Atomic Layer Deposition on Titania Nanotube Electrodes for Sodium-Ion Batteries

advertisement

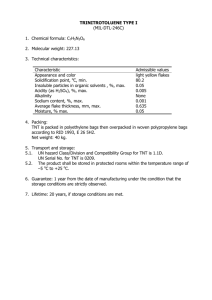

Atomic Layer Deposition on Titania Nanotube Electrodes for Sodium-Ion Batteries Michael A. Reinisch, Aaron Forde, Griffith Allen, Steven Letourneau, Riley Parrish, Hui (Claire) Xiong, Elton Graugnard * Department of Materials Science & Engineering, Boise State University, Boise, ID 83725 USA (*email: eltongraugnard@boisestate.edu) 1. INTRODUCTION Background: • Lithium-ion batteries suffer from safety concerns and high precursor cost • Sodium-ion batteries serve as cost-effective alternatives for large-scale energy storage systems • Due to their size, sodium ions (ion radius: 1.06Å) do not intercalate into anode materials efficiently as lithium ions (ion radius: 0.76Å) Hypothesis: • Growth of TiO2 by atomic layer deposition will lower surface energy and facilitate sodium-ion intercalation 2. MECHANISM Titania Nanotube Schema;c of ;tania nanotubes (TNTs) in a sodium electrolyte. 3. TITANIA NANOTUBES Materials for Electrochemical Anodiza1on • Etchant/Electrolyte: Dilute Ammonium Fluoride (NH4F) in Formamide and water • Two-­‐electrode Cell: Working electrode – Ti foil Counter electrode – Pt mesh Electrochemical Anodiza1on 1. A posi;ve voltage of 25 V is applied to Ti foil through DC power supply for 30 min 2. As-­‐prepared samples are rinsed with DI water and immersed in IPA for a TEM r evealed t hat t he T NTs few hours synthesized b y e lectrochemical 2 3. 1.6 cm discs are anodiza;on have an average punched out from anodized FOIL for baLery wall thickness of 15 nm and inner d iameter o f 8 0 n m. fabrica;on 5. SURFACE ENERGY Surfaces are higher energy because surface atoms are less ;ghtly bound than atoms in the bulk. Lowering surface energy improves sodium ion diffusion into the TNT walls. While charging, sodium ions adsorb to the sidewalls of the TNTs. As the sodium-­‐ion concentra;on increases near the sidewall, the ions begin to diffuse into the TNT’s structure. 4. ATOMIC LAYER DEPOSITION Transmission electron microscope (TEM) images of TNTs aUer TiO2 Surface energy, γ, is defined to be the Gibbs atomic layer deposi;on (ALD). free energy per unit area. Thicker tube walls indicate growth towards the top of the TNTs. Thinner walls near the boLoms of the TNTs indicate that precursor residence ;mes were insufficient. Key: Precursor combina1ons: 1. H2O with one of the following 2. Titanium (IV) Isopropoxide (TTIP) Dimethylamino Titanium (TDMAT) Titanium Tetrachloride (TiCl4) 1. TTIP aLaches to TiO2 surface. IPA leaves as by-­‐product. 2. Water reacts to form hydroxyl terminated surface. 3. IPA leaves as by-­‐ product. Cycle starts over, releasing TTIP. Process repeats un;l the desired film thickness has been achieved. 6. DISCUSSION Progress to Date • Uniform growth of Al2O3 was successful, valida;ng processing and characteriza;on procedures. • Only minimal growth of TiO2 has been observed using TTIP or TDMAT despite published growth protocols. • The lack of TiO2 growth is aLributed to the low vapor pressure of TTIP and TDMAT. • ALD-­‐TiO2 will be grown using TiCl4, which has a significantly higher vapor pressure than TTIP or TDMAT. • Lack of growth with TiCl4 will indicate surface chemistry issues. Summary • TNTs offer performance advantages through increased electrochemical ac;vity and poten;ally enhanced capacity. • Increasing the TNT radius of curvature lowers its surface energy, thus improving sodium-­‐ ion intercala;on into the anode material. • ALD deposited ultra-­‐thin ;tania coa;ngs on TNT anodes should improve the baLery capacity and cycling stability of TNT anodes. Acknowledgments: This project was supported by the REU in Materials for Energy & Sustainability at Boise State University (Research grant number DMR 1359344), funded by the National Science Foundation. We also thank the students and staff of the Nanoscale Materials & Device Research Group (nano.boisestate.edu). ICUR 2014