Nano-ionic nonvolatile memory devices – basic as medium for them

advertisement

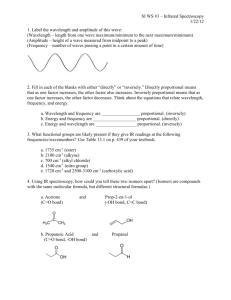

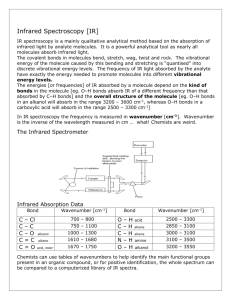

Chapter 14 Nano-ionic nonvolatile memory devices – basic ideas and structural model of rigid Ge-S glasses as medium for them Maria Mitkova, Yoshifumi Sakaguchi Dept. of Electrical and Computer Engineering, Boise State University, Boise, ID 832725-2075, USA One of the most fascinating applications of chalcogenide glasses is related to the formation of nanoionic conductive bridge nonvolatile memory. It is realized in programmable metallization cell (PMC) memory devices, which utilize the oxidation and reduction of nanoscale quantities of metal ions in solid electrolyte films. The formation of a robust but reversible conducting pathway by way of electrodeposition at low voltage and current reduces the resistance of the electrolyte by several orders of magnitude. In this manner, non-volatile memory is realized in elements that are highly electrically and dimensionally scalable. The main active materials for the solid electrolyte films for creation of the PMC devices so far are Ag doped Ge-chalcogenide glasses. This medium is achieved due to the photodiffusion of Ag into the Ge-chalcogen matrix. At this process phase, separation occurs by which the hosting chalcogenide glass becomes depleted in chalcogen thus becoming rigid and a silver containing material is formed. A model of the structure of very Ge rich Gechalcogenide glasses is developed and the Raman signature of the new appearing highly rigid structure is demonstrated. Introduction The semiconductor industry is under constant pressure for continuous scaling of active memory devices. Physical size reduction of memory based on charge storage (e.g., DRAM, Flash) will result in unacceptable state detection or retention characteristics. Operational requirements and manufacturing issues associated with proposed replacement technologies will almost certainly make them undesirable for most consumer applications, where cost and power consumption are dominant factors. Additional stress comes from the recent dominance of portable electronics where low power consumption and embedding of nonvolatile memory are the major requirements. The scaling issues in the charge storage based memory technologies have led to the development of alternative memory technologies like Ferroelectromagnetic Memory (FeRAM), Ovonics Unified Memory (OUM) and Magnetoresistive Random Access Memory (MRAM), which do not employ capacitive charge storage. A new memory technology, which departs from all existing memory technologies, including those currently in developments, is the Programmable Metallization Cell memory (PMCm) technology [1]. The PMCm is a high-density nonvolatile solid-state memory, with low operational voltage, small power consumption and extremely good storage cell scalability. In the PMCm, the information is stored by growing or dispersing of a metal dendrite. An oxidizable anode and an inert electronsupplying cathode formed in contact with a solid electrolyte create a device that exhibits polarity dependent switching property. The intrinsically high resistance of the device can be switched to a low resistance state by growing a stable silver electrodeposit from the cathode to the anode. A reverse bias disperses the electrodeposit, causing the device resistance to increase. PMC devices are quite simple and inexpensive to produce. Furthermore, this memory technology meets the requirements of the new generation of portable computer devices by operating at a relatively low voltage while providing high storage density and a low manufacturing cost. The basic and most successfully used materials for these devices are Ag-doped chalcogenide glasses, mainly those from the tetrahedrally coordinated family (containing Ge) chalcogenide glasses which form the active material – the solid electrolyte of the devices. Electrical characteristics of the PMC devices The electrically stimulated injection and removal of metal in the solid electrolyte at very low voltage is the basis of PMCm devices technology [1]. The solid state electrolyte material is formed by Ag diffusion in Ge - Chalcogenide glasses (ChG). This electrolyte allows the movement of silver ions under the influence of an electric field. If electrodes are formed in contact with a layer of solid electrolyte, an anode which has oxidizable silver and an electrochemically inert electron-supplying cathode, a metal ion current flows in the electrolyte when sufficient bias is applied (typically in the order of a few hundred mV), and as long as there is oxidizable metal available from the anode. The electron current from the cathode reduces an equivalent number of ions as injected from the anode and a metal-rich electrodeposit is thereby formed in (or on) the electrolyte. The amount of metal deposited depends on the magnitude and duration of the ion current, i.e., the total Faradic charge. The electrodeposit is electrically neutral and the deposition process is reversible by applying a reverse bias so that the electrodeposited metal is now the oxidizable “anode”. The reverse ion current flows until the previously electrodeposited material is oxidized and deposited back on the electrode, which originally supplied the metal – Fig. 1. - WRITE + + - - Electrons Ag ions Electrons Ag ions - ERASE + + Fig. 1. Schematic of (a) PMCm device modeled as an electrochemical cell. a. Unwritten device. (b) Device during WRITE: A very small voltage rapidly “injects” into the electrolyte excess silver ions, which are reduced by the electron current to form highly stable silver dendrites within the electrolyte. (c) Written Device: The electrondeposition process stops when a conducting link is formed. Metallic link reduced the resistance of the structure by many orders of magnitude.(d) Device during ERASE: A very small reverse voltage (a few hundred mV) removes excess silver from the electrolyte. Excess silver is backed on the silver electrode by an easily reversible reaction. The structure of the solid electrolyte, which will be further discussed in detail, is formed by the hosting backbone of the chalcogenide glass and the interstitial phase of Ag-containing clusters. The electrodeposition effect in the glassy interstitial material greatly reduces its resistivity. Since the electrolyte resistance is dominated by the interstitial material, its reduced resistivity results in a profound reduction in the overall resistance of the film. The ‘ON’ characteristics of the PMCm are therefore determined by the “strength” of the electrodeposited links - the more reduced silver in the linking regions, the lower the effective film resistance. However, the low resistivity of the silver-rich electrodeposits (less than 10-3Ω.cm) means that a nanoscale “link” in the order of a few tens of nm in diameter will still result in an acceptable ‘ON’ resistance (less than 100 kΩ). The existence of this nanoscale connection is confirmed by the fact that the ‘OFF’ resistance is a function of device geometry, whereas the ‘ON’ resistance is independent of the device area. This insensitivity of on resistance to the device area has been established for devices ranging from 5 µm down to 100 nm in diameter [1]. In addition, the ‘ON’ resistance is a simple function of the applied current limit since electrodeposition only proceeds if the voltage across the device is in excess of 200 mV, the typical “write threshold” for selenide glasses. When a forward bias in excess of the write threshold is applied to the ‘OFF’ device, the resistance decreases and the current rises to the set limit. However, once the resistance falls to the point at which the voltage is beyond the write threshold, the electrodeposition halts and the resistance is then fixed. This effect may be expressed simply as Ron = Vw/Iprog (1) where Ron is the ‘ON’ resistance, Vw is the electrodeposition threshold, and Iprog is the maximum programming current. This is a very important dependence showing that in fact we can program the Vw based on the programming current so achieving switching at different threshold voltage, depending upon the programming current. For example, a current limit of 10 µA will result in an ‘ON’ state resistance of ~30 kΩ for a write threshold of 200 mV, which is many orders of magnitude lower than a typical ‘OFF’ state. If a reverse bias in excess of approximately 50 mV is applied, the electrodeposited silver is oxidized to disperse the conducting link and the silver is replaced on the oxidizable electrode (now the cathode). This reverse reaction is self-limiting and terminates when all the excess silver in the electrodeposit is oxidized, so the devices cannot be over-erased–Fig.2. Fig. 2. Current-voltage schematic of a PMCm device. The ‘OFF’ state in both forward and reverse bias has a non-ohmic character due to the nature of the electrolyte and the electrode-electrolyte interfaces. Preparation and electrical characterization of PMC devices The PMC devices are usually prepared utilizing an active-in-via concept, see Fig. 3. The memory cell is a multi-layered structure consisting of a bottom electrode (the inert cathode), the active material (solid electrolyte), the top electrode (the oxidizable anode) and a top metallization for electrical contact [2]. This stack is surrounded by a dielectric material for Fig. 3. Sketch of a cross-section of one memory cell. isolation and encapsulation. The most important step during the device preparation is formation of a solid electrolyte, since its composition and structure are responsible for the performance of the devices. Germanium chalcogenides are usually doped with Ag via photoinduced diffusion [3]. This method is preferred because it is fast and allows introduction of a higher amount of Ag compared to thermal diffusion [4,5] due to light induced defects created by illumination in the chalcogenide glasses [6]. The introduction of Ag results in formation of a phase separated product [7] formed by a Ge-chalcogen host structure filled with clusters of Ag containing chalcogenides, which will be discussed in more detail further in this chapter. The small cluster size of this structure [8] allows formation of highly scaled devices. Since the cluster size is of the order of 6 – 10 nm, the devices could be easily scaled to a 20 nm lateral size. Fig. 4. shows a cross section of a 40 nm lateral dimension via which could be the active part of a PMC device. Fig. 4 Field emission scanning electron micrograph of a cross section of a PMCm device with 50 nm thick Ag33Ge20Se47 solid electrolyte on Ni cathodes with 40 nm diameter active area. Charging of the relatively insulating PMMA and solid electrolyte (Ag33Ge20Se47) layers leads to poor contrast so the solid lines have been added as a guide to the eye. A representative current-voltage plot from a 75 nm device is presented in Fig. 5 (a), which shows 32 consecutive write/erase operations (voltage sweeps from –0.5 to +0.5 to –0.5). The ‘OFF’-sate for forward bias is in the 7 8 10 ~ 10 Ω - Fig.5 (b). The device switches to its low resistance state around 0.2 V, at which point the current reaches its compliance limit of 10 µA. The current stays at the compliance until the negative-going sweep reaches 4 approximately 0.1 V, at which point the measured ‘ON’ resistance is 10 Ω, around 3 - 4 orders of magnitude lower than the ‘OFF’ state. Note that the apparent rise in resistance between 0.1 and 0.5 V is an artifact of the current compliance control in the measurement instrument. The appearance of the lower threshold following switching is typical of all PMCm devices and represents the minimum voltage required for electrodeposition once the process has been initiated and a metal-rich region has formed in the electrolyte (or more specifically on the cathode). Electrodeposition within the electrolyte will continue as long as the voltage drop is greater than 0.1 V for this physical configuration. The device transitions to its high resistance state around -0.04 V, but is not actually erased at this point as it will switch back to its low resistance state at an applied bias closer to 0.1 V rather than C u rre n t (n A ) 600 500 400 300 200 100 0 -100-0.5 -200 -300 -0.3 -0.1 0.1 0.3 0.5 Voltage (V) 1.0E+09 Roff > 10 MΩ Resistance(ohm) 1.0E+08 1.0E+07 1.0E+06 1.0E+05 1.0E+04 1.0E+03 -0.6 -0.5 -0.4 -0.3 -0.2 -0.1 0 0.1 Ron = 10 kΩ 0.2 0.3 0.4 0.5 Voltage(V) Fig. 5 (a) Current-voltage characteristics of a 75 nm PMCm device. 32 consecutive sweeps were performed from –0.5 V to +0.5 V to –0.5 V with a compliance of 10 µA. (b) ‘OFF’ resistance is around 4 x 107 ~1.5 x 108 Ω and ‘ON’ resistance was 1 x 104 ~1.12 x 104Ω for these conditions. Write and erase thresholds were around 0.2 V and –0.04 V respectively. 0.6 at the 0.2 V necessary to write a fully erased device. To fully erase the device, the reverse bias must be at least -0.5 V. The sudden increase in resistance at low voltage is due to the initial breaking of the conducting pathway, leading to a device resistance that is dominated by the high resistivity of a small portion of unbridged electrolyte. However, at this point, there is still part of an electrodeposited pathway present, albeit incomplete, and this allows reclosure at the lower threshold. A device that has been fully erased at -0.5 V has very little or none of this residual electrodeposit left and so requires around 0.2 V to rewrite. This is useful in the context of noise immunity in that a “read” voltage of 0.15 V is insufficient to switch a fully erased device but will reclose a device that was initially on but had been put in a “soft erase” state by a low (negative) voltage unintended disturb event. The above results demonstrate the low voltage and low power switching and large ‘OFF’/’ON’ ratios that nanoscale PMCm devices are capable of and our previous work has demonstrated excellent retention characteristics of PMCm device in general [2]. One of the most favorable features of the PMC devices is the fact that they are very fast. Experiments have been conducted demonstrating switching within 100nsec pulse. It was confirmed that switching was occurring within this timeframe by applying single 100 nsec wide pulses from the waveform generator and measuring the resistance using the semiconductor parameter analyzer before and after each pulse. The Ni cathode 75 nm x 75 nm via PMCm device was switched with a 100 ns single pulse. The resistance sensed at 100 mV was for the device before applying the pulse and it was sure that the device was in its high ‘OFF’-state before applying the 100 ns pulse. The resistance was recorded as 3 x 106 Ω. After the 100 ns pulse, the device resistance was sensed at 100 mV and the resistance was 1.8 x 104 Ω, which confirmed the writing at 100 ns, as shown in the Fig.6. 1.0E+08 Before Pulse After 100 ns Pulse Resistance (ohm) 1.0E+07 1.0E+06 1.0E+05 1.0E+04 1.0E+03 1.0E+02 -0.5 -0.3 -0.1 0.1 0.3 0.5 Voltage (V) Fig. 6. R-V results obtained with a 100 ns write pulse on a 75 nm PMCm device. The ultimate speed of the device can be predicted by considering the nanostructure of the electrolyte. The maximum ion mobility of silver is 10-3 cm2/V.s. The nano phase separated glass structure explained in section 1 has 3 an interstitial structure in the order of 1.5 nm and by assuming a high ion mobility as mentioned above, it would be expected that it takes less than 1 ns to electrodeposit silver in each of these interstitial glass layers. The electric 3 field associated with the electrodeposition volume of 1.5 nm will be around -1 -6 5 -3 2 10 V/10 cm, which is 10 V/cm. The velocity would then be 10 cm /V.s x 5 2 10 V/cm = 10 cm/sec. It would then take 10 ns or less in a 10 nm film to bridge the high resistivity glass region by silver-rich regions formed by electrodeposition. The same explanation would hold good for sub 10 ns erase time as well [9]. Structure of the solid electrolyte – general concepts An explanation of the fast switching process in the PMC devices can be found in their structural characteristics. In the nano-phase separated material of the solid electrolyte, the Ag containing interstitial phase (so far binary and ternary Ag-chalcogenide compositions have been confirmed by XRD studies) is dispersed, filling the Ge-rich insulating phase. It is this particular nanostructure that allows the films to exhibit relatively high resistivity, typically around 100 Ω.cm or higher, while still possessing good superionic characteristics such as high ion mobility and availability for conduction [10]. Such characteristics are important for PMCm device operation, since the electrolyte resistivity coupled with the geometry of the device defines the off resistance and the mobility and availability of Ag ions for electrodeposition within the electrolyte determine the switching characteristics. The distance, s, between the Ag-containing phase regions (and therefore the thickness of Ge rich material between them formed after Se is consumed from the initial glass to form Ag containing phase) can be estimated by assuming that these regions are spherical and uniform in size and dispersion, so that -1/3 s = d(Fv – 1) (2) where d is the measured diameter of the crystalline Ag-containing phase and Fv is the volume fraction of this phase. Since the volume fraction of Ag2Se in Ag33Ge20Se47 is 0.57 (for a molar fraction of 0.63), the average spacing between the Ag-rich regions is 0.2 times their diameter. Structural analysis using XRD showed the nano size particle nature of Ag2Se film with orthorhombic structure as confirmed in [11]. Analysis of the peaks associated with Ag2Se suggests that the average diameter of these regions is in the order of 7.5 nm, which means that by Eq. 2 above, they should be separated by 1.5 nm of glassy Ge-rich material. The maximum ion mobility of silver is 10-3 cm2/V.s. The nano phase separated glass structure discussed in section 1 has interstitial glass in the order of 1.5 nm3 and by assuming a high ion mobility as mentioned above, it would be expected that it takes less than 1 ns to electrodeposit silver in each of these interstitial glass layers. The electric field associated with the electrodeposition volume of 1.5 nm3 will be around 10-1 V/10-6 cm, which is 105 V/cm. The velocity would then be 10-3 cm2/V.s x 105 V/cm = 102cm/sec. It would then take 10 ns or less in a 10 nm film to bridge the high resistivity glass region by silver-rich regions formed by electrodeposition. The same explanation would hold good for sub 10 ns erase time as well. The Ag2Se phase forms conductive islands that make the switching in the devices based on the solid state electrolytes very fast as switching is realized only in the limits of the distance between these islands. As shown in our studies on the bulk Ag containing material [12] and Ag doped thin films [11, 13] when Ag is introduced in the Ge- ChG system, it reacts with the hosting material, forms phase separated Ag containing crystalline phase which leaves the chalcogenide glass host very much enriched in Ge. In other words, even if we mix Ag with a floppy or glass from the intermediate phase, the product forming after Ag reaction with the material is a very rigid chalcogenide glass. The structure of this material is not studied in detail, and we would like to demonstrate our vision of its structural organization in the case of a very Ge rich glasses, which could be obtained predominantly in thin films. Structure of the Ge rich Ge-ChG glasses Study on the Raman spectra Raman spectroscopy is a powerful technique to study the structure of chalcogenide glasses because it provides a chance to collect information about the particular structural units building them. Fig.7 shows the Raman spectra of Ge-rich Ge-S glasses (Ge 33%, 36%, 40%, and 46%). The three Raman spectra, (a)-(c), are from the results of Takebe et al. [14], which were measured using bulk samples. The spectrum at Ge 46% was obtained using thin film prepared by a thermal evaporation in the present study. There are three main regions where peaks are observed: below 175 cm-1, 200-300 cm1 and 300-450 cm-1. At Ge 33%, there are intensive peaks in the 300-450 cm-1 region. When Ge concentration becomes 36%, a peak in the 200-300 cm-1 (a) Ge36S64 (b) Scattered intensity Ge33S67 (c) Ge40S60 (d) Ge46S54 50 100 150 200 250 300 350 -1 Raman shift (cm ) 400 450 500 Fig. 7. Raman spectra of Ge-S glasses. The spectra (a), (b) and (c) are from [14]. The spectrum (d) is measured in the present work. The dash curves in (b), (c) and (d) are drawn by authors to show the continuous background component in the spectra. region appears. At Ge concentration larger than 36%, a peak appears in the region below 175 cm-1. These features are consistent with the results reported in the 1970’s by Lucovsky et al. [15] and those reported in 2001 by Kotsalas and Raptis [16, 17]. In addition to the peaks, there is a large continuous background in the spectra at Ge 36, 40 and 46%. It looks like a tail from a low frequency scattering. The low frequency scattering for this system has been studied in terms of the relative intensity of boson peak [18] and fraction model [19, 20] so far. However, the background component is quite strong at frequencies higher than 100 cm-1and the relative intensity of the background component to that of the peak component becomes larger with increasing Ge concentration. At Ge 46%, the background component persists at least up to 400 cm-1, which is no longer the low-frequency region. The background component is quite intense to affect an evaluation of the peak intensities in the spectra. Therefore, we assumed a smooth background curve obtained by taking into account the parts of the spectra between the peak regions, and subtracted the background component from the spectra. After the subtraction, we performed curve fits with Gaussians to the spectra as shown in Fig.8. 340 430 Ge36S64 Scattered intensity (a) 370 Ge33S67 255 (b) 410 220 50 Ge40S60 (c) Ge46S54 (d) 100 150 200 250 300 350 -1 Raman shift (cm ) 400 450 500 Fig. 8. Curve fit of the Raman spectra of Ge-S glasses. The dots show the experimental Raman spectra. In (c) and (d), the continuous background, which is indicated in Fig.7, was subtracted. The sum of the intensities of the peaks is indicated by a solid curve in each figure. In the curve fits, we assumed the presence of the peaks, which have already been assigned. Among the peaks, the peak at 340 cm-1 is attributed to the symmetric breathing mode of S atoms at Ge(S1/2)4 tetrahedron [21, 22] as the assignment is widely accepted by many researchers. The intensity of this peak decreases with increasing Ge concentration. This suggests that the number of the tetrahedral units decreases with increasing Ge concentration. However, the peak still exists even at Ge 36% and more, where the tetrahedral unit is not supposed to exist according to the results of Mössbauer spectroscopy [23]. So, for the case of Ge 36% and more, we attribute the peak at 340 cm-1 to the one of the vibrational mode of the ethane-like Ge2(S1/2)6 units, whose Raman active frequencies are at 240, 340 and 376 cm-1 [24]. The presence of the ethane-like units indicates the presence of Ge-Ge bonds, in other words, chemical disorder in the system. The peak at 370 cm-1 is often referred as the companion mode A1c. The peak is attributed by some researchers [25, 26] to the stretching motion of the outrigger raft (OR) accompanied by S-S bond. Other researchers regard this peak as the modes to the vibration of S atoms on the edge-sharing double bonds [27, 28]. In addition, there is the vibrational mode of the ethane-like units, which is at 376 cm-1 [24]. Jackson et al. suggested from first-principles molecular-dynamics simulations that there are two peaks near 370 cm-1; a peak at 373 cm-1 attributed to the mode of the edge-sharing cluster, and a peak at 366 cm-1 attributed to the mode of the ethane-like cluster [29]. According to the results of Mössbauer spectroscopy [23], at Ge 33%, there are 70% of the phase composed of tetrahedral unit (A phase) and 30% of the phase composed of the ethane-like units (B phase) as shown in Fig.9. Fig. 9. Mössbauer site-intensity ratio in g-(Ge0.99Sn0.01)xS1-x deduced from a deconvolution of the spectra [23]. Therefore, at Ge 33%, the peak at 370 cm-1 contains two components; the component of ethane-like units and the component of either edge-sharing double bonds or the stretching motion of OR. The relative intensity of I(370 cm-1) to I(340 cm-1) increases from Ge 33% to 36%. This is consistent with the results of Mössbauer spectroscopy, where A phase decreases from 70 to 0% while B phase increases from 30 to 80%. The peak at 430 cm-1 is regarded as the stretching mode of dimerized S atoms on the edge of the OR [25, 30]. This is also a peak indicative of a chemical disorder at a stoichiometric composition of Ge 33%. The peak decreases with a composition change from Ge 33% to 36%, and almost vanishes at Ge 40%. One can expect that the chance for creation of S-S bond declines with decreasing S concentration and the result is consistent with the expectation. In 200 to 300 cm-1, there seems to be two peaks. From the curve fit, we obtained two peaks located at 220 and 255 cm-1. The relative ratio of I(220 cm-1) to I(255 cm-1) increases with increasing Ge concentration. According to the calculation by Lucovsky et al. [21], there is a vibrational frequency of the ethane-like units at 240 cm-1. This is close to 255 cm-1. A recent first-principle study performed by Jackson et al. also provides the peak at 254 cm-1, which is attributed to the ethane-like units [29]. Therefore, the peak at 255 cm-1 is assigned to the vibrational mode of the ethane-like units. An abrupt increase of the peak at 255 cm-1 from Ge 33% to 36% and the persistence of the peak at Ge 40 and 46% are consistent with the change of B phase in the results of Mössbauer spectroscopy [23]. The peak at 220 cm-1 is attributed to the mode of the double layer, which crystalline(c-) GeS possesses. In the spectra of c-GeS, there are two intensive peaks [31]. One is at 212 cm-1, which is assigned to the rocksalttype mode along lattice parameter a. The other is at 238 cm-1, which is assigned to the layer-breathing mode. The peak at 220 cm-1 is considered to originate from these peaks. The relative intensity of I(220 cm-1) to I(255 cm1 ) increases from Ge 36% to 40%. This is consistent with the results of Mössbauer spectroscopy, where B phase decreases from 80 to 60% while the C phase, which is composed of double layer structure units like GeS crystal, increases from 20 to 40%. The Raman peaks in the region below 175 cm-1 also support the presence of layer-like structure, analogous to the double layer structure of c-GeS. In the spectrum at Ge 40%, there are two sharp peaks at about 65 and 80 cm-1. In c-GeS, there are two peaks; a peak at 48 cm-1, which is the rigid-layer shear mode along a, and a peak at 55 cm-1, which is the rigid-layer shear mode along b. Therefore, the peaks at 65 and 80 cm-1 are also considered to be related to the double layer structure. In the spectrum at Ge 46%, there is a broad peak in the region. This must have the same origin as the peaks at 65 and 80 cm-1 in the spectrum at Ge 40%. Also, such low frequency peaks are observed in the Ge-Se system in Ge-rich region from 44 to 50% [32]. There might be a common nature in the systems. So far we made curve fits only using the peaks whose presence has already been assigned. However, at high Ge concentration (35% and more) we could not fit the spectra in the range from 300 to 450 cm-1 without considering a peak at 410 cm-1, which becomes larger with increasing Ge concentration. The peak at 410 cm-1 is not originating from the shift of the 430 cm-1 peak, because both the 410 cm-1 and 430 cm-1 peaks were required to fit the spectrum at Ge 36%. It seems that the increase of the peak at 410 cm-1 is related to the increase of C phase. But there is no peak with such a high frequency in the spectra of c-GeS. We would expect from the results that there is a structural unit, which has a stronger bond than that in the double layer, and it results in such a high frequency vibration, in C phase. To the best of our knowledge, there is no evidence or suggestion of the existence of such a structural unit. In order to get a better idea about the structural transformation occurring at higher Ge concentrations from the Raman spectra, we have evaluated the peak components as shown in the bar charts in Fig.10. Ge33S67 (a) A Ge36S64 A Intensity C B Ge40S60 Ge46S54 150 200 250 300 350 400 450 500 1 Ge33S67 Ge36S64 Intensity (b) A A B C Ge40S60 Ge46S54 150 200 250 300 350 -1 Raman shift (cm ) 400 450 500 Fig. 10. The intensities of the Raman peaks. The intensity indicates the product of the height and the width of the Gaussian peak. Red bars indicate the Raman peaks related to A phase. Blue bars indicate the Raman peaks related to B phase or the ethanelike units. A green bar indicates the Raman peak related to C phase or layer-like structure. The olive bar indicates the unassigned peak, which becomes larger with increasing Ge concentration. The white parts indicate the unassigned components in the peaks. (a) We assumed that the intensity ratio for the ethane-like units (B phase) is determined at Ge 46 %. (b) We assumed that the intensity ratio for the ethane-like units (B phase) is determined at Ge 40 %. In the figure, the intensity indicates the product of the height and the width of the Gaussian peak. In the peak at 340 cm-1, there are two components; the vibrational mode of the tetrahedral units, which belongs to the A phase, and the vibrational mode of the ethane-like units, which belongs to the B phase. In the peak at 370 cm-1, there are also two components; the vibrational mode of the edge-sharing tetrahedral units or the bond-stretching mode of S-S dimers at the edge of OR, which belongs to the A phase, and the vibrational mode of the ethane-like units, which belong to the B phase. The peak at 255 cm-1 contains only the vibrational mode of the ethane-like units. It is considered that the ratio of the peak intensities related to the ethane-like units, I(255 cm-1) : I(ET, 350 cm-1) : I(ET, 370 cm-1) is always the same even if the Ge concentration of the sample changes. The ratio can be obtained from the spectral peaks containing no contribution from the A phase. In Fig.10 (a), we assumed that the ratio is determined by the spectrum at Ge 46%. The ratios are applied in the bar charts at Ge 36 and 40%. With this assumption, the content of the B phase increases with increasing Ge concentration. But there are some questionable points in the result: (1) There is a fairly large number of the tetrahedral units even at Ge 40%. (2) The edge-sharing tetrahedral structure units or S-S dimers remains in the spectra at Ge 36%, and the content does not change much from Ge 36 to 40%. (3) The content of C phase does not increase from Ge 40 to 46%. In Fig.10(b), we assumed that the ratio is determined by the spectrum at Ge 40%. With this assumption, we obtained some reasonable results. The main points are as follows; (1) The existence of a small number of tetrahedral units at Ge 36%. (2) The edge-sharing tetrahedral structure disappears at Ge 36%. (3) The content of C phase increases throughout the concentration region from Ge 33 to 46%. However, at Ge 46%, two other unassigned components appear at 250 and 370 cm-1. If these are true, these components are attributed to either the appearance of new structural units at Ge 46% or to the structural disorder caused by the sample preparation since these are data obtained from a thin film. For the peak at 410 cm-1, the intensity increases with Ge concentration regardless of the assumption. It increases independently from the peak at 220 cm-1. Therefore, the structural origin of 410 cm-1 must be different from the double layer structure. Structural model In order to find out the nature of the appearance of such a new structural unit with a vibrational mode at 410 cm-1, we have performed a virtual structural modeling. Fig.11 shows the structural development of virtually-made crystalline Ge-S. High temperature crystal phase of GeS2 consists of Ge(S1/2)4 tetrahedral units. There are streams of Ge-S chains. Between two Ge-S chains, there are edge-sharing tetrahedra. It looks as if the edge-sharing tetrahedra connect the two Ge-S chains on both sides. Fig. 11. Structural development of virtually-made crystalline Ge-S material. In c-GeS2, there are tetrahedral clusters of Ge(S1/2)4 with the largest numbers in this system (indicated by light blue) and there are streams of Ge-S chains (indicated by yellow curves). By subtracting S atoms, the number of the tetrahedral clusters decreases while the Ge-S chains are preserved. In GeS, the tetrahedral units completely disappear and a new Ge-S chain is supposed to be made between the two Ge-S chains, which have already existed. Starting from this structure, we subtract S atoms to make a Ge-rich compound. Here, we assumed that the Ge-S chain structure is preserved. By subtracting S atoms, the number of the tetrahedral units decreases. At the beginning of the subtraction, the absence of edge-sharing tetrahedral units is remarkable. This is natural because removing one S atom among four S atoms in a tetrahedral unit makes one loss of the tetrahedral unit while removing one S atom among six S atoms in the edge-sharing tetrahedra makes one loss of the tetrahedral set. The trend coincides with the result of Fig. 4(b), in which the edge-sharing tetrahedral set decreases rapidly from Ge 33 to 36%. Losing the edge-sharing tetrahedral set affects the structure in the middle portion between the two Ge-S chain streams. By subtracting more S atoms, the number of the tetrahedral units decreases further. The trend qualitatively coincides with the result in Fig.10 (a) and (b), in which the peak component related to the tetrahedral units at 340 cm-1 decreases with increasing Ge concentration. As long as the tetrahedral units cling to the GeS chain at a stoichiometric composition of Ge 33%, the bond angle of S-GeS is supposed to be fixed to that in a tetrahedron, 109.47 o. However, when large number of tetrahedral units is removed from the Ge-S chain, the bond angle in the Ge-S chain can change. We will discuss this possibility in the next section. Finally, the Ge-S chain completely loses the tetrahedral units. In the middle portion between the two Ge-S chains, a new Ge-S chain must be formed. We would expect that the Ge-S chain, from which the tetrahedral units are removed, and the newly formed Ge-S chain at the middle portion combine together and form the layer structure, which c-GeS possesses. In Fig.11, we assumed a crystal structure. However, we are now dealing with the amorphous phase. In order to find the structure in the amorphous phase, we virtually constructed a structure starting from high temperature crystal phase, then changing to liquid phase, and finally to amorphous phase, by quenching from the liquid, as shown in Fig.12. Fig. 12. A structural model, which explains how chemical disorder is formed in amorphous GeS2 from crystalline GeS2 through the liquid phase. First, some of Ge-S bonds break when crystalline GeS2 becomes liquid by melting. Then, the neighboring broken S atoms bond together forming the edge dimmer of ‘outrigger raft’, which was proposed by Bridenbaugh et al.[25]. Broken Ge atoms also bond together and form ethane-like units, whose presence was proposed in amorphous Ge-rich germanium sulfide by Lucovsky et al.[15] and even in a-GeS2 by Boolchand et al.[23] and Salmon and Petri [33]. After quenching from the liquid, the chemical order and disorder are preserved. When c-GeS2 is heated and molten GeS2 is obtained from the high temperature crystal phase, we can expect some Ge-S covalent bonds to break. In figure 12, we assumed the breaking of the two Ge-S bonds, which form the edge-sharing tetrahedral units and connect with the tetrahedral units on the Ge-S chain. Due to the bond breaking, two neighboring S atoms become free and there is a chance to form a new S-S bond. This corresponds to the S-S dimer on the edge of the outrigger raft, which was suggested by Bridenbaugh et al. [25]. With the breaking of the Ge-S bonds, the other counterparts of Ge atoms also become free. If these two atoms are close, the atoms can bind to each other and form a new Ge-Ge bond. As a result of forming the new bond, the ethane-like (S1/2)3Ge-Ge(S1/2)3 units are formed as shown in the figure. We would expect that such structure in the liquid phase is preserved in the amorphous phase by quenching the sample from the liquid phase. This picture provides an answer to the fundamental question, why the chemical disorder exists in the stoichiometric composition and in the amorphous phase, and explains the characteristic features of amorphous (a-) GeS2, such as the presence of S-S dimer and the ethane-like structure. The presence of the chemical disorders is an intrinsic nature in a-GeS2. Now we have subtraction of S atoms starting with the a-GeS2 as shown in Fig.13. Here we also assume that the subtraction is not made in the Ge-S chain, and the Ge-S chain is preserved. The S atoms are classified into three groups by their position; 1st, 2nd and 3rd columns, as shown in the figure. The S atoms in the 1st column are the compositional elements of the Ge-S chain. The S atoms in the 2nd column are the edges of the tetrahedral units on the Ge-S chain, but they are not in the Ge-S chain. The S atoms in the 3rd column are in the middle of the two Ge-S chains, and are out of the 2nd column. If the ethane-like unit loses the S atom in the 3rd column, Ge atom in Fig. 13. A model of the structural development in Ge-rich Ge-S glasses. By subtracting S atoms, the number of the tetrahedral clusters decreases while the Ge-S chains are preserved. By losing S atoms in the 2nd column, the broken Ge atom on the ethane-like cluster will bond with the S atom on the Ge-S chain. As the result of the formation of the new bonding, the interaction between the two Ge-S chains is expected to be large. For more details, see text. the ethane-like unit will seek other S atom and bond with the neighbored S atom in the 2nd column. If the ethane-like unit loses the S atom in the 2nd column, the Ge atom will bond with the S atom in the 1st column, which is on the Ge-S chain. As a matter of fact, it is not necessary for the S atom on the Ge-S chain to form one more additional bond because two p electrons in the outermost electrons are already used for covalent bonding, and the rest of the two p electrons form the lone-pair orbital. However, the Ge atom, which has lost one bond with the S atom, will seek one atom to bond in order to maintain four-fold coordination and the S atom, on the Ge-S chain, can afford to form one additional bond using the electron in the lone-pair orbital. Through such dynamics, we would expect that the interaction between the two streams of the Ge-S chains becomes stronger, which means that the two streams approach each other. Here, the ethane-like units, which exist between the two streams of the Ge-S chains, play a role of a glue. In fact, the density variation as a function of concentration indicates that there is more volume contraction in the region from Ge 33 to 45% [14, 34] as shown in Fig.14. 4.4 Ge-Se 4.2 3 density (g/cm ) 3.4 3.2 3.0 2.8 2.6 2.4 2.2 Ge-S 2.0 1.8 0 5 10 15 20 25 30 35 40 45 50 Ge (at %) Fig. 14. Concentration variation of the mass density. The closed circles and open triangles are the data for Ge-S glasses obtained by Takebe et al. [14] and Kawamoto and Tsuchihashi [34], respectively. The closed squares are the data for Ge-Se glasses obtained by Feltz et al. [35]. The dot lines are drawn in order to show the change at Ge 33 %. The same tendency is also observed in Ge-Se system [35]. It is considered that the large volume contraction in the region arises from the increase of the interaction between the Ge-S(Se) chains. When Ge concentration reaches 50%, the chains bridge each other and they must form layer structure as the one, which c-GeS possesses. Formation of layered structure When the Ge concentration becomes larger, close to 50%, layer-like structure is supposed to be formed as the Raman spectra suggest. Further information about the structural nature of the Ge-S glasses close to Ge 50%, can be obtained from a diffraction study. Table 1 shows the summary of the neutron diffraction results by Salmon and Petri [33] and Petri et al. [36] for a-GeSe2, l-GeSe2 and l-GeSe. In a-GeSe2, the bond length of Ge-Se is 2.36 Å and the bond angle of Se-Ge-Se is 111.01 o. In l-GeSe2, the bond length of Ge-Se is 2.42 Å and the bond angle of Se-Ge-Se is 101.57 o. Table 1. r1 N1 r2 N2 GeSe2 glass Ge-Se Ge-Ge Se-Se 2.36 2.42 2.32 3.70 0.25 0.20 3.57 3.89 3.2 9.3 liquid Ge-Se Ge-Ge Se-Se 2.42 2.33 2.30 3.50 0.25 0.23 3.59 3.75 2.9 9.6 GeSe liquid Ge-Se Ge-Ge Se-Se 2.54 2.36 2.34 3.20 0.80 0.22 3.81 3.76 7.4 8.6 θ Se-Ge-Se Ge-Se-Ge 111.01 98.29 Se-Ge-Se Ge-Se-Ge 101.57 95.76 Se-Ge-Se Ge-Se-Ge 94.82 97.18 Those angles are close to 109.47 o, which is the angle of Se-Ge-Se in a perfect tetrahedron. In addition, the coordination number with respect to Ge-Se bond is 3.70 for a-GeSe2 and 3.50 for l-GeSe2. The value is close to four, which is the number of Se atoms surrounding a Ge atom in Ge(Se1/2)4 tetrahedron. Therefore, the results support the view that a-GeSe2 and l-GeSe2 consist of Ge(Se1/2)4 tetrahedral units. In l-GeSe, the bond length of Ge-Se is 2.54, which is longer than that in l-GeSe2 and the bond angle of Se-Ge-Se is 94.82 o, which is close to 90o. Recent ab initio molecular-dynamics simulations by Van Roon et al. [37] have shown that the bond angle Se-GeSe is about 90 o in l-GeSe while it is 103 o in l-GeSe2. Assuming that the GeS(Se) chain structure is preserved from GeS(Se)2 to GeS(Se) as we discussed in the previous section, and taking these values into account, the molecular structures of Ge-Se chains in a-GeSe2, l-GeSe2 and l-GeSe can be depicted as shown in Fig.15. a) b) Fig. 15. Chain configurations in glassy GeSe2, liquid GeSe2 (a) and liquid GeSe (b). By constructing a tetrahedral structure, the Se-Ge-Se angle is fixed at the value close to 109.47 o in a- and l-GeSe2. However, in l-GeSe, the angle changes from the fixed value by taking off the tetrahedral units. Such structural change can be explained in terms of the atomic orbital theory. The outermost electronic configuration of Ge is (4s)2(4p)2 and that of Se is (4s)2(4p)4. In Se atom, two s electrons are low in energy and they do not participate in bonding. Two electrons among four p electrons are used to form a covalent (σ) bond with the other two atoms. Hence, the Se atom makes two- fold coordination. The other two p electrons do not participate in bonding and form a pair called “lone-pair electrons”. On the other hand, there are two cases for the Ge atom. When a tetrahedral unit, in which Ge atom centers, is formed, sp3 hybridization is supposed to occur by the promotion of one s electron to p level as it occurs in a carbon atom in CH4 molecule [38]. The four sp3 orbitals overlap with another orbital from other atoms and that results in the equivalent four covalent (σ) bonds. The atomic orbitals of a Ge atom are drawn in Fig. 16(a), while the atomic orbitals of S are shown in Fig. 16(b). a) b) c) Fig. 16. Atomic orbitals in a fourfold coordinated Ge atom (a), a S atom (b) and a twofold coordinated Ge atom (c). This situation explains the molecular shape of the Ge-Se (S) chain in Fig. 15(a). On the other hand, when the Ge-Se(S) chain, which consists of twofold coordinated Ge and Se atoms as shown in Fig.15(b), is formed, only two p electrons are supposed to be used for bonding, leaving s electrons in bonding without forming hybridization. Hence, the coordination number of Ge atom becomes two. Since the two p orbitals are normal to each other, the bond angle of Se-Ge-Se is fixed at 90 o. The atomic orbitals of Ge are drawn in Fig. 16(c). The experimentally obtained value is close to 90 o. Therefore, such molecular orbital picture is supposed to be valid for the case of l-GeSe. The change of the bond length is also explained by the energy levels of these orbitals. By giving rise to four equivalent sp3 hybrid orbitals, the energy levels of the hybrid orbitals become lower than the level of p orbitals. The energy gain must be larger than the energy loss by the promotion of electron from s level to p level. This is the reason why the hybridization is formed. Taking these energy considerations into account, we can obtain the relationship of the bond strength for these two cases. The bond, in which sp3 orbital participates is stronger and the bond, in which p orbital of a Ge atom participates is weaker. This is consistent with the experimental result that the Ge-Se bond length in the tetrahedral unit is shorter than that in the Ge-Se chain in l-GeSe. X-ray diffraction study on Ge-S glasses by Rowland et al. [37] also provided the result that the nearest neighbor distance in Ge42S58 (2.3 Å) is longer than that in Ge33S67 (2.2 Å). The only thing which cannot be explained by the picture above is the result of the coordination number related to the Ge-Se bond in l-GeSe. The coordination number is 3.2, which is close to three. Recent ab initio molecular-dynamics simulations by Van Roon et al. [38] have shown that the threefold coordination is the dominant coordination for both Ge and Se in liquid GeSe and suggested the presence of the subunits GeSe3 and SeGe3. To understand the meaning of this number, it is worth looking at the layer structure in c-GeSe. Although the structure itself is always the same, the structure of c-GeSe has been presented in different ways [39-43] because of a different view on the formation of the bond. The coordination number in cGeSe was sometimes regarded as 6. However, the difference of the bond lengths is not considered in this estimation. Hsueh et al. [41] pointed out that the structure can be understood by threefold coordination. Onodera [42] also sketched the structure, in which each atom is connected by three coordination geometry. Based on this view, the double layer in c-GeSe is illustrated in Fig.17. In the figure, we add our original view that the Ge-Se chains, which are aligned along the b-axis, are connected to each other having the longer third bond, which is formed along the c-axis, in each atom. The Ge-Se chains are alternatively aligned at a different height on the c axis. In this way, a layer structure is formed from the Ge-Se chains and the layer becomes ‘double’. Ch Ch Ge Ge Fig. 17. Double layer structure in c - GeSe. To clarify such a view, the Ge-Se chains are indicated by bands with two different colors and two types of bonds are indicated by different colors in the figure. Comparing the structure with the model structure in Fig.11 and 13, the streams of the Ge-S chains on both sides in Fig.11 and 13 correspond to the Ge-Se chains indicated in yellow bands in Fig.17. The middle portion in Fig.11 and 13 corresponds to the Ge-Se chain indicated in the blue band in Fig.17. In the double layer, each atom has threefold coordination. This coincides with the number which was given in the neutron diffraction measurement for l-GeSe. Therefore, it is considered that the double layer structure is also built up in l-GeSe with the Ge-Se chains in Fig. 15(b). We would expect that Ge-S glasses close to Ge 50% also possess such double layer-like structure. Next we consider how the third bond can be formed in terms of the atomic orbital theory. As long as we notice the formation of threefold coordination in the Ge atom, the formation of sp2 hybridization can be considered. In this case, a strong double bond is formed and three bonds are fixed on one plane. However, as seen in Fig.17, the third bond is longer than the other two bonds and the three bonds are not on the same plane. Therefore, this possibility is excluded. The formation of sp3 hybridization is also excluded because it leads to the fourfold coordination of Ge atom and the Se-Ge-Se bond close to 109.47 o. In Fig.18, we depicted a plausible possibility. In the chalcogen atom, two p electrons are used for covalent bonds and two p electrons remain as lone-pair electrons. The three p orbitals are normal to each other. In the Ge atom, we assume that hybridization is not formed and that two p electrons are used for covalent bonds. In this case, one p orbital is empty. As well known in the formation of ammonium ion NH4+, a coordinated bond is formed using lone-pair electrons and an empty orbital [44]. Applying this concept to the considered situation, a new coordinate bond can be formed between a Ge and a Se atom, which are in different neighboring chains. Usually, a coordinate bond can be equivalent to other covalent bonds. However, in this case, a large chain structure involves the two covalent bonds. In addition, the two lone-pair electrons originally belong to a Se atom and may not be shared completely with the orbital in a Ge atom. Due to these reasons, the coordinate bond cannot be equivalent to Fig. 18. Formation of a new bond, which bridges two Ge-Ch chains. ‘Ch’ represents S or S atom. the two covalent bonds and hence the bond length becomes longer. This accounts for the difference in the bond length depicted in Fig.17. The bond angle, which is approximately 90 o, can also be explained by the formation of the p orbital, which is normal to other two p orbitals. We would expect that there is such an atomic orbital structure not only in c-GeSe, but also in lGeSe(S) and Ge-Se(S) glasses close to Ge 50%. Takebe et al. [14] suggest from the measurements of X-ray photoelectron spectroscopy that the valence of Ge is Ge2+ in c-GeS while it is Ge4+ in c-GeSe2 (α) and that the change of the valence also occurs in the amorphous state when Ge concentration changes from 36% to 43%. The change of the valence is considered to correspond to the change of the number of covalent bonds. Our view on the change of the coordination number is consistent with this experimental result. Origin of the peak at 410 cm-1 The important point in the third bond formation in the double layer is that the bond formation is possible only for a hetero-polar pair. This is completely different from the case of the covalent bond. According to the neutron diffraction results, a homo-polar bonds exist in the l-GeS(Se). The formation of homo-polar bonds is allowed only in the Ge-S(Se) chain composed of covalent bonds. Therefore, a chain, in which Ge atom and S(Se) atom are not alternatively positioned, can be formed. When such chain exists in the system, a different situation from c-GeS(Se) can appear. Suppose that two chains are aligned to each other. Some atoms face homopolar atom. At this portion, the atoms do not bond. As a result, the chains can fail to form a double layer. In the region, the Ge-S(Se) chain is left as a single chain without being involved in the layer. In the amorphous phase, such structure might be quenched. But the structure does not appear in the crystalline phase. This would be a possible structural origin of the peak at 410 cm-1. In order to investigate the possibilities of the presence of single GeS(Se) chain in Ge-S(Se) glasses, it is worth to look at the nature of chalcogen (S, Se, Te) chains. A strong peak is observed at 250 cm-1 in the Raman spectrum of a-Se [45-48]. In crystal selenium, α-Se, which is composed of Se8 rings, the frequency of the A1 mode is 256 cm-1, while in trigonal Se, which is composed of helical chains, the frequency of the A1 mode is 237 cm-1. Although these are close and it is difficult to distinguish them, the peak in a-Se is assigned to the A1-mode (the bond-stretching mode) of Se chain considering the study on the dissolution in CS2 [45]. The peak position of the bond-stretching mode of the selenium chain in a-Se is also confirmed by the calculation using valence force field theory [49] and the recent moleculardynamic simulations [50]. For sulfur, the Raman spectrum changes around the polymerization temperature (159oC), at which the compositional molecules change from S8 rings to the mixture of S8 rings and polymeric chains [51, 52]. Since the S8 rings and the polymeric chains always co-exist above the temperature and the peak from the polymeric chains is close to that from S8 rings, the peak from the polymeric chains is not clear. However, recent precise measurements revealed that the peak position is 461 cm-1 [52]. In trigonal Te, where helical chains are aligned as well as in trigonal Se, the frequency of A1 mode is 120 cm-1 at 295 K [53]. One can refer to these frequencies of the bond-stretching mode of chalcogen chains in order to determine if the frequency of 410 cm-1 is the bond-stretching mode of the Ge-S chain. One important factor to determine the frequency is force constant. Bond length can be a good indicator to compare the magnitude of the force constant (although not always). The Se-Se bond length in a-Se is 2.34 Å [54]. The S-S bond length in liquid sulfur above the polymerization temperature is 2.06 Å [55]. The Te-Te bond length in trigonal Te is 2.835 Å [56]. To see the relationship between the frequency and the bond length, we have plotted these values as shown in Fig. 19. The shorter bond 500 S-S 450 Ge-S -1 Raman peak (cm ) 400 350 300 Se-Se 250 Ge-Se 200 Te-Te 150 100 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 o bond length (A) Fig. 19. Correlation between the position of the Raman peak of the bond-stretching mode of the chalcogenide (chalcogen) chain and the bond length. For details, see text. approximately means the larger force constant. Therefore, the plot indicates that a larger force constant yields in a higher frequency. This is consistent with what one can expect for a simple case of diatomic molecules. Now let us look at the cases of Ge-S chains and Ge-Se chains. For the Ge-S chains, we suppose that the frequency of the bond-stretching mode of Ge-S chain is 410 cm-1. The Ge-S distance is estimated to be 2.14 Å from the results of X- ray diffraction measurements by Fueki et al. [57]. For the Ge-Se system, a peak at 175 cm-1 appears at Ge 35% and grows with increasing Ge concentration [32, 58, 59]. The position is close to the calculated vibrational mode of the ethane-like units in Ge-Se which is 182 cm-1 [21] or 179 cm-1 [29, 60]. However, the concentration variation of the intensity in the Mössbauer spectroscopy results [23] seems to be related to the content of C phase rather than B phase. Therefore, the peak at 175 cm-1 can be regarded as the stretching mode of a Ge-Se single chain. The Ge-Se bond length in a GeSe chain is estimated to be 2.54 Å as listed in Table 1. As one can see in the Figure 19, the data points for Ge-S chains and Ge-Se chains lie on a line between the data points of chalcogen chains.This result seems to support the idea that the peaks at 410 cm-1 and 175 cm-1 indicate the bond-stretching modes of Ge-S single chains, respectively. Finally, we comment on the other possible structural origin of the peak at 410 cm-1. Considering a new structure in liquid GeSe, the presence of the GeS3 or Ge3S subunits suggested by van Roon et al. [38] is one of the possibilities. However, GeS3 can be regarded as a part of the ethane-like S3Ge-Ge-S3 structure. It can also be regarded as a part of the double layer structure in Fig. 11. Therefore, it seems difficult to assert the possibility because the peak at 410 cm-1 only appears in the amorphous phase, not in crystal, and becomes larger at Ge-rich region close to 50%, where the content of B phase composed of the ethane-like units decreases. The S3GeGeS2-GeS3 unit, whose presence in Ge43S57 was suggested by Lucovsky [21], is another candidate [61]. This is a kind of a structural unit developed from the ethane-like units. Such a structural unit would exist in the Ge-rich region. However, the intensity of the peak at 410 cm-1 increases as the Ge composition approaches to 50%. Considering the Ge concentration of the S3Ge-GeS2-GeS3 unit, which is 27%, it seems to be unlikely that these units can be dominant in the system, which is close to Ge 50%. Summary In this work we showed an attractive application possibility for the chalcogenide glasses doped with silver. After the diffusion of silver the chalcogenide backbone is very Ge rich and occurs in a very rigid structure which was not considered so far. To explain what the constitution of the chalcogenide material in which the electrochemical process of non-volatile memory occurs is, we investigate the structure of Ge very rich films by Raman spectroscopy. We proved the appearance of a new vibrational mode at 410 cm-1. Based on a number of structural data published and our results, we suggest a structural model of the Ge very rich films in which the appearance of a double layer structure is envisaged. References [1] R. Symanczyk, et al., Proceedings of the Non-Volatile Memory Technology Symposium, San Diego, CA, 17-1 (2003). [2] M. N. Kozicki, M. Mitkova, M. Park, M. Balakrishnan and C. Gopalan, Superlatt. & Microstr. 34/3-6, 459 (2004). [3] M. T. Kostyushin, E. V. Mikhajlovskaya and P. F. Romanenko, Soviet Phys. Solid State 8, 451 (1966). [4] M. Mitkova, M. N. Kozicki, H. C. Kim, T. L. Alford, J. Non-Cryst. Solids, 338-340, 552 (2004). [5] M. Mitkova, M.N. Kozicki, H. Kim, T. L. Alford, Thin Solid Films, 449, 248 (2004). [6] K. Shimakawa, A. Kolobov and S.R. Elliott, Adv. in Physics, 44 (1995) 475. [7] M. Mitkova, M.N. Kozicki, J. Non-Cryst. Solids 299 – 302,1023 (2002). [8] M. N. Kozicki, M. Mitkova, J. Zhu and M. Park, Microel. Eng. 63,155 (2002). [9] M. N. Kozicki, M. Park M. Mitkova, IEEE Trans. On Nanotechnology 4, 331(2005) [10] T. Kawaguchi, S. Maruno, and S.R. Elliott, J. Appl. Phys., 79, 9096 (1996). [11] M. Mitkova, M.N. Kozicki, H.C. Kim, T.L. Alford, J. Non-Cryst. Sol. 352, 1986 (2006) [12] M. Mitkova, Y. Wang, P. Boolchand, Phys. Rev. Lett., 83, 3848 (1999). [13] M. Balakrishnan, M. N. Kozicki, C. D. Poweleit, S. Bhagat, T. L. Alford, M. Mitkova J. of Non-Cryst. Sol. 353 1454 (2007). [14] H. Takebe, H. Maeda and K. Morinaga, J. Non-Cryst. Solids 291, 14 (2001). [15] G. Lucovsky, F. L. Galeener, R. C. Keezer, R. H. Geils and H. A. Six, Phys. Rev. B 10, 5134 (1974). [16] I. P. Kotsalas and C. Raptis, J. Optoelectron. Adv. Mater. 3, 675 (2001) [17] I. P. Kotsalas and C. Raptis, Phys. Rev. B 64, 125210 (2001). [18] Y. Wang, M. Nakamura, O. Matsuda and K. Murase, J. Non-Cryst. Solids 266-269, 872 (2000). [19] M. Nakamura, O. Matsuda and K. Murase, Phys. Rev. B 57, 10228 (1998). [20] H. Ogura, K. Matsuishi and S. Onari, J. Non-Cryst. Solids 299-302, 973 (2002). [21] G. Lucovsky, J. P. deNeufville and F. L. Galeener, Phys. Rev. B 9, 1591 (1974). [22] G. Lucovsky, R. J. Nemanich, S. A. Solin and R. C. Keezer, Solid State Commun. 17, 1567 (1975). [23] P. Boolchand, J. Grothaus, M. Tenhover, M. A. Hazle and R. K. Grasselli, Phys. Rev. B 33, 5421 (1986). [24] G. Lucovsky, R. J. Nemanich and F. L. Galeener, in Proceedings of the 7th International Conference on Amorphous and Liquid Semiconductors, Edinburgh, Scotland, 1977, edted by W. E. Spear (G. G. Stevenson, Dundee, Scotland, 1977), p.125. [25] P. M. Bridenbaugh, G. P. Espinosa, J. E. Griffiths, J. C. Phillips and J. P. Remeika, Phys. Rev. B 20, 4140 (1979). [26] K. Murase, T. Fukunaga, Y. Tanaka, K. Yakushiji and I. Yunoki, Physica 117B & 118B, 962 (1983). [27] S. Sugai, Phys. Rev. B 35, 1345 (1987). [28] K. Murase, K. Inoue and O. Matsuda, in: Y. Sakurai, Y. Hamakawa, T. Masumoto, K. Shirae and K. Suzuki (Eds.), Current Topics in Amorphous Materials: Science and Technology, Elesevier, Amsterdam, 1993, p.47. [29] K. Jackson, A. Briley, S. Grossman, D. V. Porezag and M. R. Pederson, Phys. Rev. B 60, R14985 (1999). [30] M. Yamaguchi, T. Shibata and K. Tanaka, J. Non-Cryst. Solids 234, 715 (1998). [31] J. D. Wiley, W. J. Buckel and R. L. Schmidt, Phys. Rev. B 13, 2489 (1976). [32] P. Tronc, M. Bensoussan, A. Brenac and G. Errandonea, J. Phys. (Paris) 38, 1493 (1977). [33] P. S. Salmon and I. Petri, J. Phys.: Condens. Matter 15, S1509 (2003). [34] Y. Kawamoto and S. Tsuchihashi, J. Am. Ceram. Soc. 54, 131 (1971). [35] A. Feltz, H. Aust and A. Blayer, J. Non-Cryst. Solids 55, 179 (1983). [36] I. Petri, P. S. Salmon and H. E. Fischer, J. Phys.: Condens. Matter 11, 7051 (1999). [37] S. C. Rowland and, S. Narasimhan and A. Bienenstock, J. Appl. Phys., 43, 2741 (1972). [38] F. H. M. van Roon, C. Massobrio, E. de Wolff and S. W. de Leeuw, J. Chem. Phys. 113, 5425 (2000). [39] For example, P. Atkins, “Physical Chemistry, 6th edition” W. H. Freeman and Company, New York, 2000. [40] N. Kh. Abrikosov, V. F. Bankina, L. V. Poretskaya, L. E. Shudnove, in “Semiconducting II-IV, IV IV-VI, and V-VI Compounds” (Plenum, New York, 1969), Chap.II. [41] H. C. Hsueh, H. Vass, S. J. Clark, G. J. Ackland and J. Crain, Phys. Rev. B 51, 16750 (1995). [42] A. Onodera, I. Sakamoto, Y. Fujii, N. Môri and S. Sugai, Phys. Rev. B 56, 7935 (1997). [43] M. Durandurdu, Phys. Rev. B 72, 144106 (2005). [44] For example, see F. Basolo and R. C. Johnson, “Coordination Chemistry –the Chemistry of Metal Complexes” (W. A. Benjamin, Inc. New York, Amsterdam, 1964). [45] G. Lucovsky, in “The Physics of Selenium and Tellurium”, edited by E. Gerlach and P. Grosse (Springer-Verlag, New York, 1979) p.178. [46] G. Lucovsky, A. Mooradian, W. Taylor, G. B. Wright and R. C. Keezer, Solid State Comm. 5, 113 (1967). [47] S. N. Yannopoulos and K. S. Andrikopoulos, Phys. Rev. B 69, 144206 (2004). [48] S. N. Yannopoulos and K. S. Andrikopoulos, J. Chem. Phys. 121, 4747 (2004). [49] G. Lucovsky and C. K. Wong, Phil. Mag. B 52, 331 (1985). [50] K. Nakamura and A. Ikawa, Phys. Rev. B 67, 104203 (2003). [51] A. T. Ward, J. Phys. Chem. 72, 4133 (1968). [52] A. G. Kalampounias, K. S. Andrikopoulos and S. N. Yannopoulos, J. Chem. Phys. 118, 8460 (2003). [53] A. S. Pine and G. Dresselhaus, Phys. Rev. B 4, 356 (1971). [54] R. Kaplow, T. A. Rowe and B. L. Averbach, Phys. Rev. 168, 1068 (1968). [55] R.Winter, T. Bodensteiner, C. Szornel and P. A. Egelstaff, J. Non-Cryst. Solids 106, 100 (1988). [56] P. Cherin and P. Unger, Acta Cryst. 23, 670 (1967). [57] N. Fueki, T. Usuki, S. Tamaki, H. Okazaki and Y. Waseda, J. Phys. Soc. Jpn. 61, 2814 (1992). [58] N. Kumagai, J. Shirafuji and Y. Inuishi, J. Phys. Soc. Jpn. 42, 1262 (1977). [59] H. Kawamura and M. Matsumura, J. Non-Cryst. Solids 35&36, 1215 (1980). [60] K. Jackson, Phys. Stat. Sol. (b) 217, 293 (2000). [61] C. Raptis, private communication.