ASH FORMING MATTER IN PEAT -THE ROLE OF IRON-

advertisement

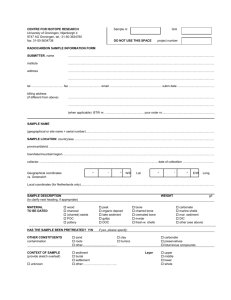

ASH FORMING MATTER IN PEAT -THE ROLE OF IRONMARIA ZEVENHOVEN§, JAAKKO LEHTOVAARA¤, STEFAN STORHOLM†, MIKKO HUPA§ § Process Chemistry Centre, Åbo Akademi University, Turku, Finland, mzevenho@abo.fi, +358 2 2154718 ¤ Vapo Oy, Jyväskylä, Finland † Katterno Group, Jakobstad, Finland ABSTRACT In Finland, some 9.6 million ha consist of peat land from which only 0,6% is used for peat production. With respect to energy consumption peat comes on the 6th place with a share of some 7.2% thus being placed behind oil, wood, coal, nuclear power and natural gas. Although heated discussions have and are taking place in Europe on the sustainability of peat production and its use for heat and power production, peat is considered as a serious alternative as replacement of imported fossil fuels, especially in areas were peat production takes place. Peat may have both positive and negative effects on the combustion process depending on the combustion technology chosen and the composition of the peat considered. Therefore thorough analysis of peat composition and ash forming matter is important in order to understand combustion behaviour. Many sorts of Finnish peat are found to be very different when compared to peat originating from other parts of Europe, and they may thus show different behaviour when fired. In an attempt to explain fouling and slagging, ash forming matter has been analysed extensively with different methods. Chemical fractionation, i.e. stepwise leaching with water, ammonium acetate and hydrochloric acid combined with thermodynamic studies and SEM/EDX analysis of gently ashed fuels showed to be a useful technique for prediction of alkali induced fouling. For explanation and prediction of iron induced slagging, different methods have been studied in an attempt to distinguish between different forms of iron, such as iron oxides, organically associated iron and iron silicates, three forms of iron that each may play a role in slagging in boilers. Sequential leaching using both oxidative and reductive agents was found useful for determination of these forms of iron. Further research is needed to explain which form of iron is responsible for initial slag formation in large scale boilers. Keywords: Iron, Ash, Slagging, Sequential leaching INTRODUCTION In Finland, some 9.6 million ha consist of peat land from which only 0,6% is excavated for use as fuel. With respect to energy consumption peat comes on the 6th place with a share of some 7.2% thus being placed behind oil, wood, coal, nuclear power and natural gas. Although heated discussions have and are taking place in Europe on the sustainability of peat production and its use for heat and power production, peat is considered as a serious alternative as replacement of fossil fuels, especially in areas were peat production takes place. Peat may have both positive and negative effects on the combustion process dependent on the combustion technology chosen and the composition of the peat considered. Therefore thorough analysis of peat composition and ash forming matter is important in order to understand combustion behaviour. Many sorts of Finnish peat are found to be very different when compared to peat originating from other parts of Europe, and they may thus show different behaviour when fired. Figure 1 Slag sample taken from the boiler wall. The slag seemed more sintered at the outside (above) when compared to the side facing the boiler wall, (below) that seemed to contain a large amount of fine powdered iron oxide. Iron has shown to be the cause of severe slagging problems in firing West-Finnish peat in a pf-boiler. Standard fuel analysis i.e determination of the total iron content in the fuels burned could only partly explain the slagging in the boiler. It is believed that also the association of iron in the fuels may play a significant role in the slagging process. Hereto different analytical methods available at Åbo Akademi Universty have been studied in an attempt to find an easy way of analysing iron in peat. EXPERIMENTS Peat samples were analysed focusing on ash forming matter especially iron. Since some samples contained a high moisture content and the mean particle size was larger then 5 mm these samples were dried and milled before further analysis was carried out. The solubility of iron in aqueous solutions at different pH The solubility of iron in aqueous solutions at different pH was determined using a sequential leaching method, i.e. chemical fractionation. Chemical fractionation is a method based on selective leaching by water, ammonium acetate and hydrochloric acid and has been used for characterization of all eight fuels. Increasingly aggressive solvents, i.e. water (H2O), 1M ammonium acetate (NH4Ac) and 1M hydrochloric acid (HCl) leach samples into a series of four fractions (including the unleached residue) for analysis. The untreated samples, liquid fractions and the remaining solids were analyzed [Baxter 1994, Benson and Holm 1995, Skrifvars et al. 1998, Zevenhoven et al. 2000, 2001, 2001b, 2003, 2005]. All chemical analyses were carried out by an external laboratory. Dry matter was determined at 105°C. Samples were dissolved in HNO3/H2O2 for determination of As, Cd, Cu, Co, Hg, Ni, Pb, Sb, and Se. For determination of the other main ash and heavy metals the samples were molten with LiBO2 and dissolved in HNO3. Analysis took place either with ICP-AES or ICP-SFMS. Special care was taken to obtain reliable analyses of Fe. (Analyses of other elements was seen as bonus) SEM/EDS In order to allow ash forming matter to be seen in SEM, fuels were ashed in air in a laboratory furnace at 500, 700 and 900°C respectively. The ashing time was 15 minutes. After ashing both untreated fuel and ashed samples were mounted on carbon tape and the samples were mounted in the SEM. SEM/EDS analyses were carried out wit 30, 250 and 5000x magnification. At 30x magnification an overall area analysis was Figure 2 Chemical fractionation method performed. At 250x and 5000x point analyses were performed. At 250x elemental maps were scanned for Al, C, Ca, Cl, Fe, K, Mg, Na, O, P, Pb, S, Si, Zn. All analyses were calculated on a carbon free basis. Determination of different forms of iron Exchangeable + weak acid soluble fraction HAc NH2OH·HCl Reducible fraction: Inorganic Fe i.e. oxides and hydroxides Analysis Oxidizable fraction (e,g,, metals associated with organic matter and sulfides) H2O2 NH4Ac Residual fraction, silicates Figure 3 Sequential leaching for determination of different forms of iron The Community Bureau of Reference (BCR, now Standards, Measurements and Testing Program of the European Commission) developed a sequential extraction program in 1987 to harmonize the sequential schemes for the determination of metals in soils and sediments. [Kazi et al.2005, Ure et al.1993, Wang et al. 2006]. So far, this procedure has been successfully applied to a variety of sediments, sewage sludges and soil samples. The sequential extraction procedure is briefly given in Figure 3. This scheme consists of three leaching steps by using acetic acid, hydroxyl ammonium chloride and ammonium acetate separately. Leached by the three steps, the metal species in the sample are divided into four different fractions: An exchangeable and weak acid soluble fraction, a reduced fraction, an oxidised fraction and a silicate fraction. RESULTS AND DISCUSSION Standard fuel analysis shows that Peat 16 and 6 were peats with the highest amount of iron ~5.5% wt in fuel), whereas Peat 13 represented a peat sort low in Fe (0.3%wt in fuel) (Figure 4) 6 5 % ds 4 3 2 1 0 13 1 12 14 2 15 9 4 3 10 5 Figure 4 Content of iron in West-Finnish peat (#16) 7 8 6 16 Figure 5 shows the results of chemical fractionation of 22 Finnish peats. It shows that the major part of iron in the fuel dissolved at low pH in HCl. Silicates, potassium and sodium are 100 remaining mainly insoluble after the leaching procedure indicating that they may be present as alkali silicates. av H2O av NH4Ac av HCl av rest 90 80 70 % 60 Ca and Mg seem to be more organically associated and are found mainly ion exchangeable with NH4Ac. 50 40 30 20 10 0 A substantial part of sulfur is usually found nonFigure 5 Chemical fractionation results of Finnish peat (#22, 95% soluble indicating that confidence limit) sulphur may be present covalently bonded in peat. The chemical fractionation results showed that the procedure can not distinguish between different forms of iron in peat. Si Al Fe Ca Mg P Na K S As stated in the introduction combustion behaviour of peat with different iron content showed different slagging behaviour not always proportional to the total iron content and thus the form of iron present in the fuel and formed during combustion is believed to play a significant role MgO Al2O3 SiO2 P2O5 SO3 K2O CaO Fe2O3 Na2O Cl MgO Al2O3 SiO2 P2O5 SO3 K2O CaO Fe2O3 Na2O Cl 4 5 6 7 4.62 18.25 9.88 3.79 5.03 7.91 18.63 28.65 2.52 0.34 3.55 16.78 19.38 3.91 3.60 7.12 14.02 28.66 1.94 0.39 4.18 17.75 5.65 4.03 4.64 4.37 15.99 41.76 0.95 0.34 4.78 15.72 4.15 4.00 4.94 4.45 19.61 41.04 0.63 0.30 14 15 16 17 3.70 13.87 46.62 3.06 2.09 0.25 10.61 18.69 0.31 0.00 7.25 16.56 20.80 4.19 3.26 0.28 16.74 29.69 0.63 0.13 5.59 18.59 14.49 3.61 1.66 0.23 14.82 40.56 0.36 0.00 6.51 22.09 4.74 4.26 4.06 0.21 16.02 41.25 0.18 0.03 Figure 6 Example of SEM/EDX analyses of peat ashed at 500°C (above) and 900°C (below) SEM/EDX analyses showed that gentle ashing helped to reveal the inorganic components without disturbing too much the place they were situated. At ashing temperatures below 700°C alkali metals remain present in the ash, whereas the alkaline metals will have volatilised at higher temperatures and will be lost for SEM analysis. This problem does not appear for iron. Figure 6 shows that iron can be found in different forms in the fuels, either as discrete “mineral” particles or distributed evenly over the fuel indicating iron could be present in the organic matrix. 4.5 4 3.5 The oxidation state of iron in eight peat fuels was determined with help of the reducing agent of hydroxyl-amino-hydrochloride and the oxidising agent peroxide in an acid environment. Fe-silicates Fe2O3, Fe(OH)3 FeS and organic Fe exchangable Fe %wt ds 3 2.5 2 1.5 1 0.5 0 Peat 1 Peat 2 Peat 3 Peat 4 Peat 5 Peat 6 Peat 7 Peat 8 Figure 7 Different forms of iron in West-Finnish peat 2.2 Organic Fe/Inorganic Fe 2.0 Iron may be present in different forms in all eight peats (#1-8) subjected to this leaching scheme. The main part seems to be either organic reduced iron (Fe2+) or mineral Fe2O3 or Fe(OH)3. In the three peats with high iron content more than 20% of total iron may be present as Fe-silicates giving possible slag properties, which may lead to formation of low melting silicates. 1.8 1.6 1.4 1.2 1.0 Peat 1 Peat 2 Peat 3 Peat 4 Peat 5 Peat 6 Peat 7 Peat 8 Figure 8 Ratio of organic//inorganic iron in West-Finnish peat Fe3+ may be released from the fuel as oxides and particles may hit the wall of the boiler and remain there. Fe2+ may be release partly as reduced species, which usually have a lower melting point than Fe3+ compounds. When still partly reduced when hitting the boiler walls these particles could from a sticky deposit enabling other particles to stick to the wall as well. CONCLUSIONS AND FUTURE RESEARCH NEEDED Iron may be the initiator of slagging phenomena in peat fired boilers. This has consequences for the way the boiler is operated. For good operation better understanding of total iron contents and forms of iron present in the fuel was found to be vital. During these studies different analytical methods have been used to analyse iron in peat in an attempt to find a fast and easy way to predict slagging risks in the boiler. Standard fuel analysis showed total concentration of Fe in fuel and is useful to estimate the risk of slag formation. This type of analysis is always needed. SEM showed distribution of Fe in the fuel. Ashing is often needed to reveal ash forming matter hidden in fuel matrix. Sometimes SEM analyses give valuable extra information. Sequential leaching with aqueous solutions at different pH have shown in the past to be very useful to understand deposit formation in heat exchanger areas when caused by alkali metals. However this method was found not suitable for Fe since no differentiation could be made between different forms of iron. Standard fuel analysis i.e determination of the total iron content in the fuels burned could only partly explain the slagging in the boiler. It is believed that also the association of iron in the fuels may play a significant role in the slagging process. Sequential leaching with oxidative and reducing solutions showed that iron may be present as weakly associated and organically associated (Fe2+), as oxidised minerals (Fe3+) or as iron silicates. These three different groups all could play a role in the slagging encountered. This means that, for determination of slagging risk factors knowledge of total Fe, organic Fe, inorganic Fe, ratio organic Fe/inorganic Fe and Fe-silicates could be helpful. The results as described in this paper show how forms of iron in peat fuels can be determined. Further studies are needed to study the reaction pathways of different iron compounds under combustion conditions. REFERENCES BAXTER L.L., (1994), Pollutant emission and deposit formation during combustion of biomass fuels, Livermore, (CA), BENSON S.A., HOLM P.L., (1985), ”Comparison of inorganic constituents in three low-rank coals”, Ind. Chem. Eng. Prod. Res. Dev., Vol 24, pp 145-149. KAZI, T.G., JAMALI, M.K., KAZI, G.H., ARAIN, M.B., AFRIDI, H.I. AND SIDDIQUI, A., (2005) Evaluating the mobility of toxic metals in untreated industrial wastewater sludge using a BCR sequential extraction procedure and a leaching test. Analytical Bioanalytical Chemistry, Vol 383, pp 297–304. Skrifvars B-J., Blomquist J-P., Hupa M., Backman R., (1998), Predicting the ash behaviour during biomass combustion in FBC conditions by combining advanced fuel analysis with thermodynamic multicomponent equilibriumcalculations”, Proceedings of the 15th Annual International Pittsburgh Coal Conference, Pittsburgh, (PA), USA, URE, A.M., QUEVAUVILLER, P.H., MUNTAU, H. AND GRIEPINK, B., (1993) Speciation of heavy metals in soils and sediments. An account of the improvement and harmonization of extraction techniques undertaken under the auspices of the BCR of the Commission of European Communities. International Journal of Environment Analytical Chemistry, Vol 51, pp 135-151 WANG, C., LI, X.C., MA, H.T., QIAN, J. AND ZHAI, J.B., (2006) Distribution of extractable fractions of heavy metals in sludge during the wastewater treatment process. Journal of Hazardous Materials, Vol 137 (3), pp 1277-1283. ZEVENHOVEN, M., BLOMQUIST, J-P., SKRIFVARS, B-J., BACKMAN, R., HUPA, M, (2000), Prediction of behavior of ashes from five different solid fuels in fluidized bed combustion, Fuel, Vol 79, pp 1353-1361 ZEVENHOVEN, M., SKRIFVARS B-J., YRJAS P., HUPA M., NUUTINEN L., LAITINEN R., (2001) Searching for imporved characterisation of ash forming matter in biomass, Proceedings of the 16th International Conference on Fluidized Bed Combustion, Reno, NV, USA, ZEVENHOVEN M., (2001b), Ash-forming matter in biomass fuels, Academic dissertation, Åbo Akademi University, Turku, Finland, ISBN 952-12-0813-9 ZEVENHOVEN M., SKRIFVARS B-J, YRJAS P., BACKMAN R., MUELLER C., (2003), Co-firing in FBC-A challenge for fuel characterization and modeling, Proceedings. of the 17th International Conference on Fluidized Bed Combustion, Jacksonville, (FL), USA ZEVENHOVEN M., YRJAS P., BACKMAN R., SKRIFVARS B-J., HUPA M., (2005), “The Åbo Akademi database-fuel characterization” FBC2005-78093, Proceedings of the 18th International Conference on Fluidized bed Combustion, Toronto, Ontario, Canada,