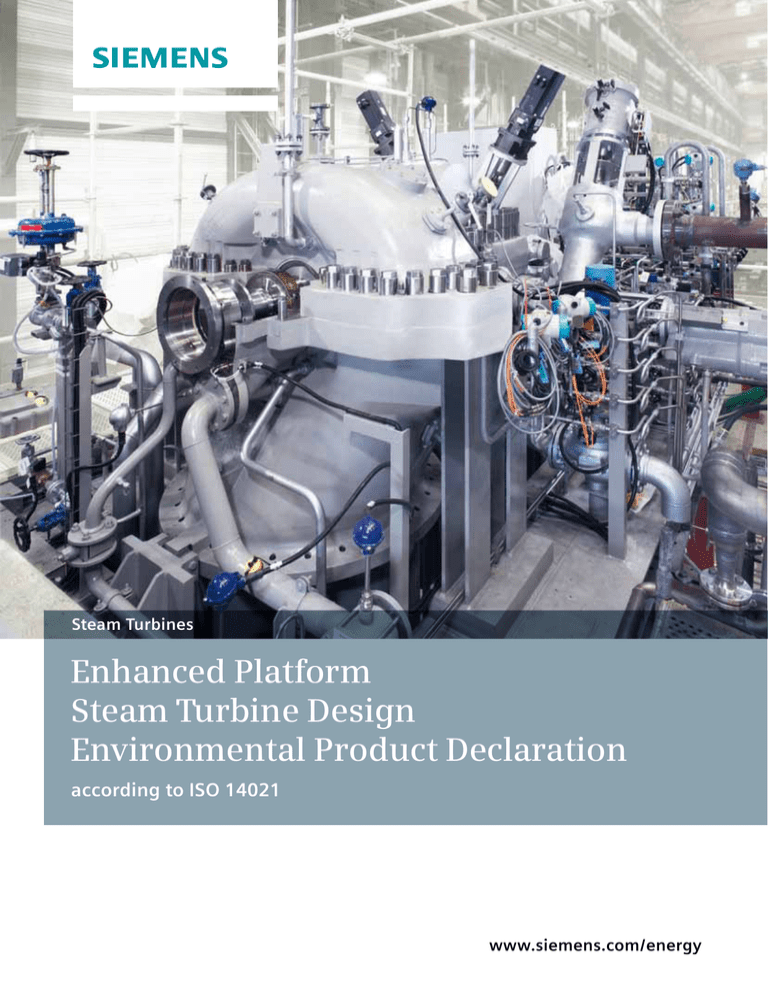

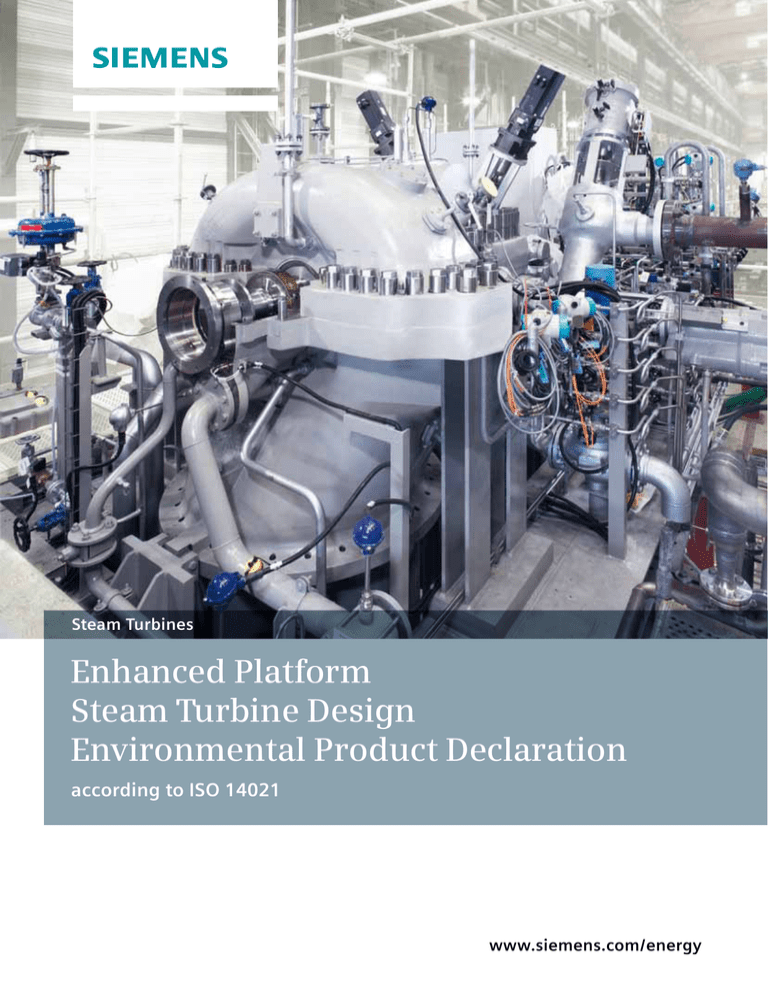

Steam Turbines

Enhanced Platform

Steam Turbine Design

Environmental Product Declaration

according to ISO 14021

www.siemens.com / energy

2

Sustainability as Opportunity

Sustainability is the basis for how we do business

Our goal is to create value for the long term by treating

people and the environment in a responsible manner.

Innovative products and solutions are the foundation

for our success

They help our customers to achieve their business goals

while meeting global challenges such as urbanization,

demographic change, climate change and resource

scarcity.

We walk the talk

We pursue ambitious goals with regard to resource efficiency and environmental protection; we see our employees as our most valuable asset and develop them for the

long term; we value a corporate culture with a strong

emphasis on integrity; and we promote education, social

issues, arts and culture wherever we operate.

Siemens aims to set the highest standards for environmental protection. We urge our business partners to share

this ambition. We cooperate with both customers and

­suppliers in an honest and open dialog in order to drive

forward a joint effort to attain continuous improvement.

The main objective of our environmental work is to

­prevent pollution and continually reduce the environ­

mental impact from our activities in order to protect

the environment for future generations.

To meet these objectives, we will maintain and further

develop a culture in which reducing the environmental

impact of the product life-cycle is an integral part of our

daily work practice. Our integrated management system

for environment, health and safety, ISO 9001, 14001

and OHSAS 18001, is implemented worldwide within

the Siemens Energy Sector.

Mechanical Drive Steam Turbine

3

Steam Turbine for Steam Conditioning

and Power Generation

Industrial Steam Turbines Based

on the Enhanced Platform Building

Block Technology

The world is faced with the challenge of balancing

increasing worldwide energy consumption with the need

to reduce greenhouse gas emissions. This can be reached

by replacing fossil fuels by renewables, using e.g. sun

or biomass, and the enhancement of the conversion

­efficiency of heat into electricity. These are the most

important challenges for the power generation industry.

Siemens offers an extensive steam turbine portfolio –

recently complemented by the Enhanced Platform steam

turbine design – in order to meet these challenges.

Product Stewardship:

The Siemens Environmental Protection Standards

Environmental compatibility is a cornerstone of product

design at Siemens. In 1993, we published an in-house

standard to advance an environmentally compatible product design throughout the company. The standard has

since been expanded to provide product development

engineers with a comprehensive toolbox.

4

This Siemens Environmental Protection (EP) Standard

Provides the Basis for

environmentally compatible product and system design

recording and declaration of substances

requirements regarding battery containing products

requirements regarding packaging

environmental product declarations

These requirements and regulations are accompanied

by a guideline giving examples of how to implement the

standard’s requirements; a semi-quantitative tool for

evaluating a product’s environmental footprint is also

available.

The standard describes how to address the needs of

­environmentally compatible product and system design

in management systems.

Environmental Product Declaration

The data in this Environmental Product Declaration (EPD)

are related to one steam turbine type of the SST-800

Enhanced Platform for power generation with an average

output power of 58 MW. This turbine is a single casing

configuration with center admission.

The environmental impact is given by the specific material

footprint and by the global warming potential (GWP)

related to the product. The global warming potential

(GWP) has been evaluated within a full scale life-cycle

assessment according to ISO 14040.

Product Description

Enhanced Platform – A Modular Approach to

Designing the Perfect Industrial Steam Turbine

The Enhanced Platform is a technology basis used to

update several well-known Siemens steam turbine product lines as SST-300/400/600 and 800.

Depending on the final application, single and multi casing solutions are possible. A special application field is

not defined due to the fact that the customization level is

very high and allows solutions for both industrial power

generation and mechanical drive applications. Thereby

state of the art blading technologies are available dealing

with 3D optimized high-pressure (HP), intermediate-pressure (IP) and low-pressure (LP) sections to ensure high

efficient solutions. Depending on customer demands and

train arrangement HP, IP, and LP can be covered in one

casing or in multi casing solutions with the option of different rotational speeds between the several casings.

The design philosophy employed in the resulting

Enhanced Platform steam turbines delivers higher efficiency, faster startup, enhanced availability, a broader

application range, and greater ease of maintenance.

Since all Enhanced Platform components have been

­optimized, tested and verified, the finished machines

can be manufactured to much tighter tolerances at

very cost-effective prices.

With the Enhanced Platform not only an improved structure for the update of the existing multistage reaction

­turbines is built. But also the application field focused on

live steam is extended and the advanced platform features

a combination of well proven technologies in the field of

valves, controlled extraction, exhaust casings and standard bladings. The power ranges where the Enhanced

Platform components can be applied are 25 to 250 MW.

Material Allocation

Enhanced Platform steam turbines consist of nearly

100 percent of ferrous metals, predominantly lowalloyed steel. The figure below shows shows the material

­allocation of the product.

0.2%

9%

39%

7%

45%

High alloyed steel

Low alloyed steel

Non alloyed steel

Iron

Others

5

Key Environmental Performance Indicators

Siemens uses standard life-cycle software for the evaluation of the environmental impact of all product life-cycle

stages. All results are verified by internal reviews.

Global Warming Potential

Global warming is the rising of the global temperature due

to emissions of greenhouse gases such as carbon dioxide

and methane. The GWP is evaluated in CO2 equivalents.

The GWP of the Enhanced Platform steam turbine design

is shown in the figure below. The diagram is separated

into the four life-cycle sections “Materials”, “Manufacturing”, “Packaging” and “Operation & Service” as explained

on page 7.

Nearly half of the environmental impact of global warming are caused by the “Material inventory”. The operational phase, on the other hand, has no real impact on

the GWP of the product.

40

44%

Less total weight leads to benefits for both packaging

and logistic.

In terms of decentralized power generation special steam

turbines are required which are optimized for their complex and challenging cycle conditions. Enhanced Platform

steam turbines meet all these environmental and technological challenges.

Additionally, the following advantages of the Enhanced

Platform steam turbine solutions assure improved performance what at the same time underlines the environmental benefit of the advanced design compared to conventional steam turbines:

reduced startup time up to 50 % (due to optimized

casing)

48%

improved efficiency up to 2 % (due to improved blade

and seal concept)

30

20

10

0

Applying pre-standardized components leads to reductions in both engineering and manufacturing effort.

high reliability (screws are 50000 operating hours

maintenance free)

Global Warming Potential

50

L ong term experiences in material behavior lead to

­efficient material inventory for all components and

result in a total turbine weight reduction.

Materials

Manufacturing

5%

3%

Packaging

Operation &

Service

“End of Life” – Recycling reduces the environmental impact of

the product and gives a positive contribution to the overall GWP

of the product (not shown).

long life-cycle – increased life-time (approximately

200000 operating hours)

The SST-800 Enhanced Platform for concentrated solar

power (CSP) services saves around 3,760kt CO2 over its

life-time compared to the world fossil average (see calculation below). Thus it makes a tremendous contribution to environmental protection.

Environmental Benefit

Amongst other application areas, Enhanced Platform

steam turbines are utilized for decentralized power generation based on renewable or fossil sources (e.g. biomass,

waste to energy, combined cycle, and solar power plants).

These applications allow generating power by using less

fuels or heat due to higher efficiencies. Using less or no

fossil fuels protects our natural resources and helps to

avoid the emission of greenhouse gases.

A CO2 emission reduction up to 15 % will be achieved

applying the Enhanced Platform gains. A reduction of the

produced CO2 mass according to the main influence factors like material, manufacturing, packaging, service and

transportation is possible due to the following facts:

6

Greenhouse Gas Emission Savings of one

SST-800 Enhanced Platform, 58 MW, CSP

Power Generation:

CO2 Savings:

4,350 GWh

in 25 years of

operation*

3,760kt CO2

in 25 years of

operation**

* referring to 3000 h of

operating per year

** a

gainst world fossil average

of 865 kg CO2/MWh

Description of the

Life-Cycle Stages

An important product focus for Siemens is to minimize the environmental impacts from resource extraction through to ultimate disposal. At every stage, Siemens has developed trendsetting solutions in accordance with sustainable life-cycle thinking.

Materials

The life-cycle stage “Materials” includes the material

inventory which involves the extraction of natural

resources, transport to the processing sites and the production of raw materials.

All product materials have been chosen with regard to

minimizing environmental impact.

The Enhanced Platform steam turbines consist mainly of

ferrous and non-ferrous metals. This ensures a high

degree of recyclability.

Manufacturing and Transport

The “Manufacturing” section covers all production processes up to the assembly of the finished product at the

manufacturing site. The essential data like energy, water

and gas consumption are based on the annual manufacturing data of the site.

The “Transportation” section includes the transport, mainly

per sea, to the customer site. For this LCA a customer site in

the south of Spain was assumed.

Operation & Service

The life-cycle stage “Operation and Service” covers all

environmental impacts of the described product system

during its operation phase. This also includes the related

service equipment. For steam turbines, and therefore also

for this LCA, a normal operation time of about 25 years

is assumed.

Its flexibility and inherent reliability have made Enhanced

Platform steam turbine solutions to the choice for decentralized power generation (e.g. biomass, waste to energy,

combined cycle, and solar power plants), district heating

applications, process steam conditioning, and mechanical

drives.

End of Life

The end of life scenario includes the disassembly, recycling and thermal treatment of all recyclable materials and

also the disposal of all other materials.

Recycling reduces significantly the consumption of primary materials. A high degree of recyclability is given due

to the high amount of steel for the Enhanced Platform

steam turbines. In the case of steel, the recycling rates are

nearly 100 %.

7

Published and copyright © 2013:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens AG

Energy Sector

Oil & Gas Division

Wolfgang-Reuter-Platz

47053 Duisburg, Germany

For more information, please contact

our Customer Support Center.

Phone: +49 180 524 70 00

Fax: +49 180 524 24 71

(Charges depending on provider)

E-mail: support.energy@siemens.com

www.siemens.com/energy

Oil & Gas Division

Order No. E50001-D410-A125-X-4A00

Dispo 34806, K12 130060, WS 0913

Printed on elementary chlorine-free bleached paper.

All rights reserved.

Trademarks mentioned in this document are the property

of Siemens AG, its affiliates or their respective owners.

Subject to change without prior notice. The information in

this document contains general descriptions of the technical

options available, which may not apply in all cases.

The required technical options should therefore be specified

in the contract.