Biowaste to power plants at high portions ”Biosafe” TEKES 40181/06 T 5

advertisement

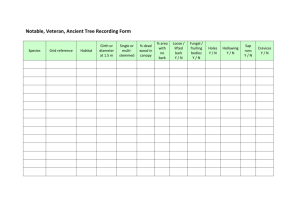

Biowaste to power plants at high portions ”Biosafe” TEKES 40181/06 F uels T2 T1 P ilo t- sc ale ex p erim en ts w ith a B F B re a cto r: p ro tective re a ctio n s VTT F u el selectio n , D eta iled a n a lysis Å A U , V T T (J ) H arm ful a nd pr ote c tive c om p ou nd s T3 F u rn a ce sam pling (N a , K C l, UKU T e st op tim isation T5 T o valid ation K loor in K err ostum inen, likaa ntu m in e n M ix ing o f ad d itive in a fu rn a c e U T sin g hu an L iu otetut S uoja aine et T4 R eliable sam pling of risk y com p oun ds D ep o sition m od el (Å A U ) E ffective u tilisatio n o f b io w a ste In en ergy p rodu ction Martti Aho, VTT, Liekki IV Day 23.1.2008 Biosafe/ members of the leading group TEKES/TE-keskus VTT prosessit Åbo Akademi Kuopion yliopisto Kvaerner Power Kemira OYJ Lassila & Tikanoja Helsingin vesi *Climbus-ohjelman Henkilö Asema Puh. Mauri Marjaniemi teknologia010 521 5224 Jatta Jussila* asiantuntija Martti Aho** johtava tutkija 040 558 6945 Var. Pasi Vainikka tiimin vetäjä 014 672 514 Mikko Hupa professori 02 215 31 Var. Patrik Yrjas TkT 02 215 31 Jorma Jokiniemi: professori 040 5050 668 Var. Olli Sippula DI Jaani Silvennoinen Tutkija 020 14 121 Jari Kukkonen Tutkija Oulun yks. 010 862 5611 Lassi Hietanen Tuotepäälllikkö 010 636 5412 Yrjö Lundstöm Ympäristöpäällikkö 09 4734 3425 koordinaattori, jakelulistalla ** Projektiyhteenliittymän kokoonkutsuja Background CASE 1. BARK/FOREST RESIDUE Heat transfer surface COMPOUN D ALKALI CHLORIDES S RI Y SK Cl releases ä corrosion Lack of protecting compounds Low ash content BARK/FOREST RESIDUE Risk description: Cl deposition which can lead to high temperature superheater corrosion Fouling of superheater tubes Superheater tubes damaged by high temperature chlorine corrosion Optional ways to problem solution R SILICATES, SULPHATES Y COMPOUN ALKALI CHLORIDES S ISK ING REACT ECT IO T O ALKALI FOREST RESIDUE NS PR CASE 2. PROTECTING POWER OF COAL PROTECTIVES SULPHUR DIOXIDE, Al-SILICATES COAL Co-combustion Problem solution by co-firing means: Coal contains sulphur and aluminium silicates: Alkali chloride destruction Possible by a) Sulphation SO3 + 2 KCl+ H2O -> K2SO4 + 2 HCl Note: sulphur in SO3 form! b) Alkali aluminium silicate formation: Al2O3*2SiO2 + 2KCl +H2O -> M2*Al2SiO3*2SiO2 + 2 HCl Note: Sulphation may need high S mass flow to be effective increasing SO2 emissions New and patented: Effective alkali chloride destruction by additives forming SO3 at critical furnace zones 2MCl + SO3 + H2O -> M2SO4 + 2 HCl Na2SO4 K2SO4 HCl SO3 attach NaCl, KCl Very effective S => small dosages, no increase of SO2 emissions This project •Utilisation of effective sulphur present in different sludges to alkali chlorides destruction in the boiler furnace •Destruction of alkali chlorides with minimum sludge portions and SO2 slip •No bed agglomeration allowed •Toxic emissions must controlled •Note: Emissions limits are determined by the co-incineration directive Plant idea • Dried and pelletised sludge is transported from selected sources to a particular power plant equipped with a bag filter and chemicals to clean the flue gases • The plant has high efficiency (with high steam values , > 500 C steam) • The main fuel can be for example forest-based biomass and also include biomass components classified to waste (demolition wood, impregnated wood) Workprogramme briefly Goals • Main goal: Basis to utilise demanding biowaste in energy production in effective power plants will strengthen • Sub goals (serving power plant availability): (a) Improved furnace probing tools for risky compounds (b) Improved control of formation and destruction of risky furnace compounds (c) Utilisation of the protective compounds in sludges Tasks and time schedule Tasks Fuels T2 T1 Pilot- scale experiments with a BFB reactor: protective reactions VTT Fuel selection, Detailed analysis ÅAU, VTT (J) Harmful and protective compounds T3 Furnace sampling (Na, K Cl, UKU Test optimisation T5 To validation Kloorin Kerrostuminen, likaantuminen Mixing of additive in a furnace U Tsinghuan Liuotetut Suoja aineet T4 Reliable sampling of risky compounds Deposition model (ÅAU) Effective utilisation of biowaste In energy production Time schedule 1.8.2006-> 02 T1 T2 T3 T4 T5 04 x x x x 06 x x x x 08 x x x x 10 x x x 12 x x x x 14 16 18 20 22 24 26 x x x x x x x x x x x x x x x x x x x x 28 x Task 1 Fuels •Risky fuels as sources of KCl and NaCl Bark, bark/recycled fuel (REF) Protective sludge with effective sulphur • 2MCl + SO2 + ½ O2 + H2O -> M2SO4 + 2 HCl where M is K or Na Power of fractionation analysis: instead of element contents it gives information of the reactivity of the elements REF to be used Biosafe REF ppmW By Åbo Akademi 20000.00 18000.00 16000.00 14000.00 12000.00 10000.00 8000.00 6000.00 4000.00 2000.00 0.00 Rest HCl Acetate Water Untreated Si Al Fe Ti Mn Ca Mg P Na K S Cl To stack Task2: Reactor 20 kW BFB pilot plant Observation port Gas cooling Sampling port Deposit probe Temperature control Gas sample Gas probe Sampling port Bag filter Heating zone 4 Sampling port Obervation port/ Deposit probe Cyclone Heating zone 3 Tertiary air optional Tertiary air optional Obervation port Tertiary air (preheated) Heating zone 2/ Cooling zone 2 Fuel container 2 Fuel container 1 Additive container Obervation port Heating zone 1/ Cooling zone 1 Obervation port BED made of quarz Secondary air (preheated) Primary gas heating PC control and data logging system Nitrogen Air Tasks 2, 3 related to probing of Cl, S, Na and K compounds dib. air Ejektor ELPI Cyclone T 800-1000°C VTT diluter Ejektor Cyclone MFC Cooling system DLPI Exh nitrogen Ftir & CO2 Task 2 Deposit probing to analysis Further illustration: To: Åbo Akademi 30mm 16mm Results from first tests Cl concentrations at critical positions of the deposit: base fuel: spruce bark 8 Bark alone p-% Cl kerrostumassa 7 Tmetal 500 C Tflue gas. 650 C 6 5 4 3 2 Tmetal 500 C Tflue gas 850 C 2 % enb sludge 1 mixed to bark 1 0 Kuori FB Kuori FB Kuori FB Kuori Kuori Kuori 2% VKM 2% VKM 2% VKM 2% VKM 2% VKM 2% VKM tulo sivu jättö VK tulo VK sivu VK jättö FB tulo FB sivu FB jättö VK tulo VK sivu VK jättö Cl concentrations in the fine fly ash with different sludges and dosages Klooripitoisuudet välikanavanäytteissä eri polttoaineilla 6 4.02 - 10 µm 1.61 - 4.02 µm 0.64 - 1.61 µm 0.26 - 0.64 µm 0.1 - 0.26 µm 0.03 - 0.1 µm <0.03 µm 5 mg/Nm3 4 3 ! 2 ! 1 0 Kuori Bark alone 2%VKM 4%VKM 6% VKM 8%VKM 4%KEMC Conclusion: • Even a small portion of sludge mixed to bark destroyed the alkali chlorides in the furnace and prevented Cl deposition to the superheaters during bark combustion • Next stage: More demanding startpoint will be used: 10% enb. REF will be mixed to bark • Old aspect: Sludges make only harm to the boilers by increasing emissions etc. • New aspects: Sludges can protect boiler furnaces!