Document 10471776

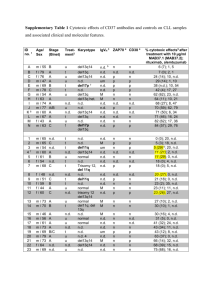

advertisement

Identification of Performance Drivers for an Antibody Producing CHO-S Cell Line Culture in the Allegro™ XRS 20 Single-Use Bioreactor Utilizing Historical Data Todd Sanderson, Alex Martino, Ing-Kae Wang, Amanda Rose, Byron Rees, Lisa Bradbury, Pall Life Sciences, 20 Walkup Drive, Westborough, MA, USA 01581 Figure 2 Data from Six Fed Batch CHO Cultures Set Up as Three Paired Runs A B 30 EXPERIMENTAL APPROACH 25 Two different Allegro XRS 20 bioreactors were used for the 20 L fed batch runs. A monoclonal antibody producing CHO-S cell line was grown in CD FortiCHOu media fed with EfficientFeedu C on five consecutive days and glucose as needed. In all cases the final expansion was done in the XRS 20 biocontainer. An initial evaluation of CHO fed batch cell culture in the Allegro XRS 20 bioreactor in terms of growth curve and viability, antibody production, and contaminants demonstrated excellent reproducibility. This provides an opportunity to identify relatively small output differences due to process variation. For the analysis of cell culture performance drivers, the following input variables were considered: passage number; initial and final post expansion seed density; VCD at first feed; agitation; viability at harvest; and total days in culture (Table 2). In addition to almost daily sampling for cell count, viability, metabolite/nutrient, gases and pH measures, the final harvest was assayed for mAb, host cell protein (HCP), and DNA concentrations. These outputs were used in the analysis as well. The data from these runs was compiled and analyzed for trends linking the variations in run parameters with the critical outputs of maximum viable cell density and mAb titer. Summary of Bioreactor and Process Conditions Table 1 Allegro XRS 20 Bioreactor Fed Batch Process Conditions Cell line: Industrial suspension CHO producing mAb biosimilar Seed: 0.3 – 0.5 x 106 viable cells/mL in 5 L CDFortiCHO (Life Technologies) Expansion: Expand at 2 – 4 M viable cells/mL to 14 L Feeding strategy: CD EfficientFeed C (EFC, Life Technologies), initial feed at 8.0 ± 2.0 M viable cells/mL. Additional bolus feeds every 24 hours for a total of 5 feeds (1.2 L/feed) Carbon source: Glucose kept above >2 g/L (bolus target >5g/L) Antifoam C: Added as needed Aeration rate: 1.0 L/min 37 °C Table 2 Fed Batch Culture Information for Eleven Allegro XRS 20 Bioreactor Runs December CPM VCD @ EFC Addition 1 30 26 7.3 December 2 30 26 6.6 March 1 30 26 5.9 March 2 35 26 5.2 April 1 35 19 8.5 April 2 30 19 8.0 July 1 30 9 11.5 September 1 30 9 10.8 October #1 2 30 26 8.8 October #2 2 30 28 9.0 October #3 1 30 26 9.4 Data Color RESULTS 4 2 mAb (mg/mL) Dec 30 rpm Mar 30 rpm 0 HCP (mg/mL) Mar 35 rpm Apr 35 rpm dsDNA (ug/mL) Apr 30 rpm The analysis of the first six Allegro XRS 20 fed batch cultures at our site did not clearly identify the performance drivers for high mAb yield or high VCD, although these are obviously linked. Thus, additional data was incorporated into the analysis as it was generated. The growth and viability plots from five additional Allegro XRS 20 bioreactor fed batch cultures are shown in Figure 3. Overall the curves from different run dates are similar. They have, on average, higher VCD than the earliest cultures (Figure 1). There were minor variations in the culture set up, either allowed by the process ranges or outside those ranges but agreed to based on intended use of the final harvest. Additionally the metabolite and glucose consumption data are very similar across all eleven runs (data not shown). Preliminary data from shake flask studies suggested that passage number influenced final [mAb], with passage number >22 associated with reduced productivity. Data from shake flasks and XRS 20 fed batch cultures showed some indications that the VCD window for the first nutrient feed (EFC) should be more narrow (data not shown), as feeding too early resulted in lower maximum VCD and thus lower [mAb]. To evaluate this more fully, these parameters along with several others were analyzed in pairwise combinations. Figure 3 Growth Curves from an Additional Five Separate Fed Batch CHO Cultures 40 100 35 90 Figure 4 Pairwise Analysis of Final mAb Production vs. CHO Clone Passage Number 80 70 25 60 20 50 15 40 30 10 July Sept Oct #1 Oct #2 Oct #3 1.6 1.4 1.2 1 0.8 0.6 0.4 0.2 0 0 5 10 15 20 Passage Number 25 30 Color coded to match run colors shown in previous figures. Note that some data points overlap 20 10 0 3 4 5 6 7 8 9 10 11 12 13 Elapsed Time (Days) Figure 4 shows data looking at passage number and final mAb concentration. For this non-GMP process the passage number is generally kept below 20, but for reasons of timing higher passage ViCell data average of replicate samples (2 or 3) number was allowed for some of these runs. This provided an Agitation at 30 rpm for all runs opportunity to use these outside values to revisit the importance of passage number on mAb production. Note that some other parameters vary as well (Table 2). Interestingly, the highest and lowest mAb yields were achieved with high passage number, suggesting that this is not a strong performance driver. 0 1 2 Figure 5 Pairwise Analysis of Final mAb Production vs. Maximum VCD (A) and VCD at First Feed (B) 1.6 1.4 1.2 1 0.8 0.6 0.4 0.2 0 10 15 20 25 30 Maximum Viable Cell Density (million/mL) 1.6 1.4 1.2 1 0.8 0.6 0.4 0.2 00 2 4 6 8 10 VCD at 1st EFC Feed (million/mL) 12 Color coded to match run colors shown in previous figures, 11 fed batch cultures in total Excellent Reproducibility in Parallel Allegro XRS 20 Bioreactor CHO Runs In the first analysis, the focus was on three separate pairs of fed batch cultures (6 runs total, Table 2). In each of these, two parallel fed batch cultures were set up from the same inoculum. The first of these was a training run, the second and third looked at agitation of 30 vs. 35 rpm. An initial comparison of cell growth and viability plots (Figure 1) and metabolite and glucose consumption data (not shown) from these three separate parallel culture runs show: Parallel culture (same date) show extremely high level of reproducibility Repeat cultures (different dates) are very similar December training run was good, but minor process changes led to viability and VCD improvements in April run Figure 1 Growth Curves from Six Fed Batch CHO Cultures Run as Three Paired Runs 40 100 35 90 ViCell data average of replicate samples (2 or 3). Agitation at 30 or 35 rpm as indicated, Dec runs were technical replicates 80 70 60 20 50 15 40 30 Cell V Viability iability (%) VCD (million/mL) 6 Analysis of Historical Data from Eleven Fed Batch Cultures in the Allegro XRS 20 Bioreactor 0 December, March, and April runs were each a pair of parallel cultures from the same seed train 5 8 mAb assay using ForteBio Octet system with Protein A sensors, HCP using Cygnus CHO HCP ELISA kit 3G, Invitrogen DNA determination with Life Technologies PicoGreen assay 5 CHO Passage # @ Expansion 10 10 mAb conc (mg/mL) Run Date Allegro XRS 20 Bioreactor ID Max VCD (mil/mL) Dec 30 rpm VCD (million/mL) 5 L: 25 RPM, 5°X, 5°Y; 14 – 20 L: 30 or 35 RPM, 15°X, 5°Y Temperature: 25 5 0 14 C 12 30 7.2 ± 0.05 Agitation: 30 10 O2 control at 40% pH set point: Dec #1, 30 rpm Dec #2, 30 rpm Ma r, 30 rpm Mar, Ma r, 35 rpm Mar, Apr, 35 rpm Apr, Apr, Ap r, 30 rpm 15 mAb Conc (mg/mL) DO set point: 20 1.6 1.4 1.2 1.0 0.8 0.6 0.4 0.2 0.0 Conc (mg/mL) During the development of processes for high production CHO fed batch cultures, there is usually insufficient time for thorough process optimization. Once defined, these processes often have ranges rather than specific values for many parameters, resulting in minor variations in the runs. These small process variations, combined with resultant differences in performance, can be used to further optimize the process. Over the course of one year, eleven 20 L fed batch cultures of an antibody producing CHO-S cell line were generated in the Allegro XRS 20 bioreactor. In addition to normal minor process variation, small process changes occurred due to method optimization efforts or culture timing requirements. An analysis of the combined historical data was undertaken to better understand the specific culture performance drivers, leading to further improvement in culture outputs, specifically final antibody concentration and maximum viable cell density (VCD). Excellent Reproducibility in Parallel Allegro XRS 20 Bioreactor CHO Runs The data summary in Figure 2, showing maximum VCD (panel A), concentration determinations for mAb and host cell protein (panel B), and double stranded DNA (panel C) in the harvest sample indicate: Parallel cultures give similar results, especially mAb titer & max viable cell density (VCD) Cultures with highest maximum VCD also had highest mAb titer, as expected. The degree of mAb increase (~50%) was surprising and the reason for the increased VCD was not obvious from this data Comparison of 30 vs. 35 rpm data shows these agitation settings have limited or no impact, but further testing with a broader range of agitation settings could be explored Cell Viability (%) BACKGROUND AND NOVELTY 20 10 0 0 1 2 3 4 5 6 7 8 9 10 11 11 12 13 3 Elapsed Time (Days) Post Final In-biocontainer Expansion 0 Contact: 800.717.7255 (USA and Canada) • 1.516.484.5400 (Outside USA and Canada) • www.pall.com/biopharm • E-mail: biopharm@pall.com A plot of maximum VCD against the final mAb concentration (Figure 5A) shows a clear correlation between higher mAb and higher VCD, which was not a surprise. However, this data does not indicate why higher VCD was achieved. An analysis of the [mAb] against VCD at the time of the first addition of the efficient feed C supplement (Figure 5B) showed that there is a relatively narrow optimal VCD for this step. Although the preliminary testing identified a VCD range for EFC addition, this analysis suggested that the window was set too wide. By raising the lower limit from 6 to 8 x 106 cells/mL, the mAb production was significantly increased. Setting the initial feed range to 8-10 x 106 cell/mL results in higher maximum VCD as well (data not shown). If the initial feed is delivered before or after that VCD, both maximum VCD and final [mAb] are reduced. Analysis of other variables did not show a significant relationship with mAb production or maximum VCD. CONCLUSION The Allegro XRS 20 single use bioreactor generated highly reproducible cell culture performance for this CHO mAb production process, allowing for a holistic analysis of relatively small changes in process conditions and the resultant differences in performance. In three separate paired runs, the first being identical and the second two differing by 30 vs. 35 rpm agitation, the parallel culture results are extremely similar, highlighting the overall reproducibility of the system. This bioreactor reproducibility makes it possible to review historical data to identify performance drivers that were missed in limited optimization testing done at smaller scale prior to the 20 L runs. The VCD at the time of the first feed addition proved very important for overall mAb yield. Although a relationship was not surprising, the optimal range was tighter than previously believed. Nutrient feed timing can be easily modified as there is very good understanding of the growth curves for this CHO-S cell line in the Allegro XRS 20 bioreactor. This opportunistic analysis of historical data has some limitations compared to experiments designed specifically to look at process controls. Despite these limitations the value is clear, it can provide additional process understanding without additional experimentation. Thus, this approach could further understanding of performance drivers for any production run, and can be expanded to other cell line / media combinations in any culture system having sufficient reproducibility to distinguish relatively small changes in process conditions and the resultant small but significant differences in performance. © 2015, Pall Corporation. Pall, , and Allegro are trademarks of Pall Corporation. ® indicates a trademark registered in the USA. uFortiCHO and EfficientFeed are trademarks of Life Technologies . 5/15, GN15.6279