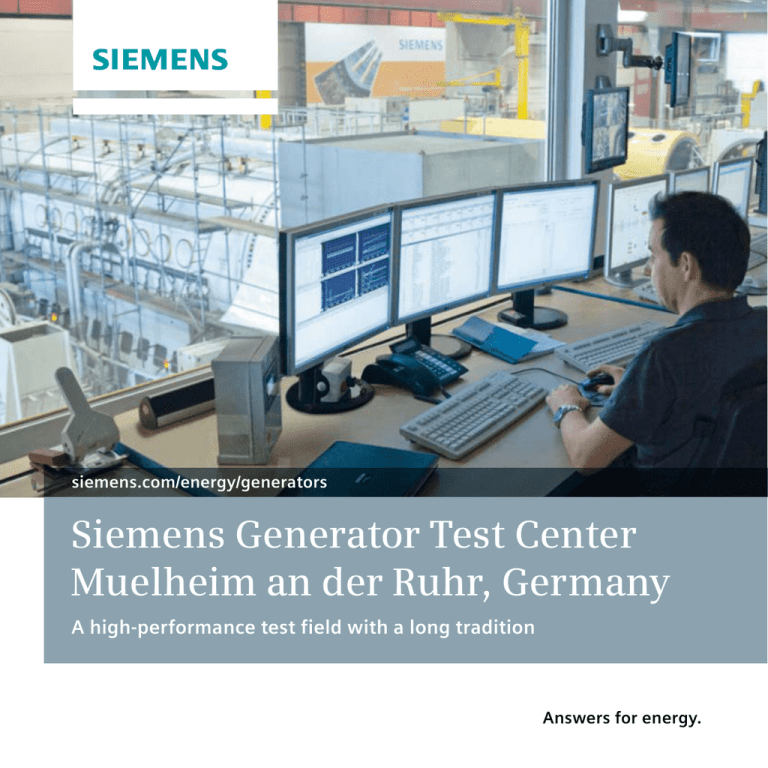

siemens.com/energy/generators

Siemens Generator Test Center

Muelheim an der Ruhr, Germany

A high-performance test field with a long tradition

Answers for energy.

Test with the best:

Siemens Test Center Muelheim

“The key benefit for our

customers is providing them

with reliable information on

the potential operational

capability of their generators

under simulated operating

conditions, with engineering

and manufacturing

right next door.”

Axel Blinn

Head of Turbo-Generator

Test Center

Technology and tradition

After its completion in early 1972,

the first machine to be tested in the

Muelheim generator test field was

a water-cooled 900 MW generator.

In the meantime, more than 450 generators of different type and power classes

from Siemens’ large portfolio of generators, ranging from 25 MVA to 370 MVA,

have been tested in accordance with

IEC 6034 and their distinctive specifications. After the center’s modernization in

2006, even the world’s largest generator,

SGen5-4000W, with a power output of

up to 2,235 MVA, can be type-tested here.

Today the Muelheim test field is one of

the most modern and powerful generator

test fields in Europe.

Why should a generator be tested?

In increasingly quality-oriented energy

markets, each and every power plant

component needs to be reliable and fully

functional. Testing a generator provides

an opportunity to prove that the function

and performance characteristics of the

generator are compliant with those stated

in the contract. The advantage is obvious:

higher availability. In addition a generator

test in Mülheim serves to prove the

machine’s functionality and verify

performance parameters and their

tolerance design (only for prototypes).

“Wedding” of large air-cooled SGen5-1200A generator

2

The unique test bed at Siemens Test Center Muelheim: A testing facility with no limitations or compromise on quality

3

A large SGen5-3000W water-cooled generator in the test bed

Testing the world’s largest generator, the SGen5-4000W

In accordance with IEC6034, the following

tests* can be carried out:

■■ Determination

of exact electromagnetic

performance parameters to secure

the generator’s ability to resist grid

disturbance conditions

■■ Determination of individual losses

and efficiency

■■ Determination of mechanical

and technical behavior

■■ Proof of scalability of the results of

type-tested generators to larger or

smaller models

■■ Proof of tightness under rotating conditions (for H2-cooled machines only)

■■ Proof of machine functionality and

verification of performance parameters

and of their tolerance design

(for prototypes only)

■■ At predefined witness points, the

customer can be present for some of

the tests performed on his generator

live in the control room

4

* For detailed testing list, please see enclosed

attachment

Why choose Siemens Test Center

Muelheim?

In Muelheim, your generator is being

tested in one of the most advanced test

fields in Europe. The center offers a broad

range of test types for nearly all machine

sizes. Its most important advantage is the

unique combination of an experienced

testing and engineering staff with a backlog of more than 450 test runs in over

40 years with well proven state-of-the-art

technical equipment.

Two test beds with rotating testing up

to 3,600 rpm for 50/60 Hz application

and all power ranges:

Test bed 1: 2 x 8 MW DC drive + gear box

n=1:3 for 4-pole or 1:6 for

2-pole generators

Test bed 2: 1 x 2 MW + 1 x 3 MW DC

drive + gear box

n=1:3 for 2/4-pole generators

Cutting-edge calibration instruments

Transport of a hydrogen-cooled generator on a specially designed Schnabel car

Real-time online display of all measures

and calculated results through state-ofthe-art infrastructure and software:

Calibration laboratory in accordance

with ISO 17025 for calibration of

numerous electrical measurement

equipment:

■■ Independent

network environment

measurement hardware for power analysis and tailored

multi-channel process system for

comprehensive data acquisition

and analysis in the control room

■■ Data transfer via optical fiber guide

system

■■ Measurement infrastructure with

500+ channels enables the tracking

and monitoring of all relevant parameters like pressure, flow, temperature, vibration, and electrical values

■■ Leading-edge infrastructure allows

plug&play online monitoring for engineering purposes and provides direct

interfaces for special measurements

■■ State-of-the-art

■■ Phase

power meters

multi-meters

■■ Small current transformers

■■ Small voltage transformers

■■ Shunts

■■ Digital

Flexible logistic infrastructure supports

all scales of machines – from small

industry generators with 25 MVA to

large water-cooled machines with an

output of up to 2,235 MVA:

■■ Overhead

crane with 600 t capacity

and external railway connection to international train logistic

■■ Water connection (to river Ruhr)

■■ Internal

5

Testing facilities at Siemens Test Center Muelheim

Kurzzeichen/

Abbreviation

Vorgang/

Procedure

Generator Baureihe/

Generator series

SGen-100A-4P

SGen-100A-2P

SGen-1000A

SGen-1200A

SGen-2000H

SGen-2200H

SGen-3000W

SGen-4000W

RG-Erreger/

RR exciter

S1

Messen des Nach- und Endladestromes der Ständerwicklung/

Charge- and discharge-current measurement on stator end-winding

●

●

✖

S2

Messung der Intensität der Teilentladungen/Partial-discharge measurement

●

●

✖

S3

Stichprobenprüfung einzelner Stäbe oder Spulen nach VDE 0530/

Random tests on sample bars or coils according to VDE 0530

●

●

✖

S4

Einstellung des Erregerzubehörs/Adjustment of excitation accessories

●

✖

✖

S5

Messung des Luftspaltfeldes mit Leiterschleifen oder Sonden/

Measurement of air-gap field with an air-gap probe

●

●

✖

S6

Messung der Temperatur bzw. des Schwingungsverhaltens spezieller Maschinenteile

mit zusätzlich für die Messung eingebaute Sonden/Measurement of temperature or

vibration behavior on special machine components with detectors additionally installed

●

●

●

S7

Funktionsprüfungen an Überwachungs- und Diagnosesystemen/

Functional tests on monitoring and diagnostic systems

●

●

●

St 1

Wuchten im Prüffeld/Balancing in the test field

●

●

●

St 2

Prüfung des Laufverhaltens/Testing of running behavior

●

●

●

St 3

Bestimmung der Kühl- und Schmiermedien für Lager und Wellendichtung/

Determination of temperature increases of coolants and lubricants for bearings and shaft seals

●

●

●

St 4

Druckmessung zur Kontrolle der Kühlgasverteilung und Bestimmung des Volumenstromes/

Pressure measurements to check cooling-gas distribution and determination of volumetric flow rate

●

●

✖

St 5

Aufnahme der hydraulischen Kennlinien der Primärwasserkreise/

Recording of hydraulic primary water-circuit characteristics

✖

●

✖

St 6

Ermittlung der Reibungsverluste/Determination of friction losses

●

●

●

St 7

Aufnahme der Leerlaufkennlinie und Ermittlung der Eisenverluste/

Recording of open-circuit characteristic and determination of core losses

●

●

✖

St 8

Messung der Wellenspannung/Measurement of shaft voltage

●

●

✖

St 9

Prüfung der Phasenfolge und der Klemmenbezeichnung/

Verification of phase sequence and appropriate terminal marking

●

●

✖

St 10

Messung des Erregerstromes und Ermittlung der Verluste im Kurzschluss bei Nennstrom/

Measurement of excitation current and determination of losses at rated current on short circuit

●

●

✖

St 11

Funktionskontrolle der Querfeldmessspulen/Functional test of cross-field measurement coil

✖

✖

●

St 12

Messung der Leerlaufspannung + Kontrolle der Phasenfolge an der Hilfserregereinrichtung

(Statische Erregung der Hilfserregermaschine)/Measurement of open-circuit voltage +

check of phase sequence at the auxiliary exciter equipment (static excitation of pilot exciter)

✖

✖

●

St 13

Rechnerische Bestimmung des Wirkungsgrades aus den Einzelverlusten/

Calculation of efficiency from the individual losses

●

●

✖

St 14

Messung der Isolationswiderstände der Wicklungen/Winding insulation resistance measurement

●

●

●

St 15

Hochspannungsprüfung an den Wicklungen/High voltage test on windings

●

●

●

St 16

Funktionsprüfung des Zubehörs und der Anbauteile/Functional test of accessories and attachments

●

●

●

6

Kurzzeichen/

Abbreviation

Vorgang/

Procedure

Generator Baureihe/

Generator series

SGen-100A-4P

SGen-100A-2P

SGen-1000A

SGen-1200A

SGen-2000H

SGen-2200H

SGen-3000W

SGen-4000W

RG-Erreger/

RR exciter

T1

Aufnahme der Kurzschlusskennlinie und Ermittlung der Kurzschlussverluste/

Recording of short-circuit characteristics and determination of short-circuit losses

●

●

✖

T2

Ermittlung der Erwärmung im mechanischen Leerlauf/

Determination of temperature increases at mechanical no-load

●

●

●

T3

Messung der Erwärmung im Leerlauf erregt/

Determination of temperature increases at no-load excited

●

●

●

T4

Messung der Erwärmung im Kurzschluss/

Determination of temperature increases at short circuit

●

●

✖

T5

Ermittlung der Nennlasterwärmung aus T 2 – T 4/

Determination of temperature increases at rated load from T 2 – T 4

●

●

✖

T6

Ermittlung der Ventilations- und Lagerreibungsverluste/

Determination of windage and bearing friction losses

●

●

✖

T7

Harmonische Analyse der Leiterspannung und Ermittlung des THF/

Harmonic analysis of line-to-line voltage and determination of THF

●

●

✖

T8

Feldstrom-Abkling-Versuch (Offene Ankerwicklung)/

Field current decay test with the armature winding open-circuited

●

●

✖

T9

Bestimmung der Inversreaktanz/

Determination of negative-sequence reactance

●

●

✖

T 10

Bestimmung der Nullreaktanz/

Determination of zero-sequence reactance

●

●

✖

T 11

3-strängiger Stoßkurzschlussversuch und Bestimmung der Kenngrößen/

Sudden three-phase short-circuit test and determination of parameters

●

●

✖

T 12

Ermittlung der Ankerreaktanz bei ausgebautem Läufer/

Determination of armature reactance without rotor

●

●

✖

T 13

Auslaufversuch zur Ermittlung des Trägheitsmomentes/

Retardation test and determination of moment of inertia

●

●

✖

T 14

Geräuschmessung/Noise measurement

●

●

●

T 15

Aufnahme der Belastungskennlinie und Ermittlung der Lastverluste/

Recording of load characteristics and determination of load losses

✖

✖

●

T 16

Ermittlung der Erwärmung bei Belastung/

Determination of temperature increases at load

✖

✖

●

T 18

Ermittlung der Erregungsgeschwindigkeit (nur mit original Erregereinrichtung möglich)/

Determination of excitation response (only possible with original excitation device)

✖

✖

●

T 19

Hilfserregermaschine: Ermittlung der Erwärmung bei Belastung, Aufnahme der

Belastungskennlinie bei cos phi = 1, Messung des Kurzschlussdauerstromes/

Pilot exciter: Determination of temperature rises at load, recording of load characteristics

at p.f. = 1, measurement of the sustained short-circuit current

✖

✖

●

● wird angeboten/offered

✖ wird nicht angeboten/not offered

7

Published by and copyright © 2014:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

For more information, please contact

our Customer Support Center.

Phone: +49 180/524 70 00

Fax:

+49 180/524 24 71

(Charges depending on provider)

E-mail:support.energy@siemens.com

Power Generation Division

Order No. E50001-G210-A429-X-7600 | Printed in Germany |

Dispo 34802

TH 214-140044 | WÜ | 433360 | WS | 04141.0

Printed on elementary chlorine-free bleached paper.

All rights reserved.

Trademarks mentioned in this document

are the property of Siemens AG, its affiliates,

or their respective owners.

Subject to change without prior notice.

The information in this document contains general

descriptions of the technical options available, which

may not apply in all cases. The required technical

options should therefore be specified in the contract.