Journal of Non-Crystalline Solids 352 (2006) 1986–1990

www.elsevier.com/locate/jnoncrysol

Crystallization effects in annealed thin Ge–Se films

photodiffused with Ag

M. Mitkova *, M.N. Kozicki, H.C. Kim, T.L. Alford

Center for Solid State Electronics Research, Arizona State University, Tempe, AZ 85287-6206, United States

Abstract

Ge–Se glasses with composition ranging from Ge20Se80 to Ge40Se60 photodoped with Ag and annealed at moderate temperatures are

investigated. Raman spectroscopy suggests that Ag photodiffusion brings about the formation of a Ge–Se backbone that is deficient in Se

and that the structure is depolymerized due to the extraction of Se during the formation of crystalline products. X-ray diffraction shows

that after Ag diffusion into the glass, nanocrystals of Ag2Se and Ag8GeSe6 form, depending on the composition of the host. The crystal

size is affected by the molecular clustering of the host.

! 2006 Elsevier B.V. All rights reserved.

PACS: 78.30.!j; 61.10.Nz; 61.43.Fs

Keywords: Amorphous semiconductors; Raman scattering; X-ray diffraction; Raman spectroscopy

1. Introduction

Photodiffusion of silver is one of the most interesting

effects that occurs in chalcogenide glass films as it dramatically changes the properties of the starting material and

forms a ternary that has a multitude of potential applications [1]. One system that has attracted significant community attention in the research is Ag-diffused Ge–Se. The

kinetics of Ag photodiffusion in Ge–Se has been shown

to be dependent on the hosting backbone [2]. The form

of the resulting structure has been proposed [3]. X-ray diffraction and scattering studies have been carried out on

Ge10Se90 and the stoichiometric composition GeSe2 showing the formation of Ag2Se and in some cases Ag2SeO4 [4]

or Ag2Se and Ag8GeSe6 on a very fine scale of phase separation [5].

Our recent studies show that the introduction of Ag in

chalcogenide glass films by photodiffusion results in significant changes of the hosting backbone’s structure [6]. This

*

Corresponding author. Tel.: +1 480 965 9481; fax: +1 480 965 8118.

E-mail address: mmitkova@asu.edu (M. Mitkova).

0022-3093/$ - see front matter ! 2006 Elsevier B.V. All rights reserved.

doi:10.1016/j.jnoncrysol.2005.09.051

is caused not only by the interaction of the material with

light but also by the reaction between the Ag and the hosting material [7]. The result of this is a higher amount of Ag

being able to be incorporated into the film compared with

the case of bulk material [8]. Furthermore, we have found a

correlation between the composition of the hosting material and the morphology of Ag electrodeposits grown on

these photodiffused films [9].

In our opinion, one of the most important unresolved

issues regarding the photodiffusion process is the relationship between the hosting backbone composition and the

composition and morphology of the diffusion product.

Closely related to this problem is crystal growth during isothermal annealing of the diffusion product since, in real

world of applications of these materials, thermal processing

is often applied or they are operated at elevated temperatures. In this work, we investigate these topics.

2. Experimental

Samples were prepared by sequential thermal evaporation of GexSe1!x thin films (x being 0.2; 0.3; 0.33 and

1987

M. Mitkova et al. / Journal of Non-Crystalline Solids 352 (2006) 1986–1990

a

Ge20Se80

b

Ge30Se70

c

Ge33Se67

d

Ge40Se60

e

3. Results

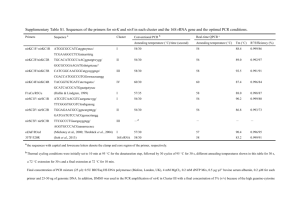

The RBS data confirmed that the initial composition of

the hosting backbone was within ±2 at.% of the composition of the source material, which corresponds well with

200

300

400

500

Raman shift, cm-1

Fig. 1. Raman spectra of the undoped Ge–Se glasses and spectrum of the

photodiffused material. Compositions are noted in the figure.

ð1Þ

where t is crystallite size, k is X-ray wavelength, B is the full

width at half maximum of the peak, h is the angle at full

width at half maximum. This approach is suitable to estimate the particle size of very small crystals. We used X-Pert

Peak Find software to identify the peaks since the spectra

were noisy due to the very small amount of crystalline

inclusions and small crystallite size. In this particular case,

the diffraction peaks were rather broad. The calculated

data give average sizes in the case where several peaks

are available for a particular crystalline product.

Film resulting after photodiffusion

100

*

Intensity, Arb. units

t ¼ ð0:9 $ kÞ=B cos h;

the results of our earlier studies [6]. As far as the structure

of the hosting glass backbone is concerned, the spectra of

non-diffused glasses show the specific Raman features closely matching those of bulk materials with the same composition, as illustrated in Fig. 1(a)–(d). However, after

diffusion, the spectra of all samples show a vibrational

band at 180 cm!1 and a higher frequency band at

200 cm!1 independent of the composition (Fig. 1(e)), suggesting the formation of a structure containing ethane-like

units with Ge–Ge bond as well as the Ge–Se tetrahedra.

These spectra remained unchanged following the moderate

annealing applied in this study.

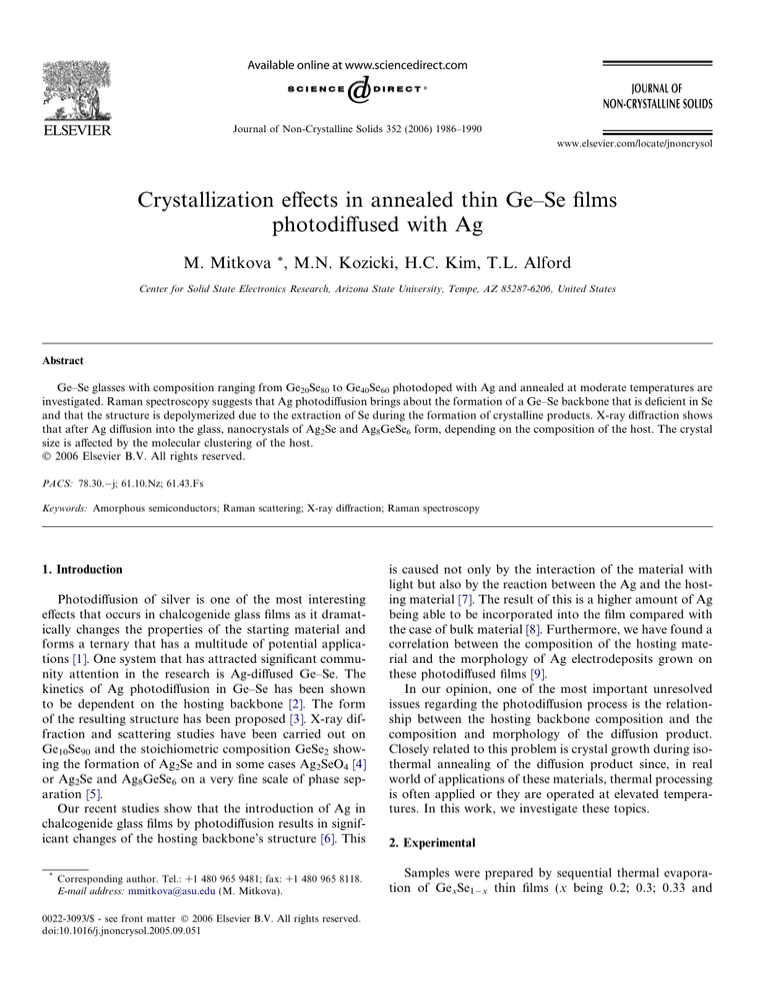

Fig. 2 gives representative curves of the XRD spectra of

the photodiffused glasses for an initial composition of

Ge33Se67. In all cases, the hosting Ge–Se glass remained

amorphous during the annealing while the silver containing

species formed nanocrystals. We found orthorhombic

Ag2Se with peaks at 2h = 33.510, 34.882, – JCPDS card

20-1063; 39.083, 41.378 and 42.365 – JCPDS card

25-0766; as well as cubic Ag2Se with 2h = 35.891 – JCPDS

Intensity, Arb. Units

0.4) and Ag, using the technique described in [7], at a pressure of 2 · 10!6 Torr on silicon substrates. The thickness of

the Ge–Se films was 250 nm while the thickness of the Ag

was 80 nm. To promote silver diffusion, the samples were

illuminated with 436 nm light at room temperature for

10 min with an optical power density of 6.5 mW/cm2.

These experimental conditions were established as being

sufficient to saturate the films with Ag while leaving little

residual Ag on the surface [7]. Any remaining Ag was dissolved in 1 mol solution of Fe(NO3)3.

The compositions of the films before (i.e., only the Ge–

Se glass film) and after the diffusion process were studied

using Rutherford backscattering spectrometry (RBS) analysis, performed with a 2 MeV 4He+ with the beam at normal incidence to the sample and a backscattering angle of

65" at a reduced charge of around 0.25 lC/mm2.

Raman spectra were obtained to provide information on

the short range order occurring in the hosting films following the diffusion processes since they retain an amorphous

component following all treatments. Because of the light

sensitivity of the materials investigated, the need to excite

Raman scattering at low energy is of paramount importance. For this reason, resonant enhancement of the scattering by tuning the laser energy close to the optical band

gap of the glass is particularly desirable. Raman studies

were therefore performed in the micro Raman mode with

the following conditions: illumination with the 647.1 nm

wavelength of a Kr+ ion laser, 15 accumulations of 15 s

with 1.5 mW of light power at the sample. The phases

formed in the films were characterized using X-ray diffraction (XRD) performed with Cu Ka radiation with

k = 0.15418 nm in the 2h range from 23" to 100" at a step

size of 0.05".

The fabricated Ag-diffused films were annealed at 85 "C,

110 "C, 125 "C and 150 "C in an inert atmosphere to avoid

oxidation for either 15 or 120 min. After annealing, the

XRD spectra were measured at room temperature and

the crystal size of the diffused products was evaluated using

the Scherrer equation;

*

*

*

+

+ +^

+

*

*

+

*

20

+ + ^

+

30

+ +

*

*

d

**

c

+^+ +

* *

b

+

* *

a

^ + +

40

50

2Theta, Deg.

60

70

Fig. 2. Representative XRD plots of Ge33Se67 glass photodiffused with Ag

annealed (a) at 85 "C for 15 min, (b) at 85 "C for 120 min, (c) at 150 "C for

15 min and (d) at 150 "C for 120 min; * peaks characteristic for Ag8GeSe6;

^ peaks characteristic for aAg2Se; + peaks characteristic for bAg2Se.

Some peaks were reduced to fit on a single graph.

1988

M. Mitkova et al. / Journal of Non-Crystalline Solids 352 (2006) 1986–1990

β Ag 2Se

8

Cluster size, nm

8

annealing for 120'

annealing for 15'

7

6

annealing for 120'

7

αAg 2Se

5

20

6

annealing for 15'

40

60

80

100 120

o

Annealing temperature, C

140

Fig. 6. Cluster sizes for annealed Ge28Se42Ag30 for the conditions shown

on the figure.

α Ag Se

2

annealing for 120'

5

annealing for 15'

20

40

60

80

100

120

140

Annealing temperature, oC

Fig. 3. Cluster sizes for annealed Ge10.5Se42.3Ag47.2 for the conditions

shown on the figure.

9

β Ag 2Se

annealing for 120'

8

Cluster size, nm

Ag 8GeSe6

annealing for 120'

annealing for 15'

annealing for 15'

7

6

α Ag 2Se

annealing for 120'

5

20

annealing for 15'

40

60

80

100

120

140

o

Annealing temperature, C

Fig. 4. Cluster sizes for annealed Ge18Se42Ag40 for the conditions shown

on the figure.

10

αAg 2Se

β

annealing for 120'

annealing for 15'

Cluster size, nm

9

Cluster size, nm

card 27-0619 and Ag8GeSe6 with 2h 27.139, 28.070, 46.976

and 49.357 – JCPDS card 71-1690. Crystal growth during

annealing is presented in Figs. 3–6 for different compositions of the hosting glass. One can see not only fluctuations

in the nanocluster size but also in the composition of the

crystal fractions depending on the chalcogenide host.

9

Ag 8GeSe6

annealing for 120'

annealing for 15'

8

7

20

α Ag 2Se

annealing for 120'

annealing for 15'

40

60

80

100 120

o

Annealing temperature, C

140

Fig. 5. Cluster sizes for annealed Ge22.1Se44.9Ag33 for the conditions

shown on the figure.

When Ag is diffused in Ge20Se80 only Ag2Se forms while

for diffusion in more Ge-rich compositions (over 33 at.%

Ge) the formation of Ag8GeSe6 occurs as well.

A progressive increase in nanocrystal size with the Ge

content of the hosting backbone occurs until the stoichiometric composition GeSe2 is reached, beyond which the crystal size decreases to that seen in the more Se-rich glasses. Of

course, the annealing temperature and time also have an

influence over the crystal size and these results are

discussed next.

4. Discussion

First, we would like to stress the fact that the photodiffused films contain more Ag than can be introduced in bulk

glasses while retaining a glassy character of the films. During our studies of the Ge–Se–Ag system in bulk or thin film

form, we have consistently found Ag to be chemically

bonded. Furthermore, illumination with light causes formation of a number of charged defects that react with

Ag. This fact has important consequence since some Se is

extracted from the initial Ge–Se backbone to react with

the diffused Ag. So the remaining chalcogenide glass backbone becomes Se deficient, as demonstrated by the appearance of a Raman signature that is characteristic of a

Ge-rich glass, independent of the initial composition of

the host. In this composition the underlying molecular

phase consists of face-sharing quasi one-dimensional

ethane-like Ge2(Se1/2)6 chain fragments whose presence is

manifested on the Raman spectra by the appearance of

the mode at 180 cm!1 [10] depicted in Fig. 1(e). The Raman

spectrum of the resulting material shows a lower intensity

ratio between the modes at 180 cm!1 and the mode of

the Ge-tetrahedral units at 200 cm!1 when compared to

the intensity ratio of these modes for a Ge40Se60 initial glass

film indicating that the number of ethane like units is lower

than in Ge40Se60 glass. However this structure still contains

Ge–Ge bonds. They are the result of the spontaneous reaction of Ag with charged metastable states on the chalcogen

[11] initiated by light illumination and with charged defects

M. Mitkova et al. / Journal of Non-Crystalline Solids 352 (2006) 1986–1990

occurring at bond conversion [12]. This reaction will be

preferred since the energy that it requires is less than the

energy for the Ge–Se bonding (48.4 kcal/mol versus

113 kcal/mol). We suggest that this is the reason for the

extraction of some Se from the Ge–Se backbone for the

formation of Ag2Se in addition to the reaction of Ag with

the initially available free Se chains. Formation of Ag8

GeSe6 also brings about this effect since its six Se atoms

are related to the extraction of one Ge atom from the

glassy material while in the case of initial glass there are

on average two Se atoms for each one Ge atom in the

Ge–Se tetrahedral structure excluding face sharing units.

The structure of Ge–Se backbone formed after photodoping is depolymerized to some extent due to the extraction of

Se and formation of crystalline products. It is for this reason that the organization of the photodiffused hosting glass

does not change with the moderate annealing applied, as

happens with pure Ge–Se films [13] where the local stressed

configurations with a high free energy relax through breaking of the Ge–Ge bonds and formation of Ge–Se cornersharing units due to reaction with Se–Se wrong bonds.

Considering the results from the XRD analysis, the crystals forming after diffusion are relatively small because they

can only form in the free interspaces available in the matrix

of the hosting glass. Although in the case of Ge20Se80 glass

the initial structure is floppy, following the initial silver

inclusion and formation of Ag2Se, the glass structure

becomes depleted in Se and stiffer. The internal space limitation produces the same effects as elevated pressure, stabilizing some clusters in the high temperature form which

has the closest packing. With Ge-enrichment of the hosting

backbone, the intensity of the peaks of aAg2Se becomes

higher, suggesting reflectance from a larger number of

planes. At the same time, Ag8GeSe6 clusters are formed

and we assume that these occur at terminal defects on the

Ge–Se tetrahedra in the case of the Ge33Se67 host or

develop within the volume of the films when Ag is diffused

in a Ge40Se60 host. Indeed, Mössbauer spectroscopy definitely shows that replacement of Ge by Ag occurs in Gerich glasses [8] so a combined effect could be the reason

for the development of the three-component composition.

During annealing at 150 "C, additional cubic Ag2Se likely

forms but transforms back to the orthorhombic structure

after cooling to room temperature.

The other specific feature that we would like to discuss is

the average size of the crystal nanoclusters and how this is

related to the host composition. Within the limits of accuracy of the method, there is a noticeable fluctuation in the

crystal size as shown in the results section (see Figs. 3–6).

We suggest that this effect is related to the molecular clustering of the hosting glass. As pointed out by Feltz et al.

[14] the evolution of molar volume with composition has

a maximum at x = 0.33, i.e., for GeSe2, where the structure

is less densified. Although the lattice parameters of Ag2Se

are smaller, in the cases when Ag8GeSe6 crystallizes in a

more dense and rigid backbone, its initial clusters are smaller than the Ag2Se clusters developed in a structure with

1989

larger free volume and higher flexibility of the hosting

backbone.

One last point for discussion is the development of the

crystal growth at elevated temperatures. The conditions

discussed in this work are relatively mild since our final

goal is to deduce information useful for the processing of

these materials for applications in semiconductor technologies and particularly in the formation of programmable

metallization cell (PMC) memory devices [6]. The annealing results showed that there are no changes in the composition of the crystalline products with time at the

temperatures chosen. In the case of Ag2Se clusters, the

crystalline phases are different than the surrounding material and we assume that their growth is limited by atomic

diffusion, which is somewhat restricted considering the heterogeneous character of the medium, and allows only at

about 5–8% growth after annealing. In the case of the formation of Ag8GeSe6 clusters, their growth is much more

affected by annealing and their size changes by about 8–

10%. This situation corresponds closely to homogeneous

growth. We suggest that the adjacent clusters fuse with

Ge atoms cross-linking the cluster edges and leading to

the formation of a common structure combining the three

elements. The consequence of the crystallization nature in

photodiffused films is that the structure that forms is very

stable and there are no compositional changes caused by

the temperatures used.

5. Conclusions

We have investigated the products of Ag diffusion in

Ge–Se films with varying initial composition and also collected information about their development during isothermal annealing. The main results of our work can be

summarized as follows.

1. Regardless of the initial composition of the hosting

glass, the photodiffused material shows Raman features

characteristic of Ge-rich material. The glassy component becomes Se-deficient due to consumption of Se in

the formation of the diffusion products.

2. The diffusion products are nanocrystalline regions dispersed into the glassy matrix and their composition is

dependent upon the hosting glass composition and

develops from Ag2Se to a combination of Ag2Se and

Ag8GeSe6 with enrichment of the host in Ge.

3. The cluster size of the crystalline products depends on

the molar volume of the host in close relation to its

rigidity.

4. Isothermal annealing at moderate temperatures results

in diffusion limited slow growth of the Ag2Se clusters

and homogeneous growth of the Ag8GeSe6 clusters.

Acknowledgement

This work was sponsored by Axon Technologies Corp.

1990

M. Mitkova et al. / Journal of Non-Crystalline Solids 352 (2006) 1986–1990

References

[1] N. Yoshida, M. Itoh, K. Tanaka, J. Non-Cryst. Solids 198–200 (1996)

749.

[2] G. Kluge, A. Thomas, R. Klabes, R. Grötzschel, P. Süptitz, J. NonCryst. Solids 124 (1990) 186.

[3] T. Kawaguchi, S. Maruno, S. Elliott, J. Appl. Phys. 79 (1996) 9096.

[4] C.H. Chen, K.L. Tay, Appl. Phys. Lett. 37 (1980) 605.

[5] A. Fischer-Colbrie, A. Bienenstock, P.H. Fuoss, M.A. Marcus, Phys.

Rev. B 38 (1988) 12388.

[6] M. Mitkova, M.N. Kozicki, J. Non-Cryst. Solids 299–302 (2002)

1023.

[7] M. Mitkova, M.N. Kozicki, H.C. Kim, T.L. Alford, J. Non-Cryst.

Solids 338–340 (2004) 552.

[8] M. Mitkova, Yu Wang, P. Boolchand, Phys. Rev. Lett. 83 (1999)

3848.

[9] M. Mitkova, M.N. Kozicki, J.P. Aberouette, J. Non-Cryst. Solids

326&327 (2003) 425.

[10] P. Boolchand, in: P. Boolchand (Ed.), Insulating and Semiconducting

Glasses, World Scientific, 2000, p. 214.

[11] K. Shimakawa, A. Kolobov, S.R. Elliott, Adv. Phys. 44 (1995)

475.

[12] N.V. Bondar, N.A. Davydova, V.V. Tishchenko, M. Vlcek, J. Mol.

Struct. 555 (2000) 175.

[13] Y. Wang, K. Tanaka, T. Nakaoka, K. Murase, J. Non-Cryst. Solids

299–302 (2002) 963.

[14] A. Feltz, H. Aust, A. Pelyer, J. Non-Cryst. Solids 55 (1983)

179.