Total-Ionizing-Dose Effects on the Resistance Switching Characteristics of Chalcogenide Programmable Metallization Cells

advertisement

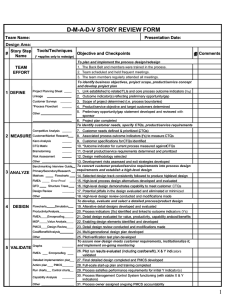

IEEE TRANSACTIONS ON NUCLEAR SCIENCE, VOL. 60, NO. 6, DECEMBER 2013 4563 Total-Ionizing-Dose Effects on the Resistance Switching Characteristics of Chalcogenide Programmable Metallization Cells Y. Gonzalez-Velo, Member, IEEE, H. J. Barnaby, Senior Member, IEEE, M. N. Kozicki, Member, IEEE, P. Dandamudi, Student Member, IEEE, A. Chandran, Student Member, IEEE, K. E. Holbert, Senior Member, IEEE, M. Mitkova, Member, IEEE, and M. Ailavajhala Abstract—Programmable metallization cells (PMCs) are emerging ReRAM devices exhibiting resistance switching due to cation transport in a solid-state electrolyte and redox reactions at the electrodes. Their non-volatility and low power requirements have led to increased interest in their development for non-volatile memory applications. Investigation of the total dose response of PMCs will contribute to our understanding of radiation induced effects in these novel memory devices as well as assess their suitability for use in ionizing radiation environments. This work investigates the impact of total ionizing dose on the switching characteristic of silver doped PMC memory devices. The results obtained show that the resistance switching characteristic of these cells which use a solid state electrolyte based on is not affected by a total dose exposure of up to 10 Mrad( ). Index Terms—Cation, chalcogenide glass, ECM, electrochemical metallization, memristors, nanoionic memory, photo-diffusion, photodoping, PMC, programmable metallization cell, radiation effects, ReRAM, resistive switching, total ionizing dose. I. INTRODUCTION E MERGING non-volatile memory devices referred to as “programmable metallization cells” (PMCs) [1]–[5], or “electrochemical metallization cells” (ECM) [5]–[7] or “memristors” [8], [9] have been identified as a promising memory technology [10]. These memory devices have been recognized to exhibit scaling potential for several generations beyond the 16 nm node, where current memory technologies such as DRAM, SRAM and Flash will encounter difficult issues related to continued scaling [10]. PMC characteristics, such as non-volatility, very low-power operation, speed and scalability, have hastened the development Manuscript received July 05, 2013; revised September 11, 2013; accepted October 13, 2013. Date of publication December 03, 2013; date of current version December 11, 2013. This work was funded by the Defense Threat Reduction Agency under grant no. HDTRA1-11-1-0055. Y. Gonzalez-Velo, H. J. Barnaby and K. E. Holbert are with the School of Electrical, Computer and Energy Engineering, Arizona State University, Tempe, AZ 85287-5706 USA (e-mail: yago.gonzalezvelo@asu.edu). M. N. Kozicki, P. Dandamudi, and A. Chandran are with the School of Electrical, Computer and Energy Engineering and also with the Center for Applied Nano-Ionics, Arizona State University, Tempe, AZ 85287-5706, USA. M. Mitkova and M. Ailavajhala are with the Department of Electrical and Computer Engineering, Boise State University, Boise, ID 83725 USA. Color versions of one or more of the figures in this paper are available online at http://ieeexplore.ieee.org. Digital Object Identifier 10.1109/TNS.2013.2286318 Fig. 1. Micrographs of the actual implementation of a PMC in the BEOL of a circuit and detail view of a single storage cell [12]. of Conductive-Bridging Random Access Memory (CBRAM), a new low-power non-volatile memory technology currently in production [11]–[17]. In CBRAM circuits, PMCs are implemented in the back-end-of-line (BEOL) of a CMOS process (see Fig. 1) [12]. Thus, this technology may be used not only as a standalone memory microcircuit but also as embedded memory in system-on-chips. PMCs rely on the processes of ionic transport through a solidstate electrolyte and reduction/oxidation (redox) reactions occurring at the electrode terminals [3]–[7] to grow or conversely remove conductive nano-filaments within the device. This allows for a controllable resistance change from a high resistance state (HRS) to a low resistance state (LRS). These different resistance states are used to represent bit information in memory circuits [11]–[17]. Common solid-state electrolytes used in PMCs are chalcogenide glass (ChG) films that are photodoped with metals such as Ag or Cu. As early as the mid-1960s, it was shown that silver could be “photo-diffused” in chalcogenide materials, i.e., diffusion of silver (or copper) into chalcogenide materials can be activated by light via electron-hole pair generation [18]. This process also causes variation in the material conductivity [5]–[7], [19]–[22]. After photo-diffusion, the silver doped chalcogenide glass exhibits high ionic conductivity. High-energy ionizing radiation may induce unintended effects on PMCs similar to photo-diffusion as well as bond reconfiguration [23]. These effects could impact the operation of the devices by influencing the electrical properties of ChG materials. 0018-9499 © 2013 IEEE 4564 IEEE TRANSACTIONS ON NUCLEAR SCIENCE, VOL. 60, NO. 6, DECEMBER 2013 In this work, we investigate the effects of Co-60 gamma-ray exposures on silver doped chalcogenide based PMCs to assess the influence of total ionizing dose (TID) on resistance switching. In Section II, the basic operation of PMC devices is described. Section III provides the details of PMC processing and the experimental protocol used in this work. In the subsequent section, experimental results obtained after Co-60 exposures up to 10 Mrad ( ) are presented. The results are then analyzed and discussed in the final “discussion” section. II. DEVICE BASIC OPERATION AND CHARACTERISTICS PMCs are two terminal devices exhibiting controllable resistance switching. The devices are usually composed of an active electrode, made of an electrochemically active metal that is easily oxidized (i.e. Cu, Ag), a counter electrode composed of an electrochemically inert metal (Ni, Pt, W) and a solidstate electrolyte in between the two electrodes. The active electrode is generally used as the anode, and the inert electrode is used as the cathode of the device. The material connecting the two electrodes could be comprised by some oxide films [5]–[7] or ChG films [1]–[7]. Bulk chalcogenide glasses are usually formed upon water quench of alloyed melts of group IV and/or group V elements with those of group VI (chalcogens S, Se, and Te) [24] and are used as a source material for thin-film deposition in most PMC manufacturing [25]. In this work, we focus on PMCs with an active electrode composed of silver, and a solid-state electrolyte that is a silver doped thin-film. The resistance switching process is illustrated in Fig. 2, where the process of growing a conductive filament within a PMC is shown along with the typical current-voltage characteristic of one of the PMC devices studied in this work. Initially, there is no conductive filament formed in the PMC, and the device is in a high resistance state as represented in Fig. 2(a). When the silver active electrode is positively biased, silver is oxidized (i.e., loss of an electron that produces silver ions) according to (1) (1) (2) will transport via a field dependent Once Ag oxidizes, process through the ChG film as illustrated in Fig. 2(b). When the ions reach the inert electrode (cathode), they are reduced according to (2) and electrodeposition of silver occurs giving rise to a filament growth (see Fig. 2(c)). The growth of the Ag filament at the inert electrode continues while the cell is under positive bias. Growth of the filament (or collection of filaments) leads to a decrease in cell resistance, reaching LRS once the filament(s) form(s) an electrical connection between the two electrodes, i.e., a conductive-bridge between electrodes is formed (Fig. 2(d)). By reversing the voltage applied on the structure, it is possible to oxidize the silver filament and thus switch the resistance back to the initial HRS as represented in Fig. 2(a). The current–voltage characteristic and the resistance value of the PMC obtained during the electrical characterization (DC Fig. 2. Schematic representation of the mechanisms of conductive-bridge formation in PMCs is depicted in sketches (a) to (e), along a typical current–voltage m diameter Ag doped PMC. Incharacteristic measured on a serted sketches are from [6]. Arrows presented on the curve indicate the direction followed when voltage is swept. The sketches representing the PMCs are not to scale, i.e. the width of a conductive filament is a few nanometers, and does not represent an important portion of the actual PMC via. Fig. 3. PMCs DC current-voltage characteristic in log scale (solid line) and corresponding resistance change characteristics (dashed line). The LRS and HRS are reported on the right axis (dashed line). sweep) are presented in Fig. 3, this time with a logarithmic scale for the current. In Fig. 3, HRS and LRS resistances are indicated with the dashed line, and range from M in the HRS to k in the LRS state. In this case the current flowing through the device during the electrical characterization has been limited to A. This maximum value of the current is referred to as the programming current. These two different resistance states are used to represent bit information in memory circuits. The programming current ( ) level is a parameter to control the magnitude of the on-state resistance, [26]–[29]. A higher programming current produces a lower . This dependence of with is shown in Fig. 4, which plots values vs. for measurements on PMCs with m via diameters. The decrease of with is attributed to the filament growth dependence on the current flow through the device. The higher enables a higher number of cations to reach the inert electrode and/or the growing filament. As a consequence, once the cell is effectively shorted by an initially thin conductive filament, if cations still flow, they will contribute to a lateral growth of the filament, thereby reducing [5]–[7], [10]–[17], GONZALEZ-VELO et al.: RESISTANCE SWITCHING CHARACTERISTICS OF CHALCOGENIDE PROGRAMMABLE METALLIZATION CELLS 4565 Fig. 4. as a function of programming current measured on a set of 23 is taken on the current-voltage (I–V) sweep characPMCs on one die. The teristic for an applied voltage of 50 mV. [26]–[29]. This dependence of with allows PMCs to be considered for use as multi-level cells (MLC). III. TEST STRUCTURES AND RADIATION TEST PROTOCOL A. PMC Processing and Description PMCs studied in this work were The Ag-doped fabricated at the Arizona State University Center for Applied Nano-Ionics. The electrodes are an active silver anode (on the top) and an inert nickel cathode (on the bottom). The first step used in the fabrication process is the deposition of 100 nm of on a p-doped silicon wafer using a TorrVac VC-320 electron-beam evaporator. The second step is the deposition of a 100 nm blanket film of nickel (cathode) using the TorrVac VC-320. An additional 100 nm layer is deposited on top of the nickel layer and then etched to form vias in which a 60 nm film of is deposited using a Cressington 308 thermal evaporator. A 30 nm thick Ag film is then deposited on top of the and the wafer is exposed to UV light in order to allow photodoping of the ChG with Ag. The photodoping step used on the devices studied in this work consisted of a 1 hour exposure of the wafer to UV light ( nm). Once the photodoping is completed, the active electrode is formed by depositing an additional 35 nm of Ag on top of the silver-doped (Ag-ChG) layer. Contacts to the bottom (inert Ni) and top (active Ag) electrodes are formed by depositing 800 nm of aluminum. In Fig. 5, a top view microphotograph of a 10 μm diameter PMC (Fig. 5(a)) is presented together with a cross-section of the device (Fig. 5(b)). B. Experimental Details A set of several dice with m and m diameter PMCs were exposed to Co-60 gamma-rays at a dose-rate of 8.95 rad( s in a Gammacell 220 irradiator at Arizona State University. Exposures were conducted at room temperature and samples were left floating in the high resistance state during exposure. A set of devices was step-stressed to a maximum TID of 5.2 Mrad( ), and electrical characterizations were performed at several dose levels in order to retrieve the evolution of Fig. 5. (a) Top view of a PMC with a diameter equal to section of PMCs manufactured and studied in this work. m. (b) Cross- the switching characteristics with increasing exposure. A set of additional devices was exposed to a TID of 10 Mrad( ) and was characterized without being step-stressed to intermediate TID levels (characterization before and after exposure, with only one high TID step). The devices were electrically characterized on a probe-station by measuring DC current-voltage characteristics with an Agilent 4156 C parameter analyzer. The voltage between the electrodes is swept from–0.5 V to 0.5 V, where the varying voltage is applied on the anode, while the inert cathode is fixed at 0 V. Current-voltage (I–V) measurements were performed prior to and shortly after the end of the exposure steps. In this work, devices with different were also characterized in order to assess the impact of TID on memory elements switched to different on-state resistances. IV. EXPERIMENTAL RESULTS From the typical switching characteristic plots presented in Figs. 2 and 3, and of the devices can be extracted. In this work both resistances were obtained at an applied voltage of 50 mV. Resistance data are plotted in cumulative probability graphs in order to quickly assess the HRS and LRS distribution pre- and post-irradiation. On these graphs the abscissa is the resistance value of the PMC, and the ordinate represents the probability that the resistance is lower than a given resistance value. Five different PMCs have been switched five times at each dose level in order to obtain a large data set. A. TID Effects on On- and Off-state Resistance for Fig. 6 shows the cumulative probability graph of PMCs step stressed and switched with an of A for TID level up to 5.21 Mrad. The LRS resistance does not exhibit 4566 IEEE TRANSACTIONS ON NUCLEAR SCIENCE, VOL. 60, NO. 6, DECEMBER 2013 Fig. 6. Cumulative probability of switched 5 consecutive times with an obtained on 5 PMCs. Devices were A at each TID. Fig. 7. Cumulative probability of switched 5 consecutive times with an obtained on 5 PMCs. Devices were A at each TID. Fig. 8. Comparison of the cumulative density of (red closed symbols) and (black open symbols) obtained on PMCs switched with an A in both prerad state and after the 5 different TIDs utilized. Fig. 9. as a function of programming current measured on PMCs exposed to 2.28 Mrad and 5.21 Mrad. any noticeable variation due to exposure to Co-60 gamma-rays. The median of (resistance at in the LRS) for the set of devices across all doses is between k (mean of k ) and k (mean of k ). In Fig. 7, the cumulative probability graph of obtained on the same set of devices is shown. It can be observed that the resistance values are much higher for the HRS than for the LRS. Important horizontal shifts/discontinuities are observed in the distribution. These shifts are due to typical device to device variation in the HRS of PMCs. For the studied devices the median HRS resistance ranged from M to M . For the studied devices, a large range of values of is obtained which is a typical characteristic of ReRAM cells. The range of can be modified (made smaller) by altering the manufacturing process or by performing electrical stress/ preconditioning on the devices. No electrical stress has been performed on the studied parts between dose steps to avoid disturbing the radiation response of the PMCs. It has to be noted that for those devices even if a large range of is obtained, the important point is that the measured and are different, and in this work they are different by a factor higher than 10. No matter what the distribution of is, for all values of resistance higher than a threshold the cell will be considered as being in a given logic state, and for a resistance value lower than it will be considered as in the other logic state. This is shown in Fig. 8, where the data of Figs. 6 and 7 are combined so that both and are presented for all devices and all irradiation levels. It can be observed that the resistance distributions of the two different states of the PMCs are well separated and do not overlap, even after 5 Mrad exposures. Furthermore the median HRS is greater than the median LRS by more than a factor of 100. The studied devices showed capability for programming of as a function of before exposure as well as after exposure to Co-60 gamma-rays at high TID levels (see Fig. 9). This illustrates that programming of different resistance levels can be achieved on the devices even after high levels of TID. Thus, even for increased , where more are transported and reduced to form the filament no modification of the is observed, which indicates that even after exposure there has been essentially no modification of the solid-state electrolyte properties. This is an interesting result from the point of view of MLC capabilities of PMC after radiation exposure. Several more PMCs were characterized to higher TID levels, but without being step-stressed to intermediate total doses. Resistance switching of these devices was still observed even after GONZALEZ-VELO et al.: RESISTANCE SWITCHING CHARACTERISTICS OF CHALCOGENIDE PROGRAMMABLE METALLIZATION CELLS Fig. 10. Cumulative probability of (open symbols) and (closed symbols) obtained on 4 PMCs with 5um diameter exposed to 10 Mrad. Fig. 11. Ratio of over obtained on 3 control PMCs (solid lines) and 3 PMCs exposed to 10 Mrad (red open symbols) for a maximum of 500 consecA. utive resistance switching operation with a 10 Mrad exposure, as shown in Fig. 10. During these tests, the PMCs were characterized with A. B. Repeated Switching–PMCs Cycled After Exposure Repeated resistance switching was performed on two sets of three devices referenced as ‘exposed’ devices, and ‘control’ devices (or ‘non-exposed’ devices). ‘Exposed’ devices were subjected to 10 Mrad and electrically characterized after exposure with no resistance switching performed before exposure. Control devices (or non-exposed devices) were characterized at the end of the experiment (not cycled before exposure) to investigate the cycling behavior of devices not exposed. The characterization on control devices was performed within 24 hours of the characterization performed on exposed devices. On both sets of samples, resistance switching was performed until failure or to a maximum of 500 resistance switching cycles. The term failure here denotes devices that exhibit equal values of and (i.e., the ratio over is equal to 1). In Fig. 11, the ratios of and extracted at 50 mV on the DC-IV characteristic are presented for both control devices and exposed devices. This ratio is generally used to represent the separation between HRS and LRS. For the measurements shown in Fig. 11, two out of three of the control devices exhibit an equal to 1 before reaching Fig. 12. Cumulative probability graph of the 3 control PMCs. Fig. 13. Cumulative probability of the trol PMCs. 4567 obtained on 3 exposed and obtained on 3 exposed and 3 con- the 500 cycles, and one does so after less than 150 cycles. Moreover, the ratio is lower for control devices than those exposed to 10 Mrad. The increase in obtained on exposed PMCs is principally due to an increase in and not a decrease of their . This is illustrated in Fig. 12, which plots the distribution of , and Fig. 13, which plots the distribution of , for the 3 exposed PMCs and the 3 control PMCs. Fig. 12 shows that while the distribution in LRS resistance broadens somewhat after the 10 Mrad exposure, the average remains fairly close to k . Concerning the HRS resistance, it can be observed in Fig. 13 that the distribution of exposed devices 1 and 2 have a median value one order of magnitude higher than that of control PMCs. This is why the ratio is higher than 100 for these devices (see Fig. 11). Concerning exposed device 1, its is close to those observed on control devices but its distribution is more uniform. This “cycling” has been performed by repeating DC-IV switching. For research devices which ‘cycling’ is characterized with DC-IV sweeps, the number of cycles can go from a few tens to a few thousands of cycles. In order to check for the maximal number of cycles that PMCs can undergo (which can be higher than cycles) another set-up using pulse generators is generally used in the literature. This type of assessment will be conducted in further investigations of the radiation response of PMCs. 4568 IEEE TRANSACTIONS ON NUCLEAR SCIENCE, VOL. 60, NO. 6, DECEMBER 2013 V. DISCUSSION PMC devices exhibit resistance switching due to silver cation transport through a solid-state electrolyte. It is known that photoinduced effects like photodoping can occur on structures composed of silver and ChG materials [18], [19] leading to the incorporation of Ag into chalcogenide glasses, and formation of phases like [25], [30]–[34]. These effects are related to the generation of electrons and holes in the material and have been intensively studied and characterized in the case of UV light illumination of bulk and thin film chalcogenide materials. Depending upon the deposition conditions, there are cases when the thin films behave differently than their bulk counterparts. High energy ionizing radiation, by generating electron-hole pairs could trigger photo-induced effects that might disturb the basic resistance switching operation of PMC devices [23], [35]–[39]. The effects of higher energy ionizing radiations on these materials for either bulk or thin films have not been thoroughly studied but since PMCs could be included as the building blocks of low power non-volatile memories, the impact of higher energy radiation on PMC cells is of great interest, particularly for space based applications. A. TID Effects on On- and Off-state Resistance The cumulative probability plots presented in Figs. 6 to 8 and Fig. 10 show that resistance switching of PMCs continues even after exposure to a TID of 10 Mrad with no major variation of resistances, showing that the HRS resistance levels and the LRS levels continue to be largely different after exposure to Co-60 gamma-rays. It is known that electron-hole generation induces photodoping within Ag/ChG structures [19] and that effect could have impacted the different resistance states of the PMCs exposed to Co-60 gamma-rays and their capability to represent different logic states. In this work, we show that this effect is not happening or occurs only in a reduced way, so that there is no noticeable effect from the Co-60 exposures on PMC switching operation. The suppression of radiation response may be related to the UV photodoping conducted during processing of the PMC by which we fully saturate the chalcogenide glass with Ag. Photodoping has been shown to reach saturation levels for Ag-ChG test structures exposed to UV light [19]. Therefore, the UV photodoping step during processing may reduce the impact of any additional electron-hole generation occurring once the solid-state electrolyte is formed, and allow for inherent hardening against additional ionizing dose effects, at least to the levels that we report in this work. B. PMCs Cycled After Exposure As far as the cycling results (Figs. 11-13) of control PMCs and PMCs exposed to 10 Mrad the ratio is higher after a 10 Mrad exposure, and this increase of is related to the increase of the HRS . This is an interesting result, as it shows that the HRS is likely to be more impacted than the LRS for PMCs. The LRS is basically fixed by the grown filament, whereas the HRS is related to the properties of the solid-state electrolyte. It has to be noted that in Fig. 2 the resistance switching mechanisms are schematically represented within a uniform ChG film, but the resistance switching in PMCs does not involve the transport of in a pristine ChG or a uniformly photodoped material, but rather in a material that is thought to be made of nanophases formed after reaction of Ag with the chalcogen atoms [30]–[34], [40]–[42]. As an example, the binary phase is formed after photodoping of [30]–[34], which has ionic properties. The solid-state electrolyte is thus formed by a collection of nanophases with different Ag doping, i.e., different conductivities. Resistance switching can be related to conductive filaments being formed between these different phases, which ultimately provide a dendritic conductive path between electrodes after an appropriate bias [17], [30]–[34], [40]–[42]. It has been found by means of Raman spectroscopy and XRD studies conducted after UV-light exposures and high temperature annealing [32], [41], [42] that the nanophases/crystallites in the electrolyte can evolve in size, as well as in composition. A radiation induced modification of the composition in could lead to an increase in the HRS if crystallite size is reduced due to exposure. is an ionic conductor, and any modification of the relative composition of the solid-state electrolyte in could lead to modification in the conductivity of the electrolyte, i.e., in the PMC HRS. Even though modifications and changes occur in the electrolyte, the resistance switching performed on exposed PMCs allows us to conclude that for devices exposed to TID levels common in space based systems, cation transport still occurs, and no important changes in the voltage needed to program the parts to the LRS is observed. This occurs even if the electrolyte exhibits increased HRS (i.e. even with nanophases evolving due to ionizing radiation exposure). The increase of the ratio obtained in this work is in fact, an improvement of the resistance switching characteristics of the PMC. VI. CONCLUSION In this work, we experimentally investigated total dose effects on the resistance switching characteristics of Ag doped PMCs, an emerging ReRAM device. These devices exhibit resistance switching due to silver cation transport through a solid-state electrolyte and reduction and oxidation of the silver cation at the electrodes of the cells. The devices are shown not to be sensitive to ionizing radiation exposure to TID up to 10 Mrads, and the obtained results suggest that resistance switching could be achieved at even higher TID levels. An interesting result obtained when cycling the device is that the ratio of the devices is shown to increase after radiation exposure, which is an improvement in one of the metrics of the resistance switching process. Concerning the impact of radiation on the MLC capability of the devices, the study of the On-state resistance control with demonstrated that this capability of the cell is preserved after exposure. ACKNOWLEDGMENT The authors would like to thank Dr. James Reed of DTRA for his support of this work. REFERENCES [1] M. N. Kozicki and W. C. West, “Programmable metallization cell structure and method of making same,” US patent no. 5 761 115, Jun. 1998. GONZALEZ-VELO et al.: RESISTANCE SWITCHING CHARACTERISTICS OF CHALCOGENIDE PROGRAMMABLE METALLIZATION CELLS [2] M. N. Kozicki, M. Yun, L. Hilt, and A. Singh, “Applications of programmable resistance changes in metal-doped chalcogenides,” in Proc. Symp. on Solid State Ionic Devices, 1999, pp. 1–12. [3] M. N. Kozicki, M. Mitkova, M. Park, M. Balakrishnan, and C. Gopalan, “Information storage using nanoscale electrodeposition of metal in solid electrolytes,” Superlat. Microstruct., vol. 34, pp. 459–465, Dec. 2003. [4] M. N. Kozicki, M. Park, and M. Mitkova, “Nanoscale memory elements based on solid-state electrolytes,” IEEE Trans. Nanotechnol., vol. 4, pp. 331–338, May 2005. [5] I. Valov and M. N. Kozicki, “Cation-based resistance change memory,” J. Phys. D: Appl. Phys., vol. 46, no. 7, Feb. 2013. [6] I. Valov, R. Waser, J. R. Jameson, and M. N. Kozicki, “Electrochemical metallization memories—fundamentals, applications, prospects,” Nanotechnology, vol. 22, p. 254003, Jun. 2011. [7] R. Waser, R. Dittmann, G. Staikov, and K. Szot, “Redox-based resistive switching memories—nanoionic mechanisms, prospects, and challenges,” Adv. Mater., vol. 21, pp. 2632–2663, Jul. 2009. [8] L. Chua, “Memristor-The missing circuit element,” IEEE Trans. Circuit Theory, vol. 18, pp. 507–519, Sep. 1971. [9] L. Chua, “Resistance switching memories are memristors,” Appl. Phys. A, vol. 102, pp. 765–783, 2011. [10] Assessment of the potential and maturity of selected emerging research memory technologies, ITRS Workshop and ERD/ERM Working Group Meeting [Online]. Available: http://www.itrs.net/ Links/2010ITRS/2010Update/ToPost/ERD_ERM_2010FINALReportMemoryAssessment_ITRS.pdf [11] Adesto Technologies [Online]. Available: http://www.adestotech.com [12] C. Gopalan, Y. Ma, T. Gallo, J. Wang, E. Runnion, J. Saenz, F. Koushan, P. Blanchard, and S. Hollmer, “Demonstration of conductive bridging random access memory (CBRAM) in logic CMOS process,” Solid-State Electron., vol. 58, pp. 54–61, 2011. [13] N. Derhacobian, S. C. Hollmer, N. Gilbert, and M. N. Kozicki, “Power and energy perspective of nonvolatile memory technology,” Proc. IEEE, vol. 98, pp. 283–298, Jan. 2010. [14] H. Hönigschmid, M. Angerbauer, S. Dietrich, D. Gogl, C. Liaw, M. Markert, R. Symanczyck, L. Altimine, S. Bournat, and G. Muller, “A non-volatile 2 Mbit CBRAM memory core featuring advanced read and program control,” VLSI Circuits Dig. Tech. Papers, pp. 138–139, 2006. [15] R. Symanczyk, R. Dietrich, A. Duch, J. Keller, M. Kund, G. Müller, B. Ruf, P.-H. Albarede, S. Bournat, and L. Bouteille, “Conductive bridging memory development from single cells to 2 Mbit memory arrays,” in Proc. Nonvolatile Memory Technol. Symp., 2007, pp. 71–75. [16] S. Dietrich, M. Angerbauer, M. Ivanov, D. Gogl, H. Hönigschmid, M. Kund, C. Liaw, M. Markert, R. Symanczyk, L. Altimime, S. Bournat, and G. Müller, “A non-volatile 2 Mbit CBRAM memory core featuring advanced read and program control,” in Proc. VLSI Circuits Dig. Tech. Papers, 2006, pp. 138–144. [17] M. Kund, G. Beitel, C.-U. Pinnow, T. Röhr, J. Schumann, R. Symanczyk, K.-D. Ufert, and G. Müller, “Conductive bridging RAM (CBRAM): An emerging non-volatile memory technology scalable to sub 20 nm,” in Proc. IEDM Tech. Dig, 2005, pp. 754–757. [18] M. T. Kostyshin, E. V. Mikhailovskaya, and P. F. Romanenko, Sov. Phys. Solid St., vol. 8, pp. 451–453, 1966. [19] A. V. Kolobov and S. R. Elliott, “Photo-doping of amorphous chalcogenides by metals,” Adv. Phys., vol. 40, pp. 625–684, Feb. 1991. [20] M. Kawasaki, J. Kawamura, Y. Nakamura, and M. Aniya, “Ionic conglasses,” Solid State ductivity of Ionics, vol. 123, pp. 259–269, Aug. 1999. [21] M. Mitkova and M. N. Kozicki, “Ag-Photodoping in Ge-chalcogenide amorphous thin films–reactions products and their characterization,” J. Phys. Chem. Solids, vol. 68, pp. 866–872, 2007. [22] M. A. Ureña, A. A. Piarristeguy, M. Fontana, and B. Arcondo, “Ionic ) in AgGeSe glasses,” Solid State Ionics, vol. 176, conductivity ( pp. 505–512, Feb. 2005. [23] O. Shpotyuk, Semiconducting Chalcogenide Glass 1, R. Fairman and B. Ushkov, Eds. : Elsevier, 2004, ISBN 0127521879. 4569 [24] Z. U. Borisova, Glassy Semiconductors. New York, NY, USA: Plenum Press, 1981. [25] M. Mitkova and M. N. Kozicki, “Silver incorporation in Ge-Se glasses used in programmable metallization cell devices,” J. Non-Crystalline Solids, vol. 299–302, pp. 1023–1027, 2002. [26] D. Kamalanathan, S. Baliga, S. C. P. Thermadam, and M. N. Kozicki, “ON state stability of programmable metalization cell (PMC) memory,” in Proc. Non-Volatile Memory Technology Symp., Nov. 2007, pp. 91–96. [27] U. Russo, D. Kamalanathan, D. Ielmini, A. L. Lacaita, and M. N. Kozicki, “Study of multilevel programming in programmable metallization cell (PMC) memory,” IEEE Trans. Electron Dev., vol. 56, pp. 1040–1047, May 2009. [28] D. Kamalanathan, U. Russo, D. Ielmini, and M. N. Kozicki, “Voltagedriven on–off transition and tradeoff with program and erase current in programmable metallization cell (PMC) memory,” IEEE Electron Dev. Let., vol. 30, no. 5, pp. 553–555, May 2009. [29] N. E. Gilbert and M. N. Kozicki, “An embeddable multilevel-cell solid electrolyte memory array,” IEEE J. Solid-State Circ., vol. 42, no. 6, Jun. 2007. [30] M. Mitkova, M. N. Kozicki, H. C. Kim, and T. Alford, “Local structure resulting from photo and thermal diffusion of Ag in Ge-Se films,” J. Non-Crystalline Solids, vol. 338–340, pp. 552–556. [31] M. N. Kozicki, M. Mitkova, J. Zhu, and M. Park, “Nanoscale phase separation in Ag-Ge-Se glasses,” Microelectron. Engrg., vol. 63, pp. 155–159, 2002. [32] M. Mitkova, M. N. Kozicki, H. C. Kim, and T. L. Alford, “Crystallization effects in annealed thin Ge-Se films photodiffused with Ag,” J. Non-Crystalline Solids, vol. 352, pp. 1986–1990, 2006. [33] M. Mitkova, Y. Sakaguchi, D. Tenne, S. K. Bhagat, and T. L. Alford, “Structural details of Ge-rich silver doped chalcogenide glasses for nanoionic nonvolatile memory,” Phys. Status Solidi A, vol. 207, no. 3, pp. 621–626, 2010. [34] M. Mitkova, M. N. Kozicki, H. C. Kim, and T. L. Alford, “Thermal and photodiffusion of Ag in S-rich Ge-S amorphous films,” Thin Film Solids, vol. 449, pp. 248–253, 2004. [35] D. Nesheva, M. Ailavajhala, P. Chen, D. A. Tenne, H. Barnaby, and M. Mitkova, “Study of gamma radiation induced effects in Ge-rich chalcogenide thin films,” in Proc. RAD12 Conf., 2012, pp. 063–7, ISBN 978-86-6125. [36] P. Chen, M. Ailavajhala, M. Mitkova, D. Tenne, I. S. Esqueda, and H. Barnaby, “Structural study of Ag-Ge-S solid electrolyte glass system for resistive radiation sensing,” presented at the Proc. IEEE Workshop on Microelectronics and Electron Devices, 2011. [37] M. Mitkova, P. Chen, M. Ailavajhala, D. P. Butt, D. A. Tenne, H. J. Barnaby, and I. Sanchez Esqueda, “Gamma ray induced structural effects in bare and Ag doped Ge-S thin films for sensor application,” J. Non-Crystalline Solids, 2013. [38] M. Ailavajhala, M. Mitkova, and D. P. Butt, “Simulation and process flow of radiation sensors based on chalcogenide glasses for in-situ measurement capability,” Phys. Status Solidi C, vol. 9, no. 12, pp. 2415–2419, 2012. [39] Y. Gonzalez-Velo, H. J. Barnaby, A. Chandran, D. R. Oleksy, P. Dandamudi, M. N. Kozicki, K. E. Holbert, M. Mitkova, M. Ailavajhala, and P. Chen, “Effects of cobalt-60 gamma—rays on Ge-Se chalcogenide glasses and Ag/Ge-Se test structures,” IEEE Trans. Nucl. Sci., vol. 59, no. 6, pp. 3093–3100, Dec. 2012. [40] M. Mitkova, M. N. Kozicki, and J. P. Aberouette, “Morphology of electrochemically grown silver deposits on silver-saturated Ge-Se thin films,” J. Non-Crystalline Solids, vol. 326–327, pp. 425–429, 2003. [41] M. Balakrishnan, M. N. Kozicki, C. D. Poweleit, S. Bhagat, T. L. Alford, and M. Mitkova, “Crystallization effects in annealed thin GeS2 films photodiffused with Ag,” J. Non-Crystalline Solids, vol. 353, pp. 1454–1459, 2007. [42] R. Bruchaus, M. Honal, R. Symanczyk, and M. Kund, “Selection of optimized materials for CBRAM based on HT-XRD and electrical test results,” J. Electrochem. Soc., vol. 156, pp. 729–733, 2009.