A REGRESSION APPROACH FOR ZIRCALOY-2 IN-REACTOR CREEP CONSTITUTIVE EQUATIONS

advertisement

A REGRESSION APPROACH FOR ZIRCALOY-2

IN-REACTOR CREEP CONSTITUTIVE EQUATIONS

by

YUNG LIU, Y and A. L. BEMENT

(Energy Laboratory Report No. MIT-EL 77-012)

December 1977

11

I

A REGRESSION APPROACH FOR ZIRCALOY-2 IN-REACTOR CREEP

CONSTITUTIVE EQUATIONS

by

YUNG LIU, Y.

and

A. L. BEMENT

ENERGY LABORATORY

and

Department of Nuclear Engineering

and

Department of Materials Science and Engineering

Massachusetts Institute of Technology

Cambridge, Massachusetts 02139

Special Report for Task 2 of the Fuel

Performance Program

Sponsored

by

New England Electric System

Northeast Utilities Service Co.

under the

MIT Energy Laboratory Electric Power Program

Energy Laboratory Report No. MIT-EL 77-012

December 1977

AUTHORS'NOTES

This report contains two parts of the study on Zircaloy-2 inreactor creep constitutive equations. Part I was completed earlier

in May, 1976 in which the essentials

and the preliminary

results

of and from the analysis are given. Part II which was completed

later in November, 1976 is an addendum of Part I with additional

results and discussions. Readers are advised to follow the sequence

of presentation

in order to see the entirety

of the analysis.

A condensed version of Part I is presented at the SMiRT -4th

Conference

August,

1977 and can be found

in the conference

ceedings under Division C, paper 3/3.

*

SMiRT - Structural Mechanics in Reactor Technology

pro-

ABSTRACT

Typical data analysis procedures used in developing current

phenomenological in-reactor creep equations for Zircaloy cladding

materials are examined. It is found that the data normalization

assumptions and the curve fitting techniques generally adopted in

these procedures can make the prediction of creep strain rate from

the resulting equations highly questionable.

Multiple regression analysis performed on a set of carefully

selected Zr-2 in-reactor creep data on the basis of comparable as

fabricated metallurgical conditions indicates that models of the form

= Aaonm exp (-Q/RT) can give significant account for the data.

Both regression statistics and residual plots have provided strong

evidences for the significance of the regression equations.

ABSTRACT OF THE ADDENDUM

The addendum of this report contains the results and discussions of the analysis we made on our revised Zircaloy-2 in-reactor

creep data. Although fewer creep rate data were used, much of the

same general conclusions can be made as we did previously. The

differences between the final recommended regression Zircaloy-2

in-reactor creep equations in the report and the addendum are primarily those of the estimated coefficients. The starting model

equations continue to provide excellent correlations for the creep

strain rate data.

Our attempt to verify the additivity of thermal and irradiation

creep components directly from the creep data set show that there

is little merit in using a composite formula made up by the above

two components for ranges covered by the test parameters.

This

statement should not be looked upon as a denial to such a treatment,

however, especially in situations of combinations of high , a and

T where changes in dominating deformation mechanism are possible.

At present, we do not have reliable data in those regimes.

Part I

1;

Table of Contents

Page No.

1.

Introduction

2.

Examination of current in-reactor creep models ----------------

3

2.1

Watkins and Wood's assumptions --------------------------------

7

3.

Regression analysis ---------------------------------

10

3.1

Regression Models ---------------------------------------------

11

3.2

Regressions Programs ------------------------------------------

15

4.

Examination of Zr-2 in-reactor creep data ---------------------

18

4.1

Accuracies of data --------------------------------------------

25

-----------------------------------------------

4.1.1 Errors due to Measurement

-------------------------------------

1

25

4.1.2 Errors due to calculation -------------------------------------

26

4.2

Normalization assumptions -------------------------------------

27

4.3

Time Effects ----------------------------------------------

30

5.

Regression results ----------------------------------------

31

5.1

Residual plots ---

33

5.2

Estimated regression coefficients and 95% confidence

intervals

5.3

5.4

-----------------------------------------------------

Comparisons

of current

empirical

38

and regression

creep equations -----------------------------------------------

40

Concluding remarks --------------------------------------------

50

References ---------------------------------------

51

Appendix A:

Zircaloy-2 In-reactor Creep Data

----------------------

53

Appendix B:

The Actual Set of In-reactor Creep Data

Used in Regression Analysis ----------------------------

58

Appendix C:

Regression Statistics ----------------------------------

60

Appendix D:

Stepwise Regressions of Zr-2 In-reactor

Creep Data --------------------------------------------

70

List 'ofTables

Page No.

Table 1:

Summary of in-reactor creep models and their data

bases

Table 2:

Summary of irradiation creep data used in

assessment of Watkins and Wood's equation

Table 3:

24

Comparisons of Normalized creep rates under

two different normalization assumptions

Table 7:

20

Operating conditions of U-49 tubular creep

insert

Table 6:

19

Summary of 20% CW and stress relieved Zr-2

in-reactor creep data

Table 5:

9

Total number of data observations in each

subset

Table 4:

4

29

Multiple regressions coefficients and F

statistics

32

Table 8:

Regression coefficients and their SEE's

38

Table 9:

Overall 95% confidence intervals

39

List of Figures

Page No.

Figure 1:

Figure 2:

Comparisons

of creep

ksi, flux=10

14

Comparisons

of creep

laws at stress=7.5

2

n/cm s

5

laws at T=300 0 C, flux=

6

1O14 n/cm2s

Figure 3:

Schematic

residual

Figure 4:

A schematic

17

plots

diagram of the samll tube in22

reactor creep specimen assembly

Figure

5:

The operating conditions for the Zircaloy-2

tubular creep experiment (Ross-Ross & Hunt)

Figure

6:

Creep rate of pressure tube normalized

to 14

2

28

ksi and 1013 n/cm s vs temperature

Figure

7:

Residual plots(a), (b) for regression models

(3)

Figure

8:

34

and (5)

Residual plots(a), (b) for regression models

(6) and (10)

Figure

9:

Residual

35

(b) for regression

plots(a),

models

(11) and (12)

Figure

36

10: Residual plot for the revised Ross-Ross

Hunt's regression model

Figure

23

and

37

(14)

11: Comparison of creep laws at T250C,

flux=

5)10 1 3 n/cm 2 s

42

Figure 12: Comparison of creep laws at T=3000 C, flux=

5x1013 n/cm 2s

Figure 13: Comparison

43

of creep laws at T=350 0 C, flux=

5xl013 n/cm2s

44

Figure 14: Comparison of creep laws at

0

T=400 C, flux=

5x10 1 3 n/cm2s

Figure 15:

Comparison

45

of creep laws at stress=7.5

ksi,

flux=5x101 3 n/cm2s

Figure 16:

Comparison

of creep

flux=5x10 1 3 n/cm2s

46

laws at stress=20

ksi,

47

r

I·

1.

Introduction:

In this report results

and discussions

are given on the development

of

Zr-2 in-reactor creep constitutive equations. Although several theoretical

irradiation enhanced creep models have been proposed( '

2'

3), present fuel

rod design and fuel clad deformation analysis involving in-reactor creep

are still based largely on empirical

are often obtained

procedures.

equations.

directly from in-reactor

These

empirical

equations

creep data by certain

kinds of

Close examination of the current empirical creep models shows,

however, that various normalization assumptions are often involved, and

these assumptions are generally different among investigators. The final

forms of these equations

are arrived at by adjusting

parameters

until good

agreement is reached between the equation predicted value and the actual

creep data.

While such procedure may be adequate in obtaining an equation

which summarizes a given set of data in the test parameter ranges, the

usage of the equation for prediction purpose at other parameter values

is seriously

questionable.

large deviations

Therefore,

in the predicted

it is of no surprise

to see rather

creep strain rates from these equations

under equivalent stress, temperature and fast neutron flux conditions.

Statistical data analysis using multiple regression techniques, on the

other hand, requires

plored

no normalization

assumptions

in the original form as they are collected.

ticularly

useful in establishing

the functional

and the data can be exThe technique

relationship

is par-

between

the

dependent variable (response) and the independent variables (factors) .

In our case in-reactor creep

strain rate is the dependent

variable whereas

stress, temperature and fast neutron flux are the independent variables.

-2-

All that is required is a tentatively selected model equation which relates

the dependent variable to the independent variables with unknown coefficients.

The problem then reduces to estimating these coefficients from data.

Modern

computer statistical programs are available which not only greatly shorten

the lengthy computational effort but also provide means to check the adequacy

of the underlying

The process

model.

of model validation

is perhaps

the most

important aspect of all good data analysis and should be exercised with caution.

It is also important to point out at this time that although researchers are

aided by various means for model selection, great savings can be achieved if

one can start with a reasonably good model.

Such models may be constructed

from prior experience and/or from the understanding of the governing physical

mechanisms.

The latter may come directly from theory developments.

Starting from the next section, we shall first give a brief review on

the data analysis procedure which had been used to derive the current empirical

in-reactor creep equations.

Much of the later efforts focus on the regression

aspects of Zr-2 in-reactor creep data analysis.

The principal areas discussed

are:

(1)

The selection of tentative model equations, their physical grounds and

their use in conjunction with linear multiple regressions.

(2) The examination of Zr-2 in-reactor creep data.

ing of the data according

This includes the regroup-

to test types, material

conditions;

the removal

of improper data normalization assumptions, and the elimination of certain

improper data points.

The possible sources of errors in the data are

also discussed.

(3)

Regression results.

Regression statistics, residual plots, estimated

coefficients and confidence intervals are covered with major emphasis on

model justifications.

-3-

2.

Examination of current in-reactor creep models:

Table 1 contains five current empirical in-reactor creep models for Zr-2.

The references of the data-base upon which these models were constructed are also

indicated in Table 1.

that

One notices immediately from the list of data references

a large portion of data used for obtaining these equations really come from

the same in-reactor creep experiments. The five equations are arranged in

chronological order as they were derived so that the latter of these equations

actually use some of the more recent in-reactor creep experimental data.

Before we discuss these equations further, it would be interesting to

compare the predicted in-reactor creep rates from these equations under the

same a,

, and T values.

In (a) plots respectively

Fig. 1 and Fig. 2 show the ln(E) vs 1/T and ln(E) vs

for these

equations

radiation creel)model derived by Gittus( 4) .

and one which

is based on the ir-

In both cases the Gittus model pre-

dicts creep rates an order of magnitude lower than do the empirical models.

Among the five empirical models, reasonably good agreements are attained only at

low temperature and low stress regions.

high stresses

The deviations at high temperatures and

are 2 to 3 orders of magnitude.

An apparent

inconsistency,

therefore, exists among these models which raises serious doubts for their

applicabilities especially at high stress and high temperature regions.

In spite of the difference

in the various

constants,

the forms of the

last four equations in Table 1 look rather similar. A flux exponent of 0.85

originally obtained by Watkins and Wood for SGHWR pressure tubes in 1968 has

been used rather consistenly in recent years and is the same exponent used in

the latest model.

It is, therefore,

useful

to review the Watkins

and Wood's

The word flux is referred to the fast neutron flux (E > 1 Mev) throughout

this report.

4

U-

U-

U-

I

cnI

LA

I

a

1

ko

I

I

U-

!I

a_

I

C

S.4ca)

to

t.

l_

I

^

I _

I-

I

4-1

d

*-P

co

0

w

U-

00

LA

0

-

i-)

.I-

L

A

v

cr

I-u

CM

H

LU

o

4-

I

_

A

c-

Co

S.

z

o

i,

0-

0

00 I

X

C4-

r-I

L

C

S-

c)

o.

0

naJ

0

cn

0

C.

-w

I-

-m

S.-

x

w

Ci)

x-

C

'4

C1

o

X

I

c+

00

_xL

I

11

-l

II

oW

4-

I

00

00

Cz

0

o

5-

a

0

.4-

o

4-

c-

II

.-

II

0

4

I1

II

o

o

4-

S.-

C)

O

4) C

r-

I

O

0

-

C

S-

._

E

C)

II

C

.e

(j

a)

A

.ol

a)

~0

0

C-

S..

E

L

U)

(A

Ul

)

-o

v

tD

IC

0

=

I

oc

*'

-

co

CM

_v

0

0

O

U rc

aC

a

c)

a

4-

c)

Co

LA

-5-

J

Figure-1

dnsw

As

..

COMPARISONS OF CREEP LAWS AT STRESS=7.5 KSI,FLUX=IE+14

-iog

--- A--

.1

Af

, I

_.- (3)

I

i

I t

.11t

r-,

t. · t

m

01%

m-

.

rrl

G

i

..

tu

.

.

I

-1

.

A

.mn

m

100

:0

Z1,

9-

.j,I

eusle'4a"J

.X

$.310

1.1@(

1.10("

i.IlO

aW~le

--

I/T (1/DEG. K)*1000

"1

-6-

J

i

Figure-2

r

4n lt

COMPARISONS OF CREEP LAWS AT T=300 C,FLUX=IE+14

f

*_l'13.,

.

(31

..

(5:

(2

((4

. (I

Gittus

Z

1.1

.. 4

::

/

;

,I

.

'

I.1(

'"'.0

o I II

· .,o

,. l^.lo'°S. '

I

' ·

leo'

I

°

_._._

_

w_._

LN(STRESS) KSI

T

I

-7 -

method for deriving their creep equation.

The conditions for the Ross-Ross and

Hunt model will also be examined later because they are relevant to the data

set on which the regression analysis is performed.

Documented details for the

rest of the models can be found in the references and will not be covered here.

It suffices to mention that the analytical procedures behind these models are

essentially

no different

next section.

than the one which

is going to be discussed

in the

There are certain features on the data base for these models

which should be pointed

out as follows:

(1) The constants in Pankaskie's equation are found by fitting to

Fidleris' uniaxial in-reactor creep data.

(2) Data for

ender A and Vender

B's model come from the same two

major sources, i.e., work by Watkins and Wood and those by Ibrahim,

Ross-Ross

and Hunt.

Although

it is known that the pressure tubes tested

by these investigators are different in the amount of cold work and were

provided by different manufacturers, no recognition has been given

to these aspects, and all of the data have been used to construct

a

single equation. This is unacceptable since creep depends strongly on

the materials metallurgical conditions which are functions of the

thermal-mechanical treatments.

2.1

Watkins

and Wood's assumptions:

The basic assumption made by Watkins and Wood(6 ) in their data analysis

procedure is that each Variable (a, T, and

The effect of each variable

) affects the creep rate independently.

on creep rate is then considered

in turn by the

-8-

following assumptions:

(1) A power law relationship is assumed for fast neutron flux.

where n is a constant.

The best fit to the data is obtained with

n = 0.85, the uncertainty

in this value

being + 0.15.

(2) An activation energy form of temperature dependency is

assumed

exp( - Q/RT)

where Q is the activation

energy.

The best fit to the data is

obtained with a Q value of 14,000 cal/mole, the uncertainty

in this value being + 6000 cal/mole in the temperature range 250

to 300 0 C.

(3) Using the above expressions, the data have been normalized for

flux, temperature, and biaxiality to SGHWR conditions and are

plotted

against the remaining variable a.

a sinh curve can fit the normalized

a stress

coefficient

of 1.15xlO

-

It was found that

creep rates acceptably

with

1 /ksi and a pre-multiplier

con-

stant of 1.02xlO- ll .

(4) The entire equation then follows by joining these three separate

terms together

as

* = 1.02xlO- l l q 0.85 exp(-

14000)

1

sinh (1.l5xl0

Oa)

The set of irradiation creep data used for the construction of

the above model

is shown in Table

2.

It is interesting

to

-9-

Table 2

SUMMARY OF IRRADIATION CREEP DATA USED IN ASSESSMENT

OF WATKINS AND WOOD'S EQUATION*

Flux

Test No. and

Ref.

829

829

829

629

Temp..

Type deg C

II] .... uniax.

[2] ....

uniax.

[3]..... uniax.

tube

tube

tube

tube

tube

[4 ..... tube

[4..... tube

[3)..... uniax.

[1 .....

4].....

U2-Mk. IV [4] ....

U2-Mk. IX [4 .....

U2-Mk. III

NPD

U3-Mk. V

R4

R6

R9

RX 14

R X

R X21

R X 15

[31.....

[3].....

uniax.

uniax.

[3]..... uniax.

3].....uniax.

[3].....uniax.

[3 ..... uniax.

290

300

325

275

285

281

286

286

268

Stress,

psi

(>I MeV), Duration, Creep Rate,

25 000

16000

35 000

25 000

11 500

11 000

13 400

17 300

10 600

2.4 X 10t

2.4

3.1

3.4

2.7

2.7

3.1

3.1

1.15

3.1

0.59

0.54

0.58

0.64

0.94

327

4 900

300

300

300

300

350

300

220

30000

20 000

18 000

20 000

30000

45 000

30 000

n/cm sec

0.84

0.96

__

h.

3000

8 500

5 000

2400

5 700

11 000

3 300

3 300

29000

13000

1 300

3 600

1500

1 100

530

800

2 100

___

in./in./h

__

1.17

3

1.2

5.2

X

X

X

X

10-'

10"

1010-'

1.9 X 101.8

2.9

X 10X 10

3.6 X 10-'

5.5 X 10-'

9.1 X 10'

8

X 10'

3.5

3

3

X 10X 10 X 10-

3.2 X 10-'

1.2 X 10- S

1.5 X 10 T

* Reproduced from Ref. (6).

note that out of the seventeen creep rate data, ten of them actually came

from Fidleris'uniaxial creep tests. A biaxiality correction has been

applied to the uniaxial data so that they can be used together with the tubular data.

This is done by multiplying the stress by a factor of 1.15

and dividing the creep rate by the same factor.

0

Such a conversion method

is valid only for isotropic material, which is not the case for Zr-2.

Furthermore, uncertainty of using test results from two different sources

- 10 -

of materials is retained.

Steps (1) to

(4) above outline

the general

veloping current in-reactor creep models.

procedure

followed

in de-

The assumption that each variable

affects creep rate independently appears to be highly unsatisfactory. This

is because the creep rates used to determine the constant for one variable,

with an assumed variable dependence, contain the influences from the other

variables too.

A realistic model or data analysis procedure must, there-

fore, be able to take into account the influence from the stress, temperature, and flux simultaneously.

One convenient way for doing this is by re-

gression analysis.

3.

Regression analysis:

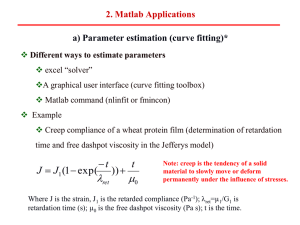

Regression analysis can be classified into two broad categories, i.e.,

linear and non-linear regressions.

By linear it is meant that the model

equation is linear in its coefficients whereas non-linear implies that the

coefficients may contain higher order terms.

tion, a non-linear model can be transformed

Sometimes by proper linearizainto a linear one and in that

case the model is said to be inherently linear.

Since the solution of

non-linear problems generally requires iteration and is much more involved

than linear problems, the standard practice is to start with a linear

model unless there are strong reasons to believe that the underlying model

is non-linear in nature.

The starting equation (being linear or non-

linear) is not that crucial because through the examination of results from

regression analysis such as regression statistics and residual plots,

- ll

the appropriateness

of the model

that a linear model

is inadequate,

-

will be revealed.

If the evidence

then it can be modified

shows

by either chang-

ing the variable dependence relations or considering non-linear models.

3.1 Regression Models:

The general form of a linear model with three independent variables can

be written

as

Y = Bo + Blf(X1 ) + B2 f(X2 ) + B3 f(X3) + B4 f(X1X 2 ) +

B5 f(X2 X 3 ) + B6 f(X3X 1) + B7 f(X1X 2 X 3 )

(1)

where Y is the dependent variable, f(X1 ),...,f (X1 X2 X 3) are some functional

dependences of individual and combinatorial effects of X,

on Y, and Bo,...

, B7 are the coefficients

.

£,

X1 =

model.

to be estimated.

, X 2 = a and X 3 = T, then (1) becomes our general

The task then is to specify explicitly

f(a), f(T),....,

X2 , and X3

If we let Y

-

linear creep

the functional

forms of f(4),

f (oT).

As we mentioned

earlier,

it would

be greatly

a model which has some physical meaning.

helpful

Studies

if one can choose

on materials

thermal

creep behavior have shown that in an intermediate temperature range and

moderate stress level, creep is best represented by a power law-type relationshiplo).

That is,

s = A an exp

(-

Q

RT

(2)

- 12 -

Eq. (2) is of the form which

vated rate processes.

is generally

used to describe

thermally

acti-

The exponential term or the Boltzmann frequency

factor is a measure of the probability of dislocation climbing over its

barriers.

The driving force for dislocation climb over obstacles on the

gliding plane comes from both stress and lattice thermal'fluctuations.

The activation energy, Q, is a measure of the barrier strength which may

be a complex

function

of both stress and temperature.

In irradiation creep where fast neutron flux is also present, we may

use a phenomenological equation of the following kind:

= A m an exp (- Q--)

(3)

RT

Namely, an additional flux dependent term is included.

relation has also been suggested by Fidleris.

This type of

Taking logarithms on

both sides, (3) becomes

= In A + m lnq + n lna -

ln

(4) is essentially

a linear model

Q

as in (1) with the following

tions:

Y =

f(X 1 )

n £

= in q

f(X 2) = In

f(X 3 ) = 1/T

a

; B o = In A

; B1 = m

; B2 = n

; B 3 = - Q/R

(4)

transforma-

-13

This means that if we transform

the original

dependent

and independent

variables into the forms given above, the multiple regression analysis

would enable us to find estimates for the coefficients B o to B 3 and hence

the values of A, m, n, and Q.

Two alternative models were also considered in which the activation energy is a function of stress:

= A

m

an exp(- Q °(

- /

)

(5)

)2 )

(6)

R T

and

e

= Am

an exp(- Q

(

1

R T

Again these models were obtained by superimposing a flux dependent

term to the thermal creep equations.

The mechanistic

content

of such

stress.dependent activation energies has been discussed by Ashby.and

Frost(l2 )

It does not require much effort to show that these

equations can also be transformed into linear models which lend themselves readily to examination by data analysis.

logarithms

Again taking

on both sides, we have

ln = In A +m lno + n In a -

1 +

R T

R

a

(7)

T

and

n

= In A + m lno + n In a -

qo 1 ++ Q . c2qQ

RT

RT

T

RT

2

.

(8)

T

- 14 -

effects

The last two terms in (7), (8) give the interaction

of a and

T on the creep rate respectively.

So far we have presented three models based on only three independent variables.

Other functional forms of these independent variables

could also be examined.

For example, we could use a parameter a/u instead

of a where u is the shear modulus or

diffusion

pendent

coefficient,

/D instead of

or a combination

u and D introduced

of the two.

where D is the

Both temperature

de-

in this manner will take some temperature

dependence outside the exponential term, and in some cases, as in thermal

creep analysis, have been shown to give better correlations.

The tem-

perature dependent shear modulus of Zr-2 is given by the following

formula{ 1 3)

u(ksi) = 4.77x103 - 1.906xT(°F)

(9)

It should be noted that the use of properly non-dimensionalized

parameters is a fundamentally appealing approach.

This is because of the

inconsistancies in parameter units in the previous creep equations.

the variables

are expressed

in their ordinary

4 in n/cm 2 sec, a in ksi, and T in

2mn

)'

cm sec

able.

m

(ksi)-n

-1

· hr

so that

units, e.g.,

If

in -hr 1,

K; the constant A must have unit of

units on both sides of the equation are agree-

But such a unit for A can hardly have any physical interpretation.

Since the exponential term is already dimensionless and we replace a by ao/(T),

the problem left is then with the flux term.

one may divide

*

by a reference

fast neutron

To make this term dimensionless,

flux

o and (3), (5), and (6)

15 -

become

=

A (-)m (

A (¢

=

a

)" exp(- Q)

)m ( u(T)

a )Q exp(

(T)

= A (S=AQ

t)m (

a)n

o

u(T)

(10)

RT

( 1 4)

A

exp(- Q°(1- R/T)'

R

)

(12)

(12)

T

o is taken to be 0.05x1013 n/cm2 sec.

result

(11)

1-al)

This is deduced from Ibrahim's

and gives approximately the fast flux threshold below which

there is no difference in irradiation and thermal creep behavior.

=

is, when

o

the creep equations

= A (a)n exp(-

After q and a

vibrational

frequency

rate processes.( 1 5)

reduce to

Q ), etc..

RT

have been non-dimensionalized, constant A should

unit of hr -l which

have

G

is reasonable

Regression

since we know the lattice

(or the Derbye frequency)

is involved

in the

There are, therefore, six regression models, (3),

(5), (6), (10), (11) and (12), considered

3.2

That

in this analysis.

Programs:

Details on the descriptions of linear multiple regression analysis

can be found from standard texts,(16)(17) and will not be covered

here.

Several computer statistical regression programs are available

- 16 -

with varying capabilities (18),(19),(20),(21)

One program(18)

which does least-squares only without giving residual plots is

rejected because the model cannot be accepted or denied based on

the regression statistics alone such as the multiple regression

coefficient, R2 .

Sciences)(21

)

The program, SPSS (Statistical Packages for Social

was selected to be our major analytical tool because of

its versatility in discriminatory data anlaysis.

Since the residual plots play a very important function in regression analysis, a brief discussion of their interpretation is warranted.

Now suppose a linear model is selected and the coefficients

have been estimated, the residuals are defined as the n differences

A

ei=yi-yi,

i1,2,...n

where yi is an observation

and yi is the corres-

ponding fitted value obtained by use of the fitted equation.

residuals can be plotted in a number of ways.

sideration

in examining

patterns.

Fig. 3 shows four residual plots.

the residual

plots

These

The most important con-

is to notice their overall

Except for the straight

band pattern (a), the other three patterns of the figure are all indicative of abnormalities that require corrective actions.

IF

- 17 -

0

*.Li

'·

5.

*

0

(a)·,~· .·.

-

-O..

·

R'.

. '.

b.I

(b)

I

0

0

* .01

-

5I

·

*.

(c)

Figure 3.

..

*

(d)

Schematic

Residual

Plots

- 18 -

For example, pattern (b) indicates that the variance of residuals is

dependent

on the value of the variable

plotted

in the horizontal

axis.

Pattern (c) indicates a linear relationship between residuals and the variable on the horizontal

axis.

Finally,

the arched pattern

of (d) indicates

curvilinearity that may be removed by the addition of polynomial terms to

the regression equation

The reason

Central

or, perhaps,

that a correct pattern

Limit Theorem

by a transformation

is indicated by (a) is not only due to the

but also because of the Gaussian

inherent in the least squares (16)

of the yi values.

N(O,1) error model

It is also intuitively

expected since

if the fitted equation is adequate in explaining the major portion of the

data, the residuals should be distributed randomly and evenly across

the zero residual

line.

Deviations

from such a pattern

then signals

that

the regression equation is probably inadequate.

Other than serving

ties, the residual

the purpose

plot has another

for visual examination

important

of abnormali-

function which

should not be

overlooked; that is, to identify stray data points. As we know human errors

or equipment malfunctions are sometimes inevitable even in well-ministered

experiments.

Accordingly,

and/or data analysts

behavior.

it is helpful to have a way for experimenters

to spot irregular points and to seek reasons for such

If it can be ascertained

that the irregularity

such data should be excluded to avoid

4.

is due to error,

the biasing of the result.

Examinations of Zr-2 in-reactor creep data:

We have recently compiled

data of Zirconium,

1974(22).

both uniaxial

and tubular

Zr-2, and Zr, 2.5% Nb in the literature

There are in total 276 data observations

in-reactor

creep

from 1962 to

and the breakdown

of

- 19 -

these observations

into subsets

TABLE 3.

is shown

in Tabl:e 3.

TOTAL NUMBER OF DATA OBSERVATIONS IN

EACH SUBLET

Zirconium

Zr-2

Zr-2.5%Nb

Uniaxial

9

89

65

Tubular

0

73

40

The subset of Zr-2 tubular in-reactor creep data was chosen for

analysis and this portion of data is included in Appendix A.

The term

"Reference" on the second column of the data Table indicates where these data

come from and can be compared with the reference list provided at the end

of this report. One notices from the fourth column that there are about

eight different cold-work and heat treatment material conditions.

Since

both cold-work and heat treatment affect the material condition and

hence the creep behavior, the data set is further subdivided according to

these material conditions.

As is shown, data taken from Reference I-11(Serial T14-T19), M-5

(Serial T39 - T56) and a portion of H-14,

I-13 (Serial T1 - T13) with

20%

C-W plus stress relief constitute the largest subdata set in this Table.

This subset is, therefore, chosen for the regression analysis.: It turns

out that all these data observations

were obtained

the same group of Canadian researchers on

by

Zr-2 pressure tubes.

The tube

fabrication method and the alloy conditions are, therefore, reasonably

similar.

The only difference is the size of the test specimens.

In

early experiments full-size pressure tubes were creep tested whereas later

for economical reasons and also for reasons of achieving higher stresses

- 20

.

.

+

+tC

_

14.0

E

U

_

0Wa

I

Co

r

I to

C.

C

_

o

C

-

o

4N

4.

Cu

oC)

.

.

.

+

+U v,

o

+ IC

oC)

cI

o0

J,

oC?

In

+

o9

o

4.2

o,,'

Cc o

o

C0)

0

o

io

(24

O

o

C)

N

o

o

E

_u,

Z;

o0

o

CD

0

o

C)

o

o

o

o

C)

z

o

oo

on

C!

C)

5I

V

C)

E

E

E

;7

N

B

0

&5

N

'.1

0

0

-4O

to

to

C'.'

o3

C)

om

C)

C

C)

Ch

C

E

Ln

C)

o

c)

co

oC0

-a

--401.~

E

C9 C,

_

vo

o

a

-4414C

·

o

0

C

O

4.

C)

O

C)

0

O

Co

03

C)

Co

0?

C)

C)

C)

O

oC)

o

O

'

C)

o

C)

C)

C

1:i

m

o

_

C)

\o

OC

4.

C)

o

o

oI

I

10

N

,:?

C)

o

.

CD

o

to

C)

C)

ot

C)

C)

C)

C)O

co

CD

o

10

m

o

Co

C)

C)

Co

cn2)

_

C)

o

C)

C)

o!

C)

0)

Co

r

'YI0

_

10

I

++

0rC

1<

C)

Co

oe4-0

C)

o

o

rC)

to

9

C)

o

o

C)

o

C)

C),

C,

0

Io

Co

o

o

o

_C)

o

to

C,

C)

C)

X

:1-.

:-4iJ> O C

oC)

oC)

or

0'

O

oo

0

o

o

oC)

r.C,

4

~t~

I

a

C

c:

..4

L4

C0

o

C)

C)

u

2

I

I

Ce

C

0

o

k

1-4

0

Co

XIW U

Qai'

W (D I

00

-o

E

1:

.o

+_

4

r

to:

SI -- 4

Z - -4

-o

ro

CD

N

cdl M

4 X

a)

O

4

.

o

M

CD

m

C)

03

to

z

:x

0)

Iz

q,11

4·

ur

E

"u

In

to

I-

Co

.,

cn

to

.

,

+,,

,gr

to

_

.·

.

n

N

I

._

_

Co

0

Co

._

'S

I I

I

01

14.

C

I

S-

C

C

C

t

¢

CMar-.

4-7

I

c:

IC,

',

II

..

IC

0=

o

r,

C

_

I

0

0,44

E

144

I

4.)

I

00'4a

@

tI

C?lrrc

c

C

n

0=

Co

Ci

I

rt

E.

4.1

Li:

q.. o

E

r

g

:'

a

7

-Q

a

0

. 0

E

E:

I

'-V)s P-

. t

-C

C

01

C.

I

J4+

-L

i

('I.a

(I

-

S0

- L

E *'

Ir

=

-t

I

IC

_a -0

C-)

C)

L

E

C

o

0

C.1

4

,

Za

=40

*.

')

S

-

E

36

r,

0

co

*I

I

I

-4a

CC

4

o

t-O$ -40

(i

Cr)

ce

4

t

n,

iz

21a

F3

_

C

I.,

,(I

of

In

.I

X

1,1

U)

m

3

U)

ce

01

.C:

.-

to. .

co

>0

a'R

C

=1

Nl

C)

V

I

0e0

1-

vC

4.

ci

C)

Z,

C)

Co

9x

-x

o

1),C

C)

0:

02

0

Q

C

A

a,

w

,-.-

I

cci

CS

>0

I-

r

;ZI

Z-

4.

rO.

C)

_:

:C

\r

...

:.

-s

J

C0

.

ICc

r0

14

I

(n

-C I)II

e

.CIIj

[:.C

a-i

.

14

h

CM

K-

441

) (1l3x

.,)

<

}

C.

.

0In> Cl

0

-L

0440

cr

IC

'>

m.

I0c L.a

rN

I V

la !-0

(L

0Cr

EU

I

.S a,

>CL

;

ei

)LU

*SCoC

V

a

C

-0

.

I

I

.

.0

InC

*i1

ac

C

v,

C)2 L

Q)"

0

O.

-o

Ll

Cl

Ua

.

a0 I I

C-

I

1

4Lu(e

04.

,

0

ka

k.

r-.

00

n

o

r

-

,

.rw

o

_

;P

t

1 2 -e

·-

T

:n

-"L'

11L

,v (

44'I

L= rX

- 20a-

<'

:4.-

-4 u,

0

")

9

a

to

0

A

r

C

Co

E

a

0:

ce

.

:E

o

C)

e

C)

C,

C

.4.

C;

_0

o°

4)

C,

0

C,

o

O

CD

C)

'0

10

0

C)

,

0

O

o

cJ

CD

C,

C)

(1

C,

O~-2Cc

0

Co

C)

ILI

c-

Ln

0:

O9

0

o

oC

o

C,

C°

to

1r3

-u

9

,

LJ1-4

ACM: CZ-

C

C

C

CD

11

_

CD

C)

C,

C

C)

C)

11:

IC)

C)

Ln

C)

C)

C,

c)

1.

03

C,

1 u

)

C

C

Ir

C

C,

-r4 1.4C.

X

C

C'

C11

O

oC

o

0°

0

C)

0

0

2

0

0

0

o

C.

0

j

C)

O)

.cc

C)

E

r

:3C

0

C')

vi)

0

o

S;

oe

2D C J'Ai

t:0@

tJ

114)

(0

C)

C

it

0

C)

0

C)

r-

_m

C

0*n

a)

C,

C

C

C)

0

E

MI

r_0

I'

C

C)

C)

n

0o

Cb

E

-

C)

C)

._

G

o14

0-

oo

0

C)

C)

0_

C,

C'

a

-4

04

14

C)

0)

:.

In

w

0i

02

In

.

In

(0

CU

10

02

"I

LI

0

-r

.0

a)

fi

VI:

41

N

la

C-a

Z

_

-Z

__

,

_

_

+r

,r

_)

CD

_

I

=1

P.0

N

a

4.

J

l.i

.,;

1-

O1

.lu

41

rC

r

E

i

4

41

.0

CO'

cn-CZ- v,

.

*O 0

oa

C3

L

I,

CZ 1

1.

.J IIn

0.

t c c

DC

q:

C1

('.,::- C)4

n

~E

'-4

OUL.

-.t)I4.)

.

r

r:

Ca

~

G'

-

6

1~~ o

==

s

cJ

C

oI

Dv,.4-

L

o1,_

(4

5

i:

4-4

L

0

t-C C)

LU

o t+C

.)OK

Ii

C

r

I-

1.

Io

i

4,

C,

C,

.r

,

tJ

U- e

*.a -,.

jr 0

dIi

1'' 14

:

h)

I

&¢

1

I

C

.4L

LU CAi

-Z

,Z:

4"

Li)

g!

O3

-_

ci

c'

"44)

rt

un

I)

Z.

t .

03

( 4)

a,

-r

6n1

(

_

vW

I

{

-

2

during creep testing, small-sized

specimens

(23 mm diameter)

were used.

The small-sized specimens are probably stronger and of finer grain size

than full-sized pressure tubes because of quicker cooling rates after extruding (due to the smaller size), giving greater residual hot work before cold

drawing(14)

Since extensive

are made when using this subset

cross references

them into a new table given by

of data, it is worthwhile

to designate

Table 4.

of this Table will follow three general areas:

Our discussions

(1) The accuracy of data, (2) normalization assumptions, and (3) time effects.

But before we proceed,

it is helpful to quickly

review some of the key

features of the tubular in-reactor creep experiments from which these data were

obtained.

These experiments were conducted in NPD (Nuclear Power Demonstration) and NRU (National Research Universal)

sure tubes and small-size

specimens.

tube, in-reactor creep test assembly

reactors with full-size pres-

A schematic diagram

is shown in Fig. 4.

of the smallSince the small-

size specimens were enclosed in a secondary containment, there is no

danger in damaging the reactor when tube rupture occurs, and, therefore,

higher applied stresses giving much higher creep strains are permitted.

Also, since the hot-pressurized water is maintained at rather constant pressure, the stress variable is altered by machining the outside of specimens

to give different wall thicknesses. Depending on their relative positions

in the reactor, three types of creep results were actually obtained

for the

fast-flux specimens, thermal-flux specimens, and out-of-flux specimens.

This is also evident

from Fig. 4.

- 22 -

IMENS

H

SPECIMENS

MENS

UEL ROD

Figure 4.

A schematic diagram of the small tube

in-reactor creep specimen assembly

(reproduced

from ref.

[I-ll ])

- 23Typical reactor operating histories are shown in Fig. 5 for Ross-Ross

and Hunt's full-size pressure tube experiments and in Table 5 for Ibrahim's

small-sized specimen, U-49 tubular creep insert.

5-1.0

E

E

a0.95

0

0.

4

w

a.

0.90

I

5.

N

E

2.8

2.4

2.4

Z

(0

2.0 i

00

TIME (hours)

Fig. 5. The operating

conditions for the Zircaloy-2 tubular creep experiment.

(The complete 18 by 40 in. chart covering the operating conditions

up to 9000 hours may be obtained from ASTM Headquarters, $3.)

Reproduced

from ref. (I-ll).

9500

- 24 -

TABLE 5

Operating conditions of U-49 tubular creep

insert.

(Reproduced

Time

Average

period

The purpose

|

1232

2419

3516

4987

6053

7597

8910

9712

10747

13626

14793

19859

20896

Average

Average

(14))

Fast neutron

temperature, pressure flux > 1 aMeV

(h)

0 to

1232 to

2419 to

3516 to

4987 to

6053 to

7597 to

8910 to

9712 to

10747 to

13626 to

14793 to

19859 to

from ref.

(C)

(7N/m))

264.4

256.7

253.4

260.7

256.7

257.1

259.2

260.3

260.4

265.6

270.4

263.2

279.1

9.24

8.96

9.09

9.05

9.08

9.09

9.14

9.57

9.17

9.54

9.40)

9.33

9.39

262

9.3

of this reviewing

(x -00-1

)

2.55

2.51

2.34

2.52

2.52

2.36

3.12

2.82

3.39

3.40

3.05

3.18

3.25

,

2.9

is to emphasize

that during

the entire period of creep testing (which may run up to 20,000 hrs.),

variables

,

, and T will have their

own histories

and are not constant

values throughout the test.

This is because the reactors are run accord-

ing to their fuel management

shcemes

and these schemes

are generally

not

-

dictated by the creep tests.

25_

Therefore,

tion takes place, it will cause changes

example of such local changes

A good

in all local conditions.

in Fig. 5.

is illustrated

in Table 4 are then only average

and T contained

opera-

each time a fuel shuffling

,

Data of

a

values obtained from the

entire operating history of each variable respectively. As will be shown

were used in some cases to re-

assumptions

later, one or more normalization

duce the data to the present values.

While normalization

is a viable pro-

cedure in data reduction, the assumptions must be carefully examined

first.

4.1

Otherwise

the original

information may be lost or distorted.

of data:

Accuracies

There are at least three major sources of error which may be introduced into the values of the dependent

as well as the independent

(1) errors due to the use of average values

(2) errors of measurement

and calculation,

variables:

(ignoring the history effects),

and (3) erros due to im-

proper normalization assumptions. We cannot do much about the first

type of error except to say that the deviations

are sufficiently

small such that there are no significant

fore, in this section only measurement

cussed, and normalization

4.1.1.

errors

Errorsdue to measurement:

Diametral

from average

and calculational

are discussed

conditions

history

effects.

errors are dis-

in the next section.

(e, T, P )

creep strains were measured

both at intermediate

and at the end of testing by linear variable differential

shutdowns

transformer

There-

- 26 -

(LVDT)( 5 ),

air gauges(1 4), and micrometers.

The accuracies of these strain

gauges have been discussed elsewhere(14)' (5 ) and are generally considered

satisfactory.

Pressure and temperature measurements were taken at inlet

and outlet only with standard instruments, and the measurement errors

should be rather small.

The errors of measurement are, in general, be-

lieved

to be small

when compared with

4.1.2

Errorsdue to calculation:

the errors due to calculation.

Two types of errors are introduced into the calculations of tangential

stresses

in the reference

data set H-14.

One is caused by the assumption

of

a linear pressure gradient along the tube made by Ross-Ross and Hunt( 5 )

and the other

convert

is the use of a thin shell approximation

the pressure

inside diameter

into tangential

stress where

and t is the wall thickness.

exact formula

for internally

pressurized

approximation

underestimates

stresses

wall thickness.

The pressure

tubes

formula,

t=P d/2t, to

d is chosen to be the tube

Calculations

using

Lame's

(23) show that the thin shell

by about

1 to 5% depending

drop and hence the localized

upon the

pressure

can be

calculated from the Darcy formula(24 ) but requires rather detailed knowledge

of the flow conditions, entrance effects, etc..

not available,

we merely

point

Since this information is

it out that the pressure

and hence the

stress in H-14 are based on the linear pressure gradient assumption.

Coolant temperatures at inlet and outlet to the tube were measured,

and the temperature gradient along the tube is calculated using fuel power

information.

Fast neutron flux (E>l Mev) is calculated from reactor physics

(5 )

using fuel bundle powers and geometry

factors.

these calculations

from the actual conditions

must be determined

The accuracies

of

and the

assumptions

in the reactor physics model.

In any case, errors due to measurement

and calculation

are probably

This is because

not major factors in these creep experiments.

of the averag-

ing procedures used to normalize the history effects would likely to overshadow the magnitudes

of the combined errors due to measurement

and calculation.

Normalization assumptions:

4.2

The empirical equation obtained by Ross-Ross and Huntin correlating

their in-reactor creep data is reproduced

Et = 4x10-2

4

t(T

as follows:

- 433)

(13)

where

Et:

hr-l

at: ksi (up to 20 ksi)

+ ; n/cm2sec

T ;

(0.5 to 3.5x10 1 3 n/cm 2 sec)

K (523 to 573QK)

The equation is obtained in a similar manner as that of Watkins and Wood

discussed previously. The stress and flux exponents were determined first

by using

t.sequentially

with

C

= Sot and

(both close to 1), the temperature

the creep rate is proportional

the reference

E

=

dependence

8

lqm.

After

is determined

to flux and stress, and

n, m are found

by assuming

is normalized

conditions of 14 ksi and 10 1 3 n/cm2sec by the following

to

formula:

- 28-

14 ksi

EN

=

EActx

Y

actual stress

actual

1013n/cm2sec

flux

(14)

actual

stress actual flux

This normalized creep rate is plotted against temperature in Fig. 6, and

(13) is derived

2

from the best fit.

AA

1.9

1.8

1.7

CREEP RATE OF PRESSURE TUBES NORMALIZED TO 14,000 PSI STRESS

AND Ix 1013 n/cm 2 s > I MeV vs TEMPERATURE

14,000 psi

I x 1013 n/cm 2 s

NORMALIZED

"ACTUAL ACTUAL STRESSx

ACTUAL FLUX

1.6

1.5

STRESS TE:'REACTCR

l

.503

oo

1.2

,1oAXFLUX

10

n/c

rnm

2

'

D-U3M1

-?

F-?

7

2

2'

5 ,00 : 1-

,10,50

6

3.

2_

c2-u't,'a7,'C0

,PD

w

C

IC-UŽ?.4rtXE|3,500G

-J2

u rIK

C-U2V7(rQ 4, 00

1.3

o

PSI

_

1.4

I

TUBE

C2

3

I

,

.

c

c2

C.W.ZIRCALOY-2

1.0

I

I

t/

-

F

ct.,IJ 0.9

w

C

0.7

w

0.6

J

0.5

N

:

o

Z

C.W.Zr 2.5% Nb

/

04

0.3

77

0.2

'Zr-2 OUT-REACTOR

14,000 psi STRESS

0.1

-

_

I

*

220

Figure 6.

230

240

250

260

270

280

290

TE 1 PE RATURE °C

300

310

_

1_

_

320

330

_

Cree2 rate of pressure tube normalized to 14 ksi and

1013

n/cm sec vs temperature.

(Reproduced from ref. (5)).

340

- 29-

Again the overall procedure is questionable. The following Table illustrates

that if the correct creep model

is given by (3) with m=0.85,

n=1.2, and Q/R =4,000 cal/mole; the difference in the normalized creep

rates from two normalization

can be quite large at the average

procedures

reactor operating conditions.

Comparison of normalized creep rates under two different

normalization assumptions

TABLE 6

Temperature

Time period

(C)

m(hr)

Pressure

Flux

(MN/m 2 )

.1

2

264.4

9.24

2.55

1.169

1232-2419

256.7

8.96

2.51

0.740

2419-3516

253.4

2.34

0.612

3516-4987

260.7

9.09

9.05

2.52

0.941

4987-6053

256.7

9.08

2.52

0.742

6053-7597

257.1

9.09

2.36

0.767

7597-8910

259.2

9.14

3.12

0.836

8910-9712

260.3

9.57

2.82

0.914

9712-10747

260.4

9.17

3.39

0.887

10747-13626

265.6

9.54

3.40

1.200

13626-14793

270.4

9.40

3.05

1.598

14793-19859

263.2

9.33

3.18

1.058

19859-20896

279.1

9.39

3.25

2.509

Average or

reference value

262.0

9.30

2.90

0-1232

s1:

Normalized

strain rate using linear dependence

in

, o, and (T-160).

Normalized strain rate using -Ocm o n exp(-Q/RT) relation with m=0.85,

n=1.2, and Q/R=4,000 cal/mole

/ (

where

)-m(rn

1

/

)-n(Tr160)

exp(Q

r' ar' and Tr are the reference

- T

values.

- 30 -

Creep strain rate data from Serial T7 to T13 in Table 4 normalized with

Ross-Ross and Hunt's assumption should, therefore, be transformed back to the

values according

to the actual stress and flux, and this is done by both (14)

and the Table insert of Fig. 6.

The back transformations

are necessary

to re-

move any bias in the data which might have occurred from improper normalization assumptions.

4.3

Time effects:

All previous creep equations of the form ~=f(o,+, T) apply only when

materials

are at a stage of constant

or steady state creep.

In thermal

creep

analysis, the creep rate is often found to be constantly diminishing with time

and the creep strain can be represented by

=

Differentiating

tm.

£

with

respect to time gives

= m

tm-l

Clearly steady state creep is possible only when m=l; for m < 1 the creep rate

is decreasing with time which is indicative of strain hardening,

In irradiation creep, although some of the early in-reactor creep experiments(6)(

hours,

results

5) did not show this kind of relationship after several hundred

obtained

by Ibrahim (1 4) over long test periods did.

The rate of

decrease in creep rate is somewhat slower for in-reactor creep than out-ofreactor creep (wiehgted mean m=0.468 for fast flux specimen and weighted mean

(14)

m=0.270 for out-of-flux specimens)

The problem

caused by this time dependence

of creep rate is as follows;

since creep strain rates must be obtained from dividing the measure diametral

creep strains

by a small time interval,

the time at which

such creep strain

31 -

measurement is taken will apparently matter.

T39 and T40 are at the same a,

For example creep rate data serial

, T values but estimated

at 5,000 and 20,000

hours correspondingly, they differ by a factor of 2.4.

When the form of time dependence cannot be incorporated readily, we must

select a convenient reference time for creep rate calculation such that the

creep rate data can be compared and analyzed

data observations

in M-5 should, thus be excluded.

tion of creep rate data were estimated

be the reference

on an equal

basis.

Since

the major

it to

time and hence the even numbers of data observations

creep data used in regression

Regression

por-

at 5,000 hours, we have chosen

20,000 hrs.) from T40 to T50 inclusive should be excluded.

5.

A number of

analysis can be found

(at

The actual set of

in Apprndix

B.

results:

Results from regression analyses using the six regression models (3),

(5), (6), (10), (11), (12) and one which

presented

in this section.

is of a similar form to (13) are

The last one is included for the purpose

strating that if such a model of regression

(T-433) P , the estimates

for the exponents

at all as obtained by Ross-Ross

should be written

analysis is given by

of demon-

= A

m an

n, m, and p will not be close to 1

and Hunt's procedures.

Instead, the equation

as

= 3.41x10- 2 6

+0.61

1.5

2

(T

-

433)2.047

(16)

Computer printouts on the details of regression statistics such as R2 , F

ratio, standard error of estimate

(SEE), etc. are given

in Appendix C.

It

- 32

to summarize

is useful

TABLE 7

Equation

and assemble

the information

into the following

R2(%)

No.

F

3

96.969

178.498

5

97.109

136.525

6

97.702

134.482

10

96.969

178.516

11

97.106

136.359

12

97.708

134.865

16

96.902

174.466

of fit or the fraction

explained by the regression equation.

hypothesis H:

Table:

Multiple regression coefficients and F statistics

R 2 stands for the goodness

of data that has been

A high F value means that the null

R=-Omust be rejected or the alternative hypothesis H1 : BiO

one or more i is true.

7.

-

Several

points are worth

noting

for

from Table

First of all, based on values of R2 and F, all regression equations can be

considered significant.

we examine

the residual

We shall further substantiate this conclusion when

plots.

Second,

R 2 increases

as we use more elaborate

forms of stress dependent activation energies, i.e., in ascending order in

groups of (3), (5), (6) and (10), (11),

(12), but the increase

is marginal.

Third, equations of non-dimensionalized parameters with a temperature-dependent

shear modulus give higher R2 than their counterparts in tteoriginal units of

a, q, and T, but the difference

In order to assess whether

is slight.

one should include product

terms

such as

o/T, and a2 /T to account for their interaction effects on a, stepwise (for-

- 33 -

ward inclusion) regressions were also performed .in which the independent variables are entered

into the equation

statistical criterion.

out the independent

one by one on the basis of a preselected

In short, this step-by-step procedure helps to screen

variables

less than the pre-selected

(be it single or product) whose partial

value.

These variables

are considered

only minor contributionsto the representation of the data.

F's are

as having

In all

stepwise cases we have studied based on an F value of 3.2, no independent

variables (single or product) have been eliminated. A more stringent criterion

is

therefore

required

if one intends to use a model with less than a maxi-

mum of five independent variables (a, , T, a/T, a2 /T).

regressions

5.1

Results from stepwise

are included in Appendix D.

Residual plots:

Fig. 7 to Fig. 10 give the standardized residual

plots for the previous regression

numbers.

models.

First we notice that the overall

look quite satisfactory.

versus standardized

They are identified

fit

by equation

patterns of these residual

plots

All residuals fall more or less into rather straight

error bands. There are no indications of "abnormalities" as discussed earlier

in Section

model

3.2.

Fig. 10 which

is based on the revised Ross-Ross

(16) shows that it is only slightly

and Hunt's

inferior to Fig. 7(a) which

based on (3) in terms of residual structures.

is

Fig. 7(a), 7(b), 8(a), 8(b),

9(a), and 9(b) show that the error band gets narrower when more

elaborate forms of stress-dependent activation energies were used.

responding

residual plots in either original parameter

less form show little difference

in their structures.

The cor-

units or in dimension-

- 34 -

i

II

!

i

I

i

- +

-

A

I

' 1

.I

.l |

'J ·

.

'1

-a

i

I

bj

I

Ii

ilI

!

O_ I

p.. I ,.

W

.

cr

I

.4o

-e

-

'a

* '

o

*

I

.I

I

I

II*)

*/

Uat

I,

4

I

*

4

* I

!_ __

.t

II

j.

i

i

I

w

'U

-

Z.4

a

N

I

--

. '

I.

-,.-~.-. -

1

II4

'

.

.

N

.

_

IIi

o

'i

*

i

I

I Iii

I.

I

_

I~

__

_-

!

_

__

I

,

*

i

'I

4:I

I

;

,

I

I

i

*

*

.

I:

,

I

.I

I

.

i

I

I

*.--

*

jL

·

· .

-

-

-

-

-

4_

,

o

.

CC

:

* in

.4,I

,.

4

, j1

__

I!

Ii

I

_-

i

II

I

.

*

I

itI

aI*

.

*I

.4

d[

0 .".a

I

.

1 .

I

'

I

I

I

I

*

-,

I

i

'

'O

I

.

C

I~

.

i

3

zCI

' "

I

i.

.

I- o u

o. ¢

i

i

i

.'·

I

I0

.&*

X-

o

.

a..

Va

N.-

·

·

on

'54*

.

WN

:

I _

I

' .. i

. 4A4

1, a. -*all

*

-I'

.1i

9:

II

I

r-

- 35 -

,

.1 i W !

.

aii

i

4,:

I

; .' '

:~~

.'':'I

!

:I

i.~~~~~~~~~~~

II~~~~~~

: . ,;'.I

'

.

01

I- 0.

I ;, i

: .

*

I3

6)-

1

or;

.

I Z

Y1

i·+;

!i

i

I

0

t~~~~~~~~~~~~

6'i'

),o

NO

01:

I iA

j~~~~~~~~~~~~~~~~~~~~~~~

Ii

'

°

i

'-4

.,_l

I

Ii

=*

-

cd

"·r ~ (II· j

iO

o

.~ a 0

.'07

I cIL· ~LIIII

i I

I

·

·I~~~~~~~~~~~~~~~~~~~~~

·· I ' · LI

.

I

a

t

ioSf~~~~~~~~~~~~~~~~~~~~~~~~~~~~o

'

60

II:I

o

Io

~ ~~~~

ii~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

.

!

I

0

~I ~~~~~~~~~,*I

~

ii' ,,~

~

~

~ ~ ~

~

Wt

a1~

:

0

!

Z

I

W

-Hl

0

~

~

i

3

t/

i,

~

i

'

I:

I

.I

i

a

]

III

I

I,

~~~~~~~~ ~~~~~~~iii

.~I I

1.!!

o 'l

Z

KI 1':

*.

,

** o, 0

0.

6

'oI!

l

I

O

!

:,·

3-

I ,

o·

~~~~~~~

i

c

U)

c)

144

Zn

:

z1o

3

:

0

O

V

r 4z

CU)!i~~~~~

4

' .I .

oc~~~ii

1 I ~~~~~

'Z

WOOa

*I

61%

0

WI

.4.

z'

t

ii~~~~~~~~~~~~(

'

Ii'

W

au

u

is

:

. us

W

O to

<F

C

A.

-0O

_r I

tJ

:

>U

.4

-

*

S

:

'

C

<

~

o

'

~1,

::

o

i*' ,

I

*6

*

'

I

i

i,

I~~

*.

.I

I

Ir!'-'

' ~~

'

t

~·

i

Ii

_

tO

w

I

,.

.

!,

,o

:t

:

I

6i

6

a

i .....

*1I1-.**..I*

I

,.,... , M. .,.4

AllI..hll.*'llEllAI,

*

i

'"I

I

O

0

_

II

0V*

o

*

·

r'l

,

qt

i.

CJ

0

*

o.

*

i.-I

c

t)

*

6

0

c'

¢.___

l-.,-*..,

0

o

E°n

I

,I~~~

I.I]ALI.I

O

S

i

~~~~~~~~~~I

1

1

96

_

*F

I:

I

*

. ' '. i

·

.

!

*O 6

u.

.( k

.ct

-

.0

*

.,

.

"i

o

--

0

!0

iI

..

·

,O

w .dS

J

.,

4t

I~~~

:

iif

i

I

:l·

,o

;

U

L

.

:

_t~~~

:

t

- 36 -

.

I

!

I

.

' i

L

:

II

i

WIZ io

1,

toI9~~~~~~

I

i

,

I

I

i

I

I

I

I

t'

A

'

i

I

_

~N~~~e.

IN

1- O

"lr*W·2X*

I

I

doi

I.

I,It

* · I

''I

1

Pd-d

uj

z wJ"

I

;00W0

WI

.

C~

iU,

d

^

i ;

O

°,

i

I*

8

I:

I

,

i,

,

I:

i

: '

'

.

I1

·

I

Pl

'.4

1;

§ v

CI(

-

i

i

Sr4

i

I

, 0

I

I'

!

I ,

!

I

- Id.

a-,

i

- -

d

!

!I

I

·

*

j 1 i'

0

·

!·

i

*q

on

i

I·

ii

us N

.

C\

I

e

·

·r

!

'

11~~1Ii"

I

.i

.

SJi

i

1

..

+

I

'I

4

I !!

I

1

.-

!

II

I .,:

I

I

~

o

,

Z

l

oo

>

0

w

,

C

'-

-1

le

c

s

I,

ZI

I

I

i

t

I i

~O

P

,!

O

,

Z0 Zr

,- -

i

·

~' __.,

_ _:._

__.

I. .

|

,.

d~d

'

I

0

I

Pd.4Pd

m

~~~~iI

t

N-

0

--

I

t,

1

i.~~~

o

N

j

0

.i

I

.4

8

.

·

'

~~~~

1,,

,1

I

I

I

I

8

1:

I

I

I

f

I

I

1

e

.

.

.

0

.io

.I

* I1

I

I

x)

t

*

I*

u~~~~~~~r

u

.

, .

I

!

,

0)rr

:o

'N

I

a~

u*;

I

'

I

4

: I.

4

!oC

Pd~~d*(~Obf

II

'I·

I

I

_

S|l,~~~~~~

*i.

.

I'|

:

·

.

0o

I::L

1

.

i:

i,

~

!,.

~

iN9

~

n8

r

fr

.

t':niII

,ii-;$

- 37 -

i

I

I.

0

rl

UI

Z

o

<O

U)

a

IUi

I4

Iw

W

I

;;

,

-

S

.

O

J~~~~~~~

jI

*

O

4

,t,.~~~~~~~~~~~~~

1 : t 5 =

t

j

I

i

lB

j

I~~~~~~~

Ii ua

t

Nllbt.*

0@,

N

C)

0

N,

;

I

'

-

2

1[

.C

Ii

Iii'

*'

;! iI r

Ii

CH

a

a,

.

"4

'.

2Z i

4

z I

I

I

It

. *

:

'

I

*

V0

u·o

->

aCo

W2

_

IN;

I? '

iI

3

'

I

cc

!

0 " 0

Iil

I

i.

!!i

' *;

:;

4

,

I

·

,-

~~i

i

4