Potential of carbon sequestration by carbonizing wood residue from industrial

advertisement

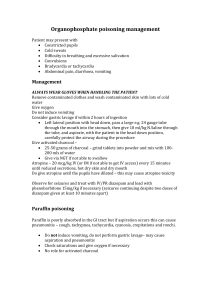

Energy with Agricultural Carbon Utilization Symposium, Georgia Potential of carbon sequestration by carbonizing wood residue from industrial tree plantation as a Clean Development Mechanism project in the Kyoto Mechanism Okimori,Y. Takahashi,F. Ogawa,M. (KANSO) Yamanaka,T. (Kansai Electric Power) 1. 1.Effective Effectivesequestration sequestrationof ofCO2 CO2in inatmosphere atmosphere and andits itsinactivation inactivation CO2 CO2ininatmosphere atmosphere Photosynthesis by plants Carbohydrate (Cellulose, Hemicelluloses, Lignin) Harvesting Harvestingfor fortimber, timber, pulp pulpetc. etc. Carbonization Carbon in a tree shall be left at 20 - 50% Wood Wood charcoal charcoal Reduction Reductionof ofCO2 CO2emission emissionand andCarbon-sink Carbon-sinkexpansion expansion are areaapair pairof ofwheels wheels 2. 2.Carbon Carbonsequestration sequestrationproject projectby byforestation forestationand andcharcoal charcoaluse use 3. 3.Charcoal Charcoalproperties properties(1) (1) General Generalproperty propertyof ofcharcoal charcoal(Fagus (Fagustree) tree) Volatile 11.0% Ash 1.6% Carbon 87.4% Surface area : 440 m2/g pH 9.9 Relationship Relationshipbetween betweenTemperature Temperatureand and Carbon Carbonof ofcharcoal charcoal (Tanaka,S. (Tanaka,S.1968) 1968) 4. 4.Charcoal Charcoalproperties properties(2) (2)::Porous Porousstructure structure --Habitat Habitatfor forSymbiotic Symbiotic microbe microbe:: mycorrhizal mycorrhizalfungi, fungi,aa filamentous filamentousfungus, fungus, an anactinomyces, actinomyces,etc. etc. --Water Water holding holding capacity, capacity, etc. etc. Photo by Yamato,M. Photo by Ogawa,M. 5. 5.Development Developmentof ofcharcoal charcoaluse use (source (source: :Japanese JapaneseCharcoal CharcoalNew-use New-useAssociation) Association) Agriculture Live stock industries Conditioning of humidity Golf course Greening/ gardening Cleaning bath water Water purification Others 20.0% 30.6% 0.5% 1.1% 3.6% Agriculture 4.0% Humidity conditioning Animal husbandry 17.9% 22.3% Charcoal use for non-fuel in Japan (1999) 6. 6.Location Locationof ofstudy studysite site South SouthSumatra SumatraProvince Province: : - -110,000 110,000sq sqkm kmas assame sameas asOhio, Ohio,Tropical Tropicalhumid humid climate climate 2 - -Population Population: :7.6 7.6million, million,density density: :70 70/km /km2 Industries Industries: :Mining Miningresources resourcesisisrich richsuch suchas as petroleum, petroleum,coal, coal,etc. etc. Agriculture Agricultureplantation plantationsuch suchas as rubber (peasants), oil palm (estate). rubber (peasants), oil palm (estate). Concession : 270,000 ha Plantation area: 190,000 ha 7. 7.Requirements Requirementsfor forCDM CDMproject project Region Region: : Plantation Plantationconcession concession270,000 270,000ha, ha,and and Pulp Pulpmill millsite site Boundary Boundary Activities Activitiesrange range: : 1) 1)Use Useof offorest forestresidue residue 2) 2)Use Useof ofwood woodwaste wasteininpulp pulpmill mill Baseline Baseline 1) 1)Socioeconomy Socioeconomy: : Are Arethere thereany anysimilar similarprojects? projects? 2) 2)GHG GHGemission emissionfrom fromForest Forestresidue residueand andWood Wood waste wasteininpulp pulpmill mill Leakage Leakage GHG GHGwhich whichwould wouldoccur occuroutside outsidethe theboundary boundarydue due to tothe theproject project(only (onlynegative negativeeffect) effect) Impact Impactfor forenvironments environments Monitoring Monitoring for forNature Natureand andSocioeconomy Socioeconomywith withnegative negative and andpositive positivefactors factors Sustainability Sustainability 8. 8.Plantation Plantationforestry forestryof of Musi MusiHutan Hutan Persada Persada(MHP) (MHP) Start of plantation in 1991 Start of harvest in1999 Growth rotation in 8〜10 years Mean Annual Increment : 20〜35 m3/ha Harvest/ replantation 10,750 ha/yr 9. 9.Wood Woodresidue residuebiomass biomassin inforests forests Small stems and branches with D< 8cm Avg. 56.4 t/ha x 10,750 ha/yr = 606,300 t/yr by Hardiyanto, et al. (2000, 2001) 10. 10.Wood Woodwaste wastein inPulp Pulpmill millof ofTanjungenim Tanjungenim Lestari Lestari Craft pulp production 450,000 t/yr Waste = Bark, Woodloss, Chip dust 180,000 t/yr 115,000 t/yr Power boiler 65,000 t/yr Landfill (unused) 11. 11.Method Methodof ofcharcoal charcoalmaking making Charcoal Charcoalproduction productioncan canroughly roughlybe beclassified classifiedinto intotwo twocategories. categories. 1) 1)Carbonization Carbonizationby bythe theauto autothermal thermalprocess, process,which whichincludes includesmany many traditional traditionaland andsimple simplemethods methods(FAO (FAO1987). 1987). 2) 2)Carbonization Carbonizationrepresents representsindustrial industrialmass massproduction productionmethods methods utilizing utilizingexternal externalheating, heating,which whichrequires requiresfossil fossilfuel fuel(FAO (FAO1985). 1985). Taking Takinginto intoaccount accountapplications applicationsinindeveloping developingcountries, countries,and andthe the participation participationof ofthe thelocal localpeople; people; --> a low cost, easier and --> a low cost, easier andsimpler simplermethod methodisispreferable. preferable. Tin Tindrum, drum,Hume Humepipe pipeand andBuilt-up Built-upbrick brickkiln kiln: :forest forestresidue residue --The Thefurnace furnacematerials materialsare areinexpensive, inexpensive,conveniently convenientlypurchased. purchased. --To Toenable enablethe theparticipation participationofoflocal localpeople, people,preventing preventingfires firesatatforest forestsites. sites. Flat Flatkiln kiln: :Pulp Pulpmill mill--Bark, Bark,woodloss, woodloss,chip chipdust dust --Often Oftenadopted adoptedininbarks barksand andwood woodfrom fromchip chipmills millsand andsawmills sawmillsininJapan Japan and andalso alsoininIndonesia. Indonesia. --Easily Easilyoperated operatedand andmaintained, maintained,But Butcareful carefulcontrol controlisisrequired requiredtotoprevent prevent the outbreak of fire. the outbreak of fire. 12. 12.Charcoal-making Charcoal-makingtest testof ofForest Forestresidue residue(1) (1) Drum Drummethod method Hume-pipe Hume-pipemethod method(Gorong2) (Gorong2) Capacity : 0.254 m3 Capacity : 5 m3 13. 13.Charcoal-making Charcoal-makingtest testof ofForest Forestresidue residue(2) (2) 14. 14.Charcoal-making Charcoal-makingtest testof ofForest Forestresidue residue(3) (3) Nutrient in forest 50% 606,000 606,000t-dw/yr t-dw/yr 50% 303,000 303,000t-dw/yr t-dw/yr X 0.80 (moisture 20%) X 0.25 (efficiency) 60,600 60,600t-Char/yr t-Char/yr (48,500 (48,500t-C/yr) t-C/yr) 15. 15.Charcoal-making Charcoal-makingtest testat atPulp Pulpmill mill(1) (1) Waste Waste==bark, bark,woodloss, woodloss,chip chipdust dust Flat Flatkiln kiln Capacity : 14 m3/kiln 16. 16.Charcoal-making Charcoal-makingtest testat atthe thePulp Pulpmill mill(2) (2) One cycle : 7 - 10 days 65,000 bdt/yr X 0.25 (efficiency) 16,000 t-Char/yr (13,000 t- C/yr) 17. Biomass/Carbon balance in tree plantation and pulp industry 18. 18.CO2 CO2reduction reductionpotential potentialby bycarbonization carbonizationfrom fromwood woodresidue/waste residue/waste 4,000,000 Reduction 3,500,000 3,000,000 2,500,000 2,000,000 1,500,000 1,000,000 500,000 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 0 Carbon Carbonreduction: reduction: 62,000 62,000t-C/yr, t-C/yr, 1.24 1.24million milliont-C t-Cinintotal total (CO2 (CO2equivalent:228,000 equivalent:228,000t-CO2/yr, t-CO2/yr, 4.56 4.56million milliont-CO2 t-CO2inintotal total)) Carbon Emission (t-C) Project Baseline 19. 19.Cost Costefficiency efficiencyand andlocal localjob jobopportunity opportunityby bythe theproject project Forest Forestresidue residue(1) (1) Forest Forestresidue residue(2) (2) Wood Woodwaste wasteinin pulp pulpmill mill Drums:25,000 Drums:25,000units units Facilities, Facilities,operation, operation, personnel expenses, personnel expenses,etc. etc.== 3.4 3.4million million$$ Brick Brickkilns:4,900 kilns:4,900units units Facilities, Facilities,operation, operation, personnel expenses, personnel expenses,etc. etc.== 3.6 3.6million million$$ Flat Flatkilns:225 kilns:225units units Facilities, Facilities,operation, operation, personnel expenses, personnel expenses,etc. etc.== 0.56 0.56million million$$ CO2 CO2reduction reduction: :223,000 223,000t-CO2 t-CO2 Workers Workers(full/part (full/part time) time)2,500 2,500men men Workers Workers(full/part (full/part time) time)2,000 2,000men men Workers Workers(full/part (full/part time) time)140 140men men Cost Costefficiency efficiencyinin20 20years years 17.1 17.1to to17. 17.77$/t-CO2 $/t-CO2 20. 20.Charcoal Charcoalapplication applicationtest test(1) (1)on onAcacia Acacia (by (byYamato) Yamato) To spray powder charcoal to 2-year-old Acacia To spray on the surface Increase of fine roots (12 months later) 21. Charcoal application test (2) : for crops (by Yamato) Long bean Corn 22. 22.Coexistence Coexistencewith withlocal localcommunity community(1) (1)in/near in/nearthe theproject project -Local -LocalSumatran Sumatranpeople people --Settlers Settlersfrom fromother otherislands islandsof ofJawa, Jawa,Bali. Bali. --265 265villages, villages,13,000 13,000people people --Livelihood Livelihood: : Rubber Rubberresin resincollection collection 23. 23.Coexistence Coexistencewith withlocal local community community(2) (2) Efforts Effortsof of MHP MHP Technical/financial Technical/financialsupport supportof of MHP MHPto tolocal localpeople peoplefor for encouraging encouragingthe thecultivation cultivationof of crop cropand andfishery. fishery. Local Localpeople's people'sexpectation expectationto to income increase besides Rubber income increase besides Rubber resin resincollection collection: : --> -->Food Foodproduction productionfor forselfselfsupport supportand andsale saleininlocal localmarket. market. Charcoal Charcoalapplication applicationfor forraising raising agricultural agriculturalproduction production 24. 24.Proposal Proposalof ofintegrating integratingcharcoal charcoalcarbon carboninto intothe thecarbon carbonaccounting accountingsystem system It is required to establish the method of accurately monitoring the carbon sequestered in charcoal in the course of charcoal production from biomass material to the end use of charcoal. 1. 1. Restriction Restrictionon onthe thesource sourceof ofbiomass biomass: : Not Notcome comefrom fromnatural naturalforest forest 2. Identification of biomass and 2. Identification of biomass andresidue residue/waste /waste: : the thechemical chemicalcomposition composition(heavy (heavy metal, a toxic substances), etc. metal, a toxic substances), etc. 3. 3. Accurate Accurateestimation estimationofofthe theinput inputamount amountofofbiomass biomassinto intothe thecarbonization carbonizationkiln kiln 4. 4. Charcoal Charcoalproduction production - -carbonization carbonizationmethod: method:mechanical mechanicalkiln kilnorormanual manualhandling, handling,external externalheating heatingororinternal internalheating heating - -charcoal yield, carbon composition, energy consumption of fossil fuel in charcoal production charcoal yield, carbon composition, energy consumption of fossil fuel in charcoal production 5. 5. Application Applicationmethods methodsof ofcharcoal charcoalfor fornon-fuel non-fueluse use - -Soil Soilamendment amendment: : totoclarify clarifythe theuse useofofsome somemedia mediaororsoil soilsubstances substances - -Charcoal compost : to identify kinds of livestock compost and Charcoal compost : to identify kinds of livestock compost andits itscomposition composition - -Method of application spraying : to clarify mechanical application Method of application spraying : to clarify mechanical applicationorormanual manualapplication application - -Water purification agent : to clarify the treatment after use Water purification agent : to clarify the treatment after use 6. 6. Impact Impactand andrisk riskfor forenvironment environment - -Prediction Predictionofofimpact impacton onnatural naturalenvironment environmentlike likesoil soiland andwater water - -Risk of fire in grassland and forest if charcoal making is carried Risk of fire in grassland and forest if charcoal making is carriedout outininthe thefield. field. 7. 7. Monitoring Monitoringof ofdifferent differentuses usesof ofcharcoal charcoal The Theend enduse useofofcharcoal charcoalshould shouldbe beclassified classifiedeither eitherinto intonon-fuel non-fueluse use(soil (soilconditioner, conditioner, water purifier, etc.) and fuel use. Some kind of monitoring system is required water purifier, etc.) and fuel use. Some kind of monitoring system is requiredtotomake makeaa balance balancesheet sheetbetween betweencharcoal charcoalproduction productionsites sitesand andmarkets. markets.