GT2010-22054

advertisement

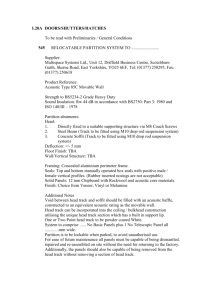

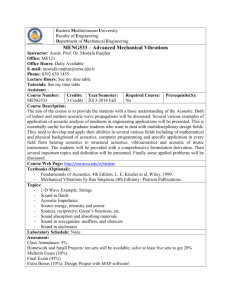

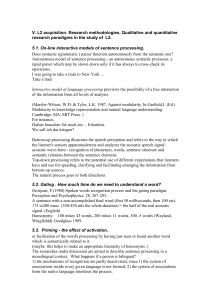

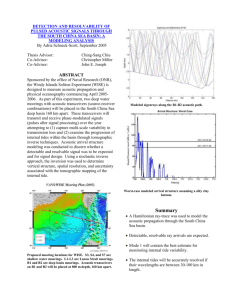

Proceedings of ASME Turbo Expo 2010: Power for Land, Sea and Air GT2010 June 14-18, 2010, Glasgow, UK GT2010-22054 EXPERIMENTAL STUDY OF ACOUSTIC RESONANCES IN THE SIDE CAVITIES OF A HIGH-PRESSURE CENTRIFUGAL COMPRESSOR EXCITED BY ROTOR/STATOR INTERACTION Nico Petry Friedrich Karl Benra University of Duisburg-Essen Institute of Energy and Environmental Engineering - Turbomachinery Duisburg, 47048 Germany Email: nico.petry@siemens.com ABSTRACT Sven Koenig Energy Sector Oil and Gas Division Siemens AG Duisburg, 47053 Germany Email: koenig.sven@siemens.com viations between predicted (simulated) and measured acoustic eigenfrequencies would be the result. Under unfavorable conditions aerodynamic and aeroacoustic excitation mechanisms may lead to fatigue failures of centrifugal compressor impellers. The mechanisms for consideration are, for example, the arising pressure patterns due to rotor/stator interactions, the so-called Tyler/Sofrin modes, or acoustic resonances in the compressor housing. In a research program, a high-pressure radial compressor has been equipped with a multiplicity of sensors to investigate the excitation and interaction mechanisms in a complete centrifugal compressor stage. The current paper deals with the experimental detection of acoustic resonances in the compressor side cavities and the excitation of these acoustic eigenmodes due to Tyler/Sofrin modes. In this context the test rig and the installed instrumentation are briefly described. The methods of measuring as well as the analyzing techniques for detecting acoustic resonances and evaluating the measurements are presented. In addition, acoustic eigenmodes have been calculated by the finite-element method for the representative numerical test rig parameters. Results are presented and compared to the experimental findings. The accomplished experiments are the first available in open literature showing that the fluid core rotation in the compressor side cavities plays a crucial role for the prediction of the acoustic eigenfrequencies with respect to the rotor frame of reference. Without taking into account the effect of fluid rotation, large de- NOMENCLATURE VARIABLES a speed of sound B number of impeller blades f frequency f∗ dimensionless frequency related to shaft frequency l axial order (number of axial nodes) m circumferential order (number of diametral nodes) n rotation speed n∗ normalized rotation speed q radial order (number of node circles) T length of time V number of stator vanes x circumferential distance β swirl factor ω angular frequency Ψ cross-correlation function τ time shift Θ phase angle INDICES ac acoustic mode exp experiment 1 c 2010 by ASME Copyright FEM TS ph res shaft simu st swirl Finite elements method Tyler/Sofrin phase resonance shaft simulation structure swirling flow aero-elastic self-excitation. Ziada et al. [15] studied an acoustic resonance in the inlet scroll of a turbocompressor. They delivered a root cause for high vibration levels, triggered by the interaction between vortex shedding and a standing wave in the ring chamber. Franke et al. [16] investigated rotor/stator interactions and the resulting mode shapes in a reversible radial pump turbine. Eisinger [17] and Eisinger and Sullivan [18] presented a basic approach to evaluate critical resonance conditions caused by acoustic modes. Now, there is less literature concerning acoustic resonances in radial compressors. Actually, to the authors’ knowledge, experimental investigation about acoustic eigenmodes in a high-pressure radial compressor do not exist. This paper is part of an extended in-house research project to gain insight into the excitation and interaction mechanisms between structural components as well as hydrodynamic and acoustic phenomena in a high-pressure radial compressor. Petry et al. [19] experimentally investigated the Tyler/Sofrin modes and the excitation of the impeller disk due to these pressure patterns. One result was that the Tyler/Sofrin modes themselves did not lead to fatigue failures for the given test rig parameters. In the same year König [20] published a theoretical study about acoustic eigenmodes in centrifugal compressors. For a comparison of 2D-analytical and 3D-FEM calculations the entire compressor test stage described later in this paper was modeled. It was found that among all calculated eigenmodes (partially expanding over the complete compressor housing) local modes exist, which are bounded to the side cavities. The shape and the frequencies of these local side cavity modes are nearly independent of the modeling of the remaining domain. For a reliable calculation of these modes the modeling of the entire compressor stage is not necessary; an appropriate domain comprising both side cavities and the impeller outlet region is adequate. These locally bounded modes are characterized by an axial node between the two cavities, resulting in a 180◦ phase shift from one cavity to the other. This leads to locally fluctuating net axial forces on the impeller. For more details on this investigation the authors refer the reader to König [20]. In a further paper König et al. [21] present a possible root cause for impeller failures including two case studies. This paper focuses on the experimental detection of acoustic eigenmodes excited by rotor/stator interaction and the comparison of theoretical and experimental results. When talking about acoustic eigenmodes the locally bounded side cavity modes are denoted. The excitation of structural components due to the excited acoustic modes is not the object of this paper. Due to the large differences between calculated acoustic and structural eigenfrequencies, no coupling between acoustic and structural modes is expected to occur for the given test rig parameters. On the assumption that coupling takes place, the coupled system will exhibit two eigenfrequencies, one slightly higher and one slightly lower than the uncoupled eigenfrequencies [22]. The paper is divided as follows: The first part describes the test rig and the installed instrumentation. The second part treats the theoretical INTRODUCTION With the development of higher performance compressors acoustic phenomena in turbomachinery move more and more into the scope of research projects. Due to stronger blade-rowinteractions and the associated increasing noise emission, effective methods for noise reduction are required. Furthermore, due to the high pressure levels in modern compressors excitation sources like acoustic modes obtain an increasing relevance with respect to fatigue failures of structural components of the turbomachine. Turbomachinery causes broadband noise by stochastic turbulent flow phenomena as well as discrete tones caused by the rotor/stator interaction and vortex shedding from blades and other flow obstructions. Among others Ffowcs Williams and Hawkins [1], Lowson [2] and Neise [3] comprehensively described the different sources of sound in rotating machinery. In their milestone paper in 1961 Tyler and Sofrin [4] discussed rotor/stator interaction and the resulting spinning modes for an axial flow compressor. The study was focused on noise; however, the rotating pressure patterns resulting from the interaction between rotating and stationary components (referred to as Tyler/Sofrin modes) may also constitute a strong excitation source - characterized by the blade passing frequency and harmonics. Based on those results Ehrich [5] focused on natural acoustic frequencies of two-dimensional annular cavities, including the influence of axial flow and flow rotation. Following those fundamental studies, a variety of investigations for axial turbomachines have been carried out during the past decades, with special focus on aircraft engines and noise. Mode measurements in the inlet of a turbofan engine were presented by Joppa [6], and it was found that even the interaction between rotating and stationary components well away from each other may lead to the generation of Tyler/Sofrin modes. Further studies on acoustic modes in axial compressors were carried out by Camp [7], Cooper and Peake [8], Enghardt et al. [9], Tsuchiya et al. [10], Cooper et al. [11], and Hellmich and Seume [12]. Though many studies exist for axial machines, very few publications are available for centrifugal compressors. One case, where a compressor failure was reported, can be found in the two-part paper by Eckert [13] and Ni [14]. According to their analysis the shroud disk of a radial fan impeller failed due to an 2 c 2010 by ASME Copyright Table 1. TEST RIG PARAMETERS number of impeller blades B 17 number of diffuser vanes VLSD 10 number of inlet guide vanes VIGV 18 number of return guide vanes VRGV 22 outer diameter of the impeller D2 350 mm max. speed of rotation nmax 15900 rpm 1 2 2 LSD 2 KuSC1,2,3 RGV 2 KuIm2 1 2 KuIm1 4 considerations comprising some theory about rotor/stator interaction and the results of the acoustic eigenmodes calculation via the finite element method (FEM). Further on, the established excitation model describing the excitation of acoustic modes in the side cavities by Tyler/Sofrin modes is introduced. The third part of the paper contains information about the experiments. The method of measuring and analysis as well as experimental results are presented in detail. impeller No. Description 1 pressure transducers (rotating) 2 pressure transducers (stationary) 3 strain gauges (rotating) 4 vibration sensor 3 1** * Cavity, prepared for pressure transducer 3 1 Figure 1. OVERVIEW OF THE FAST-RESPONSE SENSORS IN THE TEST RIG The test rig is composed of a centrifugal compressor, which is operated in a closed loop to realize high pressures and therefore high excitation forces. The rotation speed of the compressor can be continuously adjusted between 0 rpm and 15, 900 rpm. Before starting the compressor, the whole test rig is filled with nitrogen from a pressure tank. The pressure in the test rig can be adjusted between 1.4 bar and 40 bar, which corresponds to the suction pressure after starting the compressor. Unavoidable leakages in the circuit are compensated by continuously adding the leakage mass flow, so that the suction side pressure remains constant. A heat exchanger is utilized in order to keep the stage inlet temperature constant. The construction of the compressor complies with one stage of a multi-stage single shaft compressor, and exists of inlet guide vanes (IGV), a typical high-pressure closed 2D-impeller, a vaned low solidity diffuser (LSD) and return guide vanes (RGV). The relevant test rig parameters are given in table 1. A sectional drawing of the compressor is given in figure 1. To detect the different possible excitation mechanisms and the vibrations of the impeller disk, the test rig is equipped with a multiplicity of fast-response pressure transducers, strain gauges and vibration transducers on the stationary side (compressor housing), as well as on the rotating side (cover disk of the impeller). The measuring positions of the different sensors are schematically depicted in figure 1. A more detailed description of the test rig, the instrumentation and the telemetric system can be found in [19]. In the following, the sensors which are of particular importance for the analysis presented in this paper are described. On the cover disk of the impeller two pressure trans- COMPRESSOR ducers are flush-mounted to detect possible pressure fluctuations in the shroud side cavity with respect to the rotor frame of reference. These pressure transducers are labeled as KuIm1 and KuIm2 (Ku: Kulite, Im: Impeller). Sensor KuIm1 is located near the outer diameter of the impeller on a radius r/r2 = 0.92 and KuIm2 near the inner diameter on a radius r/r2 = 0.63, respectively. The angle between both transducers is 1.26 times blade pitch. In addition three more pressure transducers labeled as KuSC1,2,3 (Ku: Kulite, SC: Side cavity) measure the pressure fluctuations in the shroud side cavity with respect to the stationary frame of reference. All three have the same radial position (r/r2 = 0.97). The circumferential distances between these transducers are 1.37 and 6.46 times blade pitch. All pressure transducers have been calibrated by the manufacturers. The calibration coefficients have been proofed by gradually increasing the pressure in the non-operating test rig. Based on these tests an uncertainty of about 10% is expected for the measured pressure fluctuation. The eigenfrequencies of all dynamic pressure transducers are higher than 150 kHz. This value is well above the frequencies of interest, a maximum of 20 kHz. Therefore, uncertainties for the measured frequencies are negligible. To determine the magnitude of spurious vibration amplitudes in the pressure signals due to impeller vibration, preliminary tests have been accomplished. The signals of the pressure transducers as well as the signals of the strain gauges were recorded, while the impeller was excited by an impact hammer. 3 c 2010 by ASME Copyright Table 2. The perturbing contribution in the pressure signals strongly depend on the position of the excitation, the position of the pressure transducer, the strength of excitation and the excited mode shape of the structure. Thus, an accurate declaration of the arising mistake depending on the mentioned factors is hard to give. However, the order of magnitude of these spurious contributions has been estimated to be marginal and negligible, which coincides with the manufacture information. The signals are transmitted from the rotating into the stationary system by means of a 10-channel PCM (Pulse Code Modulation) telemetry system. The system is capable of simultaneously transmitting 10 complete measuring channels. All applied channels are simultaneously recorded by the measurement acquisition software. The sampling frequency is 51.2 kHz in order to resolve frequencies up to 20 kHz. The evaluation and analysis of the R measured data is accomplished with the use of the MATLAB software. To determine the average temperature in the side cavities of the compressor seven thermocouples have been installed there. In addition, there is a multiplicity of stationary (temporal low resolution) sensors to calculate the operating point of the compressor. EXAMPLE: THREE DIFFERENT TSMs WITH THE SAME FREQUENCY WITH RESPECT TO THE ROTOR FRAME OF REFERENCE ki j mTS S fTS R fTS const. 1 −15 17 · fshaft 32 · fshaft const. 2 2 34 · fshaft 32 · fshaft const. 3 19 51 · fshaft 32 · fshaft tor vanes Vi . The circumferential order can be calculated for the given test rig parameters by 3 mTS = j · B + ∑ ki ·Vi , (1) i=1 with the integer values j = 1, 2, 3, ... (blade harmonics) and ki = ... − 3, −2, −1, 0, 1, 2, 3... (vane harmonics). The frequencies with respect to the stationary frame of reference of all those modes are characterized by the blade passing frequency (BPF, j = 1) or harmonics ( j > 1): THEORETICAL CONSIDERATIONS This chapter contains some basics about rotor/stator interaction, the results of the acoustic eigenmode calculation via the finite element method (FEM) as well as an introduction of the model describing the excitation of acoustic modes by rotor/stator interaction. For the description of the excitation model it is necessary to describe frequencies with respect to different frames of reference. These frames of reference are the stationary reference frame, the rotor reference frame, rotating with rotor speed and the acoustic reference frame, which is described later in this paper. A superscript capital letter denotes the particular reference system (S: stationary, A: acoustic and R: rotor frame of reference). The shaft frequency fshaft is always related to the stationS ary reference frame: fshaft = fshaft . Although it has been noted in the past that integer values for j and k higher than three are practically not relevant [23], a multiplicity of different pressure patterns with the same frequency with respect to the stationary frame of reference remain (all pressure patterns exhibit the BPF or harmonics). The frequencies of the pressure patterns with respect to the rotor frame of reference are given by the equation Rotor/stator interaction In their milestone paper in 1961 Tyler and Sofrin [4] firstly investigated rotor/stator interaction and the resulting spinning modes (rotating pressure patterns) in an axial flow compressor. Petry et al. [19] experimentally validated that the basic considerations of Tyler and Sofrin are also applicable for radial compressors. The results can be summarized as follows: Due to the rotor/stator interaction a multiplicity of different pressure patterns called Tyler/Sofrin modes (TSM) rotate in the test rig compressor. The number of lobes (circumferential order mTS ) of these modes is a function of the impeller blades B and different sta- This equation is not only valid for Tyler/Sofrin modes but for all kinds of rotating pressure pattern and will be used later in this paper for the transformation of acoustic frequencies from the stationary into the rotor frame. Therefore, the author omits the indices of the variables f and m. With the before-mentioned assumption ( j < 4), it follows that, compared to the stationary reference frame, only three pressure patterns exhibit the same frequency with respect to the rotor frame of reference. An example is given in table 2. Therefore, as shown later in this paper, the most significant experimental findings are achieved by analyzing the signals of the rotating pressure transducers. S fTS = j · B · fshaft . f R = f S − m · fshaft with equ. (2) ⇐⇒ 4 (2) (3) f R = ( j · B − m) · fshaft. c 2010 by ASME Copyright Figure 2. ACOUSTIC EIGENMODE mac ‘positive‘ high pressure ‘positive‘ high pressure pressure node pressure node ‘negative‘ high pressure ‘negative‘ high pressure = 5: PRESSURE DISTRIBU- Figure 4. TION ON THE IMPELLER COVER DISK pressure node mac = 18: PRESSURE DISTRI- pressure node ‘positive‘ high pressure KuSC ‘positive‘ high pressure KuIm2 KuIm2 KuIm1 KuIm1 KuSC pressure node hub sided side cavity ‘negative‘ high pressure ACOUSTIC EIGENMODE mac pressure node shroud sided side cavity shroud sided side cavity hub sided side cavity ACOUSTIC EIGENMODE BUTION ON THE IMPELLER COVER DISK = 5: PRESSURE DISTRIBU- ‘negative‘ high pressure = 18: TION IN THE MERIDIAN SECTION Figure 5. ACOUSTIC EIGENMODE mac BUTION IN THE MERIDIAN SECTION Acoustic eigenmodes calculation Detailed 3D FEM calculations have been carried out with a commercial acoustics tool (SYSNOISE) to calculate the acoustic side cavity modes for the geometry of the test rig compressor. The computations are solved in the frequency domain and are based on the solution of the Helmholtz equation with the Block Lanczos method. Different computational domains were used to assess the influence of the boundary conditions at the cavity interfaces. The reference computational domain covers both side cavities and the impeller outlet region. It was calculated that for a reliable calculation of the locally bounded side cavity modes the modeling of the entire compressor stage is not necessary. The side cavity modes are characterized by an axial node in the impeller region between both side cavities, resulting in a 180◦ phase shift from one cav- ity to the other. Actually, other modes with no axial node also exist, but are not bounded to the side cavities. It is important to mention that if the entire compressor stage is modeled, thousands of acoustic modes are calculated in a frequency range up to 10000 Hz. These modes shall be more or less detectable in the experiments. Obviously, a correlation of all detected pressure peaks in the experiments and the calculated acoustic modes is not possible. Thus, the acoustic modes which are locally bounded to the side cavities with zero node circles are in the focus of this paper. For more details about the numerical setup see König [20]. In the following, two acoustic side cavity modes are introduced with respect to their shape and frequency. The positions of the pressure transducers available in the experiments are marked in the contour plots of the modes providing information about Figure 3. 5 PRESSURE DISTRI- c 2010 by ASME Copyright dia high pressure me tral the exciting TSM has to equal the number of diameter nodal lines mst of the corresponding structural mode shape. Due to the above-mentioned similarity of acoustic and structural modes, an excitation of acoustic modes due to TSMs is likely to occur and an establishment of analog resonance conditions for acoustic modes seems appropriate: An excitation of an acoustic mode takes place, if nod e al dia neg. displacement a) structural mode tr me no de pos. displacement low pressure 1. the frequency of the TSM is equal to the acoustic eigenfrequency with respect to the same frame of reference2 AND 2. the circumferential order of the TSM equals the circumferential order (number of diametral nodes) of the acoustic mode (mTS = mac ). b) acoustic mode Figure 6. a) STRUCTURAL EIGENMODE mst = 3: VIEW ONTO THE COVER DISK OF THE IMPELLER b) ACOUSTIC EIGENMODE: PRESSURE DISTRIBUTION ON THE COVER DISK OF THE IMPELLER mac = 3 The first enumerated condition will be labeled as the first and the second enumerated condition as the second resonance condition, respectively. For the comparison of acoustic eigenfrequencies and the frequencies of excitation, the swirling flow in the side cavities of centrifugal compressors plays a crucial role. It is common practice to think of the fluid in the side cavities of centrifugal turbo-machines as a rigid body rotation (imagine a rotating disk) with a constant angular velocity. However, in reality, due to the boundary layers and through-flow of the cavities, this is only a crude approximation. Nevertheless, it is usually a good guess to assume that the fluid-core angular velocity is half S the angular velocity of the shaft: ωswirl ≈ 0.5 · ωshaft (compare e.g. Schlichting [24]). In the following, the fluid-core angular velocity will be expressed by the dimensionless swirl factor β which is given in the stationary frame by the detectability of the acoustic modes by the different sensors. Figures 2 and 3 depict the acoustic eigenmode with mac = 5. The pressure distribution on the cover disk of the impeller and in the meridian section are shown, respectively. The positions of the pressure transducers are labeled including the introduced notation. The acoustic mode exhibits no node circles (qac = 0) and one axial node (lac = 1), which is clearly visible in the meridian section. The frequency with respect to the acoustic frame of reference is 2406 Hz1 . In the same manner the figures 4 and 5 show the acoustic eigenmode with mac = 18. Similarly, the acoustic mode exhibits no node circles (qac = 0) and one axial node (lac = 1). The frequency with respect to the acoustic frame of reference is 6522 Hz. By comparison of figure 2 and figure 4 it becomes obvious that the pressure maxima move to the outer diameter with a higher circumferential order, resulting in the fact that only the transducer KuIm1 is able to detect the higher order acoustic modes; KuIm2 is located in a pressure node (green area). In contrast, the acoustic mode mac = 5 shall be detectable by both sensors KuIm1 and KuIm2. βS = acoustic reference frame is describe in the next chapter and βR = βS −1 (4) in the rotor frame, respectively. When talking about acoustic modes in the side cavities of centrifugal compressors and if the model of a fluid rigid body rotation is adopted (the fluid roS ), the rotating fluid core will constitute the reftates with ωswirl erence system of the acoustic mode. Within this acoustic reference system (superscript A) the acoustic modes are characterized A by their eigenfrequencies fac (results of the eigenmodes calculation). These are the frequencies that an observer rotating with the swirling fluid core would experience. In this rotating frame of reference the acoustic mode may be thought of as a spinning pressure pattern rotating with the phase velocity Excitation of acoustic modes by rotor/stator interaction - theoretical model The emergence of the calculated acoustic eigenmodes and the structural eigenmodes of the impeller structure is similar (compare figure 6). Both the impeller structure and the gas in the side cavities are continuous and geometrically similar. As a result, the acoustic eigenmodes can be characterized in the same manner as structural eigenmodes, in detail by the number of axial lac , circumferential mac and radial nodes qac . Petry et al. [19] showed that an excitation of the impeller structure due to TSMs takes place, when two conditions are simultaneously achieved: The frequency of excitation has to equal a structural eigenfrequency (with respect to the same frame of reference) and the circumferential order mTS of 1 The S fS ωswirl = swirl , ωshaft fshaft A ωph,ac = A 2π · fac . mac (5) 2 For a resonance rise the frequencies have not to be exactly equal. Even if the frequencies are close to each other, the acoustic mode is detectable. However, the maximum amplitude is reached, when they are identical. 6 c 2010 by ASME Copyright For positive mac the mode rotates in the same direction as the impeller, while for negative mac it is counter-rotating. In the stationary frame of reference the circumferential phase velocity of an acoustic mode is given by the sum of the phase velocity of the acoustic mode and the angular velocity of the rotating fluid core: is an integer multiple of the shaft frequency fshaft (compare equ. (2)). Accordingly, a dimensionless frequency S A S ωph,ac = ωph,ac + ωswirl . is introduced. In the case of an integer value of the dimensionless frequency the terms order or rotation speed harmonic will be used. With integer values for j and |ki | up to three in equation (1) and the different numbers of stator vanes in the test rig (VLSD = 10, VRGV = 22, VIGV = 18) nearly all TSMs are possible for the blade/vane count at hand (compare equ. (1)). For j = 1 and j = 3 the circumferential order mTS is uneven. For j = 2 the order mTS is even. Due to this fact, the second resonance condition is achieved for all uneven modes, if the excitation frequency equals the BPF or three times BPF (see equation (2), j is uneven) and for all even modes, if the excitation frequency is two times BPF. f∗ = (6) The transformation into the rotor frame of reference leads to: R A S ωph,ac = ωph,ac + ωswirl − ωshaft . (7) To evaluate the eigenfrequency of an acoustic mode with respect to the stationary and rotor frame of reference the phase velocities must be multiplied by the corresponding circumferential mode order and divided by 2· π . With equations (4) and (5) one obtains: S A fac = fac + mac · S ωswirl A S A = fac + mac · fswirl = fac + mac · β S · fshaft , 2π (8) (12) 90 and excited by BPF excited by 2 ⋅ BPF excited by 3 ⋅ BPF 80 R A fac = fac + mac · (β S − 1) · fshaft , f fshaft 70 (9) 60 50 S fac with equ. (2), (6) ⇐⇒ = S fTS 40 30 20 0 0.5 (10) Figure 7. A fac + mac · β S · fshaft = j · B · fshaft . A s fac s · fshaft,res = 60 · . min min j · B − mac · β S mac = 5 ns, res = 9956 rpm 10 1 rotation speed nshaft in rpm 1.5 4 x 10 OVERVIEW OF ALL ACOUSTIC RESONANCES (qac = 0) EXCITED BY TSM - b) In words: The first resonance condition is achieved, if an acoustic eigenfrequency with respect to the stationary frame of reference equals the BPF or harmonics. With equation (10) the rotation speeds achieving the first resonance condition are calculated by nshaft,res = 60 mac = −18 ns, res = 9101 rpm f*R ac respectively. To the authors’ knowledge other studies about acoustic resonances in the side cavities of centrifugal compressors neglect the influence of the swirl factor, which will lead to large deviations, especially for high mode orders mac . In the following, it is theoretically investigated at what rotation speeds the resonance conditions are achieved. The condition of frequency equality (first resonance condition) of the exciting TSM and the acoustic mode can be described in general by The scope of this paper lies in the excitation of acoustic side cavity modes with zero node circles qac = 0. An overview of all these modes being possibly excited in the rotation speed range of the compressor according to the presented excitation model is obtained by plotting the function ns,res derived in equation (11) for a fixed speed of sound. This plot is depicted in figure 7. A swirl factor of β S = 0.5 is assumed. For an easy comparison of experimental and theoretical results the mode order mac is converted to the corresponding frequency of the acoustic mode with respect to the rotor frame of reference. This is accomplished using equation (11) In the event of such an acoustic resonance, the acoustic mode exhibits the same frequency as the TSM and thus, the frequency 7 c 2010 by ASME Copyright (3), which is applicable for all type of spinning pressure patterns, thus, for acoustic modes, too. In general, curves with a positive and negative slope correspond to negative and positive circumferential mode orders, respectively. Modes excited by the BPF are marked with circle. Modes excited by two and three times BPF are marked with stars and squares, respectively. The two modes presented one chapter before are exemplarily picked out in figure 7: The acoustic mode mac = −18 excited by two times BPF exhibits a dimensionless frequency with respect to the rotor frame of reference of 52. Therefore, the resonance peak of the acoustic mode is expected to appear in the 34th speed harmonic of the stationary pressure transducer signals and in the 52nd speed harmonic of the rotating pressure transducer signals. The acoustic mode mac = 5 excited by the BPF exhibits a dimensionless frequency with respect to the rotor frame of reference of 12. Consequently, the corresponding pressure peaks are expected to occur in the 17th and 12th speed harmonic of the stationary and rotating pressure transducer signals, respectively. chronous resampling procedure non-rotation speed proportional signal components vanish. The advantage of this data processing method is the sharpness of rotation speed proportional signal components in the frequency domain. Fourier transformation and harmonic analysis The resampled data is Short Time Fourier transformed (STFT). The van-Hann window is used for the windowing to minimize aliasing effects. The length of the windows corresponds to 200 rotations of the rotor. The overlap of two adjacent windows is 75% of the window length to avoid a loss of information. The resultant Fourier coefficients compose a matrix F. The number of rows and columns equals the number of time windows and dimensionless frequencies f ∗ , respectively3. In other words, each row contains the Fourier coefficients for a certain time range, which in turn is dedicated to a certain rotation speed range of the rotor (the well known power or amplitude spectrum), and each column of the matrix contains the temporal characteristic of a certain dimensionless frequency. Due to the fact that in case of resonance the acoustic eigenfrequencies equal an integer multiple of the shaft frequency, this matrix is reduced to a matrix only containing the integer dimensionless frequencies - the rotation speed harmonics. Each column of this reduced matrix, representing the temporal characteristic of a certain rotation speed harmonic, can be plotted over time or more reasonably over the rotation speed. These plots are labeled by the author as harmonic plots. The pressure amplitude is normalized to the maximal occurring value of each rotation speed harmonic. Several of these plots combined in one three-dimensional or color-coded plot is labeled as harmonic spectrogram. EXPERIMENT This chapter of the paper comprises the method of measuring and analysis as well as experimental results. Method of measuring A number of experimental investigations have been carried out on the centrifugal compressor described before to detect the different unsteady phenomena. The measurement data upon which the results presented in this paper are based were obtained by recording the different signals while the compressor rotation speed was slowly and linearly increased from 5, 000 rpm to 15, 000 rpm with different constant positions of the throttle valve (flow resistance curves). The shaft acceleration is very slow to minimize any influences on the measured signals. It should be pointed out that below 5, 000 rpm the pressure fluctuations are marginal. The conducted experiments for different throttle valve positions are labeled as run-ups. The suction pressure is 20 bar. Normalization of rotation speed With increasing rotation speed the temperature in the compressor and therewith in the side cavities rises. To permit comparison of experimental and simulation results with respect to acoustic phenomena the speed of sound characteristic over the rotation speed a(n) in the side cavities is calculated for the complete rotation speed range (5, 000 rpm − 15, 000 rpm) based on the measuring values of temperature and pressure4. By means of this speed of sound characteristic the rotation speed trend of a run-up is normalized to a speed of sound used in the simulation in the following way: Method of analysis In this chapter the different steps of data analysis and data reduction are described. n∗ (t) = n(t) · Order tracking Firstly, the recorded data are synchronously resampled with the rotor speed. This method is often labeled as order tracking. The resampled data exhibit a certain number of discrete values for each rotor revolution independent of the rotation speed. The number of discrete values per revolution was set to 200, to resolve frequencies up to 100 times shaft frequency. The tracked signal may be plotted over the number of completed rotations instead of over time. Due to the rotor syn- asimu . a(n(t)) (13) 3 Due to the procedure of order tracking the frequencies provided by the Fourier transformation are related to the rotor speed. Thus, the obtained frequencies are the dimensionless frequencies introduced in equation (12). 4 For a constant suction-side pressure and temperature as well as for a certain gas the speed of sound is only a function of the compressor operating point. 8 c 2010 by ASME Copyright the two acoustic modes mac = −18 and mac = 5 are exemplarily demonstrated. The calculated rotation speeds of resonance for these two modes taking into account the fluid core rotation or not are summarized in table 3. Further on, the table comprises the dimensionless frequencies of both modes in case of resonance with respect to the stationary and rotor frame of reference. The underlying experimental data is obtained by a run-up at the choke line of the compressor. Cross-correletion and coherence To determine the circumferential order mac of an acoustic mode the phase spectrum of the cross-correletion function of the signals of the sensors KuIm1 and KuIm2 (compare fig. 1) is calculated for the time range T in which the acoustic resonance is excited. The cross-correlation function is defined as follows: +T Z /2 1 T →∞ T Ψ (τ ) = lim s1 (t) · s2 (t + τ )dt, (14) Table 3. EXAMPLES OF ACOUSTIC RESONANCES −T /2 where s1 and s2 are the signals of the two sensors in a certain time range T . The transformation of this function into the frequency domain provides the phase spectrum, which in turn provides the information about the phase angles of the order of in∗ terest fexample . From the phase angle the circumferential order of an acoustic mode mac can be calculated by mac = ∗ Θ ( fexample ) x , mac excited by A fac,simu in Hz ns,res in rpm (β S = 0.5) ns,res in rpm (β S = 0.0) ∗S fac ∗R fac -18 2 · BPF 6522 9101 11510 34 52 5 1 · BPF 2406 9956 8492 17 12 Figure 8 depicts the 52nd harmonic diagram of the transducers KuIm1 and KuIm2, as well as the 34th harmonic diagram of the stationary mounted sensor KuSC1. These are the rotor speed harmonics in which the resonance peak of the acoustic mode mac = −18 is expected to occur (see figure 7). The 34th harmonic diagrams of KuSC2 and 3 do not provide further information with respect to the presented analysis and are omitted. All plots are normalized to the maximum value occurring in the harmonic diagram of KuIm1. A peak at a rotation speed of 9115 rpm can be clearly seen in figure 8 a). The rotation speed of resonance is near the predicted one for mac = −18, on condition that the core rotation in the side cavities is included. Equation (9) provides the acoustic eigenfrequency with respect to the acoustic frame of reference to f ac,exp A = 6532 Hz, which is only marginally higher than the calculated one (compare table 3, rel. deviation: 0.15%). The assumed value for the swirl factor seems to fit very well. Neglecting the fluid rotation (β S = 0) in the side cavities leads to a frequency of f ac,exp A = 5165 Hz, and a large relative deviation of −20.8% based on the calculated value. This demonstrates the crucial importance of considering the fluid rotation. Further on, the peak is not detectable in the pressure signal of KuIm2 (see fig. 8b). This complies with the theory - compare figure 5: KuIm2 is located in a pressure node (green area). In the third place, the corresponding peak in the stationary frame of reference appears in the 34th harmonic diagram of the pressure transducers KuSC1 - KuSC3 (see for example fig. 8c). From the equations (3) and (12) the circumferential order follows to (15) where x and Θ are the geometrical angle between the two sensors and the phase angle, respectively. This equation is only valid on condition that the circumferential distance of the pressure transducers is smaller than the distance between two adjacent pressure lobes of the acoustic mode. In other words: This equation is not definite. Therefore, this analyzing method will not serve evidence but indications. Further on, this equation is only valid, if exactly one pressure pattern with a certain frequency exists. In case of two or more pressure patterns exhibiting the same frequency this equation leads only to reliable results if the pressure pattern of interest is the dominant one. Therefore, this method of analysis is only used if an acoustic mode is excited in resonance and the acoustic mode is the dominant mode. Experimental results To verify the established excitation model harmonic plots of all rotation speed harmonics up to 90 of the sensors KuIm1 and KuIm2 were created. In the stationary frame of reference the frequencies of interest are the BPF and harmonics. Accordingly, the harmonic plots of the 17th, 34th and 51th speed harmonic of the sensors KuSC1-3 are generated (see equ. (2), j = 1, 2, 3). Peaks located in these plots were allocated to the calculated acoustic eigenmodes as far as possible. Due to the fact that theoretically thousands of these modes are thinkable, and may possibly be excited, this analysis is limited to acoustic modes with zero node circles, which are regionally bounded to the side cavities. To avoid going beyond the scope of this paper, detailed analysis of ∗S ∗R mac = fac − fac = 34 − 52 = −18. 9 c 2010 by ASME Copyright KuIm1 − 52th rotation speed harmonic KuIm1 − 12th rotation speed harmonic 1 1 a) 0.5 6000 7000 8000 9000 0 5000 10000 11000 12000 13000 normalized pressure normalized pressure 0 5000 KuIm2 − 52th rotation speed harmonic 1 b) 0.5 0 5000 6000 7000 8000 9000 a) 0.5 10000 11000 12000 13000 6000 7000 8000 9000 10000 11000 12000 13000 KuIm2 − 12th rotation speed harmonic 1 b) 0.5 0 5000 6000 KuSC1 − 34th rotation speed harmonic 7000 8000 9000 10000 11000 12000 13000 KuSC1 − 17th rotation speed harmonic 10 c) 2 0 5000 Figure 8. 6000 0 5000 7000 8000 9000 10000 11000 12000 13000 normalized rotation speed n* in rpm HARMONIC PLOTS c) 5 OF THE 52nd SPEED HARMONIC Figure 9. 6000 7000 8000 9000 10000 11000 12000 13000 normalized rotation speed n* in rpm HARMONIC PLOTS OF THE 12th SPEED HARMONIC OF KuIm1 AND KuIm2 AS WELL AS THE 34th SPEED HARMONIC OF OF KuIm1 AND KuIm2 AS WELL AS THE 17th SPEED HARMONIC OF KuSC1 KuSC1 −5.94% (β S = 0.5) and 10.27% (β S = 0.0). Without taking into account the fluid rotation a larger deviation occurs. Nevertheless, an assumed swirl factor of 0.5 is not as appropriate as for the acoustic mode mac = −18, resulting in larger deviations. The swirl factor is a function of the compressor operating point and therewith of the rotation speed (for explanations see the next paragraph). Due to the fact that the rotation speeds of resonance of the acoustic mode mac = 5 and mac = −18 differ, a change of the swirl factor is likely to occur. Further on, the swirl factor is normally not constant over the radial extension of the side cavities [25]. Therefore, for acoustic modes with maxima extending over the whole side cavity in radial direction - like the acoustic mode mac = 5 - another swirl factor may be valid than for acoustic modes with maxima extending only over a small part of the side cavities at the outer diameter - like the acoustic mode mac = −18 (see fig. 2 and 4). Further experiments are necessary for more precise statements about the swirl factor. The phase analysis provides a phase angle between the signals of KuIm1 and KuIm2 of 6.358 times blade pitch which leads to a circumferential order of 5.043 (see equ. (15)). This confirms that the peak can be assigned to the acoustic mode mac = 5. Contrary to the acoustic mode mac = −18, the peak is detectable in the signals of KuIm1 and KuIm2 (see fig. 9), which is in agreement with the results of the finite element analysis (compare fig. 3). The corresponding peak in the stationary frame of reference can be found in the 17th speed harmonic of all stationary mounted pressure transducers in the side cavities (e.g. fig. 9c). Analog to the previous paragraph the circumferential order follows to An additional phase analysis to confirm the circumferential order is not possible due to the fact that the acoustic mode is only detectable in the signal of KuIm1. Nevertheless, the three analysis steps mentioned before definitely validate that the reason for the peak in the 52nd harmonic diagram of KuIm1 is the excited acoustic mode with a circumferential mode order mac = −18. Several other peaks are visible in the 34th harmonic plot. These peaks are due to the excitation of other acoustic modes. At this point the authors would like to remind the reader, that all excited acoustic modes exhibit BPF or harmonics with respect to the stationary frame of reference. Figure 9 depicts the 12th harmonic diagram of the transducers KuIm1 and KuIm2 as well as the 17th harmonic diagram of the stationary mounted sensor KuSC1, in which the resonance peak of mac = 5 is expected to occur (see figure 7). Again, all plots are normalized to the maximum value occurring in the harmonic diagram of KuIm1. A multiplicity of peaks are observable in the harmonic diagrams of KuIm1 and KuIm2 (see fig. 9a and b), representing different excited acoustic modes. Two peaks occur near the predicted rotation speeds of resonance (compare table 3). The peak at approximately 10000 rpm does not appear in the 17th harmonic diagrams of the sensors KuSC1, 2 and 3 (see exemplarily fig. 9c). Thus, this peak can not be caused by an acoustic mode mac = 5. The peak at a rotation speed of 9363 rpm lies between the predicted rotation speeds, calculated with equation (11) for β S = 0.5 and β S = 0.0 (compare table 3). Equation (9) provides the acoustic eigenfrequency with respect to the acoustic frame of reference to f ac,exp A (β S = 0.5) = 2263 Hz and f ac,exp A (β S = 0.0) = 2653 Hz, respectively. The relative deviations between calculated and measured eigenfrequencies are ∗S ∗R mac = fac − fac = 17 − 12 = 5. 10 c 2010 by ASME Copyright Figure 10. HARMONIC SPECTROGRAM, EXPERIMENTAL DATA: = 0.0 Figure 11. HARMONIC SPECTROGRAM, EXPERIMENTAL DATA: = 0.4 RUN-UP AT THE CHOKE LINE, THEORETICAL DATA: β S RUN-UP AT THE CHOKE LINE, THEORETICAL DATA: β S The presented analysis clearly verified that the peak is founded on the excitation of the acoustic side cavity mode mac = 5. able. Figure 10 depicts a harmonic spectrogram for the complete compressor speed range and the rotation speed harmonics from 41 to 90. Each harmonic diagram is normalized to its maximum value before all harmonic plots are assembled to the harmonic spectrogram. This is necessary to make peaks of different amplitude clearly visible. The experimentally achieved data of a run-up at the choke line is color-coded. The theoretical rotation speeds of resonance calculated without taking into account the fluid core rotation in the side cavities are marked with black stars (acoustic modes are excited by 2 · BPF) and squares (acoustic modes are excited by 3 · BPF), respectively (compare equ. (11) with β S = 0.0). Excited acoustic modes in the experiments are clearly visible in terms of red and green areas. Some examples are explicitly labeled in figure 10. Large deviations between the experimentally and theoretically achieved data are distinctively noticeable, growing with larger circumferential order. In contrast, figure 11 illustrates the same experimental data, but the theoretical rotation speeds of resonance were calculated taking the fluid rotation into account. The best fit between experimental and theoretical data is achieved for a swirl factor of approximately 0.4. This factor is used for the plot in figure 11. The predicted rotation speeds of resonance match very well with the measured ones. Due to the fact that the experimental data is achieved by a run-up at the choke line of the compressor the pressure increase of the compressor and thus the radial throughflow are very small. A swirl factor of 0.4 agrees well with values found in the literature for cavities without through-flow and a radial boundary, like the housing wall at the outer diameter of the Subsequently, the second part of this chapter contains an experimental estimation of the swirl factor. The estimation is based on the simplified assumptions that the swirl factor is constant over the radial extension of the side cavities and independent of the rotation speed. The influence of the compressor operating point on the swirl factor is investigated. The underlying experimental data is obtained by a run-up at the choke line as well as a run-up passing through the design point of the compressor. It is well known that the swirl factor in the side cavities is influenced by the leakage flow through the cavities, and thus by the compressor operating point [25]. The flow entering the shroud side cavity exhibits a large circumferential component. Therefore, with increasing through-flow the swirl factor is expected to grow due to the additional amount of energy entering the system side cavity. Near the choke line the pressure increase of the impeller is very small. Accordingly, the radial through-flow of the side cavities is marginal. On the contrary, near the design point of the compressor the pressure increase of the impeller is considerably higher. This causes a centripetal through-flow of the shroud side cavity. Consequently, the swirl factor is expected to be higher for a run-up through the design point than for a runup at the choke line. The influence of the swirling flow on the eigenfrequencies of the acoustic modes in the rotor frame of reference increases with larger circumferential order (see equ. (9)). Hence, a calibration or experimental estimation of the swirl factor by means of the excitation of higher order modes is reason11 c 2010 by ASME Copyright and the acoustic eigenmodes occur. Moreover, the crucial relevance of the swirling flow in the side cavities is emphasized. To validate the excitation model a compressor test rig has been equipped with a multiplicity of fast response sensors to allow the experimental detection of acoustic modes. Further, the acoustic eigenmodes were calculated for the given test rig geometry by means of a FEA. The results can be summarized as follows: Figure 12. I) The excitation of acoustic modes by TSMs is clearly verified for the first time in a high-pressure radial compressor. II) Calculated and measured acoustic eigenfrequencies agree well, on condition that the swirling flow in the side cavities is accounted for. To the authors’ knowledge all other studies about acoustic resonances in centrifugal compressors neglect the influence of the swirl factor, resulting in enormous deviations especially for high-order modes. III) Thus, for a reliable prediction of the rotation speeds, where acoustic side cavity modes are excited in resonance in a compressor, beside the acoustic eigenmodes and eigenfrequencies, the compressor specific swirl factor has to be known. IV) The swirl factor was experimentally estimated for two different run-ups. The achieved values are plausible and in good agreement with the values found in literature. V) As expected, no coupling between acoustic and structural modes occurs. This is caused by the large differences between the acoustic and structural eigenfrequencies in the performed experiments. HARMONIC SPECTROGRAM, EXPERIMENTAL DATA: RUN-UP PASSING THROUGH THE DESIGN POINT, THEORETICAL DATA: β S = 0.6 side cavities. The assumed value of 0.5 is theoretically appropriate for cavities with infinite radial extension [25]. Even stronger evidence that the swirl factor has to be accounted for is given by figure 12. This figure shows a harmonic spectrogram, analogous to the figures 10 and 11. This time the experimentally achieved data of a run-up in the middle of the compressor operating map (passing through the design point of the compressor) form the basis of this plot. Acoustic modes are hardly excited by the second harmonic of the BPF (3 · BPF), most likely due to less developed impeller wakes, resulting in lower amplitudes of the higher harmonics. A good fit between experimental and theoretical data is achieved for a swirl factor of approximately 0.6 for the operating points under consideration in figure 12. This factor is noticeably higher than the one which fits best at the choke line. As described before, the increase of the swirl factor is ascribed to the higher radial through-flow near the design point. Therefore, the experimentally achieved data is plausible, but only if the fluid rotation in the side cavities is taken into account. Actually, the swirl factor is a function of several parameters, such as the rotation speed and the radial position. This fact complicates matters even more. By means of the presented excitation model a prediction of the compressor rotation speeds, where acoustic modes are excited in resonance, is possible. This knowledge is necessary to avoid the coexistence of an acoustic and a structural eigenmode with the same eigenfrequency (with respect to the same frame of reference) and circumferential mode order. Provided that the acoustic mode is excited, this acoustic mode in turn excites the structural mode in resonance, likely leading to considerable impeller vibration amplitudes. The measurement of vibration amplitudes in case of resonance of acoustic and structural modes is the object of further studies. Acknowledgments The authors gratefully acknowledge the permission of ’Siemens AG, Sector Energy, Oil & Gas Division, Duisburg’ to publish the results contained in this paper Conclusion Extensive experimental and numerical efforts were carried out on a centrifugal compressor to investigate the excitation of acoustic side cavity modes by pressure patterns caused by rotor/stator interaction. An excitation model is presented to predict the rotation speeds at which resonance between the TSMs REFERENCES [1] Williams, J. E. F., and Hawkins, D. L., 1969. “Theory relating to the noise of rotating machinery”. Journal of Sound and Vibration, 10(1), pp. 10–21. 12 c 2010 by ASME Copyright [2] Lowson, M. V., 1969. Theoretical studies of compressor noise. Tech. rep., Wyle Labs. [3] Neise, W., 2004. Aerodynamische Geräusche von Ventilatoren – Erzeugungsmechanismen und Minderungsmaßnahmen. Tech. rep., Haus der Technik e.V. [4] Tyler, J. M., and Sofrin, T. G., 1961. “Axial flow compressor noise studies”. SAE Transactions, 70, p. 309–332. [5] Ehrich, F. F., 1969. “Acoustic resonances and multiple pure tone noise in turbomachinery inlets”. ASME Journal of Engineering for Power, pp. 253–262. [6] Joppa, P. D., 1987. “Acoustic mode measurements in the inlet of a turbofan engine”. Journal of Aircraft, 24(9), pp. 587–593. [7] Camp, T. R., 1999. “A study of acoustic resonance in a low-speed multistage compressor”. ASME Journal of Turbomachinery, 121, pp. 36–43. [8] Cooper, A. J., and Peake, N., 2000. “Trapped acoustic modes in aeroengine intakes with swirling flow”. Journal of Fluid Mechanics, 419, pp. 151–175. [9] Enghardt, L., Tapken, U., Neise, W., Kennepohl, F., and Heinig, K., 2001. “Turbine blade/vane interaction noise: Acoustic mode analysis using in-duct sensor rakes”. In AIAA-2001-2153. [10] Tsuchiya, N., Nakamura, Y., Yamagata, A., Kodema, H., Nozaki, O., Nishizawa, T., and Yamamoto, K., 2003. “Investigation of acoustic modes generated by rotor-stator interaction”. In 9th AIAA/CEAS Aeroacoustics Conference and Exhibit. [11] Cooper, A. J., Parry, A. B., and Peake, N., 2004. “Acoustic resonance in aeroengine intake ducts”. ASME Journal of Turbomachinery, 126, July, pp. 432–441. [12] Hellmich, B., and Seume, J. R., 2006. “Causes of acoustic resonance in a high-speed axial compressor”. In ASME Turbo Expo, no. GT2006-90947. [13] Eckert, L., 1999. “High cycle fatique cracks at radial fan impellers caused by aeroelastic self-excited impeller vibrations. part 1: Case history, root cause analysis, vibration measurements”. In ASME Design Engineering Technical Conferences DETC99/VIB-8261. [14] Ni, A., 1999. “High cycle fatique cracks at radial fan impellers caused by aeroelastic self-excited impeller vibrations. part 2: Mechanisms and mathematical model”. In ASME Design Engineering Technical Conferences DETC99/VIB-8262. [15] Ziada, S., Oengören, A., and Vogel, A., 2002. “Acoustic resonance in the inlet scroll of a turbo-compressor”. Journal of Fluids and Structures, 16(3), pp. 361–373. [16] Franke, G., Fisher, R., Powell, C., Seidel, U., and Koutnik, J., 2005. “On pressure mode shapes arising from rotor/stator interactions”. Sound & Vibration Magazine, 39, pp. 14–18. [17] Eisinger, F. L., 2002. “Acoustic fatigue of impellers of ro- [18] [19] [20] [21] [22] [23] [24] [25] 13 tating machinery”. ASME Journal of Pressure Vessel Technology, 124, pp. 154–160. Eisinger, F. L., and Sullivan, R. E., 2002. “Acousticallyinduced structural fatique of impeller discs - a brief note”. In Asme Turbo Expo, no. GT-2002-30604. Petry, N., Benra, F. K., König, S., and Woiczinski, C., 2009. “Interaction between aerodynamic phenomena and impeller structure of high pressure radial compressors”. In 8th European Turbomachinery Conference, no. C71. König, S., 2009. “Acoustic eigenmodes in the side cavities of centrifugal compressors”. In ASME Turbo Expo 2009, no. GT2009-59650. König, S., Petry, N., and Wagner, N., 2009. “Aero-acoustic phenomena in high pressure centrifugal compressors – a possible root cause for impeller failures”. Proceedings of 38th Turbomachinery Symposium. Fahy, F., 1985. Sound and Structural Vibration - Radiation, Transmission and Response. Harcourt Brace and Company, Publishers. Kushner, F., Richard, S. J., and Strickland, R. A., 2000. “Critical review of compressor impeller vibration parameters for failure prevention”. Proceedings of 29th Turbomachinery Symposium, pp. 103–112. Schlichting, H., and Gersten, K., 1999. Boundary Layer Theory. Springer-Verlag GmbH. Will, B.-C., and Benra, F. K., 2009. “Investigation of the fluid flow in a rotor-stator cavity with inward throughflow”. In ASME Fluids Engineering Conference 2009, no. FEDSM2009-78503. c 2010 by ASME Copyright