Draft GT2006-90154

Operation on Process Off-gas of a 24MW SGT-600

gas turbine on an LNG plant in China

Torsten Strand,

Siemens Industrial Turbomachinery, Sweden

A privately owned LNG plant was started up at the Tuha Oil Fields in western China during 2004. The

plant is running on associated gas from the oil field and the LNG is delivered to central China by trucks.

The plant was delivered by Tractebel with Linde AG being responsible for the LNG process design. The

compression set of the refrigeration cycle consist of a three-stage Ebara compressor driven by a 24 MW

Siemens SGT-600 gas turbine operating on the off-gas from the LNG plant.

The operation of the gas turbine integrated in this plant is associated with some special challenges:

- the ambient conditions out in the desert.

- the fuel varies from natural gas to a process gas consisting of methane diluted with up to 28%

nitrogen

- the refrigeration medium circulated by the driven compressor is changing in composition with load

- the starting procedure with the compressor in the refrigeration loop

A combustion test was performed to verify that the DLE combustion system could accept the variations in

gas composition.

The control system was modified to handle the variable gas qualities in the fuel and in the refrigeration

loop.

The commissioning of the gas turbine/compressor set was a long process governed by the LNG plant

commissioning. It included some unexpected events.

In the end all is working well. It is shown that a standard SGT-600 DLE unit can start and operate

reliably and with low emissions on very much diluted natural gases.

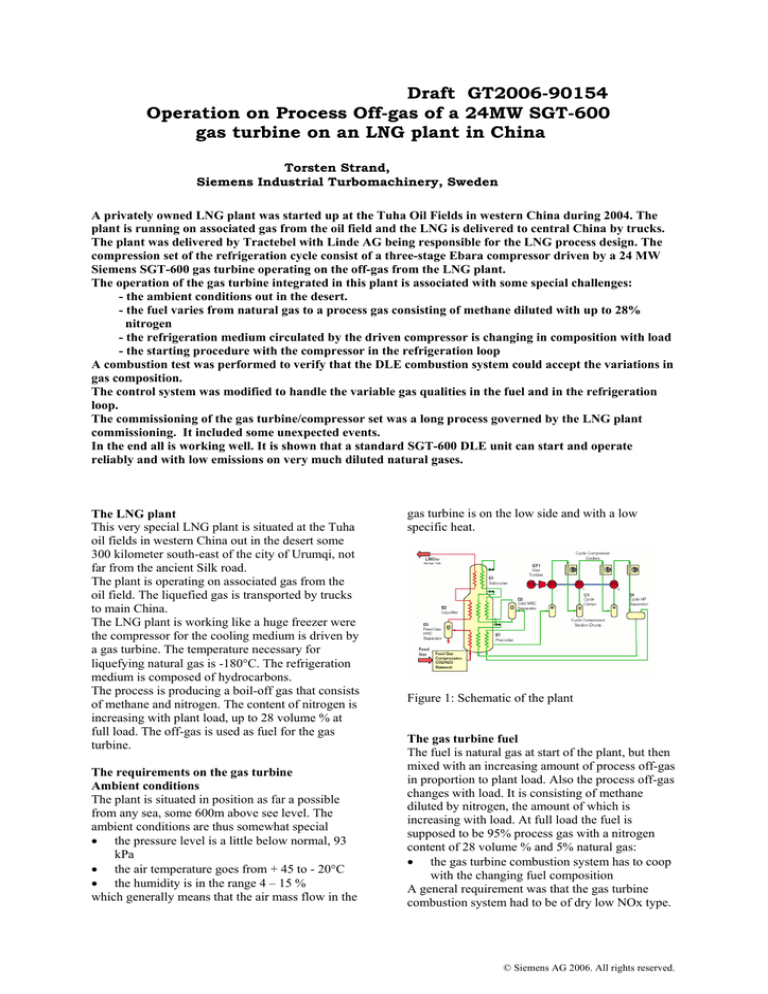

The LNG plant

This very special LNG plant is situated at the Tuha

oil fields in western China out in the desert some

300 kilometer south-east of the city of Urumqi, not

far from the ancient Silk road.

The plant is operating on associated gas from the

oil field. The liquefied gas is transported by trucks

to main China.

The LNG plant is working like a huge freezer were

the compressor for the cooling medium is driven by

a gas turbine. The temperature necessary for

liquefying natural gas is -180°C. The refrigeration

medium is composed of hydrocarbons.

The process is producing a boil-off gas that consists

of methane and nitrogen. The content of nitrogen is

increasing with plant load, up to 28 volume % at

full load. The off-gas is used as fuel for the gas

turbine.

The requirements on the gas turbine

Ambient conditions

The plant is situated in position as far a possible

from any sea, some 600m above see level. The

ambient conditions are thus somewhat special

• the pressure level is a little below normal, 93

kPa

• the air temperature goes from + 45 to - 20°C

• the humidity is in the range 4 – 15 %

which generally means that the air mass flow in the

gas turbine is on the low side and with a low

specific heat.

Figure 1: Schematic of the plant

The gas turbine fuel

The fuel is natural gas at start of the plant, but then

mixed with an increasing amount of process off-gas

in proportion to plant load. Also the process off-gas

changes with load. It is consisting of methane

diluted by nitrogen, the amount of which is

increasing with load. At full load the fuel is

supposed to be 95% process gas with a nitrogen

content of 28 volume % and 5% natural gas:

• the gas turbine combustion system has to coop

with the changing fuel composition

A general requirement was that the gas turbine

combustion system had to be of dry low NOx type.

© Siemens AG 2006. All rights reserved.

The cooling medium

The cooling medium is also changing with load,

which means that the three-stage refrigeration

compressor is operating at different conditions.

It is normally natural gas at plant start up. With

increasing plant load heavier hydrocarbons are

added to decrease the temperature in the LNG tank.

This has some implication on the gas turbine:

• the variable speed compressor, which is driven

by the power turbine of the gas turbine, is

always in the cooling loop

• the heavier the medium the higher the shaft

torque (also at start up)

• the compressor surge control, which is

included in the gas turbine controller, has to be

automatically adjusted for the change in

cooling medium composition

• the nominal compressor power demand is 17

MW at to = 32°C, but could on a cold day

reach 22MW

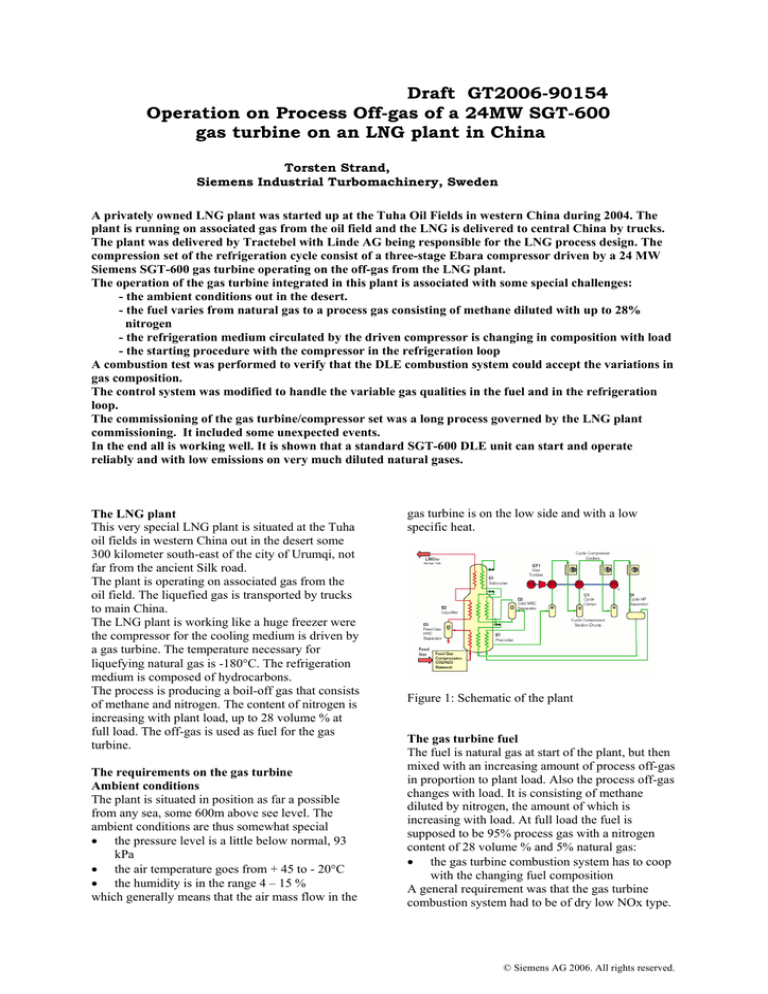

The waste heat recovery unit

The exhaust system includes a waste heat recovery

unit for oil preheating with a rather unusual

configuration, which causes a somewhat high and

variable pressure drop.

GT10B Tuha exhaust duct

Stack

Butterfly valve

GT

Silencer

Oil

heater

Figure 2. The exhaust duct with the heat recovery

unit and it´s controlling butter fly valve

The gas turbine/compressor set

The gas turbine SGT-600 with a nominal shaft

power of 25 MW at ISO conditions was chosen for

driving an Ebara three stage compressor. The

compressor has a maximum speed of 7400 rpm

which fairly well matches the two stage power

turbine, which has a nominal speed of 7700 rpm.

The gas turbine has

• a 10 stage compressor with a pressure ratio of

14:1

• a DLE combustion system consisting of a film

cooled annular combustor with 18 burner of the

lean premix type

• a two stage internally cooled compressor

turbine

• a two stage uncooled power turbine

Figure 3: Cross section of the SGT-600 gas turbine

The main initial questions for this application were

• will the combustion system handle the diluted

fuel gas

• how to modify the fuel control system for

operation on variable nitrogen content in the

fuel

• could ignition be achieved on diluted gas

• how to arrange surge control on the three

stages of the driven compressor, considering

the changing cooling medium

A gas analyser in the LNG plant was installed for

continuously supplying data on the fuel and the

cooling medium to the plant and gas turbine

controllers.

The combustion system

The DLE combustion system of SGT-600 was

developed in 1989-90 and has a long experience on

natural gas. The annular combustor is film cooled.

About 60% of the compressor air is used as

combustion air in 18 conical burners. The main fuel

is injected along the air slots of the burner and the

pilot fuel in the centre of the cone.

e

d

c

b

a

Figure 4 Cross section of the combustor and burner

a) combustor, b) one of 18 burner, c) main gas

manifold, d) pilot gas manifold, e) igniter and flame

detector

© Siemens AG 2006. All rights reserved.

The experience of operation on diluted gas was

limited to lower dilution rates. Several units are

since long in operation on diluted natural gas in the

Netherlands. The Dutch gas contains 14% nitrogen.

Combustion air

Vortex breakdown

Main Gas

Pilot Gas

Main Gas

Gas injection

holes

the burner, which was equipped with a glass slot

along the cone.

The fuel system was rebuilt for separate injection of

nitrogen into the main and pilot fuel supply lines.

The objectives of the test were in addition to the

standard measurements of combustion testing

(flows, pressure drops, temperatures etc) to

• watch the flame for changing position and

shape with variation of nitrogen content

• measure combustion pulsations and emissions

• check ignition performance

Ignition

Flame front

Main&pilot fuel pfr

mfuel, p, T

mburner

m tot, T, p

Figure 5. The DLE burner of SGT-600

Air

Main&pilot N2

Video cameras

p

The combustion system had also been operated on

propane, thus with lower fuel injection velocities.

∆p

mcool

The general philosophy for this DLE burner is that

due to the high combustion air flow (which is 80%

nitrogen) there is a very limited influence on the

combustion kinetics from a small amount of

nitrogen in the fuel.

However the nitrogen in the fuel will increase the

fuel injection velocities, which could change the

distribution of the fuel in the burners. The question

was than if the injection geometry (main hole sizes

or number of holes, pilot injector slots) had to be

modified to accept the addition of 28% nitrogen.

It was decided to perform a single burner test in

order to find out if the standard geometry would

work or is it had to be modified.

The combustion test

The single burner test was performed at the

Combustion Test Centre in Whetstone outside

Leicester, UK.

A cylindrical test combustor for one burner was

used. The geometry and wall cooling configuration

was designed to resemble the annular combustor as

closely as possible. It is always difficult to model

the effect of the neighbouring burners of an annular

combustor in a single burner test.

Test burners with standard and enlarged main

injection holes were fabricated.

Several pilot injectors with enlarged and modified

injection geometries were tested in a hydraulic rig

and the best were chosen for the combustion test.

It was believed that the increased pilot injection

momentum could have a destabilising effect on the

burner flow.

The test combustor was installed in a combustion

test cell, which had been modified for flame

visualisation. One video camera was viewing the

flame in the combustor and one was looking into

N2

m, p, T

P´

NOx, CO, TOC, O2, CO2

Figure 6. Schematic test set up

The first test object was the standard burner and

pilot fuel injector.

The test program covered a number of points on the

gas turbine operating line at different ambient

conditions. At each point the pilot fuel ratio was

varied. The testing started with operation on natural

gas. Nitrogen was first added in steps to the pilot

gas and then to the main gas.

Test result

It was found that the nitrogen injection in the pilot

had little influence on the flame position.

The flame position was however quite strongly

influenced of nitrogen injection in the main gas.

The flame was creeping more and more inside the

burner, as an effect of the stronger fuel injection

towards the centre of the burner

At very high nitrogen rates in the main gas an

unstable situation was reached: a repeated process

of

• flame slowly retracting into the burner

• instant flame back (the flame moving upstream

on the centre line of the burner, not heating the

burner walls)

• flame “spitted out”

The range for operation on diluted gas was shown

to increase by increasing the pilot fuel ratio, mainly

as an effect of reduced main gas penetration.

The standard burner could operate without coming

close to flame back on 28% nitrogen, so the test on

© Siemens AG 2006. All rights reserved.

©Siemens Power Generation 2003. All Rights Reserved

the modified burner was found unnecessary. A test

with a modified pilot injector was performed but

without any measurable influence on the

performance.

Power Generation

Figure 7. Flame back sequence

The results of the test were very positive since it

was found that

• the standard burner and pilot injector could

accept the high nitrogen content with margin

• the nitrogen dilution range could be extended

by increasing the pilot fuel ratio

• no combustion pulsations were found

• flame back conditions could be indicated in

advance by the increasing pressure drop

variations across the burner

• ignition on diluted gas could be achieved with a

slight increase in fuel flow, basically to keep the

combustible gas content constant

SGT-600 Single Burner Test at 100% load

400

N2 in pilot

NOx

60

300

N2 in main fuel

40

200

Pilot fuel ratio

20

100

CO

0

70

75

80

85

90

CO ppm v

Pfr% , N2 ratio % , NO x ppm v

500

80

95

0

100

Test reading no

Figure 8. General emission test results at 100% load

The emission performance looks basically the same

at all loads as shown in figure 9.

NOx is strongly depending on pilot fuel ratio. NOx

is decreasing with increasing N2 in the pilot fuel,

but not affected by the N2 in the main fuel.

CO is not affected by the N2 in the pilot fuel but

increased by the N2 in the main fuel.

The general conclusions are that

• the SGT-600 cone burner has a very wide

capability to accept diluted fuels

•

•

the dilution limit resulting in flame back can be

detected in advance by a standard pressure

drop measurement on the combustor

ignition can be achieved on diluted fuel

dilution of natural gas results in lower NOx

emissions

Plant commissioning

Since the refrigeration compressor is in the cooling

loop of the LNG plant, the commissioning of the

gas turbine and the plant had to go hand in hand,

which proved to be a comparatively long process.

Normally the SGT-600 is commissioned in six

weeks, but in Tuha it took several months.

11

100

•

Start procedure

The start up of the compressor set showed to be

somewhat different, since the compressor required

quite a lot of power already at low speed in spite of

fully open surge control valves. Normally the gas

generator is accelerated to an idle = no load

condition. But in this case high load was reached

already during that acceleration so the acceleration

sequence had to be modified to a slower continuous

loading process, governed by the time needed by

the plant itself.

The commissioning was mainly done during the

summer with ambient temperatures in the range of

35-45°C, somewhat low ambient pressure and a

humidity of around 4 %. The air mass flow into the

compressor could be characterised as “low and

thin”.

Too high engine exhaust temperatures were

measured during the initial gas generator

acceleration, often tripping out the gas turbine. The

start setting values (cross ignition gas level,

acceleration ramps) were adjusted with some

improvements. After some time it was found out

that the explosion proof thermo-couple wiring

between the gas turbine and the control room was

of different standard, resulting in too high readings

at high ambient conditions. The temperature limits

could with this knowledge be compensated for this

effect.

In due time the wiring was exchanged.

The gas turbine was supposed always to start on

natural gas. However after operation on process gas

there is diluted gas in the 55 m long supply piping,

not natural gas. The problem was solved by a

control program modification, so that the start

control sequence is for some time using gas data

from the last stop to calculate the fuel valve values.

A small gas pipe for natural gas was installed for

the torch burners instead of using the standard set

up with propane bottles, which were scare in supply

in this part of China.

Cross ignition on the diluted gas showed to be of no

problem, as expected after the combustion test.

© Siemens AG 2006. All rights reserved.

The increased and varying pressure drop in the

exhaust duct was at first a problem, but after some

time it was found that the controlling butterfly

valve had a 90° position error. It was closed when

supposedly open.

After correcting the valve the exit pressure drop

caused no problem.

The tuning of the compressor surge control system

showed to be rather tricky. It was no problem to

tune each bypass valve on the three stage

compressor, but it took some time to get all three

stages working smoothly together. The difficulty

seemed to be related to the changing compressor

stage characteristics with changing composition of

the operating medium.

Performance test

At the end of the commissioning a performance test

was run with a special set up of measuring

equipment including registration of combustion

pulsation, dynamic combustor pressure drop and

emissions.

The load variation on the gas turbine was governed

by the plant operation and was rather limited,

between 13 and 15 MW. Also the operating

conditions was set by the plant. A systematic test

program could not be followed. However,

increasing plant load means basically lower

refrigeration temperature and changing fuel

conditions as described above

• increasing amount of nitrogen in the fuel gas

• increasing amount of heavier hydrocarbons in

the cooling medium

During the test series at different plant loads, which

took several days, pilot fuel ratio was varied up and

down to find out if there were any risks for

combustor pulsations or flame back (indicated by

increasing amplitude of the dynamic combustor

pressure drop). The N2 content in the fuel gas also

varied due to changing plant load. Some additional

N2 was injected in the fuel in order to extend the

dilution rate somewhat. It was however not possible

to reach the absolute full load conditions during the

test.

The results of the engine test were very good

• no combustor pulsations or flame back

indications even at extreme pilot fuel ratios, so

the pre-set pilot fuel ratio schedule could be

used

• the emissions with nitrogen dilution was

following the same trends as seen at the single

burner test. NOx is increasing with pilot fuel

ratio, but decreasing with increasing N2. CO is

decreasing with pilot fuel ratio but increasing

with increasing N2.

Conclusions

The integration of the gas turbine in the LNG

process was not without problems, but they were

sorted out before and during the commissioning.

The combustion test showed that the standard

combustion system could handle up to 35 vol-% N2

in the fuel. With a modified fuel injection still

higher rates would be possible.

The site test confirmed that the SGT-600 gas

turbine could be started and operated on both

natural gas and a process gas consisting of methane

diluted with a varying amount of nitrogen.

The NOx emissions were slightly lowered by the

dilution, no combustor pulsations or instabilities

were detected.

Reference

Baseload LNG production in Xin-Jiang – a remote source of clean energy for gas consumers in China.

Xiang Dong, Xin Jiang LNG Development Co, Eginhard Berger, Linde Ag, Albert Meffert, Tractebel,

Li Wei Bin, SSEC . 2005 AIChE Spring National Meeting in Atlanta, GA, USA

© Siemens AG 2006. All rights reserved.