Towards Autonomous Control of Molecular Communication in Populations of Bacteria Chieh Lo

advertisement

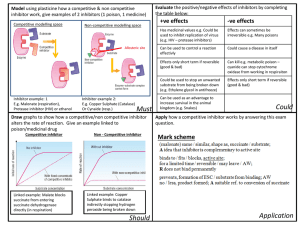

Towards Autonomous Control of Molecular Communication in Populations of Bacteria Chieh Lo Guopeng Wei Radu Marculescu Carnegie Mellon University Pittsburgh, PA, 15213 Carnegie Mellon University Pittsburgh, PA, 15213 Carnegie Mellon University Pittsburgh, PA, 15213 chiehl@andrew.cmu.edu guopengw@ece.cmu.edu radum@cmu.edu ABSTRACT Quorum sensing is a chemical communication process bacteria use to sense population density and regulate their collective behavior. By using quorum sensing inhibitors that degrade quorum sensing molecules and inactivate their receptors, one can inhibit bacterial pathogenesis, such as the production of virulence and biofilm development. To keep the level of quorum sensing molecules below the activation threshold, we propose a biological controller that can generate different concentration levels of inhibitors under different environment conditions. We provide a detailed analysis of our proposed controller that includes system response, stability, and sensitivity analysis. We also discuss the autonomous controller design under specified environment constraints and validate our results via simulation. This work represents a first step towards a paradigm change in reducing bacterial pathogenesis via controlling the dynamics of bacterial cell-to-cell communication network. 1. INTRODUCTION Cell-to-cell communication [1][4][16] mechanism known as quorum sensing (QS) [3] utilizes cell density information to monitor the environment and alter gene expressions in a competitive environment. The QS system used by gramnegative bacteria (see Figure 1(a)) is mediated by diffusible signaling molecules that belong to the acyl-homoserine lactone (AHL) family [3]. By sensing the concentration of specific types of the AHL molecules, bacteria can form biofilms, express virulence, and become resistant to antibiotics after reaching a high cell density [11]. In this paper, we aim at reducing the bacterial pathogenesis [14] by quenching the cell-to-cell bacterial communication, or more specifically, by keeping the concentration of the signaling molecules under a strain-specific activation threshold. Due to high mutation rates, bacteria can develop resistance to antibiotics quickly [17]. QS inhibitors (QSIs) [12] can block the virulence regulatory pathways without killing or affecting bacteria growth [13]. However, QSI resistant mutants which can continue to utilize QS communication Permission to make digital or hard copies of all or part of this work for personal or classroom use is granted without fee provided that copies are not made or distributed for profit or commercial advantage and that copies bear this notice and the full citation on the first page. Copyrights for components of this work owned by others than ACM must be honored. Abstracting with credit is permitted. To copy otherwise, or republish, to post on servers or to redistribute to lists, requires prior specific permission and/or a fee. Request permissions from Permissions@acm.org. NANOCOM 15, September 21 - 22, 2015, Boston, MA, USA Copyright 2015 ACM 978-1-4503-3674-1/15/09 ...$15.00. http://dx.doi.org/10.1145/2800795.2800822 have a better chance of survival. To prevent the selective pressure caused by QSIs [5], multi-inhibitor schemes can be adopted. However, synthesizing multiple inhibitors at the same time and in large quantities can not only result in wasting chemical substances but also produce toxic effects to the host [10]. Therefore, in this paper, we propose to design a biological controller which can generate the minimal amount of QSIs that can stop bacteria communication without inducing much selective pressure. To synthesize the QSIs and control the concentration of the AHL molecules [9], genetic circuits can serve as the basic control units which automatically detect and react to the environment changes. For example, we can construct genetic circuits by cloning the genes in the plasmid, such as the aiiA gene which expresses the enzyme that hydrolyzes the AHL molecules [20]. However, due to the uncertainty in the biological parameters (for example, the values of the kinetic constants) of the genetic parts [2], such systems may be unable to repress the QS regulation system at all. Therefore, stability and sensitivity analysis are needed to demonstrate the feasibility of the proposed system. Instead of implementing the genetic circuit directly within live bacteria which has potential for side effects, we propose to use artificial cells (see Figure 1(b)). For instance, we can engineer the permeability of the cell membrane [18] via paper-based techniques as recently proposed in [19]. Based on this new technology, it becomes possible to construct artificial cells by cloning the genome sequence within the genes of the bacteria host and using liposome as the cell membrane. By placing the artificial cells into the bacterial environment, it becomes possible to detect the concentration of the AHL molecules and then generate the right amount of QSIs in real-time. Consequently, the proposed system represents a paradigm shift from manual to autonomous control of bacteria communication network. In the following sections, we target the opportunistic human pathogen Pseudomonas aeruginosa which has been identified as a primary target for antimicrobial research [22]. Taken together, our contribution is threefold: • First, we develop an ordinary differential equation (ODE) based model of Pseudomonas aeruginosa QS regulation system and propose the synthetic circuitry to be used in the artificial cell. To the best of our knowledge, this is the first design that formally considers the autonomous control of the QS signal. • Second, we formulate the control problem and perform the stability and sensitivity analyses. This provides the theoretical basis for synthesizing the controller. • Third, we identify the feasible regions of operation (a) (b) P. aeruginosa &'($! &'($! (c) Artificial Cell LasR inhibition Input Signal (d(t)) '"#$! '"#$! &'(%! Plant Bacteria (X(t)) #'(%! #'($! "%%&! !"#$! $"#$! $"#$! $"#$! $"#$! AI AI2 Antagonist AiiA $"#%! !"#$! Reference Signal (r(t)) &'($! !"#%! AHL inhibition "! !! Process Variable (y(t)) Controller Artificial Cell (U(t)) Figure 1: Proposed Control System: QS Regulation System in P. aeruginosa and Proposed Controller Circuit. (a) The QS regulation system of P. aeruginosa. (b) The artificial cell contains genetic circuitry. The aiiA genes can produce the AiiA enzyme that hydrolyzes the AHL molecules. The black rectangle box produces the triangle proteins which function as the antagonists of LasR. The orange circle represents AI that moves freely through the cell membrane, the green diamond represents AI2 and the purple and black particle are AiiA and antagonist molecules, respectively. The red, orange, green and purple oval represent LasR, LasI, RhlR and RhlI, respectively. (c) The diagram of the proposed control system. and characterize the biological parameters for minimal expression of inhibitors. We verify our proposed controller via numerical methods and simulation. As such, the design procedure we provide can be used as a general guideline towards in vitro construction of synthetic cellular controllers. d[C1 ] dt d[C2 ] dt d[C3 ] dt d[R1 ] dt The remainder of this paper is organized as follows. Section 2 focuses on the mathematical modeling of the QS regulation system of P. aeruginosa and the QSIs. Section 3 discusses the genetic circuits needed to express QSIs and incorporates the QS regulation system to form an autonomous control system. Section 4 analyzes the system response, stability, and sensitivity via numerical methods. Section 5 provides a design example and some general design guidelines. Section 6 utilizes the bacterial simulator proposed in [23] to validate the model in scenarios that mimic realistic settings. Finally, some conclusions are drawn in section 7. 2. 2.1 MATHEMATICAL MODEL QS Model As shown in Figure 1(a), two interconnected circuits in P. aeruginosa form a QS cascade where the Las system sits at the top. LasI and RhlI synthases synthesize two different kinds of AHL molecules: 3-oxo-C12-homoserin lactone (3OC12HSL) and butanoyl homoserin lactone (C4HSL), respectively1 . The AHL molecules can passively diffuse through bacterial cell membrane and bound to the LasR and RhlR receptors in the intracellular space. The LasRAI complex (C1 ) and RhlR-AI2 complex (C2 ) activate the transcriptions of numerous genes including not only the virulence genes, but also the downstream lasI and rhlI genes which form the autocatalytic loop. Therefore, each cell must dump its production of AHL molecules in the extracellular space; otherwise, the accumulation of the intracellular AHL molecules will induce the QS regulation system. As the cell density increases, the diffusion process becomes less effective and the autocatalytic loop gets enabled; this results in the expression of QS signals. By adopting the model in [7] and introducing the cell density factor (ρ) [6], the following ODEs describe the QS regulation system of P. aeruginosa: 1 Denoted as AI and AI2 in this paper = α1 [R1 ][A1 ] − δ1 [C1 ] (1) = α2 [R2 ][A2 ] − δ2 [C2 ] (2) = α3 [R2 ][A1 ] − δ3 [C3 ] (3) = −α1 [R1 ][A1 ]+δ1 [C1 ]−bR1 [R1 ]+ VR1 [C1 ] KR1 +[C1 ] +R10 (4) VR2 [C1 ] d[R2 ] = −α2 [R2 ][A2 ]+δ2 [C2 ]−bR2 [R2 ]+ +R20 (5) dt KR2 +[C1 ] d[A1 ] = −α1 [R1 ][A1 ] + δ1 [C1 ] − bA1 [A1 ] dt VA1 [C1 ] d1 + ([A1EX ] − [A1 ]) + A10 + KA1 + [C1 ] ρ d[A2 ] = −α2 [R2 ][A2 ] + δ2 [C2 ] − bA2 [A2 ] dt VA2 [C2 ] d2 + ([A2EX ] − [A2 ]) + A20 + KA2 + [C2 ] ρ (6) (7) d[A1EX ] d1 =− ([A1EX ] − [A1 ]) − bA1EX [A1EX ] dt 1−ρ (8) d[A2EX ] d2 =− ([A2EX ] − [A2 ]) − bA2EX [A2EX ] dt 1−ρ (9) where [X] denotes the concentration of a particular molecular species X. C1 : LasR-AI, C2 : RhlR-AI, C3 : RhlR-AI2, A1 : intracellular AI, A2 : intracellular AI2, A1EX : extracellular AI, A2EX : extracellular AI2, R1 : LasR, R2 : RhlR, α: binding rate constant, δ: dissociation rate constant, b: degradation rate constant, A10 , A20 , R10 , R20 : basal production rate constant, V : maximum production rate constant, K: Michaelis-Menten constant, d: diffusion constant. To give some intuition, Eqs.(1)-(3) describe the binding reaction of the AHL molecules and LasR receptors. We use quasi-steady state approximation to account for the protein production rate of Eqs.(4)-(7) (the forth term) which is governed by the Michaelis-Menten kinetics. Since the cell membrane diffusion becomes less efficient when the cell density increases, the effect can be modeled as the division of diffusion coefficient over cell density in Eqs.(6)-(9). 2.2 QS Inhibitors (QSIs) The QSIs are designed for different targets. Some QSIs target the LasR receptors through the use of the AHL analogues that act as antagonists for the native AHL molecules. Due to the high affinity in binding with LasR, the antagonist molecules can out-compete the native AHL molecules and inhibit the transcription of both LasR and LasI. Another kind of QSIs target the AHL molecules that diffuse in the extracellular space. They hydrolyze the bond between the acyl tail and lactone ring of the AHL molecules in a nonreversible manner; this can directly decrease the concentration of the AHL molecules thus reducing virulence. 2.2.1 LasR/RhlR inhibitors To model the effect of LasR type QSIs, we need to add additional equations to the QS regulation system of P. aeruginosa [8]. To begin with, the LasR antagonist molecules can bind to the LasR and RhlR and form the complexes C4 and C5 which directly affect the production rates of R1 and R2 : d[C4 ] = α4 [R1 ][A1A ] − δ4 [C4 ] dt d[C5 ] = α5 [R2 ][A1A ] − δ5 [C5 ] dt d[R1 ] = −α1 [R1 ][A1 ] + δ1 [C1 ] − bR1 [R1 ] dt VR1 [C1 ] + + R10 − α4 [R1 ][A1A ] + δ4 [C4 ] KR1 + [C1 ] d[R2 ] = −α2 [R2 ][A2 ] + δ2 [C2 ] − bR2 [R2 ] dt VR2 [C1 ] + + R20 − α5 [R2 ][A1A ] + δ5 [C5 ] KR2 + [C1 ] (10) (11) (12) (13) d[A1AE ] = −d3 ([A1AE ] − [A1A ]) − bA1AE [A1AE ] dt (14) (15) where A1AE : extracellular antagonist molecules. 2.2.2 d[E1EX ] (18) = −d4 ([E1EX ] − [E1 ]) − bE1EX [E1EX ] dt 2 d[E2 ] 1 [C1 ] = PlasRE ( + 2 )−bE2 [E2 ]+d5 ([E2EX ]−[E2 ]) 2 rE2 dt KE2 +[C1 ]2 (19) The AHL inhibitor hydrolyzes the extracellular AHL molecules which can be viewed as a degradation source and assumed to follow the Michaelis-Menten kinetics. Accordingly, Eq.(8) should be modified as (16) where Enzyme denotes the extracellular AHL inhibitor. 3. CONTROL SYSTEM DESIGN 3.1 Genetic Circuit Design and Modeling The desired functionalities of the artificial cells need to provide stable control mechanisms to ensure that the concentration of the AHL molecules remains below the autocatalytic activation threshold. We now only consider AI (3OC12HSL) as the primary control targeted molecules since the activation of Rhl needs a high concentration of AI. The genetic circuit needs to perform two main functions, namely, detection and reaction. The detection of the AI concentration can be realized with a specific type of protein that can bind to the AI. In this paper, we use the same receptor protein, LasR, to detect the concentration of the AI since it can truly experience the same concentration of the (20) where E1 : intracellular AI inhibitor, E2 : intracellular LasR/RhlR inhibitor, E1EX : extracellular AI inhibitor, E2EX : extracellular LasR/RhlR inhibitor. The production rate (second term in Eqs. (17) and (19)) of the inhibitors can be characterized by the cooperation binding of the LasR-AI complex which can be modeled by the hill equation with hill coefficient n [2]. The product of the promoter strength (PlasR ) and the basal production rate (r) characterizes the minimal expression rate when there is no LasR-AI complex present. We assume that the membrane permeability of the enzyme produced by the genetic circuit is the same as the AHL molecules. 3.2 AHL inhibitors d[A1EX ] = −d1 ([A1EX ]−[A1 ])−bA1EX [A1EX ] dt VE1 [Enzyme][A1EX ] − KA1EX +[A1EX ] 1 [C1 ]2 d[E1 ] = PlasRE ( + 2 )−bE1 [E1 ]+d4 ([E1EX ]−[E1 ]) 1 rE1 dt KE1 +[C1 ]2 (17) d[E2EX ] = −d5 ([E2EX ] − [E2 ]) − bE2EX [E2EX ] dt where A1A : intracellular antagonist molecules, C4 : LasRAntagonist and C5 : RhlR-Antagonist. The last two terms in (12) and (13) describe the degradation and dissociation result from the antagonists. We assume that the antagonists follow the same rules as the AHL molecules (Eqs.(6)-(9)) which can be formulated as follows: d[A1A ] = −α4 [R1 ][A1A ] + δ4 [C4 ] − α5 [R2 ][A1A ] dt + δ5 [C5 ] − bA1A [A1A ] + d3 ([A1AE ] − [A1A ]) AI as in the bacteria. After detecting a specific concentration of the LasR-AI complex, the genetic circuit reacts to it and produces the desired amount of inhibitors. As described in Section 2, two types of inhibitors are used to regulate the concentration of the AI. To obtain variable combinations of the inhibitors with minimal expression levels that can repress the QS communication, we build two circuits separately and set different expression levels given different LasR-AI concentrations. Circuit I is built upon assembling the aiiA protein generator with the las promoter. Similarly, Circuit II is built with genes that can express the antagonists to bind with the LasR and RhlR protein (Figure 1(b)). The protein expression mechanism of the genetic circuits can be characterized by the following equations: Control Problem Formulation Consider a general control system which consists of a plant and a controller (Figure 1(c)). The plant (process) takes in the input variable (d(t)) and control variable (CV) (u(t)) generating the process variable (PV) (y(t)). The controller calculates an error (e(t)) signal as the difference between a measured process variable and a desired setpoint (SP) (r(t)). The controller aims at minimizing the error by adjusting the process through the control variable (u(t)). The control system can be characterized by the following equations. ẋ(t) = f (x(t), u(t), d(t)), u̇(t) = h(e(t), u(t)) y(t) = g(x(t)), e(t) = y(t) − r(t) (21) (22) where f , g and h are arbitrary functions. Using a similar terminology, we can formulate the control problem for the proposed system (Figure 1(c)). More precisely, the plant (process) is described by the dynamics of the QS system of P. aeruginosa, where the state variable X is the set of the concentration of chemical substances described by Eqs.(1)-(16) (X = [C1 C2 C3 C4 C5 R1 R2 A1 A1EX A2 A2EX A1A A1AE ] ); the input (d(t)) can be viewed as the environment perturbations including bacterial growth, division, death, and molecule fluctuations. The control variables (u(t)) are the QSIs which target the LasR and AI. The genetic circuit can be thought of as an integral controller which reacts to the concentration of the LasR-AI complex. To prevent the selective pressure caused by one specific type of inhibitor, two types of inhibitors are generated simul- 2 10 1 10 0 Process Variable (y) 10 −1 10 −2 10 LasR Inhibitor (ρ = 0.9) −3 10 AI Inhibitor (ρ = 0.9) LasR and AI Inhibitor (ρ = 0.9) −4 LasR Inhibitor (ρ = 0.7) 10 AI Inhibitor (ρ = 0.7) LasR and AI Inhibitor (ρ = 0.7) −5 10 −2 −1 10 0 10 10 Control Variable (u) VE1 [E1EX ][A1EX ] d[A1EX ] = −d1 ([A1EX ]−[A1 ])−bA1EX [A1EX ]− dt KA1EX +[A1EX ] (23) d[A1AE ] = −d3 ([A1AE ] − [A1A ]) − bA1AE [A1AE ] + k[E2EX ] (24) dt The process variable and reference signal is the concentration of the LasR-AI complex. We assume that the reference signal (setpoint) is set below the activation threshold of the autocatalytic process of the QS system. Therefore, the error signal is approximately equal to the process variable. There are two limitations of this scheme. First, given any arbitrary genetic circuit, there is a maximum amount of substances it can produce. If the maximum amounts of inhibitors can not suppress the regulation system, then the setpoint value is not achievable. Second, the biological parameters of genetic circuits put constraints on the realizability of the biological controller. To properly synthesize the controller, we need to first examine whether the setpoint is achievable. Once the setpoint is achieved, the minimum amount of the inhibitors needed can be recognized as the operation point for the biological controller. 4. CONTROL SYSTEM ANALYSIS 4.1 Control System Response We first examine the open loop response without adding QSIs. As shown in Figure 2, given a fixed extracellular concentration of the AI, the response curve of the LasRAI concentration shows the bistability characteristics of the QS regulation system of P. aeruginosa described by Eqs.(1)(9). When the extracellular concentration of the AI is below the activation threshold, the system maintains a relative low concentration over all state variables. However, once the concentration of the AI exceeds the activation threshold, the concentration of all state variables changes the state from low to high concentration sharply. This response is correlated well with experimental data in [21] which explains the fact that when the population density of bacteria exceeds the activation threshold (i.e. the accumulation of the AI), it could induce virulence and biofilm formation. The concentration of the LasR-AI complex in a low stable state is different compared to the concentration in a high (a) 30 25 Controller 20 15 0 10 (c) 10 5 0 0 LasR−AI (a.u.) (b) LasR AI Inhibitor (a.u.) taneously and fed into the regulation system (plant) which can be described by Eqs.(17)-(20). Hence, the control variables consist of four variables, namely, U = [E1 E1EX E2 E2EX ]. By adding kE2EX to Eq.(15) which accounts for the catalysis of the LasR antagonist and replacing Enzyme in Eq.(16) with E1EX , we form a closed-loop control system: Figure 3: Dynamic range of the process variable (PV) with different types of inhibitors where u represents concentration of inhibitors and y is the concentration of the LasR-AI complex. The sharp decrease point of the PV can be recognized as the activation threshold for the P. aeruginosa QS system. LasR−AI (a.u.) Figure 2: Bistablility of the P. aeruginosa QS regulation system. Given different cell densities (ρ), the steady state of the LasR-AI complex concentration varies with different amounts of fixed extracellular concentration of AI molecules. 0 10 500 1000 1500 2000 2500 3000 3500 Time(s) 4000 3000 3100 3200 Figure 4: System response by adding different QS inhibitors. (a) Manually placing AI, LasR inhibitors and controllers (artificial cells) at different times. (b) and (c) represent the concentration change of LasR-AI complex and inhibitors after placing the controllers. stable state (Figure 2); this significant difference results in the expression of the virulence factors. As shown in Figure 3, by varying the control variable (QSIs), the concentration of the process variable (LasR-AI complex) shows a sharp decrease at a certain point which can be recognized as the minimum amount of inhibitors that should be added to the environment. Note that by using the LasR and AHL inhibitors at the same time, the total amount of inhibitors needed to repress the QS regulation system is minimized at both cell densities (ρ = 0.7, 0.9 in Figure 3); this shows that the multi-inhibitor strategy acts more effectively (the ratio is 1:1 for both inhibitors). By manually adding AI and LasR inhibitors at time 1000s and 2000s, respectively, the concentration of the LasR-AI complex decreases as expected. As inhibitors decays, the system goes back to the high monostable state which can induce virulence (Figure 4). Therefore, in order to keep a low concentration of the LasR-AI complex, the continuous generation of inhibitors is necessary. At time 3000s, we place the artificial cells into the environment to inhibit the P. aeruginosa. The concentration of the LasR-AI decreases and remains in the low stable state which proves that the artificial cell can effectively control the concentration of the LasR-AI complex. 4.2 Stability Analysis The most important type of stability concerns solutions near the equilibrium points. This can be examined by using the theory of Lyapunov [15]. Definition 1. Consider nonlinear system ẋ = f (x), where f : Rn → Rn (Rn is the set of real numbers); a point xe ∈ Rn is an equilibrium point of the system if f (xe ) = 0. Definition 2. A system is locally asymptotically stable w/o Controller (a) 0.9 (b) 30 w/ Controller Monostable High Monostable High 0.6 Promoter Strength (P) Cell Density (ρ) 0.7 0.5 Bistable 0.4 0.3 0.1 Monostable Low 15 ρ = 0.9 10 ρ = 0.7 0.2 0.3 0.4 0.5 1 2 Fixed Extracellular AI (a.u.) 0 200 3 4 5 Figure 5: Bistability w/o and w/ controller. The black and white region correspond to monostable high and low, respectively. Without the controller, the gray region can be recognized as the bistable region. (L.A.S.) near or at xe if there is an R > 0 s.t. |x(t = 0) − xe | ≤ R ⇒ x(t) → xe as t → ∞. In the case of biological systems, if some combinations of state variables eventually converge to the same equilibrium point, then the union of all these combinations can define an asymptotically stable region. On the other hand, if some combinations of state variables can reach more than one equilibrium point, then they define a multi-stable region. As shown in Figure 5, for the P. aeruginosa QS regulation system, there exist two monostable regions and one bistable region. Given any set of initial conditions (here we only consider varying the extracellular concentration of the AHL molecules since the input signal mainly affects it) within the monostable region, then the trajectories of state variables will eventually converge to the equilibrium points. On the contrary, the bistable region is not locally asymptotically stable since it may reach low or high monostable states, given different initial conditions. QSIs generated by the genetic circuit are expected to increase the range of the monostable region since the inhibitors can stabilize the system by repressing the concentration and activity of both AHL molecules and the LasR protein. The effects of the inhibitors are shown in Figure 5. As it can be seen, the low monostable region in Figure 5(b) extends to 10 times larger (the x-axis is extended) than in Figure 5(a) which confirms the functionality of the controller. The bistable region disappears; only the monostable low and high regions remain. 4.3 20 5 Monostable 0.2 Low 0.1 Cell Density (ρ = 0.9) Cell Density (ρ = 0.7) Cell Density (ρ = 0.5) 25 0.8 Sensitivity Analysis Sensitivity analysis can provide valuable insights about how robust the biological responses are with respect to the uncertainty of biological parameters. It can also determine which model inputs are the key factors that affect the model outputs. By sweeping the model parameters compared to their nominal values, it is possible to find sensitive parameters that can considerably change the model behavior (i.e. the model is sensitive to those parameters). However, some of the biological parameters may be hard to realize due to the biological constraints [2]. Promoter strength (PlasR ) and basal production rate (r) are suitable for this design framework since we can tune their values through the evolution method [2]. Given different cell densities (ρ), certain combinations of parameters (i.e. PlasR ,r) can not repress the system (Figure 6). Hence, we should not choose parameters within the colored region since they can not repress the system toward the low monostable state. ρ = 0.5 180 160 140 120 100 80 Basal Production Constant (r) 60 40 20 0 Figure 6: Sensitivity analysis for different combinations of parameters of genetic circuit. The colored areas (red, green and blue) indicate the high monostable state with different cell densities. As cell density increases, the area expands. (Note that blue and green regions are on top of red region) 5. BIOLOGICAL PARAMETERS DESIGN In this section, we provide a design procedure to design the control circuit to produce the minimal amount of inhibitors that can repress the QS regulation system. First, we need to choose the operation points for the QS regulation system when the system is in high and low monostable states, respectively. As shown in Figure 7, given an arbitrary cell density, the minimum amount of inhibitors needed to repress the regulation system should be recognized as the operation point (i.e., points within the blue regions). Next, by assuming that the overall system is at steady state, we can set the derivatives of Eqs.(17)-(20) equal to zero and solve for the steady state value of the control variable in high and low monostable states, respectively. Noticing that the concentration of LasR-AI (C1 ) is far less than the disassociation constant (K) at low monostable state while far larger at high monostable state, also, replacing the concentration of extracellular inhibitors with the concentration of intracellular inhibitors, we can obtain: Elow = 1 bEX + d bEX + d P , Ehigh = P bE bEX + (bE + 1)d r bE bEX + (bE + 1)d (25) where Elow and Ehigh denote the minimum amount of inhibitors that should be expressed by the controller at low and high monostable state, respectively. bE and bEX denotes the degradation constant of intracellular and extracellular inhibitors and d is the diffusion constant. P is the promoter strength and r is the basal production rate. We now give a concrete design example for a particular environment. Suppose the input signal (d(t)) mainly results from the variation in the number of the bacteria. Hence, the cell density varies from time to time as a function of the number of bacteria. We further assume that there is a maximum number of bacteria that can be accommodated in a specific volume due to the fact that bacteria can not exceed the carrying capacity of the environment constraints. Since the cell density can not exceed one, it is reasonable to assume the maximum cell density is around 0.9. From Figure 7, points A and B indicate the upper and lower value needed to inhibit the regulation system. By using Eq.(25), the minimum value of the promoter strength is 10 (a.u./s) and the basal production rate r is 15. By checking the design values in Figure 6, we can ensure this can repress the QS regulation system. 0.45 4.5 0.4 4 0.35 3.5 0.3 3 0.25 2.5 0.2 2 0.15 0.1 *A 0.05 0 0 0.2 20 21.3924 18 21.3923 16 14 12 *B 10 1.08 6 1.07 1 4 1.06 0.5 2 4 SIMULATION The stability and sensitivity analysis in previous sections confirm the control feasibility by introducing artificial cells as controllers. However, we only consider deterministic models in previous section. Variation in the QS systems for each bacterium may result in different responses even with same environment configurations. In this section, we use an agent based simulator to validate the proposed system [23]. We assume that each bacterium can be modeled as a sphere with radius 1µm which occupies approximately 4 µm3 . If the cell density ρ = 0.5, for a 3D lattice with length, width, and height of 100 µm, then we need to put 1.25 × 105 bacteria to attain the required cell density. As shown in Figure 8, the spatial and system responses validate the bistability of LasR-AI and the effectiveness of the genetic circuit controller. At t = 500s, the system is in a high monostable state; we then place the controller into environment. The controller first generates large amounts of QSIs; after the system goes back into the low monostable state, the controller reduces the amount of generated inhibitors to the basal level production. As the cell density increases, the transient expression of the inhibitors gets higher due to the fact that the concentration of LasR-AI at high monostable state is higher at high cell density. Additionally, the system response (which is similar to Figure 4) validates our design. 7. CONCLUSION In this work, we have proposed an autonomous control system that incorporates the QS regulation system of P. aeruginosa and operates within an artificial cell. By analyzing system characteristics through numerical methods and detailed simulations, we have shown that the artificial cells can act as controllers able to keep the system in low monostable state; this prevents the expression of virulence and biofilm development. We have also discussed general guidelines to synthesize such autonomous controllers in vitro; This represents a first step towards a paradigm change in controlling the dynamics of the bacteria communication network. 8. ACKNOWLEDGMENTS This work was supported in part by the US National Science Foundation (NSF) under Grant CPS-1135850. 9. x 10 8 2 REFERENCES [1] I. F. Akyildiz et al. Nanonetworks: A new communication paradigm. Computer Networks, 52(12):2260–2279, Aug. 2008. ρ = 0.9 ρ = 0.7 20 15 10 5 21.3922 −5 Figure 7: Operational points for the QS system in low and high monostable states. The dark blue regions correspond to the low monostable states, while red regions are high monostable states. We choose the points which are below the activation threshold as the operation points. (i.e., the dark blue region) Here, we choose points A and B in the dark blue region in which the sum of both inhibitors is minimal. 6. 21.3922 1.5 0 0.4 0 AI inhibitor (a.u.) (c) 25 (a) High Monostable State LasR/AI (a.u.) 5 (d) (b) Inhibitor (a.u.) Low Monostable State LasR−AI (a.u.) LasR Inhibitor (a.u.) 0.5 300 1.05 200 100 Y Direction (um) 200 0 0 300 100 X Direction (um) ρ = 0.9 ρ = 0.7 60 40 20 0 0 500 Time (s) 1000 Figure 8: The simulation results of proposed autonomous control system. We activate the controller at t = 500s. (a) and (b) show the spatial distribution of LasR-AI at t = 500s and 1500s. (c) and (d) are the system response of LasR-AI and Inhibitor respectively. [2] J. Arpino et al. Tuning the dials of Synthetic Biology. Microbiology, 159(Pt 7):1236–53, July 2013. [3] B. L. Bassler and R. Losick. Bacterially speaking. Cell, 125(2):237–46, Apr. 2006. [4] L. C. Cobo and I. F. Akyildiz. Bacteria-based communication in nanonetworks. Nano Communication Networks, 1(4):244–256, Dec. 2010. [5] T. Defoirdt et al. Can bacteria evolve resistance to quorum sensing disruption? PLoS Pathog., 6(7), Jan. 2010. [6] J. D. Dockery and J. P. Keener. A mathematical model for quorum sensing in Pseudomonas aeruginosa. Bulletin of mathematical biology, 63(1):95–116, Jan. 2001. [7] M. G. Fagerlind. The role of regulators in the expression of quorum-sensing signals in Pseudomonas aeruginosa. J. Mol. Microbiol Biotechnol., 186(8):2281–2287, Apr. 2003. [8] M. G. Fagerlind et al. Modeling the effect of acylated homoserine lactone antagonists in Pseudomonas aeruginosa. Bio Systems, 80(2):201–13, May 2005. [9] G. Geske et al. Expanding dialogues: from natural autoinducers to non-natural analogues that modulate quorum sensing in Gram-negative bacteria. Chemical Society Reviews, 37(7):1432–1447, 2008. [10] J. E. González and N. D. Keshavan. Messing with bacterial quorum sensing. Microbiology and molecular biology reviews : MMBR, 70(4):859–75, Dec. 2006. [11] A. Jayaraman and T. Wood. Bacterial quorum sensing: signals, circuits, and implications for biofilms and disease. Annu. Rev. Biomed. Eng., 10:145–167, Jan. 2008. [12] V. C. Kalia. Quorum sensing inhibitors: an overview. Biotechnology advances, 31(2):224–45, 2013. [13] B. LaSarre and M. J. Federle. Exploiting quorum sensing to confuse bacterial pathogens. Microbiology and molecular biology reviews : MMBR, 77(1):73–111, Mar. 2013. [14] G. Lyon and T. Muir. Chemical signaling among bacteria and its inhibition. Chemistry & biology, 10:1007–1021, 2003. [15] R. Murray et al. A mathematical introduction to robotic manipulation. 1994. [16] T. Nakano et al. Molecular Communication. Cambridge University Press, 2013. [17] H. Nikaido. Multidrug resistance in bacteria. Annual review of biochemistry, 78:119–46, Jan. 2009. [18] V. Noireaux et al. Toward an artificial cell based on gene expression in vesicles. Physical biology, 2(3):P1–8, 2005. [19] K. Pardee et al. Paper-Based Synthetic Gene Networks. Cell, 159(4):940–954, Oct. 2014. [20] S. Park et al. The Role of AiiA, a Quorum-Quenching Enzyme from Bacillus thuringiensis on the Rhizosphere Competence. J. Microbiol., 2008. [21] J. Pearson and K. Gray. Structure of the autoinducer required for expression of Pseudomonas aeruginosa virulence genes. Proc. Natl. Acad. Sci. U.S.A, 91(January):197–201, 1994. [22] R. Smith. P. aeruginosa quorum-sensing systems and virulence. Curr Opin Microbiol, 6(1):56–60, Feb. 2003. [23] G. Wei et al. Efficient Modeling and Simulation of bacteria-based Nanonetworks with BNSim. IEEE Journal on Selected Areas in Communications, 31(12):868–878, 2013.