DRYING EASTERN HARDWOOD LUMBER AGRICULTURE HANDBOOK NO. 528 By

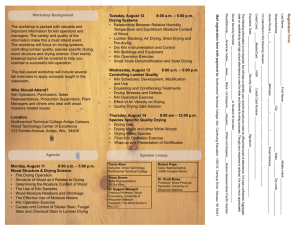

advertisement