Document 10405370

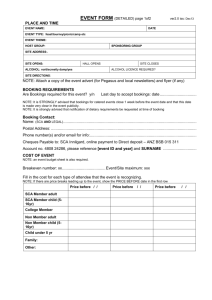

advertisement