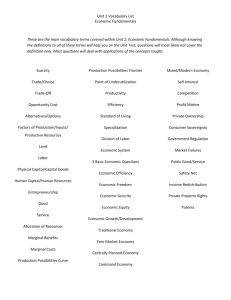

Proposed College Apprenticeship Preparation Program (CAPP) Dual Credit Courses - 2015-16

advertisement

Proposed College Apprenticeship Preparation Program (CAPP) Dual Credit Courses - 2015-16 All CAPP Programs will be offered in Semester 2 Program Name Apprenticeship Preparation CAPP - Automotive (Guelph Campus) 2 credit package Passing Grade: 55% College Course Name Precision Measuring and Basic Electricity Apprenticeship Preparation - Auto CAPP - Truck and Coach Precision Measuring and Basic Electricity (Guelph Campus) 2 credit package Passing Grade: 55% Apprenticeship Preparation - Truck and Coach College Course Ministry Course Course Description Code Code MOTV1635 TNM4T This course will introduce students to a variety of precision measuring tools, and students will use them in solving Motive Power related trade problems. It will also cover a basic understanding of the electrical flow and sources, and a basic understanding of schematic interpretation and trade symbol usage. Exemption Related Programs MOTV1190 Precision Motive Power Fundamentals; Motive Power Measuring and MOTV1210 Fundamentals - Automotive Service; Motive Drawings Schematics and Basic Power Technician - Automotive Service Electrical AUTO1450 TTE4T Students will be given a theoretical overview of automotive systems, and the safe operation of tools and equipment including meters and trade related hand and power tools. A major component of this course will deal with part and component identification and location. In addition the student will learn safe shop procedures including hoisting and jacking procedures and proper treatment of customer vehicles. Basic automotive procedures will also be covered including: fluids inspection and service, wheel and tire service, brake inspections and diagnosing, and other sub-component service. AUTO1400 Basics of Auto Motive service Theory and AUTO1410 Basics of Auto Service Shop Motive Power Fundamentals MOTV1635 TNM4T This course will introduce students to a variety of precision measuring tools, and students will use them in solving Motive Power related trade problems. It will also cover a basic understanding of the electrical flow and sources, and a basic understanding of schematic interpretation and trade symbol usage. MOTV1190 Precision Measuring and MOTV1210 Drawings Schematics and Basic Electrical Motive Power Fundamentals; Motive Power Fundaments - Truck and Coach; ITEP; Motive Power Technician - Truck and Coach; Motive Power Technician Heavy Duty Equipment, Heavy Equipment Techniques TRCK1700 TTM4T Students will be given a theoretical overview of truck systems, and the safe operation of tools and equipment including meters and trade related hand and power tools. A major component of this course will deal with part and component identification and location. In addition the student will learn safe procedures for working in a truck shop environment. Basic truck procedures will also be covered including: fluids inspection and service, general maintenance, brake systems, cab controls, engine systems, and drive trains. TRCK1520 Fluid Power for Motive Power Fundamentals Heavy Duty Equipment and TRCK1530 Engines Systems for HD Equipment Program Name College Course Name Apprenticeship Preparation CAPP - Motor Cycle Precision Measuring and Basic Electricity (Guelph Campus) 2 credit package Passing Grade: 55% CAAP - Welding (Waterloo Campus) 2 credit package Passing Grade: 55% CAPP - Machining (Doon Campus) 2 credit package Passing Grade: 55% College Course Ministry Course Course Description Code Code MOTV1635 TNM4T This course will introduce students to a variety of precision measuring tools, and students will use them in solving Motive Power related trade problems. It will also cover a basic understanding of the electrical flow and sources, and a basic understanding of schematic interpretation and trade symbol usage. Exemption MOTV1190 Precision Measuring and MOTV1210 Drawings Schematics and Basic Electrical Related Programs Motive Power Fundamentals; Motive Power Fundamentals - Motorcycle and Power Sport Vehicles; Motive Power Technician Motorcycle and Power Sport Vehicles Apprenticeship Preparation - Motorcycle MOTV1625 TTV4T Students will be given a theoretical overview of motorcycle and recreational vehicle systems, and the safe operation of tools and equipment including meters and trade related hand and power tools. A major component of this course will deal with part and component identification and location, and scheduled maintenance. In addition the student will learn safe procedures for working in a power sport shop environment. Basic motorcycle and power sport procedures will also be covered including: basic service to motorcycles, quads, and snowmobiles, fluids inspection and service, lubrication, wheel and tire service, track service, power drive systems, and controls. MOTV1450 Basic Motor Cycle, Motive Power Fundamentals RV, Small Equipment - Theory and MOTV1460 Basic Motor Cycle, RV, Small Equipment Shop Thermal Cutting and Brazing WELD1660 TLO4T Application and set-up of thermal cutting processes used for the cutting, piercing, bevelling and gouging of various metals will be studied in this course. Hands-on practice will stress safety and quality using the oxy-fuel gas cutting, plasma arc cutting, and air-carbon arc gouging processes. WELD1660 Thermal Cutting and Brazing; WELD1290 Thermal Cutting; In combination with WELD1645, exemptions would also include WELD1450; WELD1000; WELD1550; WELD1110; WELD2200; WELD1100; WELD1560; WELD1250; WELD1570; WELD1740; WELD1610 (partial exemption); WELD 1090 Welding Techniques, Welder Apprenticeship; Welding and Fabrication Technician; Welding Engineering Technology; Manufacturing Engineering and Technology; Mechanical Techniques -Plumbing; Women in Skilled Trades; Plumber Apprenticeship; Carpenter Apprenticeship; Renovation Technician; Construction Techniques; Motive Power Fundamentals; Industrial Mechanic (Millwright) Apprenticeship. Note: Final mark of at least 70% for apprenticeship course exemption Shielded Metal Arc Welding WELD1645 TLG4T This course will develop basic welding skills with the Shielded Metal Arc Welding (SMAW) process, commonly referred to as "stick" welding. Techniques will be developed for producing fillet welds in all welding positions while groove welds will be produced in the flat, horizontal and vertical positions with a variety of electrode types. WELD1660 Thermal Cutting and Brazing; WELD1290 Thermal Cutting; In combination with WELD1645, exemptions would also include WELD1450; WELD1000; WELD1550; WELD1110; WELD2200; WELD1100; WELD1560; WELD1570; WELD1740; WELD1250; WELD1610 (partial exemption); WELD 1090 Welding Techniques, Welder Apprenticeship; Welding and Fabrication Technician; Welding Engineering Technology; Manufacturing Engineering and Technology; Mechanical Techniques -Plumbing; Women in Skilled Trades; Plumber Apprenticeship; Carpenter Apprenticeship; Renovation Technician; Construction Techniques; Motive Power Fundamentals; Industrial Mechanic (Millwright) Apprenticeship. Note: Final mark of at least 70% for apprenticeship course exemption Metrology MACH1140 TZF4T This course introduces the fundamentals of dimensional metrology and the use MACH1140 Metrology of basic measuring equipment. The operating principles, techniques, inspection and checking procedures will be emphasized. Mechanical Techniques- General Machinist, Mech. Technician - General Machinist, Mech. Technician -Tool and Die, Mech. Techniques Too and die, Tool Maker. Mech. , Technician tool and Die Tool maker, Mech. Techniques CNC Set Up, Mechanical Technician- CNC, Mech Techniques- General Machinist, Mechanical Engineering Drawings I DRWG1330 TDH4T This module is designed to introduce the apprentice to the skills necessary to DRWG1330 Mechanical read shop-related blueprints. The apprentice will then be able to transfer Engineering Drawings dimensioned information to measurements on a work piece, identify the features of a work piece by interpreting a two or three view mechanical drawing, sketch to scale the three principle views of a work piece or a pictorial view, and demonstrate layout procedures. Mechanical Techniques- General Machinist, Mech. Technician - General Machinist, Mech. Techniques-Tool and Die, Mech. Technician Tool and Die, Mech. Techniques - Too and die, Tool Maker. Mech. Technician - tool and Die Tool maker, Mech. Techniques CNC Set Up Program Name Apprenticeship Preparation CAPP- Culinary (Waterloo Campus) 2 credit package Passing Grade: 55% College Course Name Applied Baking Techniques Applied Culinary Techniques College Course Ministry Course Course Description Exemption Code Code CUL1145 TUS4T This learning lab provides the student with an understanding of all practical basic CUL1145 Applied Baking preparation methods and general terminology related to the baking and pastry Techniques department. The student will prepare basic pastry, pies, cookie dough, sponges, pudding and meringues. Note: this course is a credit course offered in Culinary Skills and Culinary Management full time program (1025C/1026C) CUL1130 TUI4T This practical learning lab provides the opportunity to practice and develop the CUL1130 Applied Culinary fundamental skills, methods of cookery and presentation of dishes suitable for a Techniques variety of food service settings. The student will have ample opportunity to practice knife handling and familiarize themselves with basic kitchen equipment. (Note: This course is a credit course offered in Culinary Skills and Culinary Management programs 1025C/1026C) Related Programs Culinary Skills and Culinary Management Programs Culinary Skills and Culinary Management Programs January 22, 2016 Students will be reimbursed for travel to the College Apprenticeship Preparation Program All Dual Credit courses will be run based on funding approvals and student interest