Modeling of black liquor gasification Rikard Gebart, LTU Per Carlsson, ETC

advertisement

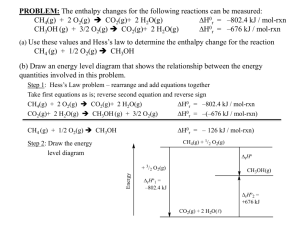

Modeling of black liquor gasification Rikard Gebart, LTU Per Carlsson, ETC Magnus Marklund, ETC 1 Black liquor •By-product from chemical Kraft pulping • ~8.1 Mton dry biomass (~40 TWh/y) •1/3 water, 1/3 combustibles and 1/3 ash •Conventionally combusted in recovery boilers to recover heat and chemicals •Highly viscous fluid •Heating value ~12 MJ/kg (Oil: ~42 MJ/kg) •Gasification of black liquor and catalytic conversion of syngas could replace about 25% of Swedish gasoline and diesel demand if all black liquor is gasified 2 BLACK LIQUOR COOLING WATER OXYGEN AND ATOMIZING MEDIA GAS COOLER REACTOR RAW GAS QUENCH GREEN LIQUOR 3 CONDENSATE WEAKWASH Courtesy of Chemrec AB COOL DRY RAW GAS Experimental measurements with a suction probe in the lower part of the reactor 4 MEASURING POSITION Species CO2 (% mol) CO (% mol) H2 (% mol) CH4 (% mol) H2 S (% mol) COS (ppm mol) 5 Probe measurements After CCC 33.9±0.3 28.7±0.2 34.3±0.2 1.36±0.07 1.65±0.04 468±22 33.6±0.2 28.5±0.2 34.8±0.1 1.44±0.07 1.71±0.02 122±5 Conceptual model for conversion Spray burner Initial droplet Drying 2.3 m Refractory lining Dry solids Devolatilization Char Char gasification Smelt Smelt formation Sampling probe 0.6 m 6 Reactor inlet BL O2 aOH(l) NaOH(l) Na2C Na2CO3(l) O3(l) Na2S(l Na2S(l) ) Na2SO Na2SO4(l) 4(l) H2O(l) Volatil Volatiles es C(s) CH4 H2 NaOH(l) Conversion steps Volatiles Na2CO3(l) CO2 C(s) Na2S(l) CO Na2SO4(l) NaOH(l) H2S C(s) Na2CO3(l) Na2SO4(l) Na2S(l) NaOH(l) Na2S(l) Na2CO3(l) 7 H2 + ½O2 → H2O CH4 + ½O2 → CO + 2H2 CH4 + H2O → CO + 3H2 CO + H2O ↔ CO2 + H2 C + H2O → CO+H2 C + CO2 → 2CO C + ½Na2SO4 →½Na2S + CO2 Reactor outlet A few words about tars • Benzene concentration was below 100 ppm which indicates a very low tar content • This has later been confirmed in dedicated tar measurements • Tar species are typical for high temperature formation (i.e. multi-ring tars like phenantrene) • The heaviest compound in the pyrolysis model is methane • Equivalent to assuming infinitely fast cracking of tars that are formed during pyrolysis 8 CFD model • Multi-phase flow formulation with discrete particles and continuous gas phase (EulerLagrange) • Turbulence modeled with Reynolds averaged equations and an eddy viscosity model • Heat transfer from convection and radiation • Iterative solution with alternating gas and droplet phase computations • Droplet size distribution from experimental measurements 9 Particle phase • Particles are assumed to be spherical • Heat transfer is directly computed from the gas phase and radiation solution • Step 1: Drying can be directly computed from the heat transfer to the droplet • Step 2: Devolatilisation consists of two parts – Volatile composition is computed beforehand from the fuel analysis enforcing element conservation – Devolatilisation rate is computed from an Arrhenius expression taken from literature (rate depends on droplet temperature) 10 Particle phase/2 • Step 3: Char gasification is limited by mass transfer at the droplet surface – Mass transfer rate is computed from the gas phase solution at the droplet surface • Step 4: Smelt formation is limited by mass transfer at the droplet surface 11 Gas phase reactions • First attempt to model with the Jones & Lindstedt 4-step scheme over-predicted methane destruction • Comparison with a detailed kinetic model (GRIMECH) showed large errors in the Jones & Lindstedt model at reducing conditions and temperatures below about 1200 C • Modified model with an assumed infinitely slow methane conversion for T < 1400 K agreed well with GRI-MECH and experiments 12 Carlsson, P., Iisa, K., & Gebart, R. (2011). Computational Fluid Dynamics Simulations of Raw Gas Composition from a Black Liquor Gasifier—Comparison with Experiments. Energy & Fuels, 25(9), 4122–4128. doi:10.1021/ef2003798 Assumed volatile composition that conserves elements (8 simple assumptions and solution of an overdetermined system of equations) 13 All heats of reaction add up to the experimental heating value (energy is conserved) 14 15 16 17 18 19 38.0 Variable Pressure Black liquor mass flow rate Black liquor pre-heat temperature O2 mass flow rate λ Normalized gas residence time Variations in Unit equivalence ratio bar 28 28 28 kg/h 870 870 870 °C 140 140 140 kg/h 232 254 265 0.396 0.434 0.452 1.019 1 0.991 - 36.0 H2 34.0 CO2 32.0 30.0 28.0 Data from: Carlsson, P., Wiinikka, H., Marklund, M., Grönberg, C., Pettersson, E., Lidman, M., & Gebart, R. (2010). Experimental investigation of an industrial scale black liquor gasifier. 1. The effect of reactor operation parameters on product gas composition. Fuel, 89(12), 4025–4034. doi:10.1016/j.fuel.2010.05.003 20 CO CO2 26.0 H2 CH4 24.0 3.0 2.5 2.0 CO CH4 1.5 1.0 0.5 0.38 0.40 0.42 0.44 0.46 0.48 λ 38.0 Variable Pressure Black liquor mass flow rate Black liquor pre-heat temperature O2 mass flow rate λ Normalized gas residence time Variations in Unit equivalence ratio bar 28 28 28 kg/h 870 870 870 140 140 140 °C kg/h 232 254 265 0.396 0.434 0.452 1.019 1 0.991 - 36.0 H2 34.0 CO2 32.0 30.0 28.0 CO CO2 26.0 H2 CH4 24.0 3.0 2.5 2.0 CO CH4 1.5 1.0 0.5 0.38 0.40 0.42 0.44 0.46 0.48 λ 21 38.00 Variable Pressure Black liquor mass flow rate Black liquor pre-heat temperature O2 mass flow rate λ Normalized gas residence time Variations in Unit pressure 16 21 28 bar kg/h 487 645 870 140 140 140 °C kg/h 151 196 254 0.460 0.451 0.434 0.977 0.989 1 - CO2 36.00 34.00 H2 32.00 30.00 28.00 CO CO2 26.00 H2 CH4 24.00 1.50 1.25 CO CH4 1.00 0.75 0.50 14 16 18 20 22 24 26 28 30 Pressure 22 38.00 Variable Pressure Black liquor mass flow rate Black liquor pre-heat temperature O2 mass flow rate λ Normalized gas residence time Variations in Unit pressure 16 21 28 bar kg/h 487 645 870 140 140 140 °C kg/h 151 196 254 0.460 0.451 0.434 0.977 0.989 1 - CO2 36.00 34.00 H2 32.00 30.00 28.00 CO CO2 26.00 H2 CH4 24.00 1.50 1.25 CO CH4 1.00 0.75 0.50 14 16 18 20 22 24 26 28 30 Pressure 23 Conclusions • Simplified model yields results that agree well with experiments – Absolute values for syngas composition – Trends when the process parameters are changed • Based on this it is assumed that scale up effects should also be predicted reasonably well 24 Future work • Idealized experiments; distribution of Na2SO4-Na2S-H2S and time resolved measurement of the pyrolysis gas composition for high heating rates • Turbulence models and chemistry • Investigation of numerical errors from finite number of particles • Comparison of experimental flame dynamics with simulations • Tar measurements • Tar modeling if necessary 25