Developing 3D Anisotropic Mechanics Model of Powder Compaction Wenhai Wang 12-10-2004

advertisement

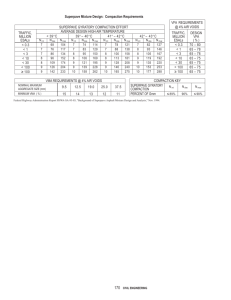

Developing 3D Anisotropic Mechanics Model of Powder Compaction Wenhai Wang Advisor: Dr. Antonios Zavaliangos Department of Materials Science & Engineering 12-10-2004 1 Outline 1. INTRODUCTION Powder compaction Literature review 2. PHENOMENOLOGICAL MODELS AND VUMAT Phenomenological models Introduction of VUMAT Results and discussion 3. ANISOTROPY IN POWDER COMPACTION Anisotropy in powder compaction Anisotropic models 4. CONCLUSIONS AND FUTURE WORK 2 Powder Compaction Metal Industry Pharmaceutical Industry Chemical Industry Ceramics Industry Food Industry 3 Research Motivation How do we get there? How the product performs? ¾ To understand the physics of compaction mechanisms. ¾ To develop robust and rigorous mathematical models of compaction. ¾ To Provide via models and FEM a design and optimization tool for the engineers. 4 Length Scales & Models Macroscopic Meso-scopic Microscopic 10 mm Phenomenological Models 50 µm Micromechanical Models Network Models MPFEM Atomistic Simulation 5 Past Work Macroscopic The powder is considered as a continuum. References: 1-10 Meso-scopic Study the particle collection. (statistics information are inherently considered) References: 11-18 Microscopic Look into microscopic level, the local anisotropy is considered and macrobehavior is deduced. References: 19-20 Selected References: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. H.A. Kuhn, C.L. Downey, Int. J. Powder Metall. 7 (1) (1971) 15-25 R.J.Green, Int. J. Mech. Sci. 14 (1972) 215-224 S. Shima, M. Oyane, Int. J. Mech. Sci. 18 (1976) D.C. Drucker, W. Prager Q. Appl. Math. 10 (1952) 157-175 A.N. Schofield, C.P. Wroth, McGrawHill, London, 1968 F.L. DiMaggio, I.S. Sandler, J. Eng. Mech. Div., Proc. – ASCE 96 (1971) 935-950 PM Modnet Computer Modelling Group, Powder Metall. 42 (1999) 301311 I.C. Sinka, J.C. Cunningham, A. Zavaliangos, Powder Tech. 133 (2003) 33-43 Sofronis P, Memeeking RM, Mechanics of Materials 18 (1): 55-68 May 1994 A, Zavaliangos L, Anand J. of the Mech. and Phy. Of solid 41 (6): 10871118 JUN 1993 N.A. Fleck, J. Mech. Phys. Solids 43 (1995) 1409-1431 12. 13. 14. 15. 16. 17. 18. 19. 20. A.L. Gurson J. Eng. Mater. Tech. (Trans. ASME) (1977 January) 2-15 B. Storakersa, N.A. Fleck, R.M. McMeeking, J. Mech. Phy. of Solids 47 (1999) 785-815 M.Kailasam, N. Aravas, P. Ponte Castaneda CMES, Vol. 1, pp. 105-118 2000 N. Aravas a, P. Ponte Castaneda, Comput. Methods Appl. Mech. Engrg. 193 (2004) 3767–3805 P.R. Heyliger & R. M. McMeeking, J. Mech. Phy. Of Solid 49 (2001) 2031-2054 P. Redanz, N. A. Fleck, Acta mater. 49 (2001) 4325–4335 C.L. Martin, D. Bouvard, Acta Mate. 51 (2003) 373–386 Francisco X. –Castilloa S. and Anwarb J., Heyes D.M. J. of Chem. PHy. Vol 18(10) Mar. 8 2003 A.T. Procopio and A. Zavaliangos, submitted to J. Mech. Phy. of Solids 6 Phenomenological Models σ Ellipse Model Relative density increase tensile compressive p Φ (σ , p, D ) = A( D)σ 2 + B ( D ) p 2 − 1 = 0 σ P D equivalent stress hydrostatic pressure relative density Yield is pressure dependant Single state variable – Relative Density Model parameters can be calibrated by experiments They can be implemented in FEM to simulate complex shape compaction operations. 7 Examples of Phenomenological Models Soil mechanics Classical elastoplasticity 1 2 “Kuhn-Shima” model (1970’s) 3 4 = Experimental Measurements 8 Which Phenomenological Model to Use? 180 160 Effective Stress, MPa 140 120 100 80 60 40 20 0 0 20 40 60 80 100 120 140 160 180 Hydrostatic Stress, MPa • Cap region is “OK” for these models • Shear (σ ) region is not well captured • Drucker-Prager Cap model is the best but needs more experiments 9 Phenomenological Models and FE Simulation ¾Numerical implementation of phenomenological models in FE program to solve engineering problems. ¾ABAQUS is one of the commercial finite element program software. ¾A lot of applications can be found in literature. W. Wang, J. Cunningham and A. Zavaliangos, PM2Tec, Las Vegas, Nevada, June 8-12, 2003 I.C. Sinka, J.C. Cunningham and A. Zavaliangos Powder Technology 133 (2003) 33– 43 PM Modnet Computer Modeling Group, Powder Metallurgy, Vol. 42, 1999, 301-311 10 Phenomenological Model Success Un-lubricated Die Lubricated Die ¾ Apply Drucker-Prager Cap model (DPC) into ABAQUS/Standard simulation (All parameters are taken as function of RD); ¾ Model predicts the inversion of radial variation of relative density and hardness (lubricated V.S. unlubricated die). I.C. Sinka, J.C. Cunningham and A. Zavaliangos Powder Technology 133 (2003) 33– 43 11 Why Do We Need VUMAT? ABAQUS X i (t ), Vi (t ), Fi (t ) Integrating X i (t + ∆t ) σ i (t ) Fi (t + ∆t ) σ i (t + ∆t ) VUMAT ∆ε i Solving equations of mechanics ¾ Current DPC model in ABAQUS/Standard is OK but convergence is a problem. ¾ ABAQUS/Explicit does not have flexible enough DPC model but it can address more complex geometry problems. ¾ To this end, a versatile version DPC model (All parameters are taken as function of RD) was implemented in VUMAT of ABAQUS/Explicit. 12 Unit Cell Comparison Against ABAQUS/Standard Loading conditions: Hydrostatic tensile Constraint tensile Simple tensile Hydrostatic compression Porosity Constraint compression Simple compression s11/s22 0.75 140000 ABAQUS /Standard VUMAT 0.74 0.73 0.72 120000 100000 80000 60000 0.71 40000 0.7 20000 0 0.69 0 0.01 0.02 0.03 Tim e (s) 0.04 0.05 0.06 0 0.01 0.02 0.03 0.04 0.05 0.06 Tim e (s) 13 Material: Avicel Unit Cell Comparison Against ABAQUS/Standard Loading conditions: Hydrostatic tensile Constraint tensile Simple tensile Hydrostatic compression Constraint compression S11 Porosity Simple compression S22 20000 90000 0 80000 0.75 0 70000 -20000 60000 0.73 -40000 50000 40000 -60000 30000 0.71 0.05 0.1 0.15 0.2 ABAQUS /Standard VUMAT -80000 20000 10000 -100000 0 0.69 0 0.05 0.1 Tim e (s) 0.15 0.2 0 0.05 0.1 Tim e (s) 0.15 0.2 -120000 Tim e (s) 14 Material: Avicel Unit Cell Comparison Against ABAQUS/Standard Loading conditions: Hydrostatic tensile Constraint tensile Simple tensile Porosity Hydrostatic compression Constraint compression Simple compression S22 S11 0.7 0 0 -0.2 -0.15 -0.1 -0.05 0 -500000 0.68 -1000000 0.66 -0.2 ABAQUS /Standard VUMAT -0.15 -0.1 -0.05 -100000 0 -200000 -300000 -400000 -1500000 -500000 0.64 -600000 -2000000 -700000 0.62 -0.2 -0.15 -0.1 Strain -0.05 0 -800000 -2500000 Strain Strain The origin of the difference is the Elastic modulus. It appears that ABAQUS/Standard does not update the modulus. Simulations with higher modulus show no difference. 15 Convex Tablet Compaction Porosity 0.50 --- EXPLICIT --- Experiment Unlubricated 0 0.0125 porosity 0.45 0.40 0.35 0.30 0.25 0 0.002 0.004 0.006 0.008 0.01 0.012 0.014 0.01 0.012 0.014 radius 0.60 0.55 Lubricated porosity 0.50 0.45 0.40 0.35 0.30 0.25 0 0.002 0.004 0.006 0.008 radius ABAQUS/Explicit results (run with VUMAT) show good agreement with experimental results! 16 Drucker-Prager Cap Model Density distribution is well predicted! How about the strength & modes of fracture prediction? σ Shear failure Region Cap Region p Non-associated plasticity Failure+Dilation Associated plasticity Densification DPC model shows the different densification trend when the stress hit different yield surface regions. (Shear failure region v.s. Cap region) 17 Tablet Diametrical Compaction Die Compaction Diametrical Compaction Diametrical compression tests are carried out in the pharmaceutical industry to test the “hardness” of tablets. Unlubricated Lubricated Tablets compacted with different die lubrication show different fracture 18 behaviors. 3-D FE Model of Tablet Diametrical Compaction Final Relative density distribution (2-D) Die Compaction Mapping Mapping Initial Relative density distribution (3-D) Diametrical Compaction Unlubricated Lubricated 19 Tablet Diametrical Compression - Unlubricated Before failure After failure Low density in the middle somewhat indicates the initial fracture development from the center. 20 Tablet Diametrical Compression -Lubricated Before failure After failure Convergence problems may happen when larger time step was selected. 21 Force-displacement Comparing with experimental data Experiment Simulation unlubricated die 200 Force Displacement 180 120 Force (N) 100 80 0.612 0.559 140 0.59 0.59 60 0.560 0.510 120 0.505 100 80 0.472 0.433 0.464 60 40 40 20 20 0 0.00 0.590 160 Unlubricated Lubricated Force, N 140 lubricated die 0.380 0.374 0 0.20 0.40 0.60 0.80 Displacement (mm) 1.00 1.20 0.422 0.416 0 0.2 0.4 0.6 0.8 1 1.2 Distance, mm Comparing with experiment results, Simulation results show good trends. 22 Phenomenological Model Limits Die Isostatic Compaction Compaction σ • • Stress path affect final property. Relative density is not the only state variable. Σ Σ Σ p Triaxial Compaction Σ=78 ;Τ∼0.5 Σ RD 85% σf 20 Ksi Τ Τ Τ Σ=Τ=60 85% 25 Ksi Σ=80 ;Τ=12 85% 55 Ksi Strength in Die ≠ Isostatic ≠ Triaxial Compaction R.M. Koerner Ceramic Bulletin Vol. 52, No. 7 1973 23 Anisotropy In Powder Compaction 24 Anisotropy of Powder Compacts - Path Dependence Loading History Triaxial Testing Dibasic Calcium Phosphate (A-Tab) d = 180 µm SR=Stress Ratio= σ radial σ axial 25 Data courtesy of Steve Galen Strength Anisotropy of Powder Compacts Transverse Strength ST Normal Strength SN The same sample after die compaction shows the different strength in transverse direction and normal direction. Anisotropy! SN ST 26 Data courtesy of Steve Galen State Variables σ Drucker-Prager Cap Φ(σ , P, RD...) p State variables: ¾Relative density ¾“B” tensor ¾“s” tensor 27 Anisotropic Mechanics Models Micromechanics model Anisotropic constitutive model N. A. Fleck M. Kailasam N. Aravas P.Ponte Castaneda ¾Micromechanics model with ¾Continuum model with isolated discrete particles; pores; ¾An internal state variable ¾Takes into account the (B tensor) is used to evolution of the porosity and describe the evolution of the development of anisotropy anisotropy under general due to change in the shape and loading. the orientation of the voids during deformation. N.A. Fleck, J. Mech. Phys. Solids 43 (1995) 1409-1431 M.Kailasam, N. Aravas, P. Ponte Castaneda CMES, Vol. 1, pp. 105-118 2000 N. Aravas a, P. Ponte Castaneda, Comput. Methods Appl. Mech. Engrg. 193 (2004) 3767–3805 28 Fleck’s Model Goal: Find the yield locus in macroscopic level. Assumes affine motion. Macro plastic strain Ù Micro velocity field E& ij Vij N.A. Fleck, J. Mech. Phys. Solids 43 (1995) 1409-1431 B. Storakersa, N.A. Fleck, R.M. McMeeking, J. Mech. Phy. of Solids 47 (1999) 785-815 vi = 2 R0 E& ij n j 29 Fleck’s Model (cont.) Anisotropic factor ----“B” Tensor : (i) The distribution of contact area; (ii) The number of contacts per unit surface area of particle; (iii)The hardness of each contact. 2 2 2 1 D − D0 E& xx (sin φ cos θ ) + E& yy (sin φ sin θ ) + E& zz cos φ Bij ni n j = [ ] 4 (1 − D0 ) E& xx + E& yy + E& zz Hydrostatic Compaction: Bij ni n j = 1 D − D0 12 (1 − D0 ) Constant! Die Compaction: Bij ni n j = 1 D − D0 ( ) cos 2 φ 4 1 − D0 30 Obtaining The Yield Surface Macroscopic stress Σ ij may be calculated by differentiation of plastic dissipation W& with respect to plastic strain rate E& ij . ∂W& Σ ij = ∂E& Hydrostatic Compaction 2 1.5 1 0.5 ∑ -1.5 0 -1 -0.5 0 0.5 1 1.5 -0.5 ij -1 Put a perturbation, calculate the differential -1.5 ∑m -2 ∆W& ∑= ∆E& Die Compaction Initial loading point 2-D Axisymmetric Plastic strain rate H& = E& ZZ + 2 E XX 2 E& = ( E& ZZ − E& XX ) 3 Macroscopic stress ∂W& ∑m = ∂H& ∂W& ∑= ∂E& 31 Critique of Fleck’s Model ¾Predicts path dependence but exaggerates the effect ¾Major “problems” : --Affine motion assumption shown to be incorrect by DEM, leads to overestimate of loads; --Cannot address triaxialities less than die compaction (can not be implemented into FEM) ¾Predicts “wrong” anisotropy in diametrical compression σ Transverse ratio = <1 σ Normal which is constant ratio and does not vary with relative density. However, experiments show opposite trend and vary with relative density. 32 Anisotropic constitutive model (P&A Model) N. Aravas a, P. Ponte Castaneda, Comput. Methods Appl. Mech. Engrg. 193 (2004) 3767–3805 33 Representative Volume Elements E3 Inclusions Voids P Magnified Cracks Grain boundaries E2 E1 P is a material point surrounded by a material neighborhood. (macro element) Possible microstate of an RVE for material neighborhood of P 34 Porous Material Representation ¾ The local state is represented by the average shapes and orientations of voids ¾ All the voids initially have the same shape and orientation and distributed randomly in a elastic-plastic matrix ¾ Under finite plastic deformation, the voids remain ellipsoidal but change their volume, shape and orientation with the “local” macroscopic deformation ¾ The size of the voids is assumed to be much smaller than the scale of variation of the macroscopic fields 35 Description of the Constitutive Model X3 1. Average rate-of-deformation tensor D = De + D p 2. Elastic part ~ 0 D =Mσ e ~ M b a 0 σ = σ& − ωσ + σ ω ~ M =M + f Q −1 1− f X2 c X1 is the effective elastic compliance tensor ω is the spin of the voids (antisymmetric tensor) f is porosity and Q is a microstructure tensor Q = L( I − s ) Q /s depend on the shape and orientation of the ellipsoidal voids. s = ( f , w1 , w2 , n (1) , n ( 2 ) , n (3) ) w1 = c / a ; w1 = c / b 36 Yield Condition and Plastic Flow The effective yield function can be written: ~ (s)σ ) σ ⋅ (m ~ Φ(σ , s) = − (σ y ) 2 1− f σ y is the yield strength in tension of the matrix material. ~ corresponds to an appropriately normalized effective m viscous compliance tensor. The plastic behavior described by the macroscopic potential ~ Φ is fully compressible. 3. Plastic part &N D =Λ p N= ∂Φ ∂σ & is the plastic multiplier, larger than zero. Λ 37 Evolution of the Microstructure When the porous material deforms, the state variables evolve and, in turn, influence the response of the material. Porosity & (1 − f ) N ≡ Λ & h(σ , s) f& = (1 − f ) Dkkp = Λ kk Shape ' ' & h (σ , s) w& 1 = w1 ( D33p − D11p ) = Λ 1 ' ' & h (σ , s ) w& = w ( D p − D p ) = Λ 2 2 33 22 2 Orientation n& (i ) = ωn (i ) (i = 1,2,3) M.Kailasam, N. Aravas, P. Ponte Castaneda CMES, Vol. 1, pp. 105-118 2000 N. Aravas a, P. Ponte Castaneda, Comput. Methods Appl. Mech. Engrg. 193 (2004) 3767–3805 38 Models Comparison Fleck’s Model P&A Model Interaction of particles Matrix with voids inside “B” tensor “s” tensor Contact area and coordination number Ellipsoid voids with shape and orientation Stage I Compaction (RD<0.9) Stage II Compaction (RD>0.9) Limitations: Affine motion Limitations: No contact area and coordination number evolution Symmetric yield surface, not appropriate for “powder” 39 Conclusions ¾ A versatile version of the Drucker-Prager model was implemented in VUMAT of ABAQUS/Explicit. ¾ State of the art models of compaction predict densification but not post processing properties because of - Path dependence - Anisotropy - Brittle behavior of compacts ¾ Fleck’s and P&A models were reviewed to check if they can address the weakness of Drucker-Prager model - Fleck’s model has major problems Affine motion assumption; Cannot address low triaxialites cases; Predicts wrong anisotropy… - P&A model is not appropriate No contact area and coordination number evolution; Symmetric yield surface, not appropriate for “powder” 40 Framework of Future Work FE Model Micromechanical Model ¾Stage I compaction ¾Take into account of the anisotropy in microscopic level (“B” Tensor) ¾Modify the assumption of “affine motion” Continuum mechanics Model ¾Combine micromechanical model and continuum mechanics model ¾Develop new model and implement it to VUMAT ¾Study the modes of fracture during diametrical compaction of tablet with new model 41