Motivation

Motivation

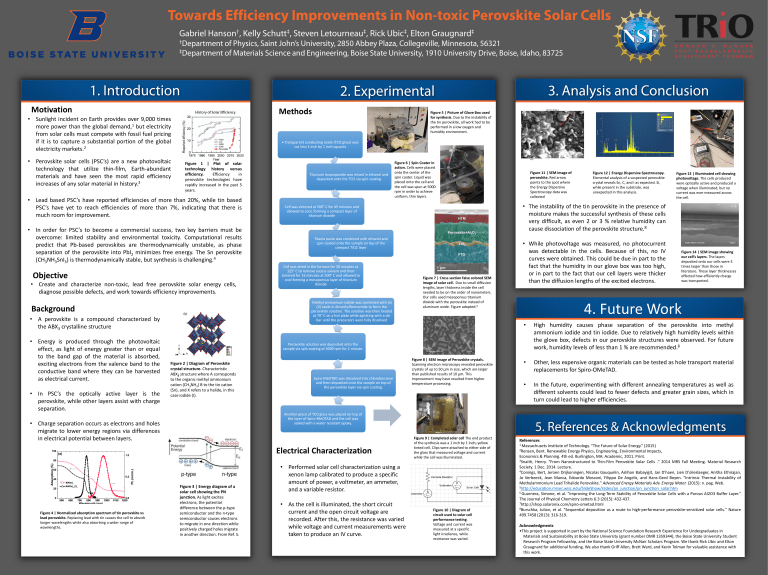

• Sunlight incident on Earth provides over 9,000 times more power than the global demand, 1 but electricity from solar cells must compete with fossil fuel pricing if it is to capture a substantial portion of the global electricity markets.

2

• Perovskite solar cells (PSC’s) are a new photovoltaic technology that utilize thin-film, Earth-abundant materials and have seen the most rapid efficiency increases of any solar material in history.

3

Figure 1 | Plot of solar technology history versus efficiency.

Efficiency in perovskite technologies have rapidly increased in the past 5 years.

• Lead based PSC’s have reported efficiencies of more than 20%, while tin based

PSC’s have yet to reach efficiencies of more than 7%, indicating that there is much room for improvement.

• In order for PSC’s to become a commercial success, two key barriers must be overcome: limited stability and environmental toxicity. Computational results predict that Pb-based perovskites are thermodynamically unstable, as phase separation of the perovskite into PbI

2

(CH

3

NH

3

SnI

3 minimizes free energy. The Sn perovskite

) is thermodynamically stable, but synthesis is challenging.

4

Objective

• Create and characterize non-toxic, lead free perovskite solar energy cells, diagnose possible defects, and work towards efficiency improvements.

Background

• A perovskite is a compound characterized by the ABX

3 crystalline structure

• Energy is produced through the photovoltaic effect, as light of energy greater than or equal to the band gap of the material is absorbed, exciting electrons from the valence band to the conductive band where they can be harvested as electrical current.

• In PSC’s the optically active layer is the perovskite, while other layers assist with charge separation.

• Charge separation occurs as electrons and holes migrate to lower energy regions via differences in electrical potential between layers.

Figure 2 | Diagram of Perovskite crystal structure. Characteristic

ABX

3 structure where A corresponds to the organic methyl ammonium cation (CH

3

NH

3

) B to the tin cation

(Sn), and X refers to a halide, in this case iodide (I).

Figure 4 | Normalized absorption spectrum of tin perovskite vs lead perovskite. Replacing lead with tin causes the cell to absorb longer wavelengths while also absorbing a wider range of wavelengths.

Figure 3 | Energy diagram of a solar cell showing the PN junction. As light excites electrons, the potential difference between the p-type semiconductor and the n-type semiconductor causes electrons to migrate in one direction while positively charged holes migrate in another direction. From Ref. 5.

Methods

• Transparent conducting oxide (TCO glass) was cut into 1 inch by 1 inch squares

Titanium Isopropoxide was mixed in ethanol and deposited onto the TCO via spin coating

Figure 6 | Spin Coater in action.

Cells were placed onto the center of the spin coater. Liquid was placed onto the cell and the cell was spun at 5000 rpm in order to achieve uniform, thin layers.

Cell was sintered at 500° C for 45 minutes and allowed to cool, forming a compact layer of titanium dioxide

Figure 5 | Picture of Glove Box used for synthesis . Due to the instability of the tin perovskite, all work had to be performed in a low oxygen and humidity environment.

Titania paste was combined with ethanol and spin coated onto the sample on top of the compact TiO2 layer

Cell was dried in the furnace for 30 minutes at

125° C to remove excess solvent and then sintered for 15 minutes at 500° C and allowed to cool forming a mesoporous layer of titanium dioxide

Methyl ammonium iodide was combined with tin

(II) oxide in dimethylformamide to form the perovskite solution. The solution was then heated at 70° C on a hot plate while agitating with a stir bar until the precursors were fully dissolved

Figure 7 | Cross section false colored SEM image of solar cell. Due to small diffusion lengths, layer thickness inside the cell needed to be on the order of nanometers.

Our cells used mesoporous titanium dioxide with the perovskite instead of aluminum oxide. Figure adopted.

6

Perovskite solution was deposited onto the sample via spin coating at 5000 rpm for 1 minute.

Spiro-MeOTAD was dissolved into chlorobenzene and then deposited onto the sample on top of the perovskite layer via spin coating.

Figure 8 | SEM image of Perovskite crystals.

Scanning electron microscopy revealed perovskite crystals of up to 50 µm in size, which are larger than published results of 10 µm. This improvement may have resulted from higher temperature processing.

Another piece of TCO glass was placed on top of the layer of Spiro-MeOTAD and the cell was sealed with a water resistant epoxy.

Electrical Characterization

• Performed solar cell characterization using a xenon lamp calibrated to produce a specific amount of power, a voltmeter, an ammeter, and a variable resistor.

• As the cell is illuminated, the short circuit current and the open circuit voltage are recorded. After this, the resistance was varied while voltage and current measurements were taken to produce an IV curve.

Figure 9 | Completed solar cell The end product of the synthesis was a 1 inch by 1 inch; yellow tinted cell. Clips were attached to either side of the glass that measured voltage and current while the cell was illuminated.

Figure 10 | Diagram of circuit used to solar cell performance testing .

Voltage and current was measured at a specific light irradiance, while resistance was varied.

Figure 11 | SEM image of perosvkite. Red arrow points to the spot where the Energy Dispersive

Spectroscopy data was collected

Figure 12 | Energy Dispersive Spectroscopy.

Elemental analysis of a suspected perovskite crystal reveals Sn, C, and I as expected. Si, while present in the substrate, was unexpected in this analysis.

• The instability of the tin perovskite in the presence of moisture makes the successful synthesis of these cells very difficult, as even 2 or 3 % relative humidity can cause dissociation of the perovskite structure.

8

• While photovoltage was measured, no photocurrent was detectable in the cells. Because of this, no IV curves were obtained. This could be due in part to the fact that the humidity in our glove box was too high, or in part to the fact that our cell layers were thicker than the diffusion lengths of the excited electrons.

Figure 13 | Illuminated cell showing photovoltage. The cells produced were optically active and produced a voltage when illuminated, but no current was ever measured across the cell.

Figure 14 | SEM image showing our cell’s layers. The layers deposited onto our cells were 3 times larger than those in literature. These layer thicknesses effected how efficiently charge was transported.

4. Future Work

• High humidity causes phase separation of the perovskite into methyl ammonium iodide and tin iodide. Due to relatively high humidity levels within the glove box, defects in our perovskite structures were observed. For future work, humidity levels of less than 1 % are recommended.

8

• Other, less expensive organic materials can be tested as hole transport material replacements for Spiro-OMeTAD.

• In the future, experimenting with different annealing temperatures as well as different solvents could lead to fewer defects and greater grain sizes, which in turn could lead to higher efficiencies.

1

References

Massachusets Institute of Technology. “The Future of Solar Energy.” (2015)

2 Rensen, Bent. Renewable Energy Physics, Engineering, Environmental Impacts,

Economics & Planning. 4th ed. Burlington, MA: Academic, 2011. Print.

3 Snaith, Henry. "From Nanostructured to Thin-Film Perovskite Solar Cells ." 2014 MRS Fall Meeting. Material Research

Society. 1 Dec. 2014. Lecture.

4 Conings, Bert, Jeroen Drijkoningen, Nicolas Gauquelin, Aslihan Babayigit, Jan D'haen, Lien D'olieslaeger, Anitha Ethirajan,

Jo Verbeeck, Jean Manca, Edoardo Mosconi, Filippo De Angelis, and Hans-Gerd Boyen. "Intrinsic Thermal Instability of

Methylammonium Lead Trihalide Perovskite." Advanced Energy Materials Adv. Energy Mater.

(2015): n. pag. Web.

5 http://education.mrsec.wisc.edu/SlideShow/slides/pn_junction/pn_junction_solar.htm

6 Guarnera, Simone, et al. "Improving the Long-Term Stability of Perovskite Solar Cells with a Porous Al2O3 Buffer Layer."

The Journal of Physical Chemistry Letters 6.3 (2015): 432-437.

7 http://shop.solaronix.com/spiro-ometad.html

8 Burschka, Julian, et al. "Sequential deposition as a route to high-performance perovskite-sensitized solar cells." Nature

499.7458 (2013): 316-319.

Acknowledgments

•This project is supported in part by the National Science Foundation Research Experience for Undergraduates in

Materials and Sustainability at Boise State University (grant number DMR 1359344), the Boise State University Student

Research Program Fellowship, and the Boise State University McNair Scholars Program. We thank Rick Ubic and Elton

Graugnard for additional funding. We also thank Griff Allen, Brett Ward, and Kevin Tolman for valuable assistance with this work.