystone bedrock were found in each of the borings underlying the existing fill or natural soils. The pertinent engineering characteristics of the soils and bedrock encountered are discussed in the following paragraphs. Existing Fill About 2 to 7 feet of silty to clayey sand fill was encountered at the existing ground surface in all but one of our borings. Results of field penetration resistance tests indicated the fill was loose to dense. The variable consistency of the fill suggests portions of the material may have been placed under uncontrolled conditions. We must therefore consider the existing fill to be of suspect quality and unsuitable to underlie the planned structures, in its current condition. If free from deleterious substances, we anticipate the fill can probably be excavated, moisture conditioned, and densely compacted as new fill within the planned development. UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 5 Natural Soils Natural, silty to clayey sand was encountered at the ground surface or beneath the existing fill in five of the eight borings and extended to depths of 6 to 34 feet. The sand was loose to medium dense based on the results of field penetration resistance tests. Six samples of the natural sand contained 14 to 35 percent clay and silt-size particles (passing the No. 200 sieve). Our experience indicates the sands are typically nonexpansive or exhibit low measured sells when wetted. A thin layer of sandy clay, about 3 feet thick, was encountered in one boring (TH-3) with the predominant sands, at a depth of 6 feet. This material typically exhibits low to moderate measured swells. Bedrock Sandy to very sandy claystone and slightly silty to clayey sandstone were found in each of the borings underlying the existing fill or natural soils at depths of 2 to 34 feet below the existing ground surface. Contours of the estimated bedrock surface elevation are presented in Fig. 2. Field penetration resistance test results indicated the bedrock was medium hard to very hard. The sandstone encountered in our borings was generally poorly to moderately cemented. However, refusal to practical auger drilling occurred in one boring (TH-1) at a depth of 27.5 feet indicating cemented sandstone layers are present. Five samples of the claystone exhibited low to very high measured swells of 1.2 to 7.4 percent when wetted under a vertical pressure of 1,000 psf. One sample of the clayey sandstone swelled 1.5 percent when wetted. Three samples of the sandstone tested in our laboratory contained 10 to 21 percent clay and silt-size particles (passing the No. 200 sieve). Ground Water At the time of drilling, ground water was encountered in one of the borings at a depth of 28 feet. When ground water levels were checked again 22 days after the completion of drilling and sampling operations, water was measured at depths of 31 and 36 feet below the existing ground surface in two of the borings. Ground water elevations UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 6 will fluctuate in response to seasonal precipitation variations and landscaping irrigation. Although ground water is anticipated to be encountered during installation of drilled pier foundations, we do not expect ground water to significantly impact construction of the proposed buildings. Seismicity This area, like most of central Colorado, is subject to a degree of seismic activity. We believe the soils and bedrock on the site classify as Site Class C (dense soil and soft rock) according to the 2009 International Building Code (2009 IBC). SITE GRADING AND UTILITIES No grading plans were available for our review during the preparation of this study. We anticipate maximum cuts on the order of about 12 to 14 feet will be necessary in the northern end of the site and maximum fills of about 5 to 10 feet will be needed in the southern end of the building footprints to achieve the desired building pad elevations. Prior to grading fill placement, vegetation and other deleterious materials such as stockpiled soils and debris, and concrete flatwork should be removed from the site. Organic topsoil can be stockpiled and placed in landscaped areas. Existing fill should be excavated to expose the underlying natural soils. If free of deleterious materials, the existing fill soils can probably be incorporated into the new grading fill. Fill materials should consist of the on-site sands and sandstone that have been moisture conditioned to within 2 percent of optimum moisture content and compacted in thin lifts to at least 95 percent of maximum standard Proctor dry density (ASTM D 698). Sandstone placed as grading fill should be mechanically broken down into particles of less than 2 inches in diameter. Claystone bedrock should be placed as fill outside of the planned building footprints or be removed from the site. The placement and compaction of the grading fill should be observed and tested by a representative of our office during construction. We believe the on-site sand soils can be excavated using conventional, heavyduty equipment. Very hard and cemented layers of sandstone, that require rock teeth or jack-hammering, could be encountered in utility trench excavations. The on-site, natural UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 7 sand soils and granular grading fill materials will likely cave into unsupported, steep utility trench excavations. Based on the Occupational Safety and Health Administration (OSHA) criteria governing excavations, the on-site, natural sands and granular grading fills will probably classify as Type C soils. The bedrock will probably classify as Type B soil. Temporary excavations in Type B and Type C materials require a maximum slope inclination of 1:1 and 1.5:1 (horizontal to vertical), respectively, unless the excavation is shored or braced. Should ground water seepage occur, flatter slopes may be necessary. Water and sewer lines are often constructed beneath paved areas. Compaction of utility trench backfill will have a significant effect on the life and serviceability of pavements. We recommend utility trench backfill be placed in thin, loose lifts, moisture conditioned to within 2 percent of optimum moisture content, and compacted to at least 95 percent of maximum standard Proctor dry density (ASTM D 698). Personnel from our firm should periodically observe utility trench backfill placement and test the density of the fill materials during construction. FOUNDATIONS Our investigation indicates granular grading fill, natural sands, sandstone, and possibly claystone bedrock will be encountered at shallow foundation levels within the basement levels of the two proposed buildings. Spread footing foundations could be designed for these types of materials. However, comparatively high foundation loads are anticipated for the multi-story structures, resulting in the need for large footings to accommodate the lower allowable soil pressure applicable to the sand soils. The soil materials and bedrock will behave differently under the foundation loads which would likely result in excessive differential settlements between the footings. We believe the more reliable foundation approach for the two proposed buildings that will reduce the risk of foundation movements and the associated damage is a drilled pier system bottomed in the underlying bedrock. The piers will transfer the foundation loads to the comparatively strong bedrock formation which will reduce the risk of excessive differential movements between the different portions of structures. We recommend the drilled pier foundations for the proposed buildings be designed and constructed in accordance with the criteria presented in the following sections. UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 8 Drilled Piers 1. Piers should be designed for a maximum allowable end pressure of 40,000 psf. We recommend an allowable skin friction of 4,000 psf for the portion of pier in comparatively unweathered bedrock. Any bedrock penetration within the top 5 feet of the pier should be neglected from the load capacity calculations. 2. Piers should be designed for a minimum deadload pressure of 15,000 psf based on pier cross-sectional area only. If this deadload cannot be achieved through the weight of the structure, the pier length and bedrock penetration should be increased beyond the minimum values specified in the next paragraph. The bedrock should be assigned a skin friction value of 4,000 psf for resistance to expansive soil uplift and tensile structural loads. 3. Piers should penetrate at least 8 feet into relatively unweathered bedrock and have a total drilled length of at least 20 feet. Pier lengths of up to 40 to 50 feet are possible in the southern end of the anticipated western building footprint to achieve the required bedrock penetration. 4. The quantity and size of column reinforcement, or the size of base plates, may dictate the most convenient size of drilled piers. Economy can be achieved by varying the depth of penetration and limiting the number of pier diameters. The minimum pier diameter will depend on the length to diameter ratio (L/D), among other considerations. We recommend the L/D ratio be kept in the range of 25 to 30. In addition, a minimum diameter of 18 inches is recommended for all piers to facilitate the use of temporary casing, if needed. 5. We anticipate a comparatively large, commercial-grade pier drilling rig will be needed to achieve the expected pier lengths and bedrock penetration. Rock augers and rock teeth may be needed to cut through cemented sandstone layers that could be encountered during drilled pier installation. 6. Pier drilling should produce shafts with relatively undisturbed bedrock exposed. Excessive remolding and caking of bedrock on pier walls should be removed by roughening. 7. Piers should be reinforced their full length. The reinforcement should extend into grade beams or foundation walls. A minimum steel/pier area ratio of 0.01 using Grade 60 steel (420 Mpa) is recommended. More reinforcement will probably be required for structural considerations. The design of pier reinforcement should consider concrete placement and the possibility of tremie placement for dewatering of shafts. 8. There should be at least a 4-inch thick, continuous void beneath the grade beams, between the piers, to concentrate the deadload of the structure onto the piers. UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 9 9. Piers should have a center-to-center spacing of at least three pier diameters when designing for vertical loading conditions, or they should be designed as a group. Piers aligned in the direction of lateral forces should have a center-to-center spacing of at least six pier diameters. Reduction factors for closely-spaced piers are discussed in the following section. 10. Piers should be carefully cleaned and dewatered prior to placement of concrete. Ground water was encountered during this investigation. The sands that overlie the bedrock may cave into large diameter, unsupported pier excavations. We anticipate temporary casing and possibly drilling slurry will be needed to properly clean and dewater some of the drilled pier shafts during installation. Concrete should be ready on-site and placed in the pier holes immediately after the holes are drilled, cleaned, and observed by our representative, to avoid collecting water and possible contamination of open pier holes. Temporary casing should be available on-site in the event it is needed to install the drilled piers. Concrete should not be placed by free fall if there is more than 3 inches of water at the bottom of the hole. If ground water is encountered in the bedrock formation and cannot be controlled through the use of temporary casing, it may be necessary to pump the concrete to the bottom of the pier holes and displace accumulated water with the rising column of concrete. 11. Concrete placed in pier holes should have sufficient slump to fill the pier hole and not hang on the reinforcement or the sides of the casing (if needed) during extraction. We recommend a slump in the range of 5 to 7 inches. 12. Some movement of the drilled pier foundations is anticipated to mobilize the strength of the bedrock. We estimate this movement to be on the order of 1/4 to 1/2-inch to mobilize skin friction. Differential movement may be equal to the total movement. Designs should consider these potential movements and accommodate them as much as practical. 13. Formation of mushrooms or enlargements at the top of piers should be avoided during pier drilling and subsequent construction operations. 14. The installation of the drilled piers should be observed by a representative of our firm to confirm the piers are bottomed in the proper bearing strata and to observe the contractor’s installation procedures. Laterally-Loaded Piers Lateral load analysis of piers can be performed with the software analysis package LPILE by Ensoft, Inc. We believe this method of analysis is appropriate for piers with a pier length to diameter ratio of seven or greater. Suggested criteria for LPILE analysis are presented in the following Table A. UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 10 The 50 value represents the strain corresponding to 50 percent of the maximum principle stress difference. The moduli of subgrade reaction for static (ks) and cyclical (kc) conditions are used by the program to generate the slope of the initial portion of the “p-y Curves”. TABLE A SOIL INPUT DATA FOR “LPILE” Soil Type Natural Sand and Sand Fill Bedrock 0.07 0.08 - 60 30 - - 0.004 90 2,000 90 1,000 Density (pci) Cohesion, c (psi) Friction Angle (degrees) 50 (in/in) ks (pci) kc (pci) Other analysis procedures require input of a horizontal modulus of subgrade reaction (Kh). We believe the following formulas listed in Table B are appropriate for calculating horizontal modulus of subgrade reaction (Kh) values. TABLE B MODULUS OF SUBGRADE REACTION Soil Type Natural Sand and Sand Fill Bedrock Modulus of Subgrade Reaction, Kh (tcf) Kh = 20 x z d Kh = 300 d Where z = depth (ft); d = pier diameter (ft). Closely-Spaced Pier Reduction Factors For axial loading, a minimum spacing of three diameters (center-to-center) is recommended. At one diameter (piers touching), the skin friction load reduction factor UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 11 for both piers would be 0.5. End bearing values need not be reduced, provided the bases of the piers are at similar elevations. Interpolation can be used between one and three diameters. Piers in-line with the direction of lateral loads should have a minimum spacing of six diameters (center-to-center) based upon the larger pier. If a closer spacing is required, the modulus of subgrade reaction for initial and trailing piers should be reduced. At a spacing of three diameters, the effective modulus of subgrade reaction of the first pier can be estimated by multiplying the given modulus by 0.6. For trailing piers in a line at three diameter spacing, the factor is 0.4. Linear interpolation can be used for spacing between three and six diameters. Reductions to the modulus of subgrade reaction can be accomplished in LPILE by inputting the appropriate modification factors for the p-y curves. Reducing the modulus of subgrade reaction in trailing piers will result in greater computed deflections on these piers. In practice, the grade beam can force deflections of all piers to be equal. Loaddeflection graphs can be generated for each pier using the appropriate p-multiplier values. The sum of the pier lateral load resistance at selected deflections can be used to develop a total lateral load versus deflection graph for the system of piers. For lateral loads perpendicular to the line of piers, a minimum spacing of three diameters (center-to-center) can be used with no capacity reduction. At one diameter (piers touching), the piers can be analyzed as one unit. Interpolation can be used for intermediate conditions. FLOOR SYSTEMS Based on our understanding of the proposed construction, subsurface conditions encountered in our borings, and the results of laboratory testing, we anticipate existing fill, natural sands, sandstone, and possibly claystone may be encountered at the finished floor elevation in the basement level of both proposed buildings. Existing fill should be excavated from floor slab areas to expose the underlying natural soils. The excavation should be backfilled with granular soils placed and compacted in accordance with the recommendations presented in SITE GRADING AND UTILITIES. UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 12 We expect conventional slab-on-grade floors are considered to be an attractive floor system alternative. We anticipate a low risk of poor slab performance will exist for slabs-on-grade underlain by at least 5 feet of the natural sand and/or new, densely compacted granular fill. We estimate floor slab movements of about 1 inch or less for this subgrade condition. Where sandstone and/or claystone bedrock is encountered at floor slab elevation or within 5 feet of the bottom of the floor slab, and a slab-on-grade floor is the desired floor system alternative, we recommend the bedrock materials be removed to a depth of at least 5 feet. The excavation should be backfilled with the on-site sand or a similar, non-expansive material that has been moisture conditioned to within 2 percent of optimum moisture content and compacted in thin lifts to at least 95 percent of maximum standard Proctor dry density (ASTM D 698). Floor slab movements on the order of about 1 inch can be expected for this condition. If the risk of possible movement of the floor slabs is unacceptable, the owner should consider construction of structurally supported floors in the basement level of the proposed buildings. If slab-on-grade floors are to be installed in the basement level of either or both of the proposed buildings, and the owner accepts the risk of movement and associated damage, we recommend the following precautions for slab-on-grade construction at this site. All parties must realize that even small movements of the floor slab (less than 1-inch) can damage comparatively brittle floor treatments, such as ceramic tile, that might be used in a restroom area. The following precautions can help reduce, but not eliminate damage or distress due to slab movement. 1. New fill placed below the basement floor slabs should consist of the onsite sand or a similar, non-expansive material moisture conditioned to within 2 percent of optimum moisture content and compacted in thin lifts to at least 95 percent of maximum standard Proctor dry density (ASTM D 698). The placement and compaction of the below-slab backfill should be observed and tested by a representative of our office during construction. 2. While, in our opinion, there is no need from a geotechnical standpoint for a vapor retarder at this site, the 2009 International Building Code (IBC) requires a vapor retarder be placed between base course or the subgrade soils and the concrete slab-on-grade floor, unless the designer of the floor (structural engineer) waives this requirement. The merits of installation of a vapor retarder below floor slabs depend on the sensitivity of floor coverings and building use to moisture. A properly installed vapor retarder (10 mil minimum) is more beneficial below concrete slab-on-grade floors where floor coverings, painted floor surfaces or products stored on the UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 13 floor will be sensitive to moisture. The vapor retarder is most effective when concrete is placed directly on top of it, rather than placing a sand or gravel leveling course between the vapor retarder and the floor slab. The placement of concrete on the vapor retarder may increase the risk of shrinkage cracking and curling. Use of concrete with reduced shrinkage characteristics including minimized water content, maximized coarse aggregate content, and reasonably low slump will reduce the risk of shrinkage cracking and curling. Considerations and recommendations for the installation of vapor retarders below concrete slabs are outlined in Section 3.2.3 of the 2006 report of the American Concrete Institute (ACI) Committee 302, “Guide for Concrete Floor and Slab Construction (ACI 302.R-96)”. 3. We recommend slab-on-grade floors be separated from exterior walls and interior bearing members with joints that allow for independent vertical movements of the slab relative to the foundation. Provision of a 1-1/2 inch thick slip joint in slab-bearing partitions can reduce the risk of cracking of drywall resulting from slab movements. If the “float” is provided at the tops of partitions, the connection between interior, slab-supported partitions and exterior, foundation-supported walls should be detailed to allow differential movement. These architectural connections are critical to help reduce cosmetic damage should foundations and floor slabs move relative to each other. We have seen instances where these architectural connections were not designed and constructed properly and resulted in moderate cosmetic damage, even though the movement experienced was well within the anticipated range. The architect should pay special attention to these issues and detail the connections accordingly. Masonry block partitions (load bearing or not) should be constructed on their own independent foundations and not a thickened floor slab. 4. Underslab plumbing should be avoided as much as possible. If underslab plumbing is necessary, service lines should be pressure tested for leaks during construction. Any utility line that penetrates a slab should be isolated from the slab with a joint to allow for free vertical movement. 5. Slab-supported mechanical systems should have flexible connections to allow for vertical movement without rupturing supply lines. 6. Frequent control joints should be provided in the slabs to reduce the effects of curling and help reduce shrinkage cracking. Our experience indicates a joint spacing of not greater than 30 times the slab thickness is effective in this area. 7. Exterior flatwork and sidewalks should be separated from the buildings. These slabs should be designed to function as independent units. Movement of these slabs should not be transmitted directly to the foundation of the structure. UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 14 BELOW-GRADE CONSTRUCTION We understand portions of the first level of each building will be constructed below exterior grades. The foundation walls will be subjected to lateral earth loads that are dependent on the height of the wall, soil type, and backfill configuration. For backfill materials that consist of the on-site silty to clayey sands and walls that are not free to rotate, such as foundation walls, we recommend the walls be designed to resist “at-rest” earth pressures. We recommend design for the “at-rest” earth pressure condition using an equivalent fluid density of at least 60 pcf. The lateral pressure described above does not include allowances for surcharge loads such as hydrostatic pressure. Drains are typically recommended surrounding habitable below-grade areas. We recommend a drain system similar to the detail shown in Fig. 5 be installed adjacent to the basement walls. The drain should include a vertical drainage column consisting of at least 12 inches of washed gravel or an approved drain board. We recommend foundation wall backfill be compacted to limit settlement. Backfill should be moisture conditioned to within 2 percent of optimum moisture content and compacted in thin lifts to at least 95 percent of maximum standard Proctor dry density (ASTM D 698). The placement and compaction of foundation wall backfill should be observed and tested by a representative of our office during construction. Even properly compacted backfill will consolidate somewhat under its own weight. Typically, consolidation on the order of about 1 percent of the backfill thickness can be expected. Utility service lines that penetrate the basement walls should be designed and installed with enough flexibility to accommodate backfill settlement of this magnitude. Rigid utility line penetrations are not recommended. PAVEMENTS We understand paved access driveways and possibly some small, automobile parking areas will be constructed in association with the proposed buildings. Our exploratory borings suggest the subgrade soils within the anticipated driveways and UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 15 parking areas will consist predominantly of natural sand soils and granular grading fill. This type of material generally exhibits good pavement support characteristics. Based on our experience, a Hveem stabilometer (“R”) value of 45 was assigned to the subgrade materials for design purposes. We anticipate the access driveways and parking areas will be subjected to automobile traffic and an occasional heavy vehicle load such as a trash truck. We considered a daily traffic number (DTN) of 2 for the access driveways which corresponds to 18-kip Equivalent Single-Axle Loads (ESAL) of 14,600, for a 20-year pavement design life. We believe the driveways and parking areas can be paved with 5 inches of asphalt concrete or 3 inches of asphalt concrete over 6 inches of aggregate base course. Any trash dumpster sites should include a concrete pavement that is at least 6 inches thick and large enough to support the entire length of the trash truck and dumpster during the emptying process. Joints between concrete and asphalt pavements should be sealed with a flexible compound. Our design considers pavement construction will be completed in accordance with the City of Colorado Springs “Standard Specifications” and the Pikes Peak Regional Asphalt Paving Specifications. The specifications contain requirements for the pavement materials (asphalt, base course, and concrete) as well as the construction practices used (compaction, materials sampling, and proof-rolling). Of particular importance are those recommendations directed toward subgrade and base course compaction and proofrolling. During proof-rolling, particular attention should be directed toward the areas of confined backfill compaction. Areas that pump excessively should be stabilized prior to pavement construction. A representative of our office should be present at the site during placement of fill and construction of pavements to perform density testing. CONCRETE Concrete in contact with soils can be subject to sulfate attack. We measured the soluble sulfate concentration in two samples from this site at less than 0.1 percent. Sulfate concentrations less than 0.1 percent indicate Class 0 exposure to sulfate attack for concrete in contact with the subsoils, according to ACI 201.2R-01, as published in the UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 16 2008 American Concrete Institute (ACI) Manual of Concrete Practice. For this level of sulfate concentration, the ACI indicates Type I/II cement can be used for concrete in contact with the subsoils. In our experience, superficial damage may occur to the exposed surfaces of highly permeable concrete, even though sulfate levels are relatively low. To control this risk and to resist freeze-thaw deterioration, the water-to-cementitious material ratio should not exceed 0.50 for concrete in contact with soils that are likely to stay moist due to surface drainage or high water tables. Concrete subjected to freezethaw cycles should be air entrained. SURFACE DRAINAGE Performance of the foundation systems, floor slabs, concrete flatwork, and pavements to be constructed at this site will be significantly influenced by the moisture conditions existing within the near-surface soils. Overall surface drainage patterns must be planned to provide for the rapid removal of storm runoff. Water should not be allowed to pond adjacent to foundations or over pavements or concrete flatwork. We recommend the following precautions be observed during construction and maintained at all times after the buildings are completed. 1. Excessive wetting or drying of the open foundation excavations should be avoided. 2. Foundation wall backfill should be graded to provide for the rapid removal of runoff. We recommend a slope equivalent to at least 6 inches in the first 10 feet. In pavement and flatwork areas adjacent to the buildings, the slope may be reduced to 2 inches in the first 5 feet. 3. Exterior wall backfill should be placed in thin, loose lifts, moisture conditioned to within 2 percent of optimum moisture content and compacted to at least 95 percent of maximum standard Proctor dry density (ASTM D 698). 4. Roof downspouts and drains should discharge well away from the structures. Downspout extensions and/or splash blocks should be provided to help reduce infiltration into the backfill adjacent to the buildings. 5. Landscaping concepts should concentrate on use of plantings that require little or no supplemental irrigation after the vegetation is established. Irrigated sod, if it is included in the landscaping plan, should not be located within 6 feet of the foundation walls. Irrigation should be limited to the UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 17 minimum amount sufficient to maintain vegetation. Application of more water will increase likelihood of slab and foundation movements. CONSTRUCTION OBSERVATIONS We recommend that CTL | Thompson, Inc. provide observation and testing services during construction to allow us the opportunity to verify whether soil conditions are consistent with those found during this investigation. If others perform these observations, they must accept responsibility to judge whether the recommendations in this report remain appropriate. GEOTECHNICAL RISK The concept of risk is an important aspect with any geotechnical evaluation primarily because the methods used to develop geotechnical recommendations do not comprise an exact science. We never have complete knowledge of subsurface conditions. Our analysis must be tempered with engineering judgment and experience. Therefore, the recommendations presented in any geotechnical evaluation should not be considered risk-free. Our recommendations represent our judgment of those measures that are necessary to increase the chances that the structure will perform satisfactorily. It is critical that all recommendations in this report are followed during design and construction. LIMITATIONS Our borings were located to obtain a reasonably accurate indication of subsurface foundation conditions and as physical access constraints would allow. The borings are representative of conditions encountered at the exact boring location only. Variations in subsurface conditions not indicated by the borings are possible. We recommend a representative of our office observe the completed foundation excavations. Representatives of our firm should be present during construction to perform construction observation and materials testing services. UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. Reports\CS17805-125-R1.doc 18 TH - 1 EL. 6386 EAST BUILDING TH - 2 EL. 6382 TH - 3 EL. 6371 6,390 6,390 6,385 6,385 6,380 22/12 WC=8.0 DD=93 -200=30 50/2 6,380 50/6 WC=4.3 -200=21 6,375 6,375 50/1 6,370 6,370 50/2 50/3 21/12 WC=4.7 DD=101 SS=<0.1 6,365 6,360 42/12 WC=20.4 DD=107 SW=7.4 6,360 6,355 50/9 WC=21.7 DD=102 SW=4.9 6,355 6,365 50/2 50/6 WC=4.9 DD=106 -200=10 50/6 WC=14.1 DD=114 SW=2.1 6,350 6,350 50/6 6,345 UNIVERSITY OF COLORADO AT COLORADO SPRINGS SUMMIT VILLAGE STUDENT HOUSING BUILDINGS CTL|T PROJECT NO. CS17805-125 S:\CS17500-17999\CS17805.000\125\2. REPORTS\CS17805-125_GINT.GPJ 6,345 Summary Logs of Exploratory Borings FIG. 3 ELEVATION - FEET ELEVATION - FEET 50/2 TABLE A-1 SUMMARY OF LABORATORY TESTING CTL|T PROJECT NO. CS17805-125 BORING TH-1 TH-2 TH-2 TH-2 TH-3 TH-3 TH-3 TH-4 TH-4 TH-4 TH-4 TH-4 TH-5 TH-5 TH-5 TH-6 TH-6 TH-6 TH-7 TH-7 TH-7 TH-7 TH-8 TH-8 TH-8 TH-8 DEPTH (FEET) 4 4 19 29 4 9 14 4 9 14 19 29 4 24 34 4 14 29 4 9 19 34 4 14 24 34 MOISTURE DRY CONTENT DENSITY (%) (PCF) 8.0 93 4.3 4.9 106 14.1 114 4.7 101 20.4 107 21.7 102 5.5 98 5.0 102 7.3 98 6.8 110 18.9 109 10.8 109 18.4 112 18.2 105 6.0 97 5.4 100 14.6 115 11.2 117 8.4 99 6.3 108 10.9 110 11.4 113 15.3 100 9.1 112 21.1 106 ATTERBERG LIMITS LIQUID PLASTICITY LIMIT INDEX (%) (%) * SWELL MEASURED WITH 1000 PSF APPLIED PRESSURE. NEGATIVE VALUE INDICATES COMPRESSION. SWELL TEST RESULTS* SWELL SWELL PRESSURE (%) (PSF) 2.1 5000 7.4 4.9 22000 12000 3.5 19000 1.2 1.5 PASSING WATER NO. 200 SOLUBLE SIEVE SULFATES (%) (%) DESCRIPTION 30 FILL, SAND, CLAYEY 21 SANDSTONE, SILTY 10 SANDSTONE, SLIGHTLY SILTY CLAYSTONE, SANDY <0.1 SAND, CLAYEY (SC) CLAYSTONE, SANDY CLAYSTONE, SANDY FILL, SAND, SILTY <0.1 SAND, SILTY (SM) 23 SAND, SILTY (SM) 18 SANDSTONE, SILTY CLAYSTONE, SANDY FILL, SAND, CLAYEY CLAYSTONE, SANDY SANDSTONE, CLAYEY 22 SAND, SILTY (SM) SAND, SILTY (SM) SANDSTONE, CLAYEY FILL, SAND, CLAYEY 17 SAND, SILTY (SM) 14 SAND, SILTY (SM) SANDSTONE, SILTY FILL, SAND, CLAYEY 35 SAND, CLAYEY (SC) 25 SAND, CLAYEY (SC) SANDSTONE, CLAYEY Page 1 of 1