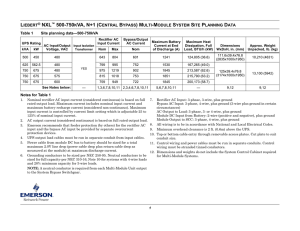

Liebert CW Thermal Management System

advertisement