Document 10446974

advertisement

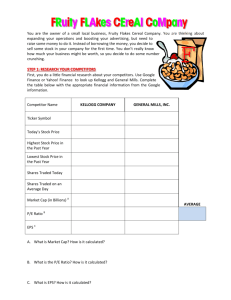

In Solution Stacking of Two-Dimensional Flakes Benjamin 1 1 Knipfer , Dale 2 Brown , David 2 Estrada Dept. of Material Science and Engineering, College of Engineering, University of Illinois at Urbana-Champaign 2Dept. of Material Science and Engineering, College of Engineering, Boise State University Introduction Materials and Methods Since the isolation of single layer graphene, the twodimensional allotrope of carbon, in 2004, there has been an abundance of interest in atomically thin materials. These 2Dlayered materials are characterized by strong in plane bonding and weak Van der Waals forces between sheets. To synthesize single and few-layered flakes for this study, we performed exfoliation using a probe-tip sonicator. The resulting solution was centrifuged and the supernatant removed twice. Imaging was done using Raman Spectroscopy. Figure 1. Depicted is a Bernal stacking pattern typical of graphene exhibiting a common 2D-layered structure [1]. Results Figure 3. Probe tip sonication creates a cavitation field in the sample which destroys the Van der Waals bonds creating few layered 2D flakes [4]. Currently, we are investigating different methods of exfoliation for a higher yield of few-layered flakes with a focus on lithium intercalation. With increased yield, restacked flakes from different materials can be plasma sintered and the resultant solid might have unique electronic and thermal properties. One procedure for lithium intercalation is shown below [6]. Figure 7. Raman mapping of flakes that were stacked with acetone. The blue intensities are relative to the height of graphene's G peak and the red intensities are relative to the concentration of MoS2. The two are mapped over the same location on the sample and share a common x-axis. Figure 4. After sonication, the sample was centrifuged for 5 minutes at 4500rpm. The supernatant was then centrifuged again for 15 minutes at 4500rpm and the supernatant was collected. As we develop our knowledge of the exfoliation and restacking of 2D-layered flakes, we expand our abilities to create new layered materials with tunable atomic properties from phonon dissipation to new electronic materials. Aim The method of depositing the sample onto the silicon wafers appeared to be affecting the energy mismatch between the flakes and the solvent, causing stacking. In order to show the flakes were restacking from the acetone alone, the absorbance of a sample was measured before and after the addition of acetone relative to a control. From this study, we showed our hypothesis to be accurate. It is clear that acetone affects the restacking of the flakes. However, how this affects the structure of graphene and MoS2 is not explicitly known. It is not known if this is diffusion limited or if the stacking can be increased by changing the interfacial energies to a higher degree. - Can 2D flakes from cosolvent-exfoliated materials be stacked in solution? Background: Changing the interfacial energies of the flakes in solution causes the flakes to quickly stack with the surrounding flakes. Figure 8. Above shows the absorbance of the solutions with and without acetone after centrifugation Previous experiments have shown that restacking of flakes has been done by vacuum filtration [2] and adding acetone to restack exfoliated flakes of a single material [3]. After centrifuging both solutions for one hour, the acetone solution showed a lower absorbance. Lower absorbance after centrifugation indicates fewer, larger flakes left in the solution, resulting in larger flake mass. Figure 5. The sample is deposited on silicon and dried and is then ready for Raman Spectroscopy [5] A1g G E12g 2D Figure 2. Visible exfoliated flakes using atomic force microscopy. Scale bar: 200nm D Figure 6. Typical Raman spectra of MoS2 (left) and graphene (right). RESEARCH POSTER PRESENTATION DESIGN © 2012 www.PosterPresentations.com Figure 9. Above shows a rough outline of the procedure that will be used for lithium intercalation. Conclusion In this project, we hope to determine the following: Hypothesis: Current and Future Work Discussion Based on the absorption data, adding acetone to cosolvent solutions of exfoliated flakes causes them to restack. Additionally, when graphene and MoS2 solutions were mixed in a 5:1 ratio, it was shown that everywhere a MoS2 flake was found, it was stacked with graphene, further indicating stacking. This result is a step towards realizing the extent to which restacked materials may be used; from thermal management to photovoltaic applications. Understanding how to restack flakes with a method that is easily scalable brings us one step closer to restacked materials implemented into daily life. Acknowledgements Benjamin Knipfer was funded by the REU in Materials for Energy and Sustainability grant number: 132G106257 and the National Science Foundation. This experiment was hosted by the Integrated NanoMaterials Laboratory at Boise State University. Dale Brown helped guide the research. AFM images were gathered by Katie and Kari Livingston. Literature Cited [1] Yacoby, A. (2011). Nature Physics. [2] Loyta, M. et al. (2009). American Chemical Society. [3]Anto Jeffery et al. (2014) The Journal of Physical Chemistry. [4]”S. Berliner, II”. (2014) Consultant in Ultrasonic Processing [5] J. Phys. Chem. C, 2011, 115 (46) pp 22761 - 22769 [6] Huang.H. et al. (2012) Journal of Materials Chemistry.