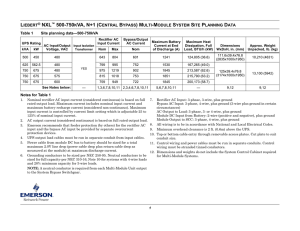

Liebert DS Thermal Management Unit

advertisement