E-

advertisement

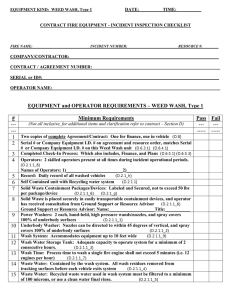

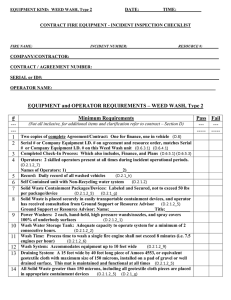

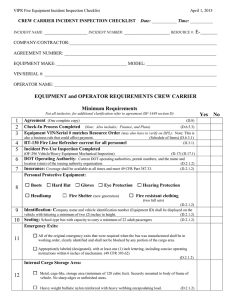

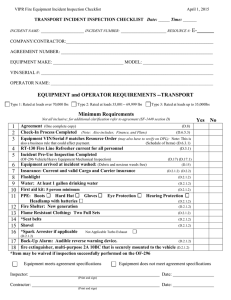

VIPR Fire Equipment Incident Inspection Checklist April 1, 2015 WEED WASH STATION INCIDENT INSPECTION CHECKLIST Date: ___________ Time: __________ INCIDENT NAME: ___________________ INCIDENT NUMBER: ____________________ RESOURCE #: E- COMPANY/CONTRACTOR:_________________________________________________________________ AGREEMENT NUMBER: ___________________________________________________________________ Unit ID/SERIAL #: _________________________________________________________________________ OPERATORS NAMES: _____________________________________________________ _____________________________________________________ EQUIPMENT and OPERATOR REQUIREMENTS WEED WASH STATION MINIMUM REQUIREMENTS YES Not all inclusive; for additional clarification refer to agreement (SF-1449 section D) 1 Agreement (One complete copy) 2 3 Check-In Process Completed (Note: Also includes; Finance, and Plans) (D.6.5.3) Equipment VIN/Serial # matches Resource Order (may also have to verify on DPL): Note: This is also a business rule that could affect payment. 4 (D.8) (Schedule of Items) (D.6.3.1) Incident Pre-Use Inspection Completed (OF-296 Vehicle/Heavy Equipment Mechanical Inspection) 5 6 7 8 surfaces 9 10 11 12 13 14 (D.17) (D.17.1) Operators: 2 skilled operators present at all times during incident operational periods. (D.2.1.1) Record: Daily record of all washed vehicles (D.2.1) Self Contained Unit: Water recycling and containment system is functional (D.2.1.1) Power Washers: 2 each, hand-held, high pressure wands/nozzles, and spray covers 100% of underbody (D.2.1.1) Underbody Washer: Washing system has nozzles that can be directed to within 45 degrees of vertical, and spray covers 100% of underbody surfaces (D.2.1.1) Wash Water Storage Tank: Adequate capacity to operate system for a minimum of 2 consecutive hours. (D.2.1.1) Waste Water: Contained by the wash system. All wash residues removed from the tracking surfaces of the vehicle before each vehicle exits system (D.2.1.1) Waste Water: Recycled waste water used in wash system must be filtered to a minimum of 100 microns, or use a clean water final rinse. (D.2.1.1) Solid Waste Containment Packages/Devices: Labeled and Secured, not to exceed 50 lbs per package/device (D.2.1.1) (D.2.1) Wash Time: Process time to wash a single fire engine shall not exceed 5 minutes (i.e. 12 engines per hour) (D.2.1.1) Wash System: Accommodates equipment up to 10 feet wide (D.2.1.1) 15 16 Lights: 17 18 2 each, 1,000 watt halogen work lights on stands, and Ground Fault Interrupter (GFI) module (D.2.1.1) All segments of Weed Washer System is in Safe Working Condition, no parts are missing (D.2.1.1) OSHA Requirements: Electric Motors--All alternating current electric motors shall be list with Underwriters Laboratory (D.2.1.1) 19 Weed Wash Operators are visually and manually inspecting hard to reach areas to ensure they are thoroughly washed and clean *Item may be waived if inspection successfully performed on the OF-296 (D.2.1.) NO VIPR Fire Equipment Incident Inspection Checklist April 1, 2015 Equipment meets agreement specifications Equipment does not meet agreement specifications Inspector: Date: (Print and sign) Contractor: Date: (Print and sign) Contractor given the opportunity to correct noted deficiencies (See Remarks) Contactor successfully corrected noted deficiencies Inspector: Date: REMARKS:__________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ 2015