SGT-300: Providing Fuel

Flexibility & Low Emissions

For Industrial Gas Turbines up to 15 MW

Answers for Energy

CHP users are under increased pressure to optimize the use of their power plant

including, at one extreme, a decision whether to keep their GT power source in

operation, especially with the external influences that affects their businesses.

Amongst these are a number of market drivers that

influence such decisions:

Low Cost Energy from alternative sources, such as

wind and wave power, is increasing

Greenhouse Gas Emissions to atmosphere need to be

reduced to much lower levels

Elimination of airborne ‘pollutants’ to improve air quality

Decreasing dependency on Fossil Fuel paralleled with

the need to reduce pollution

With our past experience of various fuel types and

compositions, Siemens is able to provide a cost-effective

solution, with low emissions and an operational capability

on fuels outside the normal standard fossil fuel range.

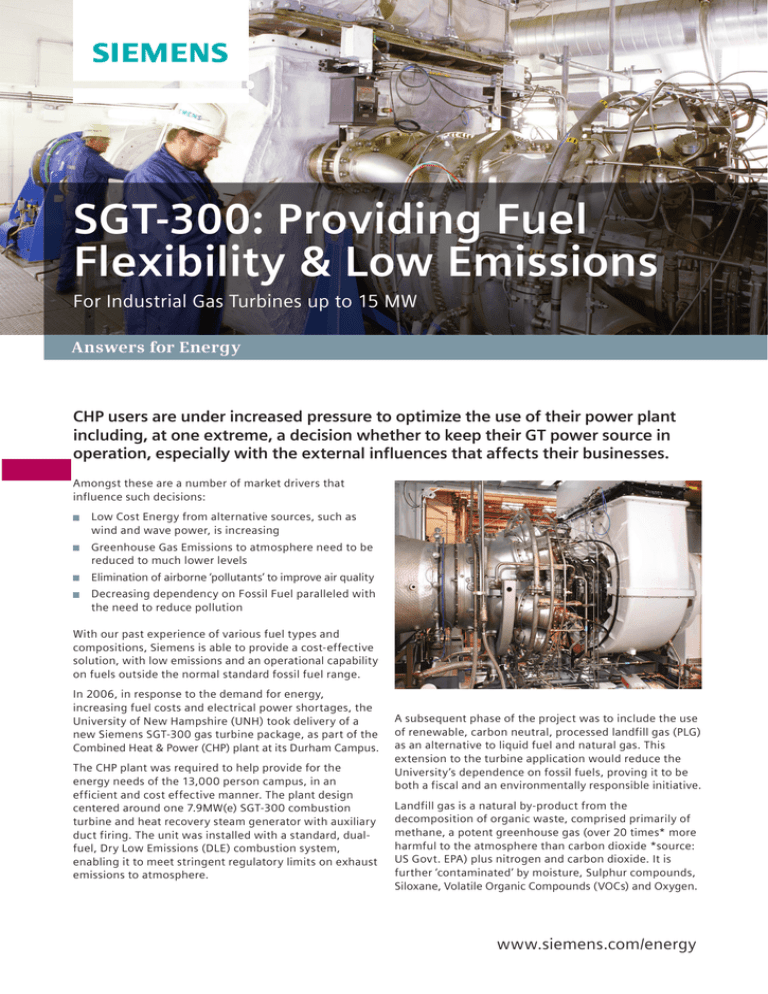

In 2006, in response to the demand for energy,

increasing fuel costs and electrical power shortages, the

University of New Hampshire (UNH) took delivery of a

new Siemens SGT-300 gas turbine package, as part of the

Combined Heat & Power (CHP) plant at its Durham Campus.

The CHP plant was required to help provide for the

energy needs of the 13,000 person campus, in an

efficient and cost effective manner. The plant design

centered around one 7.9MW(e) SGT-300 combustion

turbine and heat recovery steam generator with auxiliary

duct firing. The unit was installed with a standard, dualfuel, Dry Low Emissions (DLE) combustion system,

enabling it to meet stringent regulatory limits on exhaust

emissions to atmosphere.

A subsequent phase of the project was to include the use

of renewable, carbon neutral, processed landfill gas (PLG)

as an alternative to liquid fuel and natural gas. This

extension to the turbine application would reduce the

University’s dependence on fossil fuels, proving it to be

both a fiscal and an environmentally responsible initiative.

Landfill gas is a natural by-product from the

decomposition of organic waste, comprised primarily of

methane, a potent greenhouse gas (over 20 times* more

harmful to the atmosphere than carbon dioxide *source:

US Govt. EPA) plus nitrogen and carbon dioxide. It is

further ‘contaminated’ by moisture, Sulphur compounds,

Siloxane, Volatile Organic Compounds (VOCs) and Oxygen.

www.siemens.com/energy

9

Student population over 13,000

108

Landfill

Site

UNH /Siemens SGT-300 reported statistics:

Ambient temperature range: -28°C +32°C

Unit continuous operation 8,500 hrs/yr

16

In commercial operation since 2006

9

>3800 hrs Liquid operation from November 2008 to

March 2009

108

Unit commissioned on PLG, 30 April 2009

>8500 hrs PLG operation to date

Up to 7.8 MW(e) electrical power output

Up to 12MW of heating and cooling

Dover

16

Bellamy

Reservoir

9

Overall CHP efficiency of 77%

<10ppmVd and <25ppmVd at 100% and 59% load,

respectively, for NOx, SOx and CO

Tri-fuel operation: Gas fuel Wobbe index range 32 –

49MJ/m3 (Natural Gas, Processes Land-fill Gas and Liquid)

Tri-generation (heating, cooling, electrical power)

Installation of Active Pilot (Dynamic Fuel Schedule

management software) in October 2009, modified to

support site anomalies. As the PLG, blended with

Natural Gas, varies in composition it can lead to high

‘Band 1’ combustion dynamics and “Flame Out”

Madbury

155

108

UNH runs predominantly at part load, varies load regularly

4

4

Wobbe Index variation and PLG volume, has proven

wider and more frequent than expected

UNH

Durham

4

Fig. 2: The $49m funded University project commenced with the

construction of a gas processing plant at the nearby landfill site in

Rochester. The plant purifies and dries the gas before compressing

it down a purpose built, 12.7 mile long, underground pipeline to

the CHP plant at the Durham campus.

This application provides for the landfill gas to be

captured, converted, blended with Natural Gas and used

as a renewable energy source, instead of allowing it to

escape into the air.

99.02% average availability for the SGT-300 from

November 2009 to March 2010

The SGT-300 gas turbine was designed from the outset to

have low emissions combustion (DLE) as a capability and

is based on the Lincoln generic DLE solution. This DLE

combustion system offers among the widest operability

limits in terms of fuel type, load operation and low

emissions (it has some of the lowest levels recorded across

the SGT product line). The recent addition of ‘Active Pilot’

fuel management software, has allowed for wider

variations in PLG composition to be managed, whilst still

achieving the required emissions to atmosphere.

The landfill gas collection system consists of more than

300 extraction wells and miles of collection pipes. The

extracted landfill gas is compressed and passed to the

processing plant where it is cleaned and enriched (by

removing the Carbon Dioxide) thus making it suitable for

burning in the SGT-300.

The processed landfill gas (PLG) contains Nitrogen as the

dominant inert species, resulting in the gas being some 30

percent weaker than a ‘normal’ pipeline quality natural gas.

UNH are justifiably proud of their investment and as such

invite us to view their plant in operation, go to www.

energy.unh.edu/ to view their website, an extract of

which is shown in Figure 4. It allows the viewer direct

access to ‘live’ data on the performance of the unit,

showing the unit output power, the fuel composition that

it is burning and the level of emissions it is producing.

Gas Fuel

Water

25,140kW

Heat

Recovery

Steam

Generator

Gas Turbine

Exhaust Gas

40,000 to 95,000 lb/hr

at 180 PSI

To Process

Fig. 3: UNH Plant Schematic.

Electrical

Output

7,640kW

Cogeneration Plant - Combustion Turbine Generator Overview

Combustion Inlet Air Cooler

TV-763

-3.3

%Open

1.3 in WC

Gas Selection

Turbine Enclosure Ventilation Air Inlet Filter

0.0 in WC

Temperature Corrected Wobbe Index

Liquid Fuel Filter Differential Pressure

M

CHWS

CHWR

Combustion Air Inlet Filter

Lub Oil Filter Differential Pressure High

0.0 in WC

Generator Air Inlet Filter Differential Pressure

0.0 PSID

Instrument Air Supply Pressure

Inlet Air Temp

56.8 DegF

LCV (Low Calorific Value)

-0.2 PSID

Specific Gravity

Process Landfill Gas

32.3 MJ/Nm3

711.3 BTU/SCF

0.673

104.4 PSIG

Turbine Status

Cooling

Air Inlet

Cooling

Air Outlet

Ventilation

Ventilation

Air Outlet

RUNNING

Air Inlet

CEMS

NOx

13.0 ppm

NOx 15% 13.9 ppm

O2

15.0 %

Governing Operating Mode

KW

Selected Fuel

GAS

Running Fuel

GAS

Fire and Gas System

GENERATOR

TURBINE

Lub Oil Supply Temp.

119.8 DegF

Lub Oil Reservoir Temp.

152.4 DegF

FI-440

Process Landfill Gas

2112.0 SCFM

93.2 Volume % PLG In Blend

6.8 Volume % Natural Gas In Blend

8.9 BTU % Natural Gas In Blend

Avg. Exhaust Temp.

1026.0 DegF

Generator Output Power

Generator Output MVARS

Liquid Fuel Supply Pressure -1.1 PSIG

Generator Output Voltage

Gas Fuel Supply Pressure 303.4 PSIG

Generator Power Demand Signal

0.0 GPM

Fuel Oil Supply

To HRSG-1

MANUAL

7808 kW

2071 MVARs

4253

Volts

8304 kW

Fig. 4: Snapshot of operational mode Tuesday 20th April 2010 at 13:45 GMT, Unit delivering 7.8MW(e) on a 93.2% PLG blend with 6.8%

Natural Gas, at a Wobbe Index of 32.3 MJ/m3 and 13.0 ppm NOx.

Prior to this project, Siemens were already gaining

experience on an earlier SGT-300 project, using depleted

well head gas, containing high levels of Carbon Dioxide.

Additional supporting development testing, using a high

pressure combustion rig, along with ignition demonstration

through an atmospheric facility, enabled the standard

combustor to be released for this application.

Fleet experience continues to grow across a wide range

of applications, many years after this initial work had

been completed. This expanded fuels capability provided

the basis for working with UNH, to define a suitable

operating window, culminating in achieving tri-fuel

operation, i.e. ability to operate with Natural Gas,

Processed Landfill Gas, as well as Distillate Fuel.

In summary, the SGT-300 operating at the UNH campus

runs on three fuels (PLG, NG and distillate) and achieves

NOx guarantee limits throughout the load range, in

standard DLE configuration, without hardware changes

or additional monitoring.

Unit is meeting site energy demands (up to 7.8MW(e)

and 77% overall CHP efficiency)

Unit can tolerate a variable fuel energy content level,

Wobbe Index range 32 – 49 MJ/m3

Unit has maintained emissions level requirements

Acknowledgements:

Extracts from, Brown, J.M., Igoe, B., Bulat, G., Stellmack,

J., 2010 “Industrial Gas Turbines in an evolving and

challenging market: Fuel Flexibility and Emissions

Compliance - The SGT- 300 “.

Our thanks to the University of New Hampshire, for both their

support and for allowing us to mention the developments

that have come to fruition, through their installation.

Total cost of the project, which included construction of the

pipeline and the processing plant at TREE, is $49 million.

UNH will sell the renewable energy certificates (RECs) generated by using landfill gas to help finance the overall cost of

the project and to invest in additional energy efficiency projects on campus. In addition, UNH will sell power in excess of

campus needs back to the electric grid.

“By selling the RECs from EcoLine™, UNH will further fund its

aggressive plan toward climate neutrality,” says Tom Kelly,

UNH chief sustainability officer and director of the office of

sustainability. “With this climate action plan, called WildCAP,

UNH has committed to lowering its emissions by 50 percent

by 2020 and 80 percent by 2080.”

Quotes: DURHAM, N.H. May 19 /PRNewswire/— The University of New Hampshire’s EcoLine™, a landfill gas-to-energy project that uses purified methane gas from a nearby

landfill to power the campus, is complete, university officials

announced. The five million square-foot campus will receive up to 85 percent of its electricity and heat from purified natural gas, making UNH the first university in the nation to use landfill gas as its primary fuel source.

“This massive project, more than four years in the making,

will reduce our dependence on fossil fuels and stabilize our

fuel source and costs,” says UNH President Mark W. Huddleston. “EcoLine™ showcases UNH’s fiscal and environmental responsibility and secures our leadership position in sustainability.”

EcoLine™ is a partnership with Waste Management’s Turnkey Recycling and Environmental Enterprise (TREE) in Rochester, N.H. where the naturally occurring by-product of landfill decomposition is collected via a state-of-the-art

collection system consisting of more than 300 extraction

wells and miles of collection pipes.

The University of New Hampshire, founded in 1866, is a

world-class public research university with the feel of a New

England liberal arts college. A land, sea and space-grant university, UNH is the state’s flagship public institution, enrolling 11,800 undergraduate and 2,400 graduate students.

DURHAM, N.H. – The U.S. Environmental Protection Agency

(EPA) has named the University of New Hampshire’s EcoLine™ as a Project of the Year, the agency announced last

week. EcoLine™ is a landfill gas-to-energy project that uses

purified methane gas from a Waste Management landfill in

Rochester to provide up to 85 percent of campus power.

When EcoLine™ started in May 2009, UNH became the first

university in the nation to use landfill gas as its primary fuel

source.

“We are proud to recognize UNH’s EcoLine, a Landfill Methane Outreach Program partner which is turning trash into a

clean and profitable source of energy,” said Gina McCarthy,

assistant administrator for the EPA’s Office of Air and Radiation. “This project, and others like it, is helping us transition

into a clean energy economy and make important greenhouse gas reductions.”

After the gas is purified and compressed at a new UNH processing plant at TREE, it travels through a 12.7 mile pipeline

from the landfill to UNH’s cogeneration plant, where it will

replace commercial natural gas as the primary fuel source. In

operation since 2006, UNH’s cogeneration plant captures

waste heat normally lost during the production of electricity

and uses this energy to heat campus buildings.

Published by and copyright © 2013:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Energy, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

For more information, please contact

our Customer Support Center.

Phone: +49 180 524 70 00

Fax:

+49 180 524 24 71

(Charges depending on provider)

E-mail:support.energy@siemens.com

www.siemens.com/energy

Energy Service Division

LCN 2013 - F33.12 LN

Printed on elementary chlorine-free

bleached paper.

All rights reserved. Trademarks mentioned in

this document are the property of Siemens AG,

its affiliates, or their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should

therefore be specified in the contract.