PREPARATION OF NITROGEN-DOPED POROUS CARBON BEHAVIOR

PREPARATION OF NITROGEN-DOPED POROUS CARBON

USING N-SOURCE ADDITIVE AND ITS WATER ADSORPTION

BEHAVIOR

Toshihide Horikawa

1*

, Noriyuki Sakao

1

, Masahiro Katoh

1

, Jun’ichi Hayashi

2

, D.D. Do

3

1

Department of Advanced Materials, Institute of Technology and Science,

The University of Tokushima

2-1 Minamijosanjima, Tokushima, Tokushima, 770-8506, Japan

* horikawa@chem.tokushima-u.ac.jp

2

Department of Chemical, Energy and Environmental Engineering, Kansai University

3-3-35 Kamiyamate, Suita, Osaka, 564-8680, Japan

3

School of Chemical Engineering, The University of Queensland,

St. Lucia, Qld 4072, Australia

ABSTRACT

Nitrogen-doped porous carbons (N-RFCC) were prepared by adding either urea or melamine as the nitrogen source during the high temperature carbonization of resorcinol–formaldehyde cryogels. The pore structure of the resulting carbon depends on the nitrogen precursor and its concentration. To show the role of N-doping in adsorption we carried out water adsorption at 298K, and it was found that the amount of water adsorbed is proportional to the nitrogen content over the low pressure region (P/P

0

<

0.3) and the pore structure in intermediate and higher pressure regions. The water adsorption isotherms were analysed with the Horikawa–Do (HD) model to study the effects of nitrogen-doping on water adsorption.

INTRODUCTION

The nitrogen-doped carbon materials have caught great attention because the introduction of nitrogen atoms into a graphene surface results in a hydrophilic surface

(Strelko et al., 2000). Using water to characterize the hydrophilicity of carbon materials has not sufficiently attracted interest (Matsuoka et al., 2004), and to date there has been no explanation on the roles of nitrogen and its configuration in the carbon matrix on water adsorption, in particular which nitrogen configuration provides the strongest site for water adsorption. Recently, we used Horikawa-Do (HD) model to analyse adsorption isotherms of N-doped carbons, prepared by high temperature treating of

RFCC with N

2

-NH

3

mixture (Horikawa et al., 2012), and it is found that 10–15% of the doped nitrogen atoms into the carbon matrix act as “strong” functional groups for water adsorption, resulting in a surface with a greater hydrophilicity than the virgin carbon surface.In the present study, we prepared nitrogen-doped porous carbon materials with different N-sources: urea and melamine, and investigated the effects of the nitrogen precursor and its concentration on water adsorption.

T. Horikawa, N. Sakao, M. Katoh, J. Hayashi, D. D. Do

Experimental

RF hydrogels were synthesized by the polycondensation of resorcinol (R) and formaldehyde (F), with potassium carbonate (K

2

CO

3

) as a basic catalyst (C), and distilled water (W) as the diluent. RF mixture solutions were put into the vials, sealed and then placed in a water bath at 298K for several days. In synthesizing an RF hydrogel, the R/F molar ratio was 0.50, the R/W molar ratio was 0.04, and the R/C molar ratio was 100

(Horikawa et al., 2011, Horikawa et al., 2012).

N-doped RF hydrogels were synthesized by adding either urea (U) or melamine (M) into the RF mixture solution, denoted as URF and MRF, respectively. In this case, the molar ratios were; R/U = 1.0, 2.0, and 4.0, (R+U)/F = 0.50 for URF, R/M = 1.0, 2.0, and 4.0,

(R+M)/F = 0.40, 0.43, and 0.46 for MRF (those (R+U)/F and (R+M)/F values are stoichiometric proportion) and the R/W molar ratio was 0.04, and the R/C molar ratio was 100, the same as RF hydrogels.

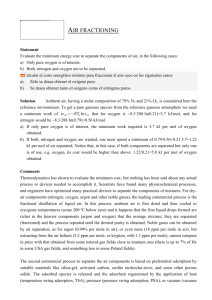

Those typical schematic structural formulas are shown in Fig. 1.

H O

(a)

OH

H

C

2

OH OH

H

N

H

N

OH

OH

N

NH

2

N

OH

OH H O

O

OH

N

H

N N

H

H O

CH

2

CH

2

CH

2

H O H O

H O

(b) (c)

OH OH

Fig. 1: The typical structural formulas of (a) RF, (b) URF, and (c) MRF.

OH

OH

The hydrogels were dried by the freeze drying method, and the resulting cryogels were placed in a ceramic boat, heated to the carbonization temperature 1173K at a heating rate of 10K/min in a N

2

flow and maintained for 1h at that temperature. The carbonized

URF and MRF indicate URFC and MRFC, respectively.

The obtained samples (1g) were soaked into 35% HCl (100 cm

3

) with stirring for 48h to remove the residual catalyst from the carbon matrix. After soaking, samples were washed with fresh water until the water was neutral, and then dried at 383K for 12h.

The weight loss during carbonization of the RF, URF, and MRF were measured using a thermobalance (Exstar6000 TG/DTA, SII). Samples were heated at a heating rate of

10K/min in flowing N

2

to 1273K which is greater than the carbonization temperature of

1173K. We characterized the N-doped porous carbons by nitrogen and carbon dioxide adsorption (Horikawa et al., 2012), CHN elemental analysis, X-ray photoelectron spectroscopy (XPS), and Boehm titration (Boehm, 1966).

The adsorption isotherms of carbon dioxide at 298K and N

2

at 77K were measured using a constant volume adsorption apparatus (BELSORP-28 and BELSORP-max, BEL

Japan). Before each measurement, samples were degassed at 473K for 5h to clean their surfaces. The specific surface area, S, was calculated by Dubinin-Polanyi equation

(Marsh and Siemieniewska, 1965), and the micropore volume, V micro

, was calculated by applying Dubinin-Astakhov equation to CO

2

adsorption data. The mesopore volume,

V meso

, and the pore radius distribution were estimated by applying the Dollimore-Heal method to the N

2

adsorption isotherm (Dollimore and Heal, 1964). Water adsorptiondesorption isotherms were also measured at 298K using a constant volume adsorption apparatus (BELSORP-max, BEL Japan).

2

T. Horikawa, N. Sakao, M. Katoh, J. Hayashi, D. D. Do

Results and Discussion

The weight loss and its rate during the carbonization process are shown in Fig. 2.

According to the TG curves, the weight loss of RF, URF, and MRF continued until around 1000 K in Fig. 2a. The DTG curves of N-doped carbons, URF and MRF, have large peaks around 500K while that of RF has no observable peak in that range; this is because URF and MRF has longer bridge structure with nitrogen atoms (see Fig. 1) and they are more readily pyrolyzed. There are another peak around 600K in the DTG curves for RF and MRF, with the peak of MRF being larger because melamine has three nitrogen atoms in the aromatic ring, which are driven off in the carbonization process.

This is conformed with the pyrolysis temperatures of urea and melamine, ca. 500 and

600K, respectively, which we measured under nitrogen flow by TG. When the nitrogen doped into the carbon matrix is greater, the weight loss is increased and the peaks of the

DTG curves were also higher as shown in Figs. 2b and 2c.

1

0.8

0.6

0.4

(a) RF

URF

MRF

0.1

0.08

0.06

0.04

1

0.8

0.6

0.4

(b) R/U = 4.0

R/U = 2.0

R/U = 1.0

0.1

0.08

0.06

0.04

1

0.8

0.6

0.4

(c) R/M = 4.0

R/M = 2.0

R/M = 1.0

0.1

0.08

0.06

0.04

0.2

0

400 600 800 1000

Temperature [ K ]

0.02

1200

0

0.2

0

400 600 800 1000

Temperature [ K ]

URF

0.02

1200

0

0.2

0

400 600 800 1000

Temperature [ K ]

0.02

MRF

1200

0

Fig. 2: TG and DTG curves of (a) RF, URF, and MRF, (b) URF with different R/U =

1.0, 2.0, and 4.0, and (c) MRF with different R/M = 1.0, 2.0, and 4.0 during carbonization.

The elemental analysis data of the samples are shown in Table 1. The nitrogen amounts based on 100g carbon amount in each precursor increased with the concentration of nitrogen precursor (i.e. decreasing R/U or R/M ratio). The nitrogen amounts of all samples decreased after carbonization comparing with those before carbonization. The nitrogen amounts of all URFCs are ca. 1g based on 100g carbon after carbonization process. On the other hand, those of MRFCs vary from 3 to 10g with the melamine amounts. The difference of the doped nitrogen atoms in the carbon matrix rests on the pyrolysis properties of N-sources, i.e. urea and melamine, during the carbonization process. Urea is pyrolyzed at lower temperature than melamine does, and the cross bridges in URF are pyrolyzed easily at lower temperature. If the pyrolysis of urea occurs at the temperature at which the formation of micropores is progressing, nitrogen atoms are readily embedded in the carbon matrix. However, the pyrolysis temperature of urea is lower, which the TG curves in Fig. 2 indicate, most of nitrogen atoms will be released as gases containing nitrogen atoms, resulting in a reduction in the nitrogen contents.

The doped nitrogen atoms in URFC and MRFC are pyridine-like structures (N-6), pyrrolic and/or pyridine-N moieties (N-5), and quaternary nitrogen (N-Q) in the carbon matrices, which were determined by XPS analysis. The results agree with our previous results (Horikawa et al., 2012).

Tab.1: Properties of samples.

3

T. Horikawa, N. Sakao, M. Katoh, J. Hayashi, D. D. Do

R/U R/C R/W

R/M

pore properties functional group

S V micro

V meso

[m

2

/g] [ml/g] [ml/g] total conc.

[mmol/g] elemental analysis

C H N O b.c. N

(a)

a.c.N

(b)

[wt%] [wt%] [wt%] [wt%] [ g ] [ g ]

RFCC

(c)

- 100 0.04 773 0.25 0.24

N-RFCC

(c)

- 100 0.04 899 0.29 0.31

URFC 4.0 100 0.04 730 0.25 0.67

2.0 100 0.04 777 0.25 0.64

1.0 100 0.04 791 0.27 1.30

MRFC 4.0 100 0.04 696 0.23 0.91

2.0 100 0.04

1.0 100 0.04

842

718

0.27

0.23

0.30

0.09

0.29

0.33

-

0.27

-

-

0.32

0.30

92.1 1.3 0.1 6.5 - 0.1

86.7 1.6 7.6 4.1

92.4 1.2 0.8 5.6

-

6.9

8.8

0.9

89.8 1.5 0.7 8.0 12.3 0.8

89.4 1.3 1.0 8.3 21.2 1.1

91.3 1.2 2.8 4.7 18.5 3.1

88.6 1.6 3.7 6.1 31.8 4.2

75.2 1.2 7.9 15.7 50.0 10.5

(a) N amounts of samples before carbonization (b.c.) are calculated from the stoichiometric molar ratio.

(b) N amounts of samples after carbonization (a.c.) are calculated from the data of CHN analysis.

(c) The reference data which are from our previous paper (Horikawa et al., 2012).

The nitrogen adsorption isotherms at 77K are shown in Fig. 3. The adsorption capacity of nitrogen in URFC increases with the amount of urea, because this incorporation of urea has led to a large increase in the mesopore volume. On the contrary, the nitrogen adsorption capacity of MRFC decreases with the amount of melamine. For URFC, since urea is pyrolyzed at low temperature, this results in mesopore spaces in the carbon matrix. On the other hand, for MRFC, since melamine is pyrolyzed at a higher temperature, the gasification of melamine occurs during or after the formation and growing of pores in the carbon matrices over the temperature range between 650 and

1000K. Therefore, the pyrolysis gases destroyed the primary particles whose interstices form mesopores (Horikawa et al., 2004), resulting a structure without a mesopore network. Because of this, it is not possible to form a solid that has large mesopore volume and high nitrogen contents as there is a trade-off between the two.

1000

800

(a) (b)

R/U = 4.0

(c)

R/U = 2.0

(d)

R/U = 1.0

600

400

200

0

0

RFCC

0.5

Relative pressure

1 0

1000

800

(e)

R/M = 4.0

600

URFC

0.5

Relative pressure

1 0

(f)

R/M = 2.0

URFC

0.5

Relative pressure

1 0

(g)

R/M = 1.0

URFC

0.5

Relative pressure

1

400

200

MRFC MRFC MRFC

0

0 0.5

Relative pressure

1 0 0.5

Relative pressure

1 0 0.5

Relative pressure

1

Fig. 3: Nitrogen isotherms at 77 K of RF, URF with different R/U = 1.0, 2.0, and 4.0, and MRF with different R/M = 1.0, 2.0, and 4.0.

4

T. Horikawa, N. Sakao, M. Katoh, J. Hayashi, D. D. Do

Fig. 4 shows the water vapor adsorption isotherm and the fitting results by Horikawa-Do

(HD) model on the experimental data of the different N-doped amount samples. The isotherms of RFCC and URFC show a two-stage uptake, with the first in the intermediate relative pressure and the second in the high relative pressure range. On the other hand, the isotherms of MRFCs only show a single uptake in the intermediate range.

The second uptake over the high relative pressure is observed when the material has distinct pore size distributions contributed by the micropores and mesopore subpopulations (Horikawa et al., 2011). MRFC with R/M=2.0 is microporous and mesoporous, with the mesopore volume comparable to the micropore volume (see Table

1). However, the pore sizes of the most of the mesopore are larger than 10nm in diameter (see Fig. 5), therefore the isotherm has only a single uptake, due to micropores, because water could not adsorb in large mesopores.

30

25

1.5

1

N = 0

20

0.5

15

0

0 0.05 0.10

RFCC

10

1.5

1

0.5

0

0

N = 0.8

0.05 0.10

URFC

(R/U=2.0)

1.5

1

0.5

0

0

N = 4.2

0.05 0.10

1.5

0.5

1

0

0

N = 10.5

0.05 0.10

5 MRFC

(R/M=2.0)

MRFC

(R/M=1.0)

0

0 0.5

Relative pressure

1 0 0.5

Relative pressure

1 0 0.5

Relative pressure

1 0 0.5

Relative pressure

1

Fig. 4: Effects of the N-doped amount in matrices on the water vapor adsorption isotherms. Inset figures show the lower pressure range water adsorption isotherms.

Fitted model solutions are presented solid and dashed lines for adsorption and desorption, respectively.

2.0

1.5

RFCC

URFC(R/U=2.0)

MRFC(R/M=2.0)

MRFC(R/M=1.0)

1.0

0.5

0

1 5 10 50 100

Pore radius [nm]

Fig. 5: Pore size distribution of RFCC, URFC, and MRFCs.

The insets of Fig. 4 show the water adsorption amount over the low pressure range of each sample. It is interesting to see that the adsorbed amount of N-doped samples are at least twice larger than that of RFCC in the low pressure range, despite the concentrations of the functional groups of each sample are almost the same (see Table

1). This suggests that the affinity between N-active sites is greater than the active sites in

RFCC because if they had the same affinity the amounts of water adsorbed would be the

5

T. Horikawa, N. Sakao, M. Katoh, J. Hayashi, D. D. Do same. This increased affinity of N-active sites toward water makes the N-doped carbon more hydrophilic, as hypothesized in some works in the literature (Strelko et al., 2000).

To quantify the increase in affinity, we applied HD model and lumped the doped nitrogen as part of the total functional group. From the fitting we have found that the packing fraction of water clusters is greater than what we had achieved in our earlier work of RF-

50 (containing no doped nitrogen) (Horikawa et al., 2012); this suggests that the affinity of N-doped nitrogen toward water is greater than other functional groups. Furthermore, the water adsorbed amount over the low pressure range increases with increasing the Ndoped amount in the carbon matrix. This allows us to tentatively conclude that the doped nitrogen atoms act as functional groups, with an affinity greater than other functional groups.

The onset of the first uptake in the water adsorption isotherm shifts to a lower pressure with increasing the N-doped amount, for example, the relative pressure of the first uptake ca. 0.5 for RFCC and URFC, 0.4 for MRFC with R/M=2.0, and 0.3 for MRFC with R/M=1.0. This is because of the possible combination of two factors (1) the growth of clusters around the functional groups is greater with N-doped carbon, reaching the same amount of clusters at lower pressures and (2) the greater affinity of the pore wall can stabilize smaller water clusters, which are otherwise not possible with non-doped carbon. This combination makes the entry of water clusters in micropores at a lower pressure as observed experimentally.

CONCLUSIONS

The N-doped porous carbon materials are prepared by using urea and melamine as nitrogen source in resorcinol-formaldehyde. The nitrogen precursor and its concentration affect the pore structures of the N-doped porous carbons and the amount of the nitrogen in the carbon matrix.

The water adsorption isotherms on the N-doped porous carbons were measured at 298K, and they are analyzed using the Horikawa-Do model. The doped nitrogen atoms act as a functional group, and they have high affinity toward water than other functional groups.

ACKNOWLEDGMENT S

This work was partially supported by the Japan Society for the Promotion of Science,

Grant-in-Aid for Young Scientists (B), 21760611 & 24750146, and the Australian

Research Council.

REFERENCES

BOEHM, H. P. 1966. Chemical identification of surface groups. Advan. Catalysis, 16,

179-274.

DOLLIMORE, D. & HEAL, G. R. 1964. An improved method for the calculation of pore-size distribution from adsorption data Journal of Applied Chemistry 14,

109-114.

HORIKAWA, T., HAYASHI, J. & MUROYAMA, K. 2004. Controllability of pore characteristics of resorcinol-formaldehyde carbon aerogel. Carbon, 42, 1625-

1633.

HORIKAWA, T., SAKAO, N., SEKIDA, T., HAYASHI, J. I., DO, D. D. & KATOH,

M. 2012. Preparation of nitrogen-doped porous carbon by ammonia gas

6

T. Horikawa, N. Sakao, M. Katoh, J. Hayashi, D. D. Do treatment and the effects of N-doping on water adsorption. Carbon, 50, 1833-

1842.

HORIKAWA, T., SEKIDA, T., HAYASHI, J. I., KATOH, M. & DO, D. D. 2011. A new adsorption-desorption model for water adsorption in porous carbons.

Carbon, 49, 416-424.

MARSH, H. & SIEMIENIEWSKA, T. 1965. The surface areas of coals as evaluated from the adsorption isotherms of carbon dioxide by using the Dubinin-Polanyi equation. Fuel, 44, 355-67.

MATSUOKA, T., HATORI, H., KODAMA, M., YAMASHITA, J. & MIYAJIMA, N.

2004. Capillary condensation of water in the mesopores of nitrogen-enriched carbon aerogels. Carbon, 42, 2346-2349.

STRELKO, V. V., KUTS, V. S. & THROWER, P. A. 2000. On the mechanism of possible influence of heteroatoms of nitrogen, boron and phosphorus in a carbon matrix on the catalytic activity of carbons in electron transfer reactions. Carbon,

38, 1499-1503.

7