ARTICLE Photolithography-free Ge–Se based memristive arrays; materials characterization and device testing 1

advertisement

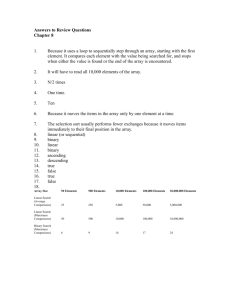

623 ARTICLE Photolithography-free Ge–Se based memristive arrays; materials characterization and device testing1 Can. J. Phys. Downloaded from www.nrcresearchpress.com by University of Saskatchewan on 07/11/14 For personal use only. M.R. Latif, I. Csarnovics, S. Kökényesi, A. Csik, and M. Mitkova Abstract: The focus of this work is on the formation of a lithography-free redox conductive bridge memristor array, comprised of different compositions of GexSe1−x chalcogenide glasses with the aim of selecting the chalcogenide material that provides the best performance. Various memristive arrays were fabricated on a metal–chalcogenide–metal stack. This structure offers high device density with the simplest configuration and allows access to each nano redox conductive bridge device. It was found that the device stability and threshold voltage were a function of the chalcogenide glass composition, with the Ge-rich film contributing to the best device performance, which is attributed to the formation of rigid structure and the availability of Ge–Ge bonds. Additionally, these parameters were dependent on the thickness and the surface roughness of the chalcogenide glass. Application of a nonlithography method for fabricating the array structure offered excellent yield, stable ON–OFF states and good uniformity. This demonstration, along with success achieved at the single cell level, suggests that the redox conductive bridge memristor is well positioned for ultrahigh performance memory and logic applications. PACS Nos.: 81.05.Gc, 81.05.Kf, 85.40.–e. Résumé : Nous nous penchons sur la préparation d’un réseau de memristors à pont conducteur redox (CBRAM) sans lithographie, comprenant différentes compositions de verres chalcogénures GexSe1−x, dans le but de sélectionner le matériel chalcogénure qui donne la meilleure performance. Plusieurs dispositifs memristors ont été fabriqués par une série de couches métal– chalcogénure–métal. Cette structure offre une haute densité de dispositifs dans la configuration la plus simple et permet l’accès à chaque nanodispositif pont conducteur redox. Nous observons que la stabilité du dispositif et le voltage de seuil dépendent de la composition du verre chalcogénure, avec les couches riches en Ge donnant les meilleures performances, ce que nous attribuons à la formation de structures rigides et à la présence des liens Ge–Ge. De plus, ces paramètres dépendent de l’épaisseur et de la rugosité de surface de la couche de chalcogénure. L’application d’une méthode sans lithographie pour fabriquer le réseau offre un excellent rendement, des états ON–OFF stables et une bonne uniformité. Cette démonstration, avec le succès obtenu au niveau de la cellule élémentaire, suggère que le memristor à pont conducteur redox est bien positionné comme dispositif mémoire d’ultra haute performance et pour des applications logiques. [Traduit par la Rédaction] 1. Introduction Resistive random access memory (RRAM) technologies are of wide interest because of their potential to replace flash memory as the next-generation nonvolatile memory [1–3]. Among the different emerging RRAM technologies, nanoionic based electrochemical system, commonly known as redox conductive bridge memory (RCBM), has attracted significant interest as a promising candidate for future high density, high performance memory and logic applications [4–6]. These devices exhibit low power consumption together with high programming speed [7, 8] and offer excellent scaling potential as their simple structure requires only one dimension to be critically controlled [9]. RCBM devices consist of two terminals: a thin film of solid electrolyte is sandwiched between an electrochemically active electrode and an electrochemically inert counter electrode, as shown in Fig. 1. The RCBM working principle is based on fielddriven generation of metallic ions at the active electrode and their reduction and deposition at the counter electrode after ion migration through solid electrolyte. Applying a positive voltage to the electrochemically active electrode (SET operation), leads to formation of a nano-sized filament bridging the two electrodes together and thus defines the low resistance state (ON state) of the RCBM cell. The filament can be dissolved by applying a voltage of opposite polarity (RESET operation), which returns the cell to high resistive state (OFF state). Such polarity-dependent switching is attainable in the nanosecond regime with a few hundred millivolts and currents in the nanoampere range [10]. By incorporating the RCBM cells into a system, these devices can fulfill the essential role of memory in various applications. RCBM cells in an array possess significant advantages for memory, including massive storage capacity with high storage density, precision, and access speed [11]. Also, the array structure provides powerful capability in information processing [12], arithmetic computation [13], pattern comparison [14], and reconfigurable field programmable gate array [15]. An array of RCBM devices can be formed by laying a nanowire over the inert electrode with chalcogenide glass film as a dielectric medium between the two electrodes, as presented in Fig. 2. In this study we demonstrate a Received 3 October 2013. Accepted 6 November 2013. M.R. Latif and M. Mitkova. Department of Electrical and Computer Engineering, Boise State University, Boise, ID 83725, USA. I. Csarnovics. Department of Electrical and Computer Engineering, Boise State University, Boise, ID 83725, USA; Department of Experimental Physics, University of Debrecen, Debrecen – Hungary. S. Kökényesi. Department of Experimental Physics, University of Debrecen, Debrecen – Hungary. A. Csik. Institute for Nuclear Research, Hungarian Academy of Sciences, Debrecen – Hungary. Corresponding author: Muhammad Latif (e-mail: muhammadrizwanlatif@u.boisestate.edu). 1This paper was presented at the 25th International Conference on Amorphous and Nanocrystalline Semiconductors (ICANS25). Can. J. Phys. 92: 623–628 (2014) dx.doi.org/10.1139/cjp-2013-0521 Published at www.nrcresearchpress.com/cjp on 11 November 2013. 624 Can. J. Phys. Vol. 92, 2014 Can. J. Phys. Downloaded from www.nrcresearchpress.com by University of Saskatchewan on 07/11/14 For personal use only. Fig. 1. RCBM memory structure with cell in (a) low resistive state, and (b) high resistive state. Fig. 2. Schematic for RCBM array. RCBM memory array on a thin films metal – chalcogenide glass – metal stack with no lithography step for device fabrication and show that the array structure offers excellent yield and repeatability. The vias were formed by bombardment of Ar+ ions using a shadow mask. To analyze the influence of the ion bombardment on surface topography and composition of the materials in the device active area; atomic force microscopy (AFM) and energy dispersive X-ray spectroscopy studies were performed, respectively. Specific attention was paid to the surface roughness in the device vias region, as it plays an important role in the growth of the conductive molecular bridge. The devices were electrically tested to show the usability of the process for fabrication of the RCBM array. 2. Experimental details The RCBM devices were fabricated on a stack of GexSe1−x/W/ SiO2/Si-substrate (where x = 0.2, 0.3, and 0.4). The thickness of the films comprising the devices was as follows: Si 具100典 substrate covered with 200 nm thermally grown SiO2; followed by 100 nm of sputtered tungsten and 1 m thermally evaporated Ge–Se films. The films were evaporated using a crucible resembling a semiKnudsen cell, thus equilibrating the vapor pressure of the gaseous products of the source chalcogenide glass material. The films’ thicknesses were verified by ellipsometry (model No. L115C-8). An INA-X type (SPECS, Berlin) secondary neutral mass spectrometer [16] was used for bombarding samples with Ar+ ions through a copper TEM-grid with mesh size of 40 m × 40 m, which was placed in close contact with the sample surface. The surface bombardment was made at low pressure by electron cyclotron wave resonance. A 350 V sputtering potential at 100 kHz frequency with 80% duty cycle was applied on the sample. A 20 nm silver layer was deposited by DC magnetron sputtering with deposition pressure of 5 × 10−3 mbar. The sputtering rate was calibrated by Ambios XP-1 profilometer. The same sample holder and copper grid was used for the Ar+ ion beam and silver sputtering. Energy dispersive X-ray spectroscopy results were acquired by averaging data over five points on each sample within the film using a Hitachi S-3400N energy dispersive X-ray spectroscopy system. The average compositional error of the films was determined to be less than 2%. The morphology of Ge–Se films were studied in tapping mode using OTESPA probe on a Veeco Dimensions 3100 AFM system equipped with Nanoscope IV controller. Electrical testing on the devices was performed with an Agilent 4155B semiconductor parameter analyzer equipped with triaxial cables to avoid residual charge build up. Tungsten and silver pads were probed with correct biasing for SET and RESET conditions. Various cells in the array were tested in dual sweep mode with a voltage step size of 2 mV and compliance current set to 50 nA. Data were analyzed and recorded by Easy Expert software provided by Agilent. The testing equipment (sample stage holder, triaxial cables, and probes) was placed inside a Faraday cage sharing a common ground to avoid static charge build up. All electrical measurements were carried out at room temperature. 3. Results The top view of the fabricated 40 m × 40 m array is presented in Fig. 3. Vias filled with Ag served as the top electrode of the array cell with tungsten as the bottom electrode. GexSe1−x (where x = 0.2, Published by NRC Research Press Latif et al. 625 Can. J. Phys. Downloaded from www.nrcresearchpress.com by University of Saskatchewan on 07/11/14 For personal use only. Fig. 3. SEM image of the fabricated RCBM array. Fig. 4. (a) (i) Formation of via in Ge20Se80 by Ar+ ion bombardment; 25 m area scan in the via of (ii) cell 1, (iii) cell 10, and (iv) cell 20 of the array. (b) (i) Formation of via in Ge30Se70 by Ar+ ion bombardment; 25 m area scan in the via of (ii) cell 1, (iii) cell 10, and (iv) cell 20 of the array. (c) (i) Formation of via in Ge40Se60 by Ar+ ion bombardment; 25 m area scan in the via of (ii) cell 1, (iii) cell 10, and (iv) cell 20 of the array. Published by NRC Research Press 626 Can. J. Phys. Downloaded from www.nrcresearchpress.com by University of Saskatchewan on 07/11/14 For personal use only. Fig. 5. IV curves with 100 sweeps in cell 20 of the RCBM array: (a) Ge20Se80; (b) Ge30Se70; and (c) Ge40Se60. Can. J. Phys. Vol. 92, 2014 Fig. 6. Surface roughness RMS and peak hillocks in the vias of the cell. between the top and bottom electrodes, causing a steep increase in the current until it reaches the compliance current, which was limited to 50 nA (cell resistance: low). The compliance current was set to protect the device during switching. Multiple IV sweeps under the same conditions are presented in Fig. 5. Analysis of these results show a relatively small variation in switching voltage of the Ge rich devices when compared to Ge30Se70 and Ge20Se80 devices. 4. Discussion 0.3, and 0.4) layer was used to isolate individual cells. The surface topography within the cell vias of the GexSe1−x layer were studied by AFM and the results are presented in Fig. 4. AFM scans were performed on cell 1, cell 10, and cell 20 in row 20 of the array structure on a 25 m2 area within the device vias. There is a clear tendency for improvement of the surface smoothness of the films with increasing Ge concentration. The electrical measurements conducted on the fabricated array with different compositions of GexSe1−x for cell 20 are shown in Fig. 5. Each cycle starts at −0.1 V. Then the voltage sweeps to +1.5 V and sweeps back to −0.1 V. At first the current is very low (cell resistance: high) until a threshold voltage of approximately 0.6 V is exceeded. At that moment a conductive connection is formed The most important outcome of this study is to establish an appropriate GexSe1−x composition for reliable array performance. The electrical tests were performed on all three compositions, which resulted in several thousand switching cycles. The memory window of threshold voltage (Vth) for high resistive state to threshold voltage of low resistive state is considered as a figure of merit for RRAM technologies [17, 18]. A higher difference in the Vth window of the two states will result in better memory performance because a small ratio will lead to more read errors. In the studied compositions, Ge30Se70 and Ge40Se60 showed a better ratio of threshold voltage for high resistive state to low resistive state, when compared to Ge20Se80 films, because these characteristics are dependent on the active film morphology. Ion bombardment in thin films may cause a surface roughness resulting in difference in film strength and can influence hillock formation and electron migration and, thus, negatively affect device reliability [19, 20]. A uniform surface is extremely important in providing locations for nucleation and growth for the conductive molecular bridge, which would otherwise result in wide variations in the switching voltage, especially taking into account the high electric field (107–108 Vm−1) [21] at the switching events. The main reason for the formation of the conductive filament is the statistical nature of the nucleation process, which is determined not only by free available adsorption sites at the electrode surface, but by the closest distance between the electrode and a hillock in the active layer. This may result in incorrect nucleation with a false switching. Thus, to have a reliable device, a smooth surface within the device via is essential. The surface roughness RMS value and peak hillock in the 25 m2 area in the device vias is presented in Fig. 6. The result shows that surface roughness and hillock formation reduces in the Ge rich compositions compared to Se rich active films. There may be several reasons for the tendency towards the surface smoothness improvement with increasing Ge concentration. First, the hillocks formation and surface roughness in the Ge–Se system could be related to the packing fraction of these Published by NRC Research Press Latif et al. 627 Can. J. Phys. Downloaded from www.nrcresearchpress.com by University of Saskatchewan on 07/11/14 For personal use only. Fig. 7. Resistance and voltage threshold plot of (a) Ge20Se80, (b) Ge30Se70, and (c) Ge40Se60. glasses. The larger free volume will correspond to a lower packing fraction [22]. According to the data for this system, the packing fraction of Ge20Se80 is the least for the compositions studied in this work [23]. This means that there is more open space for the Ar+ ions to penetrate and affect the shape of the device vias, as well as to form pockets in which later the traversing ions can be captured. Thus, Ar+ ions bombardment for via formation causes higher surface roughness and film damage in Ge20Se80 when compared to the other two compositions, and hence results in degradation of the cells’ Vth performance for the two states. If we regard the structure of the studied films, the decrease of the structure fraction is related to increased dominance of the tetrahedral structures in the films. While in the Ge20Se80 films Se–Se bonds are available, with increased Ge concentration they disappear and the structure is formed only by tetrahedrally coordinated Ge, surrounded by Se atoms and some ethane-like structural units [24]. Interestingly, the results show that the optimal coordination of 2.4 of the Ge20Se80 films, leading to high stability of the glass formation of the system, according to the constrain counting theory [25], is not the leading factor for the strength of the structure. It is the higher coordination of 2.6 and especially 2.8 that results in more stable reaction of the films to the mechanical stress. Indeed, in the studied case, the stability of the network is related to how amendable it is to continuous deformation. The covalent forces that also involve the bond length, bond angles, and the increased rigidity are important factors, which in fact keep the structure intact [26]. The floppy modes related to the Se–Se bonding within the system require much lower energy to be destroyed and they quantify the instability of the films in the studied case. The resistance and Vth plots in various cells in all three compositions are in good agreement with AFM results and are presented in Fig. 7. All cells show six orders of magnitude difference between the ON and OFF state of the device. The resistance of the device varies from tens of gigaohms in the OFF state to a few kilo-ohms in Published by NRC Research Press 628 the ON state, ensuring good memory retention of the devices [27]. However, the Vth of Ge20Se80 illustrates variations within the cells and also in different cells of the array structure. On the other hand, Ge30Se70 and Ge40Se60 offer excellent repeatability within a cell and the array. Hence, an increase in Ge concentration results in an improvement of device performance because of formation of specific structures, which are the reason for the better ratio of threshold voltage for high resistive state to low resistive state. Can. J. Phys. Downloaded from www.nrcresearchpress.com by University of Saskatchewan on 07/11/14 For personal use only. 5. Conclusion An array of RCBM devices with no lithography step is successfully demonstrated. The fabricated array structure allowed individual cell addressing. The individual cells built by thin Ge–Se films showed excellent yield with good endurance at over 103 cycles. The devices built using the Ge40Se60 film, that offered the least surface roughness in the vias region, resulted in excellent device performance. An improvement in the cells’ performance can be achieved by formation of smoother layers within the vias and filling them homogeneously with Ag. Acknowledgements This work was supported by the European Union and the State of Hungary under grant No. TÁMOP 4.2.4. A/2-11-1-2012-0001 (National Excellence Program) and TÁMOP-4.2.2.A-11/1/KONV2012-0036, which are cofinanced by the European Union and the European Social Fund. The financial support of the Czech Science Foundation (under the project No. P106/11/0506) and the Defense Threat Reduction Agency (DTRA) under grant No. HDTRA1-11-10055 are also acknowledged. The authors would also like to thank J. Reed of DTRA for his support, the Surface Science Lab at Boise State University for AFM use, and P. Davis for assistance in performing AFM. References 1. D. Ielmini, A. Spinelli, and A. Lacaita. Microelectron. Eng. 80, 321 (2005). doi:10.1016/j.mee.2005.04.085. 2. M. Kund, G. Beitel, C.-U. Pinnow, T. Rohr, J. Schumann, R. Symanczyk, et al. In Electron Devices Meeting, 2005. IEDM Technical Digest. IEEE International, 2005, pp. 754–757. 3. M.N. Kozicki, M. Park, and M. Mitkova. Nanotechnology, IEEE Transactions on, Vol. 4. 2005. pp. 331–338. Can. J. Phys. Vol. 92, 2014 4. L. Chua. Circuit Theory, IEEE Transactions on, Vol. 18. 1971. pp. 507–519. 5. J.R. Heath, P.J. Kuekes, G.S. Snider, and R.S. Williams. Science, 280, 1716 (1998). doi:10.1126/science.280.5370.1716. 6. H. Mizuta and S. Oda. Microelectron. J. 39, 171 (2008). doi:10.1016/j.mejo.2006. 10.007. 7. E. Vianello, C. Cagli, G. Molas, E. Souchier, P. Blaise, C. Carabasse, et al. In Solid-State Device Research Conference (ESSDERC), 2012 Proceedings of the European. 2012. pp. 278–281. 8. I. Valov, E. Linn, S. Tappertzhofen, S. Schmelzer, J. van den Hurk, F. Lentz, and R. Waser. Nat. Commun. 4, 1771 (2013). doi:10.1038/ncomms2784. PMID: 23612312. 9. S.H. Jo, K.-H. Kim, and W. Lu. Nano Lett. 9, 870 (2009). doi:10.1021/nl8037689. PMID:19206536. 10. I. Valov, R. Waser, J.R. Jameson, and M.N. Kozicki. Nanotechnology, 22, 254003 (2011). doi:10.1088/0957-4484/22/25/254003. PMID:21572191. 11. K.-H. Kim, S. Gaba, D. Wheeler, J.M. Cruz-Albrecht, T. Hussain, N. Srinivasa, and W. Lu Nano Lett. 12, 389 (2012). doi:10.1021/nl203687n. PMID:22141918. 12. X. Hu, S. Duan, L. Wang, and X. Liao. Sci. China Inf. Sci. 55, 461 (2012). doi:10.1007/s11432-011-4410-9. 13. K. Bickerstaff and E. Swartzlander. In Conference Record of the Forty Fourth Asilomar Conference on Signals, Systems and Computers (ASILOMAR). 2010. pp. 1173–1177. 14. B. Mouttet. In Memristors and Memristive Systems Symposium, UC Berkeley. 2008. 15. J. Cong and B. Xiao. In IEEE/ACM International Symposium on Nanoscale Architectures (NANOARCH). 2011. pp. 1–8. 16. R. Lovics, A. Csik, V. Takáts, J. Hakl, K. Vad, and G. Langer. Vacuum, 86, 721 (2012). doi:10.1016/j.vacuum.2011.07.031. 17. B. Jacob, S. Ng, and D. Wang. Memory Systems: cache, DRAM, disk: Morgan Kaufmann. 2010. 18. H. Yang, C.T. Chong, R. Zhao, H.K. Lee, J. Li, K.G. Lim, et al. Appl. Phys. Lett. 94, 203110 (2009). doi:10.1063/1.3139776. 19. H. Ji, G.S. Was, J.W. Jones, and N.R. Moody. J. Appl. Phys. 81, 6754 (1997). doi:10.1063/1.365217. 20. R.P. Vinci and J.J. Vlassak. Ann. Rev. Mat. Sci. 26, 431 (1996). doi:10.1146/ annurev.ms.26.080196.002243. 21. I. Valov and G. Staikov. J. Sol. State Electrochem. 17, 365 (2013). doi:10.1007/ s10008-012-1890-5. 22. P. Chen, M. Mitkova, D.A. Tenne, K. Wolf, V. Georgieva, and L. Vergov. arXiv:1205.6441 [cond-mat.mtrl-sci]. 2012. 23. A. Feltz. Amorphous inorganic materials and glasses. VCH Weinheim. 1993. 24. X. Feng, W. Bresser, and P. Boolchand. Phys. Rev. Lett. 78, 4422 (1997). doi: 10.1103/PhysRevLett.78.4422. 25. M. Thorpe and M. Chubynsky. In Properties and Applications of Amorphous Materials. Springer. 2001. pp. 61–96. 26. D.J. Jacobs and M.F. Thorpe. Phys. Rev. Lett. 75, 4051 (1995). doi:10.1103/ PhysRevLett.75.4051. PMID:10059802. 27. C. Kügeler, R. Rosezin, E. Linn, R. Bruchhaus, and R. Waser. Appl. Phys. A, 102, 791 (2011). doi:10.1007/s00339-011-6287-2. Published by NRC Research Press