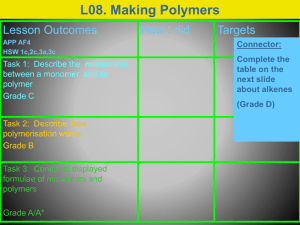

Addition polymers

advertisement

Polymers Addition polymers Addition polymers are formed when molecules add together to form a product without making any side products. All polymers made from alkenes are addition polymers. The process is exothermic because stronger sigma bonds between the monomers replace weak pi bonds within the monomer. Mechanisms of addition polymerisation There are two mechanisms, homolytic (free radical) and heterolytic (ionic). • Homolytic addition polymerisation This is the mechanism used to make low density polyethene. A free radical initiator is used, at high pressure (1000 atm) and moderately high temperature (200oC). Free radicals formed by breakdown of the initiator attack ethene molecules: The product of the above reaction reacts with more ethene to extend the chain: Individual chains can terminate by abstracting hydrogen from other chains, but this causes branching. Note that the readiness of free radicals to attack C-H bonds is responsible for the branching process. • Heterolytic addition polymerisation Heterolytic addition polymerisation can be started by cations or anions. The mechanism used to make high density polyethene is cationic. A mixture of triethylaluminium and titanium(IV)chloride (Zeigler-Natta catalyst) is heated at 60oC under 2-6 atm in an inert solvent. The Zeigler-Natta complex is attacked by an ethene molecule: The product of the above reaction reacts with more ethene to extend the chain: Chains can terminate by proton loss: Note that there is no scope for branching to occur in this mechanism. Page 1 of 5 thisisrevision.com Polymers In addition to what you know about high and low density polyethene from module two, in module four you need to know about the following addition polymers: • Polypropene By looking at the general formula of polypropene, you can see that every other carbon atom has a methyl group attached to it. If you draw out the zigzag backbone of the polymer, you can see that these groups can be orientated above or below the plane of the zigzag backbone. Show the methyl groups all oriented on the same side of the zigzag: The most useful form of polypropene is the one where the methyl groups are arranged on the same side. This packs most efficiently in the solid state, is the most dense, most resistant to wear and has the highest tensile strength. Zeigler-Natta catalysts are able to polymerise propene such that the methyl groups are oriented all on the same side, which is known as iso-tactic, which is an example of stereo-regular polymerisation. Polypropene is used for carpet tiles, sacking, ropes, fishing nets, as well as being used for kitchenware and plastic bottles, like high density polythene. Give an equation to show the polymerisation of propene: • Polychloroethene (PVC) Polychloroethene exists in two forms, though for different reasons than above. The rigid form is used for pipes and guttering and window frames, whereas the flexible form is used for waterproof clothing (in sheets, not fibres), synthetic leather and the insulating cover of electrical cables. The difference between these polymers is achieved using plasticisers, molecules that resemble fats and oils in structure, which disrupt the packing between the polymer chains. PVC with plasticisers is flexible, without plasticisers it is rigid, indeed the U in UPVC windows, stands for unplasticised. As plasticiser molecules resemble fats, they can be leached out of the plastic if it is in contact with fats, such as when PVC Clingfilm is used to wrap meat. These molecules are hazardous to health, so having PVC Clingfilm is contact with fatty foods is to be avoided. Give an equation to show the polymerisation of chloroethene: Page 2 of 5 thisisrevision.com Polymers § Polytetrafluoroethene (TEFLON, PTFE) Give an equation to show the polymerisation of tetrafluoroethene: Teflon has the unusual property of being the slipperiest synthetic substance. In addition, the replacement of C-H bonds in ethene with the C-F bonds in tetrafluoroethene results in a polymer that is resistant to chemical attack. Applications that these properties lend Teflon to are plumbers tape (dry-lubricates joints enabling them to be sealed without making them un-screwable), lab taps, non-stick coatings for clothing and pots and pans. Polyphenylethene (polystyrene) Give an equation to show the polymerisation of phenylethene: Polystyrene also exists in two forms, but again for different reasons than already discussed for other polymers. Polystyrene exists as a high-density polymer, and a low density expanded polymer. The expanded polymer is formed by injecting a gas into the liquid polymer, and as a result is full of pockets of gas, which make it lightweight, rigid, crushable and a very good insulator. These properties lend expanded polystyrene to its main application as packaging. An impact will cause damage to the polymer rather than the object that is packaged, and being lightweight it does not add to transport costs. As an insulator, it is used for hot drink cups and refrigerator insulation. Non-expanded polystyrene is also used for drinks cups, but these are much thinner and not particular good at heat insulation. It is also used for making screwdriver handles. Page 3 of 5 thisisrevision.com Polymers Condensation polymers Condensation polymers form when molecules join together and the elements of a small molecule, such as HCl or H2O are released. • Polyesters Polyesters are formed when diacid chlorides and diols polymerise. This reaction occurs readily in the lab at room temperature because diacid chlorides are very reactive. In industry, the cheaper, less reactive dicarboxylic acid is used, the lesser reactivity of the dicarboxylic acid being compensated for by more forcing industrial conditions. Show benzene-1,4-dioic acid and ethan-1,2-diol making a polyester: • Polyamides (nylons) Nylons are formed when diacid chlorides and diamines polymerise, dioic acids are used in industry for the same reasons as above. Show hexandioic acid and 1,2-diaminohexane making a nylon 6:6: Polyamides and polyesters can form from a single monomer, if one of each functional group is present at each end of the molecule. For example, nylon 6:6 can also form from 6amino hexanoic acid: Polyamides and polyesters both have strong intermolecular forces between their chains, permanent dipoles and hydrogen bonds respectively. This means they can tolerate being spun into fibres, enabling synthetic fabrics to be made. However, unlike wool, they do not allow water vapour to pass through them easily, so they do not ‘breathe’ well. Page 4 of 5 thisisrevision.com Polymers Polyamides and polyesters have relatively reactive functional groups present compared to the very inert polyalkenes. Amide and ester linkages are polar and can be hydrolysed in acidic or alkaline conditions, consequently they pose a lesser threat to the environment as waste than do polyalkenes such as polyethene. • Hydrolysis of polyesters gives the dioic acid and the diol from which the polyester was formed. If the conditions are alkaline, you get the dioc acid salt. Show the products of acidic hydrolysis of PET. Show the products of alkaline hydrolysis of PET • Hydrolysis of polyamides gives the dioic acid and the diamine from which the polyamide was formed. If the conditions are acidic, you get the diamine salt, if they are alkaline you get the doic acid salt. Show the products of acidic hydrolysis of Nylon-6,6. Show the products of alkaline hydrolysis of Nylon-6,6. Page 5 of 5 thisisrevision.com