Document 10421174

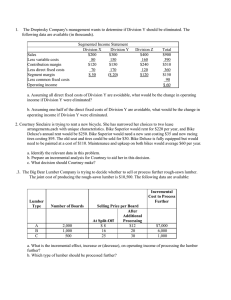

advertisement