Electrodeposit Formation in Solid Electrolytes

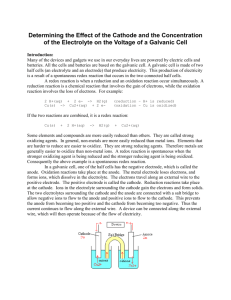

advertisement

Electrodeposit Formation in Solid Electrolytes Michael N. Kozicki, Cynthia Ratnakumar, and Maria Mitkova Center for Applied Nanoionics Arizona State University, Tempe, AZ 85287-6206, USA Abstract – Devices based on polarity-dependent switching in solid electrolytes show great promise as next generation memory and perhaps even logic devices. These elements operate by the formation of robust but reversible electrodeposited conducting pathways which can be grown and dissolved at low voltage and current. Although such devices have been well characterized, little has been presented on the exact growth mechanism and nature of the conducting links themselves. In this paper we will show and discuss examples of electrodeposition within ternary silver-chalcogenide electrolyte device structures. The electrolyte was sectioned using focused ion beam milling and imaged with an in-situ scanning electron microscope to reveal the profile of the structure. A variety of Ag electrodeposits were imaged in overwritten devices and it was clear that programming times in the order of a few seconds will create multiple deposits on the inert cathode, some of which appear to extend through to the anode. The electron beam itself was also used to reduce silver ions within the electrolyte to reveal how the electrodeposits might nucleate on the Ag-rich phases within the film. Index terms – non-volatile memory, solid electrolyte, electrodeposition, focused ion beam, electron microscopy. I. INTRODUCTION There has been considerable interest in recent times in switching devices based on reversible electrodeposition in solid electrolyte films [1-3]. One approach, known by various names including Programmable Metallization Cell (PMC) and Conductive Bridging Random Access Memory (CBRAM), shows great promise as a future low energy non-volatile solid state memory [4-7]. The technology utilizes ternary solid electrolytes, typically Ag-Ge-Se or Ag-Ge-S, sandwiched between an inert (e.g., W) and an oxidizable (Ag) electrode. A small bias, applied such that the oxidizable electrode is the anode and the inert electrode the cathode, promotes the growth of a conducting electrodeposit through the electrolyte and this reduces the resistance of the device by many orders of magnitude. A reverse bias dissolves the link and the device returns to its high resistance state. Key attributes are low voltage/low current operation, high speed, excellent scalability, retention and endurance, and a simple fabrication sequence within the back-end-of-line (BEOL) flow. Although such devices have been well characterized with respect to their electrical characteristics, little or no data has been presented in the literature on the exact growth This work was supported by Axon Technologies Corporation. 0-7803-9738-X/06/$20.00 (C)2006 IEEE 111 mechanism and nature of the conducting links that form between the electrodes within the electrolyte film. In this paper we will show examples of metal electrodeposition, starting with a discussion of our previous work on surface electrodeposits and moving to our recent analysis of growth within ternary silver-chalcogenide electrolyte device structures. In the case of the sub-surface growth, the electrolyte was sectioned using a focused ion beam and imaged with an in-situ scanning electron microscope to reveal the profile of the electrodeposited features. A variety of Ag electrodeposits were examined in devices that had been “overwritten”, i.e., an electrodeposition bias was applied for several seconds to promote as much growth as possible for the purposes of imaging. It was clear that programming times in the order of a few seconds created multiple deposits on the inert cathode, some of which appear to extend through to the anode. We also used the electron beam itself to reduce silver ions within the electrolyte to reveal how the electrodeposits nucleate on the Ag-rich phases within the film. II. ELECTRODEPOSIT GROWTH AND MORPHOLOGY In order to rapidly grow a stable electrodeposit, it is necessary to have an oxidizable anode to supply ions into the electrolyte to maintain ion concentration and overall charge neutrality, otherwise the electrodeposit will form at the expense of the ions in the electrolyte and this process quickly becomes self-limiting. In the case of a silver ion-containing electrolyte, this oxidizable anode is silver or a compound or alloy containing free silver. The inert electrode merely has to supply electrons for ion reduction but should not be readily oxidizable as this could allow growth to occur under reverse bias which would make the turning-off of the device more difficult to achieve. In a device that has an electrolyte between two such electrodes, the anode will oxidize when a bias is applied if the oxidation potential of the metal is greater than that of the solution. Under steady state conditions, as current flows in the cell, the metal ions will be reduced at the cathode. For the case of silver, the reactions are: Anode: Ag → Ag+ + e- (1) Cathode: Ag+ + e- → Ag (2) with the electrons being supplied by the external power source. The silver ions migrate through the electrolyte by a coordinated hopping mechanism toward the cathode under the driving force of the applied field and the concentration gradient [8]. At the boundary layer between the electrolyte and the electrodes, a potential difference exists due to the transfer of charge and change of state associated with the electrode reactions. This potential difference leads to polarization in the region close to the phase boundary, known as the double layer [9] and for the reduction-oxidation reaction to proceed, the applied potential must overcome the potential associated with this polarization. This leads to a threshold voltage for electrodeposition, below which the small observed steady state current is essentially electron leakage by tunneling through the narrow double layer. Above the threshold, the ion current flows and the ions are reduced to deposit on the cathode, becoming part of its structure mechanically and electrically. In the most general case, the addition of atoms to the growing electrodeposit occurs due to a diffusion-limited aggregation (DLA) mechanism [10, 11]. In this process, a seed is fixed on a plane which contains randomly moving particles and those particles that move close enough to the seed are attracted to it and attach and form the aggregate. When the aggregate consists of a number of particles, growth proceeds outwards and with greater speed as the new deposits extend to harvest more moving particles so that the branches grow faster than the interior regions. The precise shape of these features depends on parameters such as the potential difference and the concentration of ions in the electrolyte [12]. At low ion concentrations and low fields, the deposition process is determined by the diffusion of metal ions in the electrolyte and the resulting pattern is fractal in nature. For high ion concentrations and high fields, conditions common in our solid electrolyte devices, the moving ions have a stronger directional component and dendrite formation occurs. Dendrites also tend to have a branching shape but tend to be more ordered than fractals and grow in a preferred axis defined by the electric field. The general models for electrodeposit evolution assume a homogeneous electrolyte but since electrodeposit growth is obviously related to the presence of available Ag ions in the electrolyte surface, the morphology of the electrolyte will have a profound effect on electrodeposit morphology. This is of particular significance in ternary electrolytes such as AgGe-Se, which have been shown to be phase-separated into metal ion-rich crystallites dispersed in an insulating glassy material [13, 14]. The concentration of Ag in the electrolyte and its physical distribution in the dispersed crystalline phase depend on the composition of the base glass. The effect of this is illustrated in the analysis of surface electrodeposition on electrolytes formed from Se-rich and Ge-rich base glasses [15]. In the case of an electrolyte based on a Ge0.30Se0.70 glass which is over-stoichiometric in Se, we observe the growth of relatively flat (around 20 nm tall) and continuous dendritic deposits on surface of the films, as shown in Fig. 1(a). In the case of the Ge-rich glasses (Ge0.40Se0.60), we see the growth of isolated tall (>100 nm) electrodeposits as illustrated in Fig. 1(b). The Ge0.30Se0.70 material has the higher chalcogen 0-7803-9738-X/06/$20.00 (C)2006 IEEE 112 content of the two and therefore will possess greater and more uniform quantities of the ion-supplying phase (in this case Ag2Se) following the addition of Ag. This leads to dendritic growth that is closer to that expected with a homogeneous material. The isolated growth on the Ge0.40Se0.60 electrolyte is a direct consequence of the greater degree of separation of the dispersed Ag-containing phases in this material. (a) (b) Figure 1. Atomic force microscope image (3D topographical scan) of (a) Ag grown on Ag-saturated Ge0.30Se0.70. The maximum electrodeposit height is a few tens of nm and the growth is continuous. (b) Ag grown on Ag-saturated Ge0.40Se0.60. The maximum electrodeposit height is in the order of 100 nm and growth is discontinuous (from [15]). Whereas the growth of electrodeposits on the surface of an electrolyte film has some useful applications [16] and allows us to see the influence of the electrolyte morphology, it is the formation of electrodeposits within an electrolyte that is of more interest for applications in memory. The memory device configuration has the electrodes on opposite sides of a thin electrolyte film, so that the growth of the electrodeposit is forced to occur through rather than on the electrolyte. Growth within an electrolyte will tend to occur in the flexible channels and nano-voids that exist in these materials and the confining nature of the medium will distort the shape of the electrodeposit, restricting its contours to conform with the zones with the highest free volume. In addition, the nanoinhomogeneity of the electrolyte will have a significant effect on local potential and ion supply. The net result is that the electrodeposit will not appear to be dendritic in nature, instead taking a form that is governed by the shape of the glassy voids and crystalline regions in the electrolyte. In order to confirm this, we performed a series of experiments on functioning devices and these are described in the following section. III. ELECTRODEPOSITION WITHIN SOLID ELECTROLYTE FILMS The PMC device structures fabricated for the sub-surface electrodeposit characterization work consisted of a W bottom electrode, a 60 nm thick Ag0.33Ge0.20Se0.47 electrolyte formed by the photodissolution of 25 nm of Ag into a Ge0.30Se0.70 base glass, and a Ag top electrode. These layers were deposited by physical vapor deposition and the photodissolution was performed using exposure to ultraviolet light, 405 nm, 1 J/cm2, at room temperature. The electrodes were separated by a 100 nm thick silicon nitride dielectric layer and a window in this insulating layer defined the electrolyte area that contacts the bottom electrode. In this case the device area was 5 µm in diameter to allow cross-sectioning of the active region. To form sufficiently large and numerous electrodeposits for analysis, the devices were programmed using a quasi-static technique. In this, a slow voltage sweep from -1 V to +1 V with a current compliance of 10 µA was performed using an Agilent 4155C Semiconductor Parameter Analyzer. The positive part of the sweep above the write threshold of 250 mV lasted approximately 3 seconds. Programmed and unprogrammed devices were then transferred to a FEI Nova 200 Nanolab dual beam Focused Ion Beam (FIB) system with integrated scanning electron imaging for sectioning and analysis. A Ga+ ion beam current of 30 pA extracted from a liquid metal ion source at 30 kV was used to mill 2.5 µm × 2.5 µm areas from the centers of the devices, removing the top electrode and electrolyte down to the bottom electrode. The milled holes in the devices were then imaged using the system’s scanning electron microscope capability with a 5 kV, 98 pA beam. Fig. 2 shows a section taken through the (rough) top silver electrode and the Ag-Ge-Se electrolyte. The electrolyte appears to be thicker than the 60 to 70 nm expected but this is an artifact of the milling processes which produces a sloping 0-7803-9738-X/06/$20.00 (C)2006 IEEE 113 Ag Ag-Ge-Se Fig. 2. Electron micrograph of cross-section of a Ag electrode on a 60 nm thick Ag-Ge-Se solid electrolyte with no connected W electrode. sidewall. In this region, there was no connected tungsten electrode so the structure would not support electrodeposition. We see that the electrolyte in this case is essentially featureless and there is no evidence of electrodeposit formation. The programmed device cross-section shown in Fig. 3 has a multitude of electrodeposits both on the tungsten cathode and also in the electrolyte. We believe that most of these deposits, particularly those on the cathode, were created by the programming and not by the milling process as we do not see any electrodeposition in the milled sample of Fig. 2. We also performed ion imaging (no electron exposure) on the programmed sample after sectioning to confirm that the ion beam itself was not promoting growth. It should be noted, as we will see later, that the electron beam is capable of stimulating considerable growth and so the micrograph of Fig. 3 was therefore taken as quickly as possible to avoid this. Ag W Ag deposits in electrolyte Ag-Ge-Se Ag deposits on cathode Fig. 3. Electron micrograph of a cross-section of a Ag electrode on a 60 nm thick Ag-Ge-Se solid electrolyte on a W bottom electrode. The device was previously programmed to produce the electrodeposits (bright regions) on both the cathode and in the electrolyte. On close inspection of the deposits on the cathode in this and other samples in our study, they generally appear to be thicker at the base than at the tip and are frequently somewhat conical in shape. This is not surprising as the cathode is the primary supply of electrons and therefore the bulk of the electrodeposition will occur there. Fig. 4 gives an example of a particularly broad (around 250 nm diameter at its base) near-conical electrodeposit at the edge of the ion milled region that had originally formed on the cathode during device programming but continued to grow by exposure to the electron beam during imaging. This region received a higher electron dose than the material in Fig. 3 (hence the larger amount of growth) as the imaging of this smaller feature took more time. Of course, only the electrodeposits that were in physical contact with the intact portion of the electrolyte could grow during electron-beam exposure as electrodeposition requires both a supply of electrons (from the beam) and a supply of ions (from the electrolyte). The typical base diameter of the electrodeposits which formed on the cathode away from the Ag-supplying electrolyte edge, and therefore could not continue to grow during electron-beam imaging, was less than 50 nm, as is evident from Fig. 3. Fig. 5 is a magnified portion of the image shown in Fig. 3, showing the growth of an electrodeposit in the electrolyte film. The electrodeposited feature has an apparent width of 20 to 40 nm but we believe that this has grown slightly during exposure to the electron beam even though the time taken to image the sample was short. There appear to be three growth regions that make up this electrodeposit; a small growth on the cathode topped with a more prominent growth in the center of the electrolyte, and a small deposit between the central growth and the bottom of the silver electrode. This electrodeposit could very well be continuous and thereby connect the tungsten cathode to the silver anode, leading to the low on state resistance (around 25 kΩ) of the programmed device. Ag-Ge-Se Electrodeposit 40 nm Fig. 5. Electron micrograph of a small region of the electrolyte shown in Fig. 3 showing what could be an electrodeposit that connects the cathode to the anode. Fig. 6 shows an interesting effect of prolonged electron exposure of the edge of the Ag-Ge-Se electrolyte. At the start of the imaging session, only a few small dispersed electrodeposits could be seen but after several seconds (following focusing), a number of Ag deposits, which appear as light near-circular features in the micrograph, nucleated away from the electrodes and independent of one another within the electrolyte. Since electrodeposition will occur where the supply of ions is the greatest (assuming that electrons supplied by the beam are plentiful at all points), it is most likely that these features have nucleated on the Ag-rich phases within the film and grown out from these nuclei to form the larger electrodeposits, of 30 nm average diameter, shown in the micrograph. Electrodeposits Ag-Ge-Se Ag-Ge-Se Electrodeposit 30 nm 250 nm Fig. 4. Conical electrodeposit on cathode at the edge of the milled region. The feature continued to grow during imaging and is this much larger than the original electrodeposit produced by the programming process. 0-7803-9738-X/06/$20.00 (C)2006 IEEE 114 Fig. 6. Electron micrograph of a section of a 60 nm thick Ag-Ge-Se solid electrolyte film in which electron-beam stimulated electrodeposition has occurred. IV. CONCLUSIONS Building on our earlier work on the characterization of surface electrodeposits, we have studied aspects of subsurface electrodeposition within solid electrolyte films. Crosssections were taken through vertical Programmable Metallization Cell devices based on Ag-Ge-Se electrolytes using focused ion beam milling. The electrolyte sections in regions which could not support growth were largely featureless but the milled cross sections in over-programmed devices showed a variety of electrodeposited structures. Programming times in the order of a few seconds led to multiple deposits on the cathode. These features were often somewhat conical in shape, being broad and nearly circular at the electron-supplying cathode and tapering off toward their top. The base diameter of these cathode deposits was typically less than 50 nm although larger electrodeposits were observed to grow on the cathode under electron beam exposure at the edge of the milled region where the electrolyte could still supply Ag ions. All electrodeposits within the electrolyte continued to grow with electron beam exposure and appeared to be centered on and fed by Ag-rich regions in the nano-phase-separated electrolyte. We believe this nucleated growth is significant as it suggests that the same kind of electrodeposit evolution could take place during electrical programming of the structure. Fed by electrons from the cathode electrodeposits and via current leakage through the electrolyte, the relatively high resistance regions in the electrolyte are likely to be bridged by the electrodeposits which nucleate on and grow from the Ag-rich phases. The bridging electrodeposits will therefore consist of a “chain” of joined sub-deposits, which in the initial stages may even grow simultaneously rather than sequentially as long as the supply of electrons via the leakage current is sufficient. ACKNOWLEDGEMENT The authors gratefully acknowledge the help of the staff and use of the facilities within the Center for Solid State Electronics Research and the Center for Solid State Science at Arizona State University. REFERENCES [1] [2] [3] [4] [5] G. Müller, T. Happ, M. Kund, G.Y. Lee, N. Nagel, and R. Sezi, “Status and outlook of emerging nonvolatile memory technologies,” IEDM Technical Digest, 567-570 (2004). T. Sakamoto, H. Sunamura, H. Kawaura, T. Hasegawa, T. Nakayama, and M. Aono, “Nanometer-scale switches using copper sulfide,” Appl. Phys. Lett., vol. 82, 3032-3034 (2003). S. Kaeriyama, T. Sakamoto, H. Sunamura, M. Mizuno, H. Kawaura, T. Hasegawa, K. Terabe, T. Nakayama, and M. Aono, “A nonvolatile programmable solid-electrolyte nanometer switch,” IEEE J. Solid-State Circuits, vol. 40, 168-176 (2005). M. Kund, G.Beitel, C. Pinnow, T. Röhr, J. Schumann, R. Symanczyk, K. Ufert, and G. Müller, “Conductive bridging RAM (CBRAM): An emerging non-volatile memory technology scalable to sub 20nm,” IEDM Tech. Dig., 31.5, 2005. M.N. Kozicki, C. Gopalan, M. Balakrishnan, M. Park, and M. Mitkova, “Non-volatile memory based on solid electrolytes,” 0-7803-9738-X/06/$20.00 (C)2006 IEEE 115 [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] Proceedings of the 2004 Non-Volatile Memory Technology Symposium (NVMTS), 10-17 (2004). M.N. Kozicki, M. Park, and M. Mitkova, “Nanoscale memory elements based on solid-state electrolytes,” IEEE Trans. Nanotechnology, vol. 4, 331-338 (2005). M.N. Kozicki, M. Balakrishnan, C. Gopalan, C. Ratnakumar, and M. Mitkova, “Programmable Metallization Cell Memory Based on Ag-Ge-S and Cu-Ge-S Solid Electrolytes,” Proceedings of the 2005 Non-Volatile Memory Technology Symposium (NVMTS), D5, 1-7 (2005). P.L. Kirby, “Electrical Conduction in Glass,” Brit. J. of Appl. Phys., vol. 1, 193-202 (1950). C. Kotzeniewski, in The Electrochemical Double Layer, (Ed.: B. E. Conway), The Electrochemical Society Inc., 1997. T. A. Witten and L. M. Sander, “Diffusion-Limited Aggregation, a Kinetic Critical Phenomenon,” Phys. Rev. Lett., vol. 47, 14001403 (1981). P. Meakin, “Diffusion-controlled cluster formation in 2—6dimensional space,” Phys. Rev. A, vol. 27, 1495-1507 (1983). Y. Sawada, A. Dougherty, and J. P. Gollub, “Dendritic and Fractal Patterns in Electrolytic Metal Deposits,”Phys. Rev. Lett., vol. 56, 1260-1263 (1986). M.N. Kozicki, M. Mitkova, J. Zhu, and M. Park, “Nanoscale phase separation in Ag-Ge-Se glasses,” Microelectronic Engineering, vol. 63, 155-159 (2002). M. Mitkova, M. N. Kozicki, H. Kim, T. Alford, “Local Structure Resulting From Photo- and Thermal Diffusion of Ag in Ge-Se Thin Films,” J. Non-Cryst. Sol., vol. 338-340C, 552-556 (2004). M. Mitkova, M.N. Kozicki, J.P. Aberouette, “Morphology of Electrochemically Grown Silver Deposits on Silver-Saturated GeSe Thin Films,” J. Non-cryst. Solids, vol. 326/327, 425-429 (2003). M.N. Kozicki and M. Mitkova, “Mass transport in chalcogenide electrolyte films – materials and applications,” Journal of NonCrystalline Solids, vol. 352, 567–577 (2006). Michael N. Kozicki (M ’84) was born in Scotland and received his B.Sc. and Ph.D. degrees from the University of Edinburgh in 1980 and 1985 respectively. He was with Hughes Microelectronics Ltd. (now Raytheon Systems Ltd.) before joining Arizona State University (ASU) in 1985, where he is currently Professor of Electrical Engineering and Director of the Center for Applied Nanoionics. He is holder of several key patents concerning devices based on electrodeposition in solid electrolytes. He is also a founder of Axon Technologies Corp., an ASU spin-out company formed to develop and license solid-state ionic technologies, and has served as Director of ASU’s Center for Solid State Electronics Research and Director of Entrepreneurial Programs for the Fulton School of Engineering at ASU. Cynthia Ratnakumar received her B.S. in Electrical Engineering from the University of California, San Diego in 2003. She is currently pursuing an M.S. degree at Arizona State University in the Center for Solid State Electronics Research. Her current research interests are fabrication, characterization, and design integration of Programmable Metallization Cell devices. Maria Mitkova received her MS and PhD from the Technological University in Sofia, Bulgaria. She was professor at the Technological University and Bulgarian Academy of Sciences and has worked in the R&D of Ovonic memory devices in the Institute for Microelectronics. Since 1997 she has worked in the USA at the University of Cincinnati and Arizona State University. Her interests are in the field of amorphous semiconductors, including their characterization and application as optical and electronic memory media. She has specialized in a number of Ag-containing chalcogenide systems.