Influence of O during Sulphation of KCl in a Biomass

advertisement

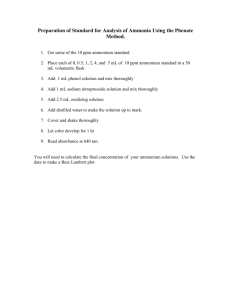

The Swedish and Finnish National Committees of the International Flame Research Foundation – IFRF Influence of O2 during Sulphation of KCl in a Biomass Fired CFB Boiler Håkan Kassman1, 2, *, Johannes Öhlin1, Jessica Bohwalli1, Lars-Erik Åmand1 1 Chalmers University of Technology Department of Energy and Environment, Division of Energy Technology Gothenburg Sweden hakanka@chalmers.se; jooh@chalmers.se; jessica.bohwalli@chalmers.se; lars-erik.amand@chalmers.se 2 Vattenfall Power Consultant AB P.O. Box 1046 Nyköping Sweden hakan.kassman@vattenfall.com * corresponding author ABSTRACT Sulphur/sulphate containing additives, such as elemental sulphur (S) and ammonium sulphate ((NH4)2SO4), can be used for sulphation of the alkali chlorides (mainly KCl) during biomass combustion. A more efficient sulphation of KCl is achieved for ammonium sulphate compared to sulphur. The presence of gaseous SO3 is thus of greater importance than that of SO2. The concentration of O2 and the presence of combustibles could also have an impact on the sulphation efficiency when injecting ammonium sulphate. This paper is based on results obtained during co-combustion of wood chips and straw pellets in a 12 MW circulating fluidised bed (CFB) boiler. Ammonium sulphate was injected at three different positions in the boiler and they were in the top of the combustion chamber, in the cyclone inlet, and in the cyclone. The sulphation of KCl was investigated at three air excess ratios (λ= 1.1, 1.2 and 1.4). Several measurement tools including, IACM (on-line measurements of gaseous alkali chlorides), deposit probes (chemical composition in deposits collected), and gas analysis were applied. Keywords: Sulphation, KCl, In situ alkali chloride monitor (IACM), ammonium sulphate, combustion of biomass, 1. INTRODUCTION Biomass generally contains relatively high amounts of alkali (mainly potassium, K) and in some biomass fuels, such as straw, the chlorine (Cl) content is also rather high. The content of sulphur (S) is normally relatively low in biomass fuels. High levels of alkali chlorides in the flue gas can cause enhanced deposit formation and high content of KCl in deposits may cause accelerated superheater corrosion during biomass combustion. Deposit formation and superheater corrosion can be reduced by co-combustion or by the use of additives. Coal, peat and sludge are among the fuels, which can be used for co- -1- The Swedish and Finnish National Committees of the International Flame Research Foundation – IFRF combustion with biomass. Elemental sulphur or other sulphur/sulphate containing additives can be used for the sulphation of alkali chlorides. Here the additive reacts with KCl and converts it to a less corrosive alkali sulphate. Both homogeneous (gas phase) and heterogeneous (liquid or solid phase) mechanisms have been proposed for formation of alkali sulphates from alkali chlorides found in deposits or in ash particles [1]. Presented below are the overall sulphation reaction, R1, as well as reactions R2 and R3, which are of particular interest for sulphation of gaseous KCl. The sulphation rate in the gas phase is limited by the presence of sulphur trioxide (SO3), and the oxidation of SO2 to SO3 (R3) is the rate-limiting step for this homogeneous mechanism [2, 3]. Meanwhile, the reactions between KCl and SO3 in gas phase have only been investigated to a certain extent. Calculations concerning the reactions of SO3 with the O/H radical pool were presented in [4]. These calculations suggested that the oxidation of SO2 to SO3 involved recombination of SO2 with O and OH radicals, and that the SO3 concentration could be limited by H radicals (R4 – R6). (R1) (R2) (R3) (R4) (R5) (R6) 2KCl + SO2 + H2O + ½ O2 → K2SO4 + 2HCl 2KCl + SO3 + H2O → K2SO4 + 2HCl SO2 + ½ O2 ↔ SO3 SO2 + O2 ↔ SO3 + O SO2 + OH ↔ SO3 + HO2 SO3 + H ↔ SO2 + OH Two sulphur containing additives were evaluated in [5] for sulphation of gaseous KCl: elemental sulphur (S) and ammonium sulphate ((NH4)2SO4). Ammonium sulphate lowered the amount of gaseous KCl and also reduced the chlorine content in the deposits significantly better than sulphur. Thus the presence of gaseous SO3 was of greater importance than that of SO2 for sulphation of gaseous KCl. These results by Kassman et al [5] support that sulphation of gaseous KCl takes place according to reaction R2. The scope of this paper is improved knowledge concerning the influence of O2 and the impact from combustibles during sulphation of gaseous KCl. The influence of O2 was investigated at three air excess ratios (λ= 1.1, 1.2 and 1.4) during injection of ammonium sulphate (AS) in a full-scale CFB boiler, which is mainly used for research purposes. The impact of combustibles was investigated by injecting AS at three different positions in the boiler. 2. Experimental 2.1 Research boiler and operating conditions The experiments were performed in the 12 MW CFB boiler at Chalmers University of Technology (CTH) shown in Figure 1. This research boiler offers the possibility to perform measurement campaigns in a full scale boiler, while maintaining control over important operation parameters such as load, air supply and composition of the fuel mix. The boiler has been described earlier in several publications including [5-10]. The combustion chamber has a square cross-section of about 2.25 m2 and a height of 13.6 m. Fuel is fed from a fuel chute (located at the front of the boiler) to the lower part of the combustion chamber.The bed material is recirculated through the cyclone back to the -2- The Swedish and Finnish National Committees of the International Flame Research Foundation – IFRF combustion chamber, whereas the combustion gases enter the convection pass where the gases are cooled down to 150 C before cleaning in a secondary cyclone and a bag house filter. 14 13 20 7 O O 19 18 O 17 12 O 10 8 O O 11 23 22 21 1 6 5 9 2 o o 3 4 16 15 Figure 1: The 12 MW CFB boiler. 1. furnace; 2. fuel chute; 3. air plenum; 4. primary air; 5. secondary air; 6. fuel feed and sand; 7. cyclone outlet; 8. primary cyclone; 9. particle seal; 10. secondary cyclone; 11: bag house filter; 12. flue gas fan; 13. IACM (In-situ Alkali Chloride Monitor); 15. bed material; 16. ammonium sulphate (AS); 17-19. injection of AS; 17. top of the combustion chamber; 18 cyclone inlet; 19. in the cyclone; 20-23. measurement positions; 20. before the convection pass; 21. in the convection pass, 22. after the convection pass; 23. before the stack. Table 1. Operating parameters for Ref during each air excess ratio Parameter Ref (λ = 1.1) Ref (λ = 1.2) Load (MW) 6.5 6.1 Bed temperature (°C) 836 839 Temperature, top of furnace (°C) 882 875 Temperature, cyclone outlet (°C) 883 841 Temperature, after bag filter (°C) 165 162 Pressure drop in furnace (kPa) 6.2 6.3 Excess air ratio 1.12 1.22 Total air flow to combustor (kg/s) 2.71 2.71 Primary air/total air flow (%) 53.9 53.4 -3- Ref (λ = 1.4) 5.4 868 876 818 162 6.2 1.36 2.71 54.4 The Swedish and Finnish National Committees of the International Flame Research Foundation – IFRF Measurements were carried out during three air excess ratios (λ= 1.1, 1.2 and 1.4) and selected operating conditions for each air excess ratio are presented in Table 1. Silica sand (dp=0.3 mm) was used as bed material. The fuel properties are presented in Table 2. The base fuel was wood chips and straw pellets (made from wheat straw and manufactured in Köge, Denmark) were used as additional fuel to increase the level of gaseous KCl with a ratio of about 20% of the energy input to the boiler. Table 2. Fuel properties Straw pellets Proximate analysis Water (wt-%, raw) Ash (wt -%, dry) Combustibles (wt -%, dry) Volatiles (wt -%, daf) Ultimate analysis (wt-%, daf) C H O S N Cl Ash analysis (g/kg dry ash) K Na Al Si Fe Ca Mg P Ti Ba Lower heating value (MJ/kg) H, daf H, raw daf = dry and ash free, raw = as received Wood chips 6.3 5.1 94.9 80.1 40.5 0.9 99.1 81.7 49.4 6.2 43.5 0.10 0.58 0.29 50.0 6.0 43.7 0.01 0.15 0.01 139 3.9 1.9 250 1.8 65 14 11 0.1 0.7 128 6.6 5.4 31.6 4.9 234 28 15 0.3 1.7 18.4 16.2 18.7 10.1 2.2 Experimental procedure Ammonium sulphate (AS) was injected into the boiler according to two different experimental procedures. The first one was a so-called transient test which was carried out for each excess air ratio according to Table 3. The purpose with the transient test was to investigate if the presence of combustibles (i.e radicals) could have an impact on the sulphation efficiency when injecting AS. Increasing amounts of ammonium sulphate were injected in a sequence. Three different positions in the boiler were selected. They were injection in the top of the combustion chamber (17), in the cyclone inlet (18), and in the cyclone (19). A typical sequence consisted of a Ref, AS1, AS2; AS3, AS4, AS5, AS6 and each of them was performed during 25 minutes. Table 3 shows which test cases were included for excess air ratio λ= 1.2. -4- The Swedish and Finnish National Committees of the International Flame Research Foundation – IFRF The purpose with second experimental procedure was to investigate the influence of O2 during sulphation of gaseous KCl. Ammonium sulphate was injected into the cyclone at three different air excess ratios (λ= 1.1, 1.2 and 1.4). Each measurement in the Test plan (Table 4) was carried out during three hours and several measurement tools including, IACM, deposit probe measurements, and conventional gas analysis were applied. The deposit measurements were carried for a reference case and two different flows of ammonium sulphate (low flow = ASL, high flow = ASH). The selected flows of AS were 7.7 l/h (ASL) and 15.5 l/h (ASH). Ammonium sulphate ((NH4)2SO4) is a part of the ChlorOut concept. It consists of IACM [11], an instrument for on-line measurements of gaseous alkali chlorides, and a sulphatecontaining additive that converts alkali chlorides to less corrosive alkali sulphates [12]. The additive is often (NH4)2SO4, and, therefore, a significant NOx reduction is also achieved parallel to the sulphation of alkali chlorides [7]. Table 3. Injection points and flow of AS during the transient test (excess air ratio λ= 1.2) Test case and flow / Top of combustion Cyclone inlet In the cyclone Injection point chamber (17) (18) (19) Ref, Flow of AS = 0 l/h x x x AS1, Flow of AS = 5 l/h -a x x AS2, Flow of AS = 7.5 l/h -a x x AS3, Flow of AS = 10 l/h x x x AS4, Flow of AS = 15 l/h x x x AS5, Flow of AS = 20 l/h x x x AS6, Flow of AS = 30 l/h x x -a a = No test was included in the sequence at this flow. Table 4. Test plan – influence of O2 and deposit measurements. Parameter/Test case Reference case Ammonium sulphate low (Ref) (ASL) 7.7 l/h Excess air ratio λ= 1.1 Ref-1.1 ASL-1.1 Excess air ratio λ= 1.2 Ref-1.2 ASL-1.2 Excess air ratio λ= 1.4 Ref-1.4 ASL-1.4 Ammonium sulphate high (ASH) 15.5 l/h ASH-1.1 ASH-1.2 ASH-1.4 2.3 Measurement equipment A so-called IACM (In-situ Alkali Chloride Monitor) located at (13) in Figure 1 measured the alkali chlorides in the gas phase [11, 13]. IACM measures the sum of the KCl (g) and NaCl (g) concentrations on-line but is unable to distinguish between these two species. The result is expressed as KCl, which is the dominating gaseous alkali specie at temperatures prevailing in a CFB boiler during biomass combustion. IACM also measures SO2 simultaneously. A schematic view of IACM is shown in Figure 2. Light from a xenon lamp is sent across the furnace or flue gas channel (measurement path). The light, which arrives at the receiver, is analysed by a spectrometer. The measuring principle is based on measurement of molecular absorption at characteristic wavelengths in the Ultra Violet (UV) - visible region (VIS). The evaluation is made by means of Differential Optical Absorption Spectroscopy (DOAS). The detection limit at a measuring length of 5 metres is 1 ppm for KCl and NaCl and 4 ppm for SO2 respectively. IACM has been used in the present boiler in several previous projects related to alkali chloride issues [5-10]. -5- The Swedish and Finnish National Committees of the International Flame Research Foundation – IFRF Measurement path Sender UV-light Receiver Spectrometer Fan Hot flue gas Fan Computer Figure 2: Schematic view of an IACM installation Flue gas was also extracted through a heated probe and heated sampling lines to a FTIR (Fourier Transform Infra-Red) analyser for the determination of HCl, SO2, N2O, NO, NO2 and NH3 on hot wet flue gases and further to on-line IR-VIS instruments measuring CO, SO2 and N2O and a paramagnetic analyser for O2 on cold dry gases. A chemiluminescence analyser was used (in connection to the cold system) for the measurement of NO. Gas concentrations were measured in locations before the convection path (20), after the convection path (22) and before the stack (23). The deposit measurements were carried out in (20) using a temperature controlled deposit probe. Deposits were collected at a ring temperature of 500°C after 3 hours’ exposure on steel rings made of Sanicro 28, a high-alloyed Fe based steel. The deposits were analysed by wet chemistry (ICP-OES and IC). The chemical analysis by ICP-OES and IC was made on all the collected deposits on the ring. 3. Results 3.1 The transient test – injection at different positions Increasing amounts of ammonium sulphate (AS) were injected in a sequence during the transient test. AS were injected in three different positions at excess air ratio λ= 1.2. The different positions were injection in the top of the combustion chamber (17), in the cyclone inlet (18), and in the cyclone (19). A typical sequence consisted of a Ref, AS1, AS2; AS3, AS4, AS5, AS6 and additional information concerning the transient test can be found in Table 3. The level of gaseous KCl in Figure 3 was approximately 45 ppm during each of the reference cases (Ref) without injection of ammonium sulphate. The level of gaseous KCl was reduced to ~ 20 ppm during test case AS1 (5l/h) when injecting AS to the cyclone. It required a significantly greater flow of AS (15l/h) to obtain a similar reduction in the cyclone inlet. The level of gaseous KCl was only lowered to approximately 30 ppm during the highest flow of AS (30l/h) when injecting in the top of the combustion chamber. The transient test revealed that the position had a great impact on the sulphation efficiency for gaseous KCl. The injection point in the top of the combustion chamber is characterised by a higher concentration of combustibles. This indicates that the concentration of SO3 was limited by the presence of H radicals [4]. Consequently, SO3 was partly consumed according to R6, instead of sulphation of KCl according to R2. -6- The Swedish and Finnish National Committees of the International Flame Research Foundation – IFRF 50 Inlet Cyclone Cyclone 40 KCl-IACM (ppm) Top Comb Chamber 30 20 10 0 Ref AS-1 AS-2 AS-3 AS-4 AS-5 AS-6 Figure 3: Concentration of KCl during the transient test. AS were injected at excess air ratio λ= 1.2. The positions were injection in the top of the combustion chamber (17), in the cyclone inlet (18), and in the cyclone (19). 3.2 Influence of O2 – Injection during different air excess ratios Ammonium sulphate was injected into the cyclone (19) at different air excess ratios in order to investigate the influence of O2 during sulphation of KCl. The air excess ratios were λ = 1.1, 1.2 and 1.4. The operating parameters for each air excess ratio are presented in Table 1 and the different test cases are presented more in detail in Table 4. The test plan included a reference case (Ref) and two different flows of ammonium sulphate (ASL and ASH) for each air excess ratio. ASL and ASH corresponded to an injection of 7.7 and 15.5 l/h of ammonium sulphate respectively. 60 λ =1.1 λ =1.2 50 λ =1.4 KCl (ppm) 40 30 20 10 0 Ref ASL ASH Figure 4: Concentration of KCl during injection of ammonium sulphate in the cyclone at three different air excess air ratios (λ = 1.1, 1.2, 1.4). -7- The Swedish and Finnish National Committees of the International Flame Research Foundation – IFRF The level of gaseous KCl in Figure 4 was approximately 50 ppm during each of the reference cases (Ref) without injection of ammonium sulphate. KCl was reduced to less than 20 ppm at a λ of 1.4 and somewhat above 20 ppm at a λ of 1.2 during test case ASL. The reduction of KCl was less efficient during the lowest air excess ratio (λ = 1.1). It required twice the flow of AS (ASH) to obtain a reduction similar to ASL for λ = 1.2. 100 λ =1.1 λ =1.2 SO2 (ppm) 80 λ =1.4 60 40 20 0 Ref ASL ASH Figure 5: Concentration of SO2 during injection of ammonium sulphate in the cyclone at three different excess air ratios (λ = 1.1, 1.2, 1.4). SO2 was measured after the convective pass at (22). 150 λ =1.1 λ =1.2 120 CO (ppm) λ =1.4 90 60 30 0 Ref ASL ASH Figure 6: Concentration of CO during injection of ammonium sulphate in the cyclone at three different excess air ratios (λ = 1.1, 1.2, 1.4). CO was measured before the stack at (23). The concentration of O2 had an impact on the sulphation efficiency when injecting ammonium sulphate in the cyclone. This could possibly be explained by the formation of SO2 from SO3 according to R3 during lower air excess ratios or the presence of combustibles. Figure 5 shows the concentration of SO2 measured after the convective -8- The Swedish and Finnish National Committees of the International Flame Research Foundation – IFRF pass at (22). The results for SO2 were somewhat contradictory since the highest concentrations were found during the highest and lowest air excess ratios. This effect could possibly be a sampling artefact and it needs to be further investigated. Figure 6 shows the concentration of CO in the stack (23). Similar trends were observed during the air excess ratios 1.2 and 1.4. Injection of ammonium sulphate resulted in a minor increase of CO at very low levels and this effect has previously been discussed in for instance [7]. The OH radicals needed for the final step of the CO oxidation are instead consumed for the formation of NH2 radicals from NH3. These results are only relevant at low levels of CO. The trend during the lowest air excess ratio was the opposite. CO was above 100 ppm during Ref indicating the presence of combustibles and it decreased during injection of AS. The lowest level of CO was actually achieved during the lowest air excess ratio at ASH. This effect has previously been described in [14], in which ammonium sulphate was used to both lower NO and CO during combustion of biomass in a boiler with high emissions of CO. Figure 7 shows the concentration of NO during injection of ammonium sulphate in the cyclone at the different excess air ratios. The formation of NO was strongly favoured by an increasing air excess ratio. The reduction of NO is, however, significantly better at higher air excess ratios. This results in a similar final NO concentration at ASH although the concentration for λ = 1.4 was almost twice the one for λ = 1.1 during Ref. Further aspects on ammonium sulphate as an additive for NO reduction in comparison with ammonia and urea are treated in [7]. 150 λ =1.1 λ =1.2 120 NO (ppm) λ =1.4 90 60 30 0 Ref ASL ASH Figure 7: Concentration of NO during injection of ammonium sulphate in the cyclone at three different excess air ratios (λ = 1.1, 1.2, 1.4). NO was measured before the stack at (23). 3.3 Concentration in the deposits during different air excess ratios Deposit measurements were also carried out for the test cases at different air excess ratios treated in 3.2. Consequently, the test plan consisted of a reference case (Ref) and two different flows of ammonium sulphate (ASL and ASH) for each air excess ratio. Figure 8 shows the composition in deposits from the whole ring analysed by ICP-OES and IC. In general, the deposit growth rate was greater during lower excess air ratios and injection of ammonium sulphate lowered the growth rate somewhat. The main elements in the -9- The Swedish and Finnish National Committees of the International Flame Research Foundation – IFRF deposits were sulphur (S), chlorine (Cl), potassium (K), calcium (Ca) and silicon (Si). Ca and Si are not further discussed since they were not affected due to injection of ammonium sulphate or due to different excess air ratios. Significantly more chlorine and less sulphur were found in the deposits in the reference cases at all air ratios. 3000 Si 2500 Deposit (mg/h*m2) P Mn 2000 Mg Al 1500 Ca Na 1000 K Cl 500 S 0 Ref-1.1 ASL-1.1 ASH-1.1 Ref-1.2 ASL-1.2 ASH-1.2 Ref-1.4 ASL-1.4 ASH-1.4 Figure 8: Composition of deposits given as elements during injection of ammonium sulphate in the cyclone at three different excess air ratios (λ = 1.1, 1.2, 1.4). 25 λ = 1.1 λ = 1.2 Cl (mol %) 20 λ = 1.4 15 10 5 0 Ref ASL ASH Figure 9: Mole % of chlorine (Cl) in the deposits during injection of ammonium sulphate in the cyclone at three different excess air ratios (λ = 1.1, 1.2, 1.4). The mole-% of chlorine during Ref, ASL and ASH are shown in Figure 9. The highest mole-% of chlorine was found in the deposits without injection of ammonium sulphate. -10- The Swedish and Finnish National Committees of the International Flame Research Foundation – IFRF Significant amounts of chlorine were also found during the lowest flow of ammonium sulphate at air excess ratio λ= 1.1. Nevertheless, only low amounts of chlorine remained during the highest flow at λ= 1.1. There was no chlorine detected in the deposits even at the lowest flow of ammonium sulphate (ASL) during the highest excess air ratio (λ = 1.4). 4. Conclusions The selected position in the boiler had an impact on the sulphation efficiency when injecting ammonium sulphate at air excess ratio λ= 1.2. Less amounts of gaseous KCl were reduced in the top of the combustion chamber due to the presence of combustibles (i.e. H-radicals). The air excess ratios had an impact on the sulphation efficiency when injecting ammonium sulphate in the cyclone. Less gaseous KCl were reduced during air excess ratio λ= 1.1 compared to excess ratios λ= 1.2 and 1.4, respectively. The highest mole-% of chlorine was found in the deposits without injection of ammonium sulphate. Significant amounts of chlorine were also found during the lowest flow of ammonium sulphate at air excess ratio λ= 1.1. Nevertheless, only low amounts of chlorine remained during the highest flow at λ= 1.1. The reduction of gaseous KCl is, consequently, less efficient in the presence of combustibles and during low air excess ratios when injection ammonium sulphate. 5. Acknowledgements The main financial support for this work was provided by the Swedish Energy Administration. The additional support from Vattenfall´s Thermal Technology Programme is also greatly appreciated. Further the authors acknowledge Akademiska Hus AB for maintaining and operating the boiler. 6. References [1] P. Glarborg, Hidden interactions - Trace species governing combustion and emissions, Proceedings of the Combustion Institute 31 (2007) 77-98. [2] S. Jimenez, J. Ballester, Formation of alkali sulphate aerosols in biomass combustion, Fuel 86 (2007) 486-493. [3] P. Glarborg, P. Marshall, Mechanism and modeling of the formation of gaseous alkali sulfates, Combust. Flame 141 (2005) 22-39. [4] L. Hindiyarti, P. Glarborg, P. Marshall, Reactions of SO3 with the O/H radical pool under combustion conditions, J. Phys. Chem. A 111 (2007) 3984-3991. [5] H. Kassman, L. Bäfver, L. E. Åmand, The importance of SO2 and SO3 for sulphation of gaseous KCl – An experimental investigation in a biomass fired CFB boiler, Combust. Flame 157 (2010) 1649-1657. [6] H. Kassman, C. Andersson, J. Högberg, L. E. Åmand, K. Davidsson, Gas phase alkali chlorides and deposits during Co-combustion of coal and biomass, 19th International Conference on Fluidized Bed Combustion, Vienna, Austria, 2006. -11- The Swedish and Finnish National Committees of the International Flame Research Foundation – IFRF [7] H. Kassman, M. Holmgren, E. Edvardsson, L. E. Åmand, J. Öhlin, Nitrogen containing additives for simultaneous reduction of KCl and NOx during biomass combustion in a CFB boiler, 9th International Conference on Circulating Fluidized Beds, Hamburg, Germany, 2008. [8] K. O. Davidsson, L. E. Amand, B. M. Steenari, A. L. Elled, D. Eskilsson, B. Leckner, Countermeasures against alkali-related problems during combustion of biomass in a circulating fluidized bed boiler, Chem. Eng. Sci. 63 (2008) 5314-5329. [9] A. L. Elled, K. O. Davidsson, L.-E. Åmand, Sewage sludge as a deposit inhibitor when co-fired with high potassium fuels, Biomass Bioenergy 34 (2010) 1546-1554. [10] H. Kassman, J. Bohwalli, J. Pettersson, L.-E. Åmand, Ammonium Sulphate and CoCombustion with Peat - Two Strategies to Reduce Gaseous KCl and Chlorine in Deposits during Biomass Combustion, Impact of Fuel Quality, Saariselkä, Finland, 2010. [11] European Patent EP 1221036 (2006). [12] European Patent EP 1354167 (2006). [13] C. Forsberg, M. Broström, R. Backman, E. Edvardsson, S. Badiei, M. Berg, H. Kassman, Principle, calibration, and application of the in situ alkali chloride monitor, Rev. Sci. Instrum. 80 (2009). [14] H. Kassman, C. Andersson (Forsberg), J. Carlsson, U. Björklund, B. Strömberg, Decreased emissions of CO and NOx by injection of ammonium sulphate into the combustion chamber, Värmeforsk (Ed.) Värmeforsk report No 908 (Summary in English), 2005. -12-