The 19

The 19 th International Symposium on High Voltage Engineering, Pilsen, Czech Republic, August, 23 – 28, 2015

1

ENHANCED CALCULATION AND DIMENSIONING OF OUTER

CORONA PROTECTION SYSTEMS IN LARGE ROTATING MACHINES

2

1

G. Schmidt 1* , A. Litinsky 2 and A. Staubach 1

Siemens AG, Rheinstr. 100, 45478 Muelheim an der Ruhr, Germany

University of Duisburg-Essen, ETS, Bismarckstr. 81, 47057 Duisburg, Germany

*Email: guido.schmidt@siemens.com

Abstract :

The primary components of electrical field grading systems in modern large rotating machines and especially in large turbo generators are applied to cope with locally increased electrical and thermal stresses affecting the electrical insulation system. In terms of future development and improvement of efficient insulation systems with a higher output to volume ratio adequate tools and techniques are necessary for dimensioning the electrical field grading system in a time and cost saving manner.

Numerical calculation models based on the Finite Element Method (FEM) allow a theoretical approach to design electrical field grading systems before approving the functionality in real test setups. Additionally these calculation models help to get an indepth understanding of specific theoretical aspects which are not possible to be measured physically or calculated with analytical equations at all.

In this essay highly specialized FEM models are introduced which allow calculations of extensively structured OCP systems. Especially the results of investigations of electrical parameters (i.e. potential, field distribution, resistive losses) depending on varying OCP resistivity are discussed. Based on this it will be illuminated if and how an optimum OCP resistance could be defined at all based on the major influencing parameters.

INTRODUCTION

The main insulation system of large rotating machines applied at high rated voltages up to 27kV is an arrangement of fundamental subcomponents.

Here the main insulation layer is embedded in the multilayer structure build up by the field grading components inner corona protection (ICP), outer corona protection (OCP) and end corona protection (ECP). These components have to cope with individual service relevant challenges. The function of the OCP system is to connect the ground potential to the main insulation surface via the laminated stator core and to control the electrical field strength distribution in the main insulation in the slot area. Here the OCP material itself is mainly characterized by its nominal resistivity which constitutes the overall resistance of the complete OCP system depending on a complex insulation system geometry and structure.

Any variation of the resistivity, i.e. due to manufacturing process parameters or service related global ageing or local degradation effects, leads to a change of the overall OCP system behaviour or the localized OCP integrity. The assessment of such variations is closely related to the still open discussions about optimum OCP resistivity on rotating machine insulation systems.

The continuously rising requirements on efficiency for rotating machines demand a simultaneous quality and resistivity improvement of insulating systems. The wish to control multiple electrical and mechanical influences raised the overall complexity of insulating systems including their components. It is assumed that especially air cooled rotating machines are exposed to higher thermal, electrical and mechanical stress due to less efficient type of cooling. These machines are usually manufactured in a GVPI (Global Vacuum

Pressure Impregnation) process, which requires special aligned solutions to handle the stress types stated above. In the last years an increased amount of issues regarding multiple kinds of insulation system deterioration could be observed on air cooled machines respectively turbine generators. Most of the published literature highlights the increased thermal and electrical stresses which could lead to severe PD related degradation as a reason for such observations [1].

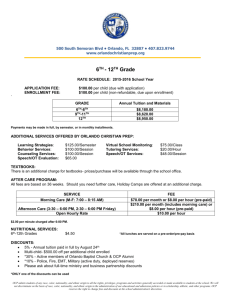

2 GVPI STATOR INSULATION SYSTEM

The insulation systems of large rotating machines and especially of large turbo generators which are manufactured according to the GVPI process and that are operated at high electrical, mechanical and thermal stresses require multi-layered field grading components and designs with high complexity. The actual electrical highly stressed main insulation sleeve consists of resin impregnated wrapped fine mica tape layers and is embedded by the ICP (on high electrical potential) and the OCP (on ground potential). In detail the high electrical potential is distributed over the full length of ICP by a copper strip, which is connected directly to the copper

Roebel bar in a certain location. Both the ICP and the OCP in combination provide a preferably homogenous electrical field.

2.1 Corona Protection System OCP and ECP

Many air cooled machines are manufactured in a cost- and assembly-effective GVPI process. After the curing cycle the stator converts to an overall compact and solid structure. Especially large generator stators have to be assessed in terms of thermo-mechanical forces under service conditions i.e. shear forces in the fixed stator bars. This fact demands customized solutions for a GVPI insulation sleeve to prevent possible damages which could lead to serious insulation damages.

Therefore all large Siemens generators are equipped with a so called double layer OCP system. In this design the relevant detail is a insulating layer of mica splitting tape which is embedded between two wrapped OCP layers

(inner OCP and outer OCP) (Figure 1) [2].

Figure 1: GVPI stator bar insulation system

This construction defines a predetermined area which could allow certain kind of relative movement of the bar without damaging the main insulation layer due to delamination from the electrode layers. The inner layer of the double layer OCP system is the active electrode on ground potential to homogenize the electrical field inside the main insulation sleeve. The outer conductive layer directly contacts the laminated stator core. For a proper electrical function the ground potential from the stator core is transported to the inner layer by an interwoven conductive tape stripe, which alternately contacts both conductive layers of the double-OCP system on one broad side of the stator bar (Figure 1 and Figure 2).

Figure 2: Taping processes of GVPI OCP system

In the slot exit area on both ends of the laminated stator core the bars drop out of the core and bend into the involute portion in end winding baskets.

The OCP layers end right after the slot exit. Hence the connection to the grounded core sheets is restricted. To prevent any surface discharge activity at the OCP ends these are cover and contacted by the end corona protection (ECP) [3].

The ECP controls the electrical potential raise from ground to nearly rated high potential. Today’s ECP materials show a complex dependency of the ECP resistance of the local field strength and of the local temperature [4]. Out of this it directly follows that the OCP and the ECP constitute a field grading system where specific electrical and thermal behaviors influence each other’s. In consequence the assessment of the overall functionality has to be performed with the analysis especially of the possible interactions between

OCP and ECP.

2.2 OCP Resistance

The resistance of the OCP in principle is a commonly used parameter for multiple discussions that deal with electrical functionality or degradation and damaging issues [1]. Here the so called square resistance often has to serve as a popular simplification of an in fact complex structure of interactions between multiple resistance influence factors [5][6]. The question after the “optimum OCP resistance” is still not answered. There are discussions ongoing but such searches for proper

OCP resistance values can hardly be answered if the relevant influencing factors are not combined to an overall sight [5].

The resistance value or range for OCP material

(i.e. tape) is obviously depending on the specific design and with consideration of all relevant boundary conditions. The consequences of lowered resistance could be electrical losses through parasitic currents. Heightened resistances could lead to insufficient field grading and therefore to discharges, which have potential to damage the insulation [7]. In reality the target value for the resistance generally varies depending on the manufacturer and type of the rotating machine. For example, most of the tapes on the market developed for application as corona protection material show a strong dependency of the resistivity on epoxy resin content results from impregnation and curing process [5].

As explained in this essay the overall OCP system could be a complex composition of conductive structures. Therefore it is more plausible to not discuss an OCP resistance but to investigate the

OCP resistivity as a strongly material related parameter. Then it also would be possible to discuss even local parameters like direction dependency of the resistivity [5].

3 IMPROVED FEM CALCULATIONS

Assuming the mentioned facts the consequences of resistivity deviations for the multi-layered insulation system will be investigated. The geometrical complexity of the whole structure can hardly be approximated with one equivalent circuit.

Here the implementation of a numerical method such as FEM (Finite Element Method) has proved its efficiency [2][5]. The previous attempt to approach the electrical characteristics of generator stator bars resulted in two initial FEM models of the straight portion and were realized based on certain

Siemens generator designs. The basic applicability of FEM as well as the dependency between resistivity and insulation system design has been demonstrated successfully [5].

But the existing models were limited to the OCP material as the only resistive component. It was already described that the overall corona protection system consists of OCP and also of

ECP components. Hence it is essential to extend the existing models by implementing the relevant

ECP components. Due to material specific nonlinear properties of the ECP material it shows a field strength and also temperature dependent behaviour. This specific aspect was deeply discussed in [4] and led to calculation results by performing extensive iterative calculations which customized the resistivity of ECP material depending on local field strength distribution and heat generation.

3.1 Extended FEM Models

The areas of interest regarding complex interactions between OCP resistivity and stator design are the straight part of the stator bars in the slot and the slot exit area where the ECP is located

(see Figure 3: yellow marks).

Especially the areas outside of generator stator core are very complex structures. The presence of specific geometrical and electrical components like the stepped iron as local distribution of the ground potential results in challenging FEM model creations (Figure 4).

OCP laminated core protection layer

Figure 4: Slot exit area at core ends

Both improved models base on a specific and real

Siemens generator design. The model of the straight part of the stator bar is a short section of a several meters long bar (Figure 5). The transparent volumes represent the stator core sections separated by ventilation ducts.

Figure 3: End winding basket of GVPI generator stator Figure 5: Section of generator stator straight part embedded in stator core sections

The FEM model of the slot exit area is shown in

Figure 6. It underlines the complex geometry where no symmetries could be used to reduce meshing and calculation effort. The model is shown here without the red protection layer to better visualize the relative positions of OCP and contacting ECP.

ECP

Figure 6:

OCP

FEM model of stator bar in slot exit area

Figure 7 gives an impression of FEM calculation status after the meshing process. stator core results with sufficient resolution. The reason for minimization of finite elements and connecting nodes is founded in the necessity of multiple iteration and calculation steps to generate plausible electrical and thermal results.

Furthermore it is still a major challenge to realize a computable FEM model where thick insulation layers of relevant length are covered by very thin layers which are the area on interest.

3.2 Calculation Results

The presentation on the calculation results concentrates on the qualitative assessment of electrical parameters like electrical potential, electrical field strength and on the temperature distributions. With this the capability of the improved FEM models should be pointed out. The investigation and discussion of quantitative results regarding optimization of OCP resistivity has to be realized in follow up essays. Therefore the calculations were performed with three different OCP resistivities: low, medium, high.

3.2.1 Straight Part: Mica Interlayer in OCP

As the mica splitting layer as a mechanical slip layer has the character of a very thin insulating material it could be relevant in terms of feasible

OCP resistivity values to assess the electrical stress in that layer. Under normal resistivity conditions this area is expected to be nearly free of electrical stress. In principle it is supposable that the specific geometric structure of the double layer

OCP could lead to locally heightened electrical field strength stress in the mica splitting layer. But only the FEM calculation could lead here to concrete evaluation of local electrical stress.

Figure 8 shows the straight part bar section and on the right the extracted mica splitting layer which is normally embedded between the inner and outer

OCP layers.

Figure 7: Meshed FEM model of stator bar in slot exit area

The completed model of this slot area contains approx. 100.000 elements. This number is the result of multiple meshing trials to determine the minimum density at hence number of finite elements. Even though this could be assessed as a relatively rough meshing it definitely provided

Figure 8: Meshed FEM model of stator bar straight part and extracted mica splitting interlayer with result path and coordinates cross

The red line demonstrates the path around the bar as origin of the electrical field strength values. The angle φ displays the direction of rotation starting at 0° to recognize the position after transformation into polar coordinates (Figure 9).

(a): low resistivity

Figure 9: Electrical field strength in mica splitting layer depending on OCP resistivity

It is obvious that the electrical field strength follows the asymmetric bar design where the interweaved layer only is located on the one broad side. On the other side the electrical field strength could reach high values due the fact that the electrical potential has to be carried around half of the bar.

3.2.2 Slot Exit Area

The field strength dependent characteristic of ECP allows a targeted manipulation of electrical potential in the slot exit area close to the end of the grounded core. The ECP is connected to the laminated stepped core on ground potential via the resistive OCP. That means that the OCP feeds the

ECP with current. This clarifies the assumption that both field grading components simply influence each other. The range of this interaction depends on the ratio of the OCP and ECP resistivity.

According to the straight part model only an FEM calculation can clarify the special potential distribution for example in the outer OCP layer.

Figure 10 shows these distributions for three OCP resistivities (low, medium, high).

The simulation results show clearly that the high electrical potential “moves” towards the laminated stator core corresponding to the increase of OCP resistivity. That means that the OCP behaves more like an ECP if its resistivity is getting very high. So it could be imagined that unexpected high OCP resistivity could lead to localized heightened electrical field strength on the surface of the OCP followed by unacceptable and probably deteriorating surface discharges.

(b): medium resistivity

(c): high resistivity

Figure 10: Electrical potential distribution in OCP and ECP areas depending on the resistivity of

OCP material

Figure 11 concentrates on the potential distribution along the center of the upper narrow side of the model bar. Here the transition area between OCP and ECP is marked as dotted line. On the one hand the increase of electrical potential with rising

OCP resistivity is obvious. On the other hand that diagram clearly shows that the heightened OCP resistivity impacts the function of the whole field grading system. The common “potential overshoot” of the ECP seems to move towards the core with increasing OCP resistivity.

Figure 11: Electrical potential distribution on the upper narrow side of the bar in the slot exit area

3.2.3 Temperature Distribution in OCP Layer

The results of the electrical parameters show that resistivity conditions could influence the functionality of the OCP ECP network. Of course resistivity aspects could directly be translated into conclusions for currents and hence into heat generation results. Here the FEM allows a coupled simulation of electrical and thermal influences depending on the defined boundary conditions.

Figure 12: Temperature Distribution caused by

Ohmic losses in the ECP and OCP

In this first step it was possible to calculate a volumetric heat generation rate caused by a proper functioning of the ECP as well as the locally heightened current flow between stator core and

ECP (Figure 12). This example shows exemplarily the result for medium OCP resistivity. The difference between low and high temperature in this example result plot is several Kelvin. But it has proved the model’s capability for heat generation calculations, too.

4 CONCLUSIONS

The FEM has the potential to generate plausible information about the insulation system of rotating machines and especially large turbo generators.

With the successful implementation of the analysis of interactions between OCP and ECP a fundamental basis for further investigations of OCP resistivity optimization is achieved.

REFERENCES

[1] W. H. Moudy, “Deterioration Mechanisms in recent air cooled turbine generators”,

Proceedings of PWR2006: ASME Power,

Atlanta, Georgia, USA, May 2-4, 2006

[2] J. R. Weidner, C. Staubach, G. Schmidt,

„Elektrische Feldsteuerung bei Ständerwicklungen von Turbogeneratoren – Anforderungen, Berechnungsverfahren, Konstruktion, Betriebsverhalten“, ETG-Fachbericht

131, Feldsteuernde Isoliersysteme, pp. 73-84,

2011

[3] R. Bruetsch, “Insulating Systems for High

Voltage Motors”, 11th INSUCON, 2009

[4] C. Staubach, S. Kempen, F. Pohlmann,

“Calculation of electric field distribution and temperature profile of end corona protection systems on large rotating machines by use of finite element model”, International

Symposium on Electrical Insulation ISEI, San

Diego, CA, USA, 2010

[5] G. Schmidt, F. Emery, H. N. Koelnberger,

„Modelling of Outer Corona Protection

Systems of Large Rotating Machines using

Finite Element Method”, ISH2011, 2011

[6] M. Liese, M. Brown, “Design-Dependent Slot

Discharges and Vibration Sparking an High

Voltage Windings”, IEEE Transactions on

Dielectrics and Electrical Insulation, Vol. 15,

No. 4, pp. 927-932, 2008

[7] M. Kaufhold, K. Schaefer, K. Bauer, A.

Bethge, J. Risse, „Interface Phenomena in

Stator Winding Insulation – Challenges in

Design, Diagnosis and Service Experience”,

IEEE Electrical Insulation Magazine, Vol. 18,

No. 2, pp. 27-36, 2002