Technical Note: Designing the Most Efficient and Reliable Row-Based Cooling Solution

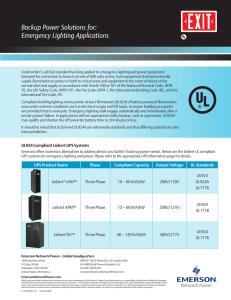

advertisement

A Technical Note from the Experts in Business-Critical Continuity™ Technical Note: Designing the Most Efficient and Reliable Row-Based Cooling Solution As the global leader in data center thermal management, Emerson Network Power has worked extensively with its customers to develop and deliver the broadest range of efficient and reliable thermal management technologies. This allows us to be technology-agnostic in order to provide the best, most unbiased solutions to our customers. As such, Emerson Network Power in 2003 was the first to introduce row-based cooling, launching the Liebert® XD™ line, which included the Liebert XDV™, Liebert XDO™, and Liebert XDH™ solutions. Since that time, we have optimized row-based cooling to provide the world’s most efficient and reliable solution, the Liebert CRV™. This technical note describes important considerations when evaluating or applying this solution. Controls Make All the Difference The Liebert CRV incorporates the most advanced and flexible unit and system controls – Liebert iCOM™ thermal controls. At the cooling unit level, the Liebert iCOM unit control provides the highest protection available, with optimal performance. At the supervisory level, the Liebert iCOM™-S system control offers a revolutionary way to optimize thermal system performance across the data center, gain quick access to actionable data and automate system diagnostics and trending. The Liebert CRV system with Liebert iCOM unit controls gives customers the option to control cooling operation based on data from the supply air sensor, rack sensors (up to 20 data points) or the return air sensor, regardless of whether the unit is deployed by itself, in a row with other Liebert CRV units, or in a containment design. Additionally, the Liebert CRV system is the ONLY row-based solution that can decouple the fan speed from the capacity to allow the servers to receive just what they need – more airflow, cooler temperatures or both AUTOMATICALLY. Liebert iCOM controls provide 5 to 7% more efficiency at the unit level and 15 – 25% greater efficiency at the system or multi-unit level. These controls have advanced machineto-machine (M2M) communication, so units can function as a team, coordinating cooling and eliminating fighting between units (some heating while some cooling). Liebert iCOM controls provide Cascade, Standby, Rotation and Lead/Lag routines, share rack sensor data over networked units (up to 32 units for 640 rack sensor data points) and 2 include a supply temperature compensation mode that provides the most efficient unit and system control on the market. In addition, Liebert iCOM controls provide the highest level of unit protection, with over 380 monitoring points, the industry’s quickest cooling restart in case of a power outage, advanced DX freeze protection and chilled water valve auto-tuning. Matching Airflow to Server Needs IT equipment fan technology is not designed to support a specific temperature difference from the air intake to exhaust – it is designed for airflow. IT equipment manufacturers have been lowering flow rate requirements to increase equipment energy efficiency. This in turn has increased the temperature difference of the air across the equipment. In 2007, the typical temperature difference of air across IT equipment was between 7°C and 17°C (12.6°F and 30.6°F). This equated to 100-250 CFM/kW. By 2010, IT equipment temperature differences ranged from 16°C to 27°C (28.8°F to 48.6°F), which is equivalent to about 55-120 CFM/kW. This range is expected to tighten to between 75 CFM/kW and 95 CFM/kW by 2020. See Figure 1. 300 250 200 CFM / kW Emerson Network Power Row-Based Thermal Management 150 100 50 0 2005 2010 2015 2020 Upper Range Lower Range Figure 1: Server Air Flow Requirements by Year of Introduction By overlaying the Liebert® CRV™ row-based unit air flow per kW (Figure 2), it is clear that the Liebert CRV system better matches IT equipment needs in either high protection or high efficiency. Other cooling products on the market are designed for obsolete IT equipment and are wasting energy by over provisioning air that is simply not needed. 300 250 200 150 For chilled water applications, we offer a range of highly efficient and reliable air-cooled chillers designed specifically for mission critical applications, using more robust electronics and components, as well as advanced controls that optimize economization hours and chilled water temperatures for reduced energy usage. The chillers generally use 15-20 percent less energy than standard air-cooled chillers. When coupled with the Liebert CRV, the overall system can save up to 35% in energy consumption over the competitive designs. Ensuring Proper Placement and Application of Row-based Cooling 100 50 0 2005 microchannel condensers communicate back to the rowbased cooling units via Canbus communications, providing precise control for optimal protection and efficiency. 2010 2015 2020 Competitor A Liebert CRV High Protection Liebert CRV High Efficiency Figure 2: Row based Equipment Air Flow Turning Vanes for Optimal Air Flow There are those who believe that turning vanes in cooling units are not necessary, because the units can capture 100% of the hot IT exhaust air. Technically, this is true, but it requires a near perfect implementation of containment and air flow management, which almost never happens. At Emerson Network Power, we design our products with turning vanes, so they perform at the highest levels of efficiency and reliability in practical, day-to-day applications. Turning vanes help direct the air to where the cooling is needed, increasing efficiency and the protection of the equipment. Understanding when to implement row-based solutions, along with how to implement them, is critical for customers. These products do not fit every data center challenge nor satisfy every customer goal. Row-based cooling is an ideal solution for quick deployment in smaller applications or spaces and where spot cooling is needed for higher rack densities. For cooling larger spaces – approaching 250kW and greater – row-based cooling becomes more expensive and no more efficient at a system level than perimeter cooling solutions. In summary, row-based cooling is best used to cool individual rows, and generally should not be used to cool racks or rows in other pods, as it will generally be very difficult to ensure proper airflow, given typical data center configurations. Be sure that data center designs do not assume perfect or ideal conditions. Make sure your designs will achieve the protection, capacity and efficiency you need under typical conditions. Factoring in Heat Rejection A large part of your thermal management system efficiency and protection is determined by how heat is rejected into the environment. For DX systems, we use microchannel condensers that are over 50% more efficient and significantly quieter than traditional fin/tube condensers. These 3 Emerson Network Power Global Headquarters 1050 Dearborn Drive P.O. Box 29186 Emerson NetworkColumbus, PowerOhio 43229 877 9222 Phone 1050800 Dearborn Drive(U.S. & Canada Only) 614 888 0246 Phone (Outside U.S.) P.O. BoxContact@EmersonNetworkPower.com 29186 Columbus, Ohio 43229 Emerson 800.877.9222 (U.S.Network & CanadaPower Only) Caribbean and Latin America 614.888.0246 (Outside U.S.) Office – United States of America +1-954-984-3452 Phone Fax: 614.841.6022 Ask.Cala@Emerson.com EmersonNetworkPower.com Emerson Network Power Canada Liebert.com 3580 Laird Rd Unit 1 Mississauga Ontario L5L 5Z7 +1 905 569 8282 Ask@EmersonNetworkPower.com Liebert.com 24 x 7 Tech Support 800 222 5877 Phone 614 841 6755 (outside U.S.) EmersonNetworkPower.com The description of competitor transformer saturation elimination methods is based on the latest information, literature, and performance data available. It is possible that some competitors may have overcome one or the other of the described disadvantages to some degree, but we believe the most effective is the Emerson Network Power method, which is based on continuously tracking the transformer flux and making precise transfer timing decisions for each phase independently and employing a voltage pulsing technique which maintains a higher average voltage to the load; this method is patented and exclusively used by Emerson Network Power. While every precaution has been taken to ensure accuracy and completeness in this literature, Liebert Corporation assumes no responsibility, and disclaims all liability for damages resulting from use of this information or for any errors or Emerson Network Power. omissions. All rights reserved throughout the world. Specifications subject to change without notice. All names referred to are trademarks or registered trademarks of their respective owners. ® Liebert and the Liebert logo are registered trademarks of the Liebert Corporation. Emerson, Business-Critical Continuity, Emerson Network Power and the Emerson Network Power logo are trademarks and service marks of Emerson Electric Co. The global leader in enabling Business-Critical Continuity™. EmersonNetworkPower. com ©2015 Emerson Electric Co. All rights reserved. AC Power Connectivity DC Power TN-00016 (R10/15) Printed in USA Embedded Computing Embedded Power Infrastructure Management & Monitoring Outside Plant Power Switching & Controls Precision Cooling Racks & Integrated Cabinets Services Surge Protection