TECH LINE9 Improving the Quality of Building Materials –

advertisement

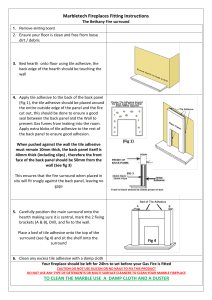

TECHLINE9 FOR THE CONSTRUCTION INDUSTRY INTRODUCTION 01 | DEFINING QUALITY AND RAISING DURABILITY – NORMS & STANDARDS 02 STARTING FORMULATIONS FOR TILE ADHESIVES & GROUTS 09 Improving the Quality of Building Materials – International Norms for Tile Adhesives & Grouts INTRODUCTION Tile adhesives are used to install tiles in residential and commercial buildings on floors or on walls. Depending on the local construction technology, regional needs and building traditions, the choice of raw material, critical performance criteria as well as norms and regulations for testing adhesives can differ from country to country. Test standards as well as high quality additives substantially contribute to long-term performance extending the durability of the whole construction – an important aspect with regard to the sustainability of buildings as well as to their maintenance costs. The standards define that an adhesive passes certain performance tests before it may be accredited with a classification. They also reflect increasing performance needs, such as fast-setting resulting, for instance, from higher time pressure during application or stronger adhesion, as a result of large-size tiles being used more often. They also allow the enduser to compare products and their performance by defining precise analytical measurements and procedures for testing. ®TM Trademark of The Dow Chemical Company (“Dow”) or affiliated companies Additives have a strong impact on many of the performance criteria which are part of the required testing. Methyl Cellulose (MC), such as WALOCEL™ and METHOCEL™, is used in tile adhesives and grouts as a thickening and water retention additive. Redispersible polymer powders (RDP), DOW™ Latex Powders (DLP), are used to improve deformability and high bonding strength on different substrates also under critical conditions. Both types of additives control fresh mortar properties, rheology and application performance as well as the final strengths of tile adhesives and grouts respectively. TECHLINE9 - 1 DEFINING QUALITY AND RAISING DURABILITY – NORMS & STANDARDS In Europe, the standards EN 12004 [e] and EN 12002 [f] define the various performance criteria for adhesives for tiles. The norm EN 12004 [e] specifies the values for performance requirements for all ceramic tile adhesives [cementitious (C), dispersion (D) and reaction resin (R) adhesives]. Each type can be divided into two classes with either normal (type 1) or improved (type 2) properties. Norm DIN EN 12002 [f] defines the deformability of cementitious mortars and grouts. Apart from defining technical requirements the CE mark is an important label affixed by manufacturers to confirm the conformity of their products with the relevant European standards. It is the manufacturer's declaration that a product complies with the essential requirements of the relevant European health, safety and environmental protection legislation, in practice by many of the Product Directives. CE marking has been mandatory for thin-bed tile adhesives since 2004 and ensures, on one hand, the free movement of the product within the EFTA & European Union indicating to governmental officials that the product may be legally placed on the market in their country. On the other hand, it permits customs and authorities the withdrawal of any nonconforming product. The minimum requirement for CE marking is a class C1 rating according to DIN EN 12004 [e]. Based on the EN standards the global standard ISO 13007 was implemented in 2005. The basic requirements were adopted from the European norms EN 12004 [e] and EN 12002 [f]. The long term goal of the International Standards Organization is the establishment of homogenized terminology and technical requirements which are adhered to by adhesive manufacturers around the world. ISO 13007 consists of four parts covering specifications (part 1) and test methods for adhesives (part 2) as well as for grouts (parts 3 and 4). Cementitious tile adhesives (C) are rated and classified in terms of tensile adhesion strength and deformability. Tensile adhesion strength is tested for four different storage conditions. Depending on the requirements cementitious tile adhesives are either classified as C1 to achieve minimum values of 0.5 N / mm² or as C2 with adhesion strengths of at least 1.0 N / mm² respectively. This classification also gives the following additional characteristics: − F = mortar with accelerated setting − T = mortar with reduced slip − E = mortar with extended open time − S = deformable (S1) or highly deformable adhesive (S2) Description Requirement 1) Tensile adhesion strength after 4 storage conditions 2) ≥ 0.5 N / mm2 (≥ 72.6 psi) Open time: tensile adhesion strength ≥ 0.5 N / mm2 (≥ 72.6 psi) after not less than 20 min Tensile adhesion strength after 4 storage conditions 3) ≥ 0.5 N / mm2 (≥ 72.6 psi) Open time: tensile adhesion strength ≥ 0.5 N / mm2 (≥ 72.6 psi) after not less than 10 min Improved adhesive type C2 Tensile adhesion strength after 4 storage conditions 2) ≥ 1 N / mm2 (≥ 145.14 psi) Slip resistance T Slip ≤ 0.5 mm Extended open time E Extended open time: tensile adhesion strength ≥ 0.5 N / mm2 (≥ 72.6 psi) after not less than 30 min Normal exterior adhesive plywood P1 ≥ 0.5 N / mm2 (≥ 72.6 psi) Improved exterior adhesive plywood P2 ≥ 1 N / mm2 (≥ 145.14 psi) Deformable adhesive S1 ≥ 2.5 mm but < 5 mm Highly deformable adhesive S2 ≥ 5 mm Cementitious Adhesive Normal setting adhesive type C1 Fast setting adhesive F Exterior adhesive plywood Transverse deformation S Table 1: ISO 13007-1 [a] – Cementitious Adhesives – Requirements 1) 1) US units given in brackets 2) Storage conditions as follows: Standard = 28 d at 23°C; Water = 7 d at 23°C + 21 d water immersion; Heat = 14 at 23°C + 14 d 70°C + 1 d 23°C; Frost = 7 d at 23°C + 21 d water immersion + 25 frost-thaw-cycles 3) Storage conditions as under 2 with one exception: Adhesion strength after standard storage of not more than 6 h 2 - TECHLINE9 The introduction of EN 12004 [e] and EN 12002 [f] as well as ISO 13007 respectively, has led to quality categories for cement based tile adhesives of classes C1 and C2 for slip resistance, adhesion strength, open time and transverse deformation (classes S1 and S2). The technical requirements for cementitious tile adhesives specified according to ISO 13007-1 [a] are outlined in table 1. The trend for increased fast-setting qualities due to earlier traffic load has been adopted by EN 12004 [e] and ISO 13007. According to both norms the requirement for the minimum adhesion strength for fast-setting tile adhesives has been changed from 0.5 N / mm² after 24 hours to 0.5 N / mm² after 6 hours. Today the thin-bed technique has replaced the thick-bed mortar method in most industrialized countries. This technology is attractive due to savings made as less material is used and due to an essentially better adhesion of the tile on the wall. With this thin-bed technique using specially designed pre-packed dry-mix adhesive mortars, technical demands on modern building industry using different types of substrates and covering materials under varying climatic conditions can be satisfied. Depending on the different demands there is now a broad range of ceramic-tile adhesives available, which can be used The overall characteristics of a thin-bed adhesive can only be achieved by pre-packed polymer-modified cementitious dry mix mortars containing cellulose ethers as a water retention aid and a rheological modifier as well as redispersible powders as a polymer binding agent. Some typical tile adhesive formulations are given in table 2. The appropriate choice of tile adhesive is governed by various criteria. Apart from varying conditions on the jobsite (humidity, heat, frost-thaw, air circulation etc.) key parameters include the nature of the substrate and the type of covering material and its characteristics (e. g. pattern, smoothness of the surface, mechanical strength, water absorption, shape and color etc.). Most popular are ceramic tiles like earthenware, stoneware, fully vitrified stoneware and Terracotta. But bonded tiles e. g. glass tiles, natural and mosaic tiles are also frequently used. Type of Cementitious Tile Adhesive Requirement / Component Standard Quality Below EN Requirements Grey Cement [%] (e. g. CEM I 32.5 R) with a broad range of substrates and tiles including standard and flexible, normal- and fast-setting, as well as special adhesives such as white mortars for fixing natural stones, waterproofing adhesives, flow-bed mortars for floor tiling, gypsum-based adhesives, lightweight adhesives with high yield, adhesives for fully vitrified stoneware and glass with virtually no water absorption. Finally there is an ongoing trend using larger tiles for walls and floors. Standard Quality Meeting EN Demands Improved Quality Meeting EN Demands Improved Deformability Meeting EN Demands 30 – 35 – – – – 30 – 35 35 – 40 25 – 40 69.8 – 64.7 69.25 – 40.15 62.15 – 44.2 69.65 – 24.2 Methyl Cellulose Ether [%] 0.2 – 0.3 0.25 – 0.35 0.35 – 0.8 0.35 – 0.8 Redispersible Powder [%] – 0.5 – 2.5 2.5 – 5.0 5.0 – 25 Special Additives [%] 1) – 0 – 2.0 0 – 10.0 0 – 10.0 Grey or White Cement [%] (e. g. CEM I 42.5 R, CEM I 52.5 R) Filler [%] (e. g. Silica sand and / or Calcium carbonate à 0.05 – 0.5 mm) Table 2: Examples of Typical Formulations for Cementitious Tile Adhesives 1) Special additives like starch ethers, inorganic or organic fibres, air-entraining agents, accelerators, retarders, superplasticizers, defoamers, Alumina cement etc. TECHLINE9 - 3 According to current international norms (ISO 13006 [d]), ceramic tiles are classified into nine groups based on two features: the level of water absorption and the shaping method. This simple classification covers the extremely wide range of existing products in the market. The chosen features are also significant factors in defining the performance specifications for different products. Test Requirement Ceramic Tile Open time dimensions of 50 + / - 1 mm x 50 + / - 1 mm Water Absorption acc. ISO 13006 [d] Remark 12 – 18 % Group B III porous body tile complying with ISO 13006 Slip dimensions of 100 + / - 1 mm and weight of 200 + / - 10 g ≤ 0.5 % Group BIa fully vitrified unglazed tile complying with ISO 13006 Tensile strength dimensions of 50 + / - 1 mm x 50 + / - 1 mm ≤ 0.5 % Group BIa fully vitrified unglazed tile complying with ISO 13006 Table 3: Technical Classification of Tiles according to ISO 13007-2 [c] There is an ongoing trend in the market for large and fullyvitrified ceramic tiles. They enjoy great popularity due to their superior resistance to a variety of environmental stresses. Thanks to their small pore sizes, a low absorption level of less than 0.5 % and a dense, smooth surface finish (e. g. glazed tiles), they are capable of withstanding the high levels of chemical (e. g. improved stain resistance), thermal (e. g. reduced risk of frost damage) and mechanical surface stress (e. g. high scratch and abrasion resistance). The requirements for tiles specified according to EN 12004 [e] (and especially ISO 13007) are already reflecting this trend. Tiles with very low water absorption values and with a more glazed and smooth surface lead to lower adhesion strength, and raise the requirements for the modified mortar. Norm ISO 13007 reflects this trend with specifications for water absorption rates of fully vitrified unglazed tiles not exceeding 0.5 %, to be used for the tensile adhesion strength tests. To meet these demands special methyl cellulose ethers and redispersible powders are used as additives in tile adhesives to avoid any application failure on the one hand and to achieve sufficient tensile adhesion strengths also under critical conditions (e. g. heat, frost-thaw) as well as long open times on the other. Apart from these basic requirements further additional properties like easy workability, less stickiness on the trowel, reduced slip, long adjustability and sufficient deformability are some further features the applicator may be looking for. Adhesive strength is the tensile strength of the total system consisting of tile, mortar and substrate. The cementitious tile adhesive between these two materials provides the adhesion strength, which is measured by a pull-off test according to EN 1348 / ISO 13007-2 [c]. The force in Newton (N) at which the system fails is divided by the cross-sectional area (mm2) of the tile resulting in the adhesive strength (N / mm2). The system can fail at the interfaces between mortar and substrate, at the interface of the mortar and the tile (adhesion failure), or within the mortar layer itself (cohesion failure). Generally, the system fails along or near the mortar-tile interface. However, due to the low water absorption and the very smooth surface finish of vitrified tiles, it is very difficult to fix these tiles to the substrate (mostly concrete or wood). Therefore, taking the trend for more critical substrates into account, the use of organic binders, e. g. dispersions or redispersible powders, DOW™ Latex Powders (DLP), in the formulation is a must to improve the mechanical properties. 4 - TECHLINE9 ®TM Trademark of The Dow Chemical Company (“Dow”) or affiliated companies Apart from high adhesion strength following different storage conditions, the open time is an important factor and is defined in the test standard EN 1346 / ISO 13007-1 [a] as the maximum time interval after application at which tiles can be embedded in the applied adhesive and meet the specified tensile adhesion strength requirement. The maximum open time of a mortar refers to the latest time a tile can be laid in without a major loss in final adhesion strength. After 28 days the pull off strength is determined with a minimum requirement of 0.5 N / mm² after a minimum of 20 minutes embedding time for standard adhesives; at least 0.5 N / mm² after a minimum of 10 minutes embedding time for fast-setting mortars and at least 0.5 N / mm² after a minimum of 30 minutes embedding time for high quality tile adhesives. However, extended open times for mortars are highly desirable when installing tiles in drier climate zones, in exterior applications where windy conditions often prevail and when installing especially large-sized tiles that require more time for adjusting grout lines. In addition, the more porous the substrate and the more absorptive the tile is, the less time the installer has available to lay tiles. While in a typical mortar this may result in loss of bonding, a tile adhesive with extended open-time properties will give the installer the necessary time to achieve optimal adhesion. According to the EN- and ISO-standard the minimum requirement for the extended open time is raised from 0.5 N / mm² after 20 min for a standard open time to 30 minutes for the adhesive with extended open time. The transverse deformation has been implemented as EN 12002 [f] first and has been adopted by the international norm ISO 13007. The intention to set up requirements for the deformation of tile adhesives reflects the fact that tile adhesives are submitted to different stresses as a result of changing mechanical or climate conditions (floor heating system, outdoor exposure – heat, frost-thaw – etc.) which the adhesive has to endure. Taking this into consideration, the test determines the deformability of a mortar which is the capacity of the hardened adhesive to be deformed by stresses between the tile and the fixing surface without damaging the surface. The deformation is recorded as deflection at the centre when a layer of the hardened adhesive is subjected to a three-point loading. The tile adhesives are categorized, according to EN 12002 [f] / ISO 13007-1 [a], into two classes and are designated as either deformable adhesives of class S1 with a deformation of at least 2.5 mm but below 5 mm or as highly deformable adhesives of class S2 with a transverse deformation of at least 5 mm. Figure 1: EN 12002 [f] / ISO 13007-2 [c] – Test Method Transverse Deformation Determination of Deformation The deformation of mortars is determined acc. to a three-point flexural strength test with defined specimens of 300 mm x 45 mm x 3 mm dimensions. Requirements S 1: deformation of deformable mortars: ≥ 2.5 mm and < 5 mm S 2: deformation of highly deformable mortars: ≥ 5 mm Without considering the requirements according to EN 12004 [e] / ISO 13007, there are different options to conduct the test by either changing the cement ratio while keeping the addition rate of the redispersible powder unaltered (Figure 2) or vice versa (Figure 3). TECHLINE9 - 5 Flexibility [mm] at 23°C Flexibility [mm] at -15°C Flexibility [mm] at 23°C 6 5 8 6 S2 bottom line level 4 Flexibility [mm] Flexibility [mm] 10 4 3 S2 bottom line level 2 1 2 0 0 20 % 30 % 40 % 6% 8% 10 % 12 % Dosage of white cement 1) Dosage of DLP 2001 1) 1) Formulation: x % White Cement à 52.5 N (Germany). 69.1 – 49.1 % Calcium Carbonate as filler, 10 % DOW™ Latex Powder 2001, 0.5 % Calciumformate, 0.40 % METHOCEL™ 10-0148; water demand according to consistency 1) Formulation: 35 % White Cement à 52.5 N (Germany). 58.1 – 52.1 % Calcium Carbonate as filler, 6 – 12 % DOW™ Latex Powder 2001, 0.5 % Calciumformate, 0.40 % METHOCEL™ 10-0148; water demand according to consistency Figure 2: EN 12002 [f] / ISO 13007-2 [c] – Changing the Cement Content Figure 3: EN 12002 [f] / ISO 13007-2 [c] – Changing the Content of the Polymer Powder In both cases the ratio of cement to the polymer binder is being altered to meet the requirements of the norm in terms of flexibility. DOW™ Latex Powders (DLP) offer a number of benefits to the wet and dry-mortar properties of tile adhesives. When the dry-mix mortar is mixed with the required amount of water, the DLP polymer powder re-disperses completely in the aqueous phase. This is the precondition for a homogeneous film formation of the polymer during the subsequent setting of the mortar. In addition to the cement matrix the polymer matrix contributes to the bonding and compressive strength of the mortar. Therefore, cementitious grouts must have good adhesion to the edges of the tiles, low shrinkage, sufficient flexibility to bear mechanical damage or thermal stress, high abrasion resistance and low water absorption. The specifications for grouts are outlined in the international standard ISO 13007-3 [b]. DLP redispersible polymer powders are required in those tile adhesive applications where – especially on different substrates – adhesion strength needs to be improved or special technical requirements (e. g. heat conditioning) have to be fulfilled. They also impart high flexibility or impact resistance and improved abrasion resistance once the mortar has hardened. Additionally, some tile adhesive formulations contain special performance DLP polymer powders which improve either the water repellency characteristics or the free flowing abilities of the mortar. Tile grouts are used to fill the joints between tiles or natural stones either on walls or on floors. In combination with the tiles they must provide not only an optically attractive surface but must also perform physical functions. 6 - TECHLINE9 ®TM Trademark of The Dow Chemical Company (“Dow”) or affiliated companies Cementitious Grout Fundamental characteristics CG 1 Fast setting CG 1F Additional characteristics Characteristic Requirement 1) 1. Abrasion resistance ≤ 2000 mm3 (< 0.122 cu.) 2. Flexural strength (standard conditions) ≥ 2.5 N / mm2 (> 363 psi) 3. Flexural strength (freeze-thaw cycles) ≥ 2.5 N / mm2 (> 363 psi) 4. Water absorption after 30 min ≤ 5 g (< 0.18 ounce) 5. Water absorption after 240 min ≤ 10 g (< 0.35 ounce) 6. Shrinkage ≤ 3 mm / m (< 0.3 %) 7. Compressive strength (standard conditions) ≥ 15 N / mm2 (> 2177 psi) 8. Compressive strength (freeze-thaw cycles) ≥ 15 N / mm2 (> 2177 psi) Requirements listed for CG 1 with one exception: Compressive strength after ≤ 24 h (standard conditions) ≥ 15 N / mm2 (> 2177 psi) 1. High abrasion resistance (A) ≤ 1000 mm3 (< 0.061 cu.) 2. Reduced water absorption after 30 min (W) ≤ 2 g (≤ 0.072 ounce) 3. Reduced water absorption after 240 min (W) ≤ 5 g (≤ 0.18 ounce) Table 4: Cementitious Tile Grouts – Requirements 1) according to ISO 13007-3 [b] 1) US units given in brackets Cementitious tile grout formulations are generally based on white cement and calcium carbonate as filler. To ensure fast setting accelerators or alumina cement are being used. The addition rate of WALOCEL™ and METHOCEL™ Cellulose Ether and DOW™ Latex Powder improves the workability and consistency as well as the water retention and final mechanical strength. Dispersion bound adhesives are commonly known as organic adhesives or mastics and are mainly used for applying wall tiles. They have become increasingly popular, serving as a prime adhesive choice for a variety of tile and stone installations because they are easy-to-use as they don’t require any mixing. ®TM Trademark of The Dow Chemical Company (“Dow”) or affiliated companies ISO 13007-1 [a] / EN 12004 [e] classifies dispersion bound adhesives as D1 (normal adhesive characteristics) or D2 (improved adhesive characteristics with resistance to water) according to their shear adhesion strength. Dispersion adhesives are most often used for interior wall installations involving larger-sized or impervious tiles respectively. Dispersion adhesives meeting D1 classification standards are appropriate for interior installation such as commercial and residential walls, but under dry conditions only. Adhesives classified as D2 can be used in interior installation with intermittent exposure to water, such as bathrooms, showers and kitchens. TECHLINE9 - 7 Dispersion Adhesive Normal adhesive of type D1 Improved adhesive of type D2 Description Requirement 1) Shear adhesion strength ≥ 1 N / mm² (≥ 145.14 psi) Shear adhesion strength after heat aging (14 d at 23°C + 14 d at 70°C + 24 h at 23°C ) ≥ 1 N / mm² (≥ 145.14 psi) Open time: tensile adhesion strength ≥ 0.5 N / mm² (≥ 72.6 psi) after not less than 20 min Shear adhesion strength after water immersion (21 d air cure and 7 d water immersion) Shear adhesion strength at elevated temp. (14 d at 23°C + 14 d at 70°C + 24 h at 23°C ) ≥ 0.5 N / mm² (≥ 72.6 psi) ≥ 1 N / mm² (≥ 145.14 psi) Slip resistance T Slip ≤ 0.5 mm Extended open time E Extended open time: tensile adhesion strength ≥ 0.5 N / mm² (≥ 72.6 psi) after not less than 30 min Accelerated drying A Shear adhesion strength after water immersion (7 d air cure and 7 d water immersion ) Shear adhesion strength at elevated temp. (14 d at 23°C + 14 d at 70°C + 1 min at 23°C) ≥ 0.5 N / mm² (≥ 72.6 psi) ≥ 1 N / mm² (≥ 145.14 psi) Table 5: Requirements 1) for Dispersion Bound Adhesives according to ISO 13007-1 [a] / EN 12004 [e] 1) US units given in brackets Dispersion adhesives exhibiting a minimum shear strength of 1 N / mm2 after dry and heat storage receive a D1 rating. The D2 rating additionally requires a minimum shear strength of 0.5 N / mm2 after water storage. Requirements for slip resistance and extended open time are optional. Due to their formulation, dispersion based adhesives and reaction resin adhesives are classified according to their shear strength values. 8 - TECHLINE9 The addition rate of WALOCEL™ and METHOCEL™ Cellulose Ether is required to provide the necessary rheology, water retention and – if required – slip resistance and open time. Especially those types with delayed solubility characteristics are recommended to impart the appropriate incorporation. Increasing the pH to 9 dissolves the cellulose ether immediately and improves standing strength, open time, adjustability time, slip resistance and adhesion strength. However, compared to cementitious tile adhesives the water resistance of dispersion bound tile adhesives is limited. ®TM Trademark of The Dow Chemical Company (“Dow”) or affiliated companies STARTING FORMULATIONS FOR TILE ADHESIVES & GROUTS The following formulations are given as tentative starting points for individual development work. As Dow Construction Chemicals has no knowledge on the other components the formulator has full responsibility for any use of these formulations. All data are parts by weight, unless otherwise stated. Cement Based Tile Adhesive [Class C1E (EN 12004 [e])] with Long Adjustability Time Dispersion Bound Adhesive Raw Material Dosage [p.b.w.] Raw Material Dosage [p.b.w.] Water 8.6 OPC CEM I 42.5 R Dispersion 17.8 Filler (silica sand à 0.09 – 0.25 mm) 40.1 WALOCEL™ MW 40000 PFV 0.3 Filler (silica sand à 0.125 – 0.5 mm) 25 Filler (sand, limestone, calcium carbonate) of various Granulometry 71.6 DLP 2001 (redispersible powder) 1 Film forming agent 1.4 Preservative 0.2 Defoamer 0.1 33 Accelerator 0.5 WALOCEL™ MKX 20000 PP10 0.4 Water demand: 26 % Cement Based Tile Adhesive [Class C1TES1 (EN 12004 [e], EN 12002 [f])] with High Yield Cement Based Tile Adhesive (Economical) Raw Material Dosage [p.b.w.] OPC CEM I 42.5 R 33 Raw Material Dosage [p.b.w.] OPC CEM I 52.5 R 50 Filler (silica sand à 0.09 – 0.25 mm) 40.35 Filler (silica sand à 0.09 – 0.5 mm) 6 Filler (silica sand à 0.125 – 0.5 mm) 25 Lightweight Filler (0.25 – 0.5 mm) 15 DLP 212 (redispersible powder) 1 Lightweight Filler (0.1 – 0.3 mm) 15 5 Accelerator 0.5 DLP 2001 (redispersible powder) WALOCEL™ MKX 60000 PF01 0.15 Latent hydraulic additive Water demand: 27 % Accelerator WALOCEL™ MKS 10000 PF 60 7.5 1 0.5 Water demand: 55 % ®TM Trademark of The Dow Chemical Company (“Dow”) or affiliated companies TECHLINE9 - 9 Cement Based Tile Adhesive [Class C2TE (EN 12004 [e])] Raw Material OPC CEM I 52.5 R Dosage [p.b.w.] 35 Filler (silica sand à 0.09 – 0.5 mm) 38.05 Filler (silica sand à 0.125 – 0.5 mm) 23 DLP 2001 (redispersible powder) 3 Accelerator 0.5 WALOCEL™ VP-M-6604 0.45 Water demand: 28 % Cement Based Tile Adhesive with Leveling Properties for Floors Raw Material Dosage [p.b.w.] OPC CEM I 32.5 R 40 Filler (silica sand à 0.06 – 0.2 mm) 40 Filler (silica sand à 0.1 – 0.4 mm) 15.3 Superplasticizer 0.2 DLP 2050 (redispersible powder) 4 Stabilizer 0.1 WALOCEL™ MT 400 PFV 0.40 Water demand: 24 % Cement Based Tile Grout with Fast Setting Properties Raw Material Dosage [p.b.w.] White cement CEM I 42.5 R 15 Alumina cement 20 Filler (Calcium carbonate) 20 Filler (silica sand) 43.33 Hydrophobic additive 0.1 DLP 2140 (redispersible powder) 0.8 Retarder(s) 0.25 Accelerator(s) 0.45 WALOCEL™ MKW 4000 PF01 0.07 Water demand: 25 % 10 - TECHLINE9 ®TM Trademark of The Dow Chemical Company (“Dow”) or affiliated companies TECHLINE9 - 11 AUTHOR Dr. R. Kiesewetter / The Dow Chemical Company REFERENCES [a] ISO 13007-1: edition 2010-09-15 [b] ISO 13007-3: edition 2010-09-15 [c] ISO 13007-2: edition 2010-09-15 [d] ISO 13006: 2nd edition 2012-03-01 [e] EN 12004 (2007) [f] EN 12002 (2009) Notice: Please follow the instructions indicated on the respective SDS (Safety Data Sheet). No freedom from infringement of any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for determining whether products and the information in this document are appropriate for Customer's use and for ensuring that Customer's workplace and disposal practices are in compliance with applicable laws and other government enactments. The product shown in this literature may not be available for sale and / or available in all geographies where Dow is represented. The claims made may not have been approved for use in all countries. Dow assumes no obligation or liability for the information in this document. References to "Dow" or the "Company" mean the Dow legal entity selling the products to Customer unless otherwise expressly noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED. For more information please send your email to dccinfo@dow.com or consult our web site www.dowcc.com 840-02001-0812