Journal of Non-Crystalline Solids 338–340 (2004) 552–556

www.elsevier.com/locate/jnoncrysol

Local structure resulting from photo and thermal diffusion

of Ag in Ge–Se thin films

M. Mitkova *, M.N. Kozicki, H.C. Kim, T.L. Alford

Center for Solid State Electronics Research, Arizona State University, Tempe, AZ 85287-6206, USA

Available online 12 April 2004

Abstract

Thermally and photoinduced diffusion of Ag in thin amorphous Ge20 Se80 films are investigated with particular attention being

given to the reaction kinetics and the local structure that results. The differences in the nature of the two diffusion processes with

regard to the amount of the diffused silver in the films and the changes in the backbone structure of the hosting film are presented

and discussed. Ag diffusion in this particular chalcogenide glass composition results in the formation of a phase separated structure

formed by the Ge–Se backbone and Ag2 Se or Ag nanocrystals.

Ó 2004 Elsevier B.V. All rights reserved.

PACS: 42.70.C; 70.66.J; 61.43.F; 46.30.P

1. Introduction

Thermal solid-state diffusion, the generation of a

matter flux due to the application of heat energy, is an

important transport phenomenon that is widely used in

semiconductor technologies. When silver is the diffusing

ion, the diffusion rate is naturally expected to be high

due to the small ionic radius of the mobile particle.

Silver diffusion in chalcogenide glasses may be also attained using light of the appropriate wavelength, a

process unique to this system known as photodiffusion.

The different stages of silver photodiffusion can produce

diverse effects such as silver surface deposition [1] or the

formation of structures with different optical constants

[2]. The process has even been suggested as a means for

producing low dimensional structures in VLSI circuit

production [3]. No matter what the driving force for the

Ag diffusion process is, the structure of the hosting

material changes significantly [4], particularly at the

nanoscale. The difficulty with the understanding of the

formation and nature of the new structure is due to

the fact that it is not possible to make general conclusions about the whole range of chalcogenide systems as

in each case different reaction products form and dif*

Corresponding author. Tel.: +1-480 965 9481/727 6243; fax: +1480 965 8118/2747.

E-mail address: mmitkova@asu.edu (M. Mitkova).

0022-3093/$ - see front matter Ó 2004 Elsevier B.V. All rights reserved.

doi:10.1016/j.jnoncrysol.2004.03.040

ferent diffusion kinetics dominate. In addition, if illumination with light is the driving force for the diffusion

process, a photoinduced change in the local structure of

the hosting chalcogenide glass occurs and this additionally influences the diffusion process and resulting

structure.

We have focused our current investigations on the

thermal and photodiffusion processes and products

arising from the diffusion of Ag in Ge20 Se80 thin films.

This chalcogenide composition has a mean coordination

number of 2.4 and this will result in the formation of a

very stable glass as predicted by the Constraint Counting Theory [5] combining the properties of floppy (undercoordinated) and intermediate glasses in this system

as shown by Boolchand et al. [6]. Besides, it is expected

that this composition will take up a particularly high

concentration of diffused Ag as it has been revealed that

diffusion kinetics and the amount of diffused Ag can be

correlated to the chalcogen content of the glass [7].

2. Experimental

Thin Ge–Se films 35 nm thick were prepared by

thermal evaporation of previously synthesized glasses on

silicon substrates covered with a film of Si4 N3 to electrically isolate the films from the substrate using a specially designed membrane evaporator with construction

similar to a Knudsen cell. The actual composition of the

M. Mitkova et al. / Journal of Non-Crystalline Solids 338–340 (2004) 552–556

mally induced diffusion at a treatment shorter than a

minute, no observable silver diffusion into the films occurs. This ‘induction period’ effect is common for thermal diffusion and has been reported in other similar

systems [9]. More interestingly, in the case of photodiffusion no induction period has been found and the results also show that the diffusion rate and the quantity

of silver at saturation of the films are higher. Fig. 1

shows the overall change in the amount of the diffused

silver with time. The kinetics curves illustrate that saturation after thermal diffusion occurs when the concentration of Ag introduced into the chalcogenide

matrix reaches 43%, while for photodiffusion the

amount of the diffused silver is 47.3 at.% (for comparison, in bulk material one can introduce an maximum of

33 at.% silver [10]).

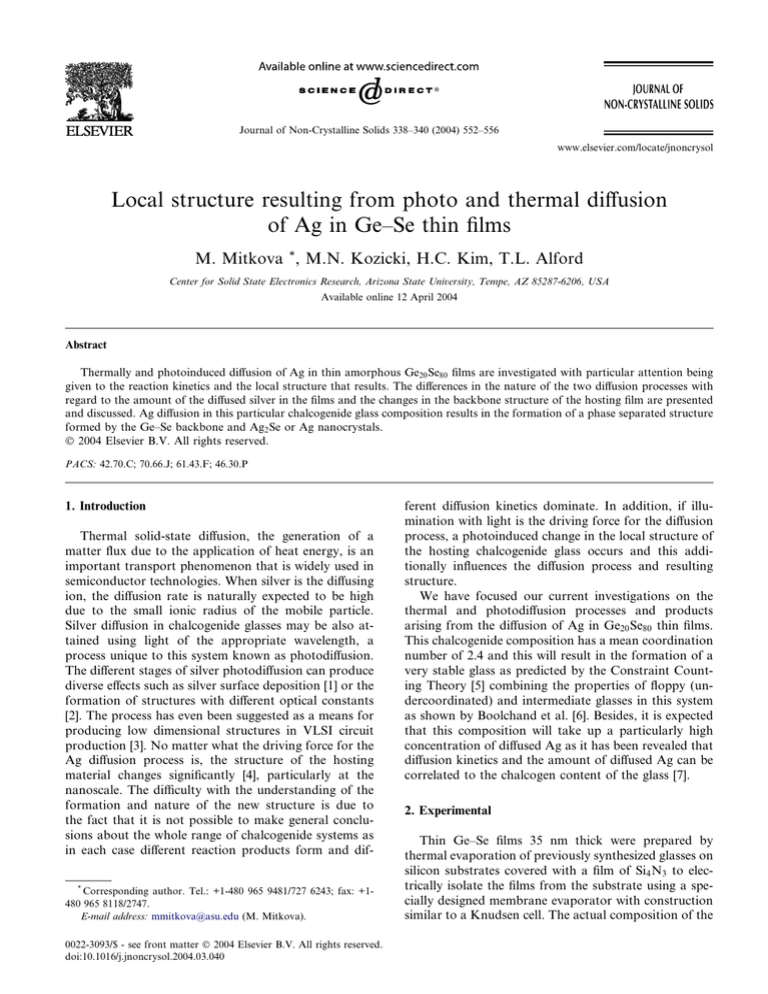

The Raman analysis gives a clear indication of the

different nature when the diffusion process is driven by

heat or by light. For thermal treatment the presence of

Ge–Se corner sharing tetrahedra at 194 cm1 are seen to

dominate (Fig. 2), as expected for Ge20 Se80 backbone

[11]. The films were placed in a heating camera, so that

we lost part of the signal due to difficulties in focusing of

the laser beam, which results in a poor signal to noise

ratio. The noisy spectra were therefore numerically

smoothed to enable extraction of meaningful information. Although the selenium concentration is high and

the initial network is expected to exhibit high flexibility

having a ‘non-stressed rigid’ structure [6], the peaks

seem to be smeared, suggesting a high degree of disorder

[12] due to strain that occurs because of the differences

of thermal expansion coefficients between the film and

the substrate. With development of the diffusion process

no changes in the position of the Raman modes occur

i.e. no modification in the original configuration of the

backbone structure of the chalcogenide glass takes

place. However fitting the spectra shows systematic

50

Amount of diffused Ag(at.%)

deposited films as determined by Rutherford backscattering spectrometry (RBS) was within ±2.5 at.% of the

initial source composition. Following deposition of the

chalcogenide, a 20-nm silver film was evaporated on top

and this sandwich structure was either subsequently

thermally treated or illuminated with light. The thermal

treatments were performed at 120 and 200 °C in repeated blocks of 10 min up to a maximum of 5 h in

nitrogen atmosphere. The optically treated samples were

illuminated with 436 nm light, which is above the optical

gap of the chalcogenide, at room temperature for various times using the light source of a Karl Suss MJB-3

contact aligner with an optical power density of 6.5 mW/

cm2 . The typical illumination time was 10 min. The

residual silver on the surface of the sandwich structure

was dissolved in 1 mol solution of Fe(NO3 )3 .

The composition of the resulting films before and after

the diffusion process was studied using RBS analysis,

performed with 2 MeV 4 Heþ with the beam at normal

incidence to the sample and a backscattering angle of

65°. As the samples were quite beam sensitive, a reduced

charge of around 0.25 lC/mm2 was used. Experimental

RBS curves were fitted with those obtained by numerical

calculation using the ‘RUMP’ software package [8]. The

chemical composition of the layer and the corresponding

number of atoms of silver were used as fitting parameters. The shape and position of the RBS yield energy

profiles have Gaussian form which is the result of the

convolution of the normalized Ag concentration distribution and another Gaussian function which models the

broadening in the RBS spectra due to the energy resolution of the detector and associated electronics. Because

the signals from Ge and Se are very close to each other, a

shoulder forms in the spectra but each of the individual

signals is Gaussian in character.

The phases formed in the films were characterized by

means of an X-ray diffraction (XRD) method performed

by CuKa radiation in the 2-theta range from 23° to 100°

at a step size of 0.05°.

Raman spectra were obtained to provide information

on the short and medium range order occurring in the

films after the diffusion processes. These investigations

were performed in the micro-Raman mode with the

following conditions: 15 s at 15 accumulations by illumination with 1.5 mW of light power on sample with

647.1 nm wavelength of a Krþ ion laser. In situ measurements at elevated temperatures placing the films in a

special thermal camera purged with nitrogen were also

performed. The experimental curves were fitted with

Labcalc software package.

The amount of diffused silver was established using

RBS analysis and the results show that in case of ther-

Photo diffusion

40

Thermal diffusion

30

20

10

0

3. Results

553

0

5

10

15

20

25

Time (min)

Fig. 1. Amount of diffused silver in Ge20 Se80 films: (a) due to photodiffusion; (b) due to thermal diffusion.

554

M. Mitkova et al. / Journal of Non-Crystalline Solids 338–340 (2004) 552–556

10

(a)

virgin film

65.0

Normalized intensity(a.u.)

Counts (arb. units)

65.5

(b)

64.5

o

HT@120 C, 10 min

64.0

63.5

(c)

o

HT@200 C, 10 min

63.0

50

100

150

200

250

300

8

6

+

4

++

Initial film

* *

*

*

HT@200°C

^ *++*

*

*

2

20

30

40

50

60

70

80

90

100

-1

Raman shift (cm )

2 Theta (deg.)

Fig. 2. Raman spectra of Ge20 Se80 film: (a) virgin film, (b) film after

thermal treatment at 120 °C for 10 min, and (c) film after thermal

treatment at 200 °C for 10 min.

Fig. 4. XRD pattern of thermally diffused Ge20 Se80 films: (a) virgin

film, (b) film after thermal diffusion at 200 °C for 10 min: * denotes

peaks of Ag, + denotes peaks of orthorhombic Ag2 Se, and ^ are peaks

of cubic Ag2 Se.

reduction in the scattering strength of the Se chain mode

at 260 cm1 (CM) with the annealing time.

In the case of photodiffusion, drastic changes in the

structure of the hosting material take place when saturation is reached as shown in Fig. 3. Prior to diffusion,

the hosting material exhibits modes of Ge–Se cornersharing tetrahedra at 194 cm1 , low scattering from edge

sharing tetrahedra at 221 cm1 , and Se chains at 260

cm1 (stretching mode) and 150 cm1 (bending mode).

However, after the diffusion process is complete, we see

at 180 cm1 the mode of the ethane-like molecule

Ge2 Se6 and at 203 cm1 the mode of the GeSe4 tetrahedron.

The XRD investigation shows that prior to any

treatment, the films consist of micro-crystalline Ag with

2-theta peaks at 38.12°, 44.30°, 81.54° and 97.89°

(JCPDS card #87-2871) and an underlying amorphous

matrix of Ge–Se glass, as shown in Fig. 4. Following

thermal diffusion at 200 °C to completion, features of

orthorhombic Ag2 Se with peaks at two theta 26.97°,

33.54°, 40.41° – JCPDS card # 06-0501; 28.83 – JCPDS

card # 25-0766; and 43.43° JCPDS card # 20-1063

emerge together with peak of cubic Ag2 Se at 35.89° –

JCPDS card # 27-0619 and silver. From the XRD data,

one can also see that the Ge–Se backbone remains

amorphous after the thermal anneal.

Counts (arb. units)

1.6

1.2

0.8

Ge 20 Se80

b)

(Ge 20 Se80 ) 53 Ag 47

c)

Ag 2Se

0.0

100

200

We now discuss the most important results of our

work regarding how and in what form silver incorporates into the Ge20 Se80 films and show in what manner

the resulting structure depends upon the way in which

the diffusion process is performed. If we assume that the

mean coordination of Ag with Se is 3 we can use the

equation proposed in Ref. [10] to estimate the composition of the glasses after Ag is introduced:

ðGex Se1x Þ1y Agy ¼ ð3y=2ÞðAg2=3 Se2=3 Þ

a)

0.4

4. Discussion

300

400

-1

Raman Shift (cm )

Fig. 3. Raman spectra of Ge20 Se80 films: (a) virgin film, (b) film after

saturation with silver at photodiffusion, and (c) Raman spectrum of

Ag2 Se.

þ ð1 3y=2ÞðGet Se1t Þ;

ð1Þ

where t ¼ xð1 yÞ=ð1 3y=2Þ is the amount of Ge in

the Ge–Se backbone. At x ¼ 0:20 and y ¼ 0:43, we get

t ¼ 0:33 for the case of thermally induced diffusion and

t ¼ 0:36 for the case of photodiffused silver when

y ¼ 0:47. Feng et al. [11] demonstrated that Ge–Se glass

containing 33 at.% Ge will consist only of CS and ES

Ge–Se tetrahedra. As shown on Fig. 2 there are not big

changes of the initial backbone structure due to the

thermal treatment and indeed the ES structures are not

developing with the diffusion as seen also for Ge30 Se70

M. Mitkova et al. / Journal of Non-Crystalline Solids 338–340 (2004) 552–556

glasses by Takeuchi et al. [13]. We are tempted to suggest that this is due to the fact that Ag only partially

reacts at the diffusion temperatures with Se from the Se

chains and partially finds place between the structural

units of the glass and remains in elemental form as

neither the annealing temperature nor time contribute

for it to fully chemically react with Se from the Se

chains. The presence of Ag2 Se and Ag is manifested also

on the XRD spectra of the diffused films.

In the case of photodiffusion, there is excellent

agreement between our Raman data and the post-diffusion calculated backbone composition of 36 at.% Ge.

As discussed by Boolchand [14], in this composition the

underlying molecular phase consists of face-sharing

quasi one-dimensional ethane-like Ge2 (Se12 )6 chain

fragments whose presence is manifested on the Raman

spectra by the appearance of the mode at 180 cm1

depicted in Fig. 3(b) following silver diffusion. This

structure supposes the appearance of Ge–Ge bonds. So

far, investigations of the photoinduced changes in Ge–

Se glasses have not revealed the formation of Ge–Ge

bonds. The act of illumination of the film results in the

creation of electron–hole pairs and is accompanied by

the formation of charged metastable states at the chalcogen [15] that can react spontaneously with the surrounding Ag ions. This reaction will be preferred as the

energy that it requires is about three times less than the

energy for the Ge–Se bonding (48.4 vs 113 kcal/mol) and

we suggest that this is the reason that in this way more

Se is consumed for formation of Ag2 Se than the initially

available free Se chains. This fast occurring reaction

could be also the reason for the lack of an induction

period in photodiffusion and presence of only Ag2 Se

phases on the XRD data as photodiffusion product [16].

The fact that the Ag2 Se modes do not interfere with

those of the Ge–Se backbone after Ag diffusion is one

more piece of evidence that no mixed ternary phase

arises as a result of this reaction [17]. We assume that the

process reaches saturation because of the strict number

of free and under-coordinated Se atoms that are available for reaction with Ag and its concentration is higher

than in bulk glasses in which the large variation in the

melting temperatures of Ag2 Se and the Ge–Se backbone

allows Ag precipitation during the quenching process

and this limits the amount of Ag in the Ge–Se backbone

to 33 at.% [10].

Considering the spectra from the XRD analysis, the

unexpected presence of the high-temperature form of

Ag2 Se, could be due to space restrictions as Ag2 Se forms

after Ag thermal diffusion in an existing solid-state

framework. During annealing, cubic Ag2 Se develops

and this transforms to orthorhombic Ag2 Se after cooling to room temperature (at which the XRD investigations are made). The orthorhombic material has a more

loosely packed structure than the cubic form and we

suggest that the surrounding hosting glass restricts its

555

expansion. Although a number of floppy units are

available in the initial structure of the host, with the first

acts of silver inclusion and formation of Ag2 Se, its

structure becomes stiffer and so the internal space limitation acts in the same way as elevated pressure, stabilizing some clusters from the high temperature form

which has the closest packing.

5. Conclusions

We have investigated photo and thermally induced

silver diffusion in Ge20 Se80 thin films. The results show

that photoinduced diffusion occurs at a higher rate and

reaches saturation at higher silver concentration due to

the photoinduced changes in the hosting glass whose

mesoscopic structure modifies and phase separates to

form the diffusion product – Ag2 Se. The local structure

of the hosting film that forms following thermal diffusion is considerably distorted due to thermal stresses

but remains almost unchanged. It is phase separated

from the diffusion product that includes Ag2 Se as well

as Ag.

Acknowledgements

This work was supported by Axon Technologies

Corporation.

References

[1] T. Kawaguchi, S. Maruno, S.R. Elliott, J. Non-Cryst. Solids 211

(1997) 187.

[2] V. Lyubin, M. Klebanov, M. Mitkova, T. Petkova, J. Non-Cryst.

Solids 227–230 (1998) 739.

[3] M.N. Kozicki, S.W. Hsia, A.E. Owen, P.J. Ewen, J. Non-Cryst.

Solids 137&138 (1991) 1341.

[4] T. Kawaguchi, S. Maruno, S.R. Elliott, J. Appl. Phys. 79 (1996)

9096.

[5] D.J. Jacobs, M.F. Thorpe, Phys. Rev. Lett. 75 (1995) 4051.

[6] P. Boolchand, D.G. Georgiev, B. Goodman, J. Optoelectron.

Adv. Mater. 3 (2001) 703.

[7] J. Calas, R. El Ghrandi, G. Galibert, A. Traverse, Nucl. Instrum.

Meth. Phys. Res. B 63 (1992) 462.

[8] L.R. Doolittle, Nucl. Instrum. Meth. Phys. Res. B 9 (1985) 344.

[9] T. Wagner, A. Mackova, V. Perina, E. Rauhala, A. Sepp€al€a, S.O.

Kasap, M. Frumar, Mir. Vlcek, Mil. Vlcek, J. Non-Cryst. Solids

299 (2002) 1028.

[10] M. Mitkova, Y. Wang, P. Boolchand, Phys. Rev. Lett. 83 (1999)

3848.

[11] X. Feng, W.J. Bresser, P. Boolchand, Phys. Rev. Lett. 78 (1997)

4422.

[12] P. Nagels, R. Mertens, L. Tichy, in: M.F. Thorpe, L. Tichy (Eds.),

Properties and Applications of Amorphous Materials, in: NATO

Science Series II. Mathematics, Physics and Chemistry, vol. 9,

2000, p. 25.

556

M. Mitkova et al. / Journal of Non-Crystalline Solids 338–340 (2004) 552–556

[13] H. Takeuchi, O. Matsuda, K. Murase, J. Non-Cryst. Solids 238

(1998) 91.

[14] P. Boolchand, in: P. Boolchand (Ed.), Insulating and

Semiconducting Glasses, World Scientific, Singapore, 2000,

p. 214.

[15] K. Shimakawa, A. Kolobov, S.R. Elliott, Adv. Phys. 44 (1995)

475.

[16] M.N. Kozicki, M. Mitkova, J. Zhu, M. Park, Microelecton. Eng.

63 (2002) 155.

[17] P. Boolchand, W.J. Bresser, Nature 410 (2001) 1070.