A Simple, Robust Leadtime-Quoting Policy Wallace J. Hopp • Melanie Roof Sturgis

advertisement

A Simple, Robust Leadtime-Quoting

Policy

Wallace J. Hopp • Melanie Roof Sturgis

Department of Industrial Engineering and Management Sciences, Northwestern University,

2145 Sheridan Drive, Evanston, Illinois 60208

W

e examine leadtime-quoting polices for minimizing average lead time subject to customer service constraints on fill rate, tardiness, or relative tardiness in simple systems

with exponential and normal processing times. By studying the resulting safety leadtimes

implied by each policy we gain insight into why some policies perform more robustly with

respect to different measures of customer service than do others. This analysis suggests that

a simple constant safety leadtime policy should work reasonably well under most conditions.

A series of simulation experiments of more complex production environments indicates that

the constant safety leadtime policy does indeed exhibit robust performance. This, plus the

fact that it is extremely simple to adapt to a wide range of production environments, makes

it an attractive basis for real-world leadtime-quoting systems.

(Leadtime Quoting; Customer Service; Available to Promise; Capable to Promise)

1. Introduction

A critical trade-off in production systems is between

responsiveness and customer service. To be competitive in the time-based sense (Stalk and Hout 1990) a

firm should quote short, responsive leadtimes. But to

be a quality supplier to its customers, the firm must

also meet promised due dates reliably. Many traditional manufacturing and service firms negotiated

this trade-off by establishing fixed leadtimes (e.g., by

publishing them in a catalog or by following a standard rule) based on experience.

But the advent of increasingly sophisticated information systems has made available many types of

data that can be used to support leadtime quoting.

Enterprise Resource Planning (ERP) and SupplyChain Management (SCM) software provide status

information on purchase orders and customer demands. Manufacturing Execution Systems (MES)

software provides job and equipment status information within the production system. Allocated

Available to Promise (AATP) and Capable to Promise

(CTP) software systems are designed to assist leadtime quoting by predicting delivery times for prod1523-4614/01/0304/0321$05.00

1526-5498 electronic ISSN

ucts that are either in stock or in production (AATP)

or for products that have not yet begun production

(CTP). Finally, the connection between customer

transactions and information in these data bases is

becoming increasingly tight as we move toward

greater use of e-commerce. As the elements of the

customer contact process are automated, however, the

incentive to ‘‘humanize’’ the experience through customized service (e.g., real-time leadtime quotes) is

growing.

Spurred by advances in technology and a desire to

provide a high-quality customer experience, firms in

many industries are making use of dynamic leadtime

quotes. For instance, Dell Computer provides online

leadtime quotes to customers ordering PCs over the

web. Walt Disney World provides estimates of waiting times at amusement park rides. And many call

centers offer automatic messages telling customers

how long they can expect to wait to talk to an associate. But in general, these leadtime quotes are not

simple estimates of the mean waiting time. Because

it is generally better to be early than late, most leadtime quotes contain some kind of safety leadtime.

MANUFACTURING & SERVICE OPERATIONS MANAGEMENT 䉷 2001 INFORMS

Vol. 3, No. 4, Fall 2001, pp. 321–336

HOPP AND STURGIS

A Simple, Robust Leadtime-Quoting Policy

This trend suggests that the problem of dynamically choosing safety leadtimes to balance responsiveness with service is increasingly important to

managing manufacturing and service systems. However, a difficulty in developing models to support the

leadtime-quoting process is deciding how to represent customer service. A standard measure is average

f ill rate (i.e., percent of jobs delivered on time). However, under the fill-rate measure, jobs that are a day

late have the same impact as jobs that are 10 days

late. Because length of delays experienced by customers may be important to service, an alternate measure

is average tardiness. But even this may fail to fully

capture customers’ perception of service, since jobs

that are a day late when quoted 100-day leadtimes

may be less offensive than jobs that are one day late

when quoted 10-day leadtimes. So a third potential

measure is average relative tardiness (i.e., average tardiness as a percent of the leadtime).

All three of these measures could apply to customers in the same system. To illustrate this, consider

three different customers at a copy shop.

(1) Customer 1. Placed an order at 10:00 this morning for copies of an important report that must go

out overnight mail and was promised a 4:00 pickup

time (i.e., just in time to get the copies in the mail).

Any amount of lateness will result in missing the

mail pickup and fury on the part of the customer. So,

fill rate is the proper measure of service for this customer.

(2) Customer 2. Placed an order yesterday for copies

of an office report and was promised a 4:00 pickup

time today. She doesn’t really need the copies until

tomorrow, but has a dinner engagement an hour

away. So, any delay in the readiness of the copies will

cause her to be late for her engagement. Since a 60minute delay is clearly worse than a 5-minute delay,

average tardiness is a reasonable measure of service

for this customer.

(3) Customer 3. Placed an order three weeks ago for

bound copies of company reports and was promised

a 4:00 pickup time today. However, he is not planning

to check on their availability until tomorrow because

he has some open time in his schedule then. He

knows from experience that a three-week leadtime

322

doesn’t mean that the job will be done in precisely

that amount of time anyway. So, for long leadtime

jobs like this, he generally picks them up on the Friday after the due date (after calling to see if they are

ready). However, he also places orders with short

leadtimes (e.g., drop off in the morning, pick up that

afternoon), which he expects to be done the same day.

Because of his differing expectations for jobs with different leadtimes, relative tardiness is a plausible measure of service for this customer.

Clearly no single measure captures service for all

customers. Given this, firms can respond in one of

two ways:

(1) They can differentiate between customers

based on information about them. This is what many

AATP and CTP systems do; they classify customers

on the basis of past sales history, source of customer

order, or other data, and apply different leadtime

rules for each category.

(2) They can apply a uniform rule to all customers

and hope that it performs robustly well. In systems

where customer information is not available (e.g.,

many call center systems) or fairness considerations

prevent differential treatment (e.g., many waiting line

situations), this approach is all that is available.

In this paper our primary focus is the second class

of environments, where customers are treated uniformly in first-come-first-serve (FCFS) order and the

objective is to find a dynamic leadtime-quoting policy

that performs well in different environments under

different measures of service. Our results may be indirectly relevant to the first class of environments as

well, since a FCFS protocol could be used to quote

leadtimes within customer categories.

The approach we take is to first derive optimal (or

near optimal) leadtime-quoting policies for simple

single-step production environments that minimize

average leadtime subject to either a fill-rate constraint, a tardiness constraint, or a relative tardiness

constraint. Then we evaluate the performance of these

policies with respect to all three performance measures to see how robustly they perform. For some

simple systems, we are able to compare performance

against the analytically optimal policy. By examining

the nature of the safety leadtimes implied by the opMANUFACTURING & SERVICE OPERATIONS MANAGEMENT

Vol. 3, No. 4, Fall 2001

HOPP AND STURGIS

A Simple, Robust Leadtime-Quoting Policy

timal policies for different measures we gain insight

into why some policies perform more robustly than

others. This analysis suggests that a simple policy using constant safety leadtimes—termed the ‘‘constant

policy’’—should be effective. We then test the constant policy, along with the others, in various complex

environments and find that it does indeed produce

robust results relative to the various measures of service. This robustness, combined with its simplicity,

makes it an attractive option for leadtime quoting in

real-world systems.

The remainder of this paper is organized as follows:

Section 2 contains a brief survey of leadtime-quoting

policies. Section 3 formalizes the leadtime-quoting

problem and derives several leadtime-quoting policies

based on different service constraints and assumptions

about the underlying production system. Section 4 reports the performance measures resulting from each

leadtime policy for a fixed average leadtime for various

production systems. Section 5 summarizes the conclusions from our work.

2. Literature Review

Cheng and Gupta (1989) surveyed due-date-setting

methods and noted that many of them specify a cost

function (e.g., average tardiness, average lateness, or

total aggregate cost) to be minimized. Examples of

this approach can be found in Adam et al. (1993),

Dellaert (1991), Fry et al. (1989), Philipoom et al.

(1994), Raman and Talbot (1993), and Udo (1993).

A number of papers address the due date problem

from a scheduling perspective. Weng (1996) considered an environment with demand from leadtimesensitive and leadtime-insensitive customers and determined the optimal leadtime policy and the

acceptance rate for both types of customers. Duenyas

(1995) also looked at due-date setting for different

customer classes and developed a heuristic for setting

due dates, as well as sequencing customer orders.

Gordon and Strusevich (1999) presented algorithms

for solving the scheduling and common slack duedate assignment problems to minimize earliness penalties subject to precedence constraints. Qi and Tu

(1998) also developed algorithms that solved this

problem where jobs were assumed independent. In

MANUFACTURING & SERVICE OPERATIONS MANAGEMENT

Vol. 3, No. 4, Fall 2001

both of these studies, a due-date-setting rule (namely,

the common slack rule) was specified.

Another approach to the leadtime-quoting problem, which we adopt in this paper, is to minimize

average leadtimes (or weighted average leadtime)

subject to some sort of service constraint. Bookbinder

and Noor (1985) solved the leadtime-quoting problem

subject to a fill-rate constraint for a single server with

exponential processing times. They modeled batch arrivals and incorporated job scheduling. Wein (1991)

looked at minimizing average weighted leadtimes

subject to a fill-rate constraint as well as a constraint

on average tardiness by examining parametric and

nonparametric leadtime policies via simulation for a

multiclass M/G/1 queueing system. Spearman and

Zhang (1999) also looked at minimizing average leadtime subject to (a) a fill-rate constraint and (b) an

average tardiness constraint. Representing the production system as an M/M/1 queue, they showed

that the optimal solution to problem (a) could lead to

unethical management decisions (i.e., deliberately

quoting zero leadtimes with no chance of on-time delivery) and the solution to problem (b) is a constant

service leadtime policy (i.e., leadtimes are quoted

such that the expected fill rate is the same for all orders regardless of the work backlog at the time of the

order). Unlike Bookbinder and Noor (1985), they considered a single-class queuing system and assumed

first-come-first-serve production. Hopp and Roof

(2000) applied the results of Spearman and Zhang’s

(1999) constant service policy and developed a statistical service control (SSC) method to dynamically set

leadtime quotes to meet fill rate constraints. Enns

(1994) also set due dates subject to a fill-rate constraint and developed a dynamic forecasting model

which encompassed flow time estimates and forecast

errors. Lawrence (1995) also estimated flow times

with a forecasting model and used empirical data on

the forecast errors to set due dates with consideration

of various objectives including fill rate, cost, mean absolute lateness, and mean squared lateness.

3. Modeling the Leadtime-Quoting

Problem

We consider the leadtime-quoting problem (LQP) in

the context of a single product, make-to-order system

323

HOPP AND STURGIS

A Simple, Robust Leadtime-Quoting Policy

in which customers are served in first-come-firstserved (FCFS) order. Many service systems (e.g., call

centers, amusement parks, banks, retail outlets) are

operated in this manner. In manufacturing, FCFS is

less pervasive but is still used. For example, a large

metal manufacturer with whom we interacted has

three divisions, two of which quote orders FCFS and

one of which reserves capacity blocks for rush orders

by high-priority customers. Since many customers

desire delivery sooner rather than later, being able to

quote reasonable leadtimes is an important determinant of a firm’s competitiveness. Firms with long

leadtime quotes are likely to lose customers to the

competition. But firms that do not deliver on their

leadtime promises are also likely to lose business over

the long term. Therefore, a natural objective under

these conditions is to quote leadtimes as a function

of the number of customers ahead of the current customer so as to minimize average leadtime subject to

a customer service constraint. Mathematically, we can

express the LQP as

min

l̃

冘 p(n)l(n) ⫽ L¯

(1)

E[g(l˜ )] ⱕ

(2)

n

s.t.

where

n ⫽ number of jobs seen by an arriving job

(i.e., the job for which we are computing

a leadtime quote) including itself,

l(n) ⫽ leadtime for jobs that see n jobs in the

system upon arrival,

l̃ ⫽ the vector of leadtimes for n ⫽ 1, 2, . . . ,

p(n) ⫽ the long-run probability that an arriving

job sees n jobs in the system,

L̄ ⫽ average leadtime,

g(l̃ ) ⫽ customer service measure (e.g., fraction

of tardy jobs, average tardiness, average

relative tardiness) as a function of l̃, and

⫽ customer service target value.

We have used average leadtime as the criterion in

the LQP because it is an extremely common measure

of responsiveness used in industry. The implicit assumption underlying this choice is that shortening a

two-day leadtime by one day is equally valued by

324

customers as shortening a 10-day leadtime by one

day. But other measures are possible. For example,

call centers often focus on a percentile (e.g., the 80th

percentile) instead of the mean. Furthermore, if customer preferences were such that a one-day reduction

in leadtime is valued more for short leadtimes than

for long leadtimes (i.e., because it is a greater percentage reduction), then average leadtime could be

replaced by a strictly concave function of leadtime.

Although we have never encountered a firm that actually used a measure like this for evaluating leadtimes, it would be an interesting future research topic

to determine how robust various leadtime-quoting

policies are under this and other plausible objectives.

As we show below, the solution to the LQP depends strongly on what measure is used to represent

customer service in Equation (2). In this paper we

consider three possibilities: fraction of tardy jobs (one

minus fill rate), average tardiness, and average relative tardiness. The solution to the LQP also depends

on flow times, which are in turn dependent on processing times. In this paper we consider simple M/

M/1 and M/G/1 (with normal processing times)

models of flow time, as well as more complicated

multistation production systems.

To develop solutions to the LQP, we will make use

of the following notation.

FT(n) ⫽ flow time of a job that sees n jobs in the

system, a random variable,

(n) ⫽ mean flow time of a job that sees n jobs

in the system,

(n) ⫽ standard deviation of flow time of a job

that sees n jobs in the system,

z␣ ⫽ ␣-percentile of the standard normal distribution,

⫽ control parameter used to adjust a leadtime policy to ensure the customer service constraint is met,

f n( ) ⫽ probability density function (pdf) of flow

time of a job that sees n jobs in the system,

Fn( ) ⫽ cumulative distribution function (cdf) of

flow time of a job that sees n jobs in the

system.

MANUFACTURING & SERVICE OPERATIONS MANAGEMENT

Vol. 3, No. 4, Fall 2001

HOPP AND STURGIS

A Simple, Robust Leadtime-Quoting Policy

Since M/M/1 and M/G/1 models are not representative of real-world production environments, policies derived for them may not satisfy the customer

service constraint when used in more complex environments. Therefore, we modify the leadtime policies

to contain a single control parameter, , that allows

us to adjust them to ensure the service constraint is

met. Hopp and Roof (1998) used such a control parameter to dynamically adjust due dates to meet a

fill-rate constraint.

3.1.

Leadtime Policies Subject to a Fill-Rate

Constraint (LQP-F)

If we represent the production system as a simple M/

M/1 queue, the LQP subject to a fill-rate constraint

(LQP-F) can be formulated as

min

冘 p(n)l(n)

(3)

n

s.t.

冘 p(n)F [l(n)] ⱖ ␣,

n

n

(4)

where ␣ is the target fill-rate value. To be consistent

with our original formulation of the LQP, note that ␣

⫽ 1 ⫺ .

3.1.1. Fill-Rate Constraint—Exponential Processing Times. Spearman and Zhang (1999) solved the

LQP-F for an M/M/1 system by finding l(n) values

such that f n(l(n)) ⫽ 1/ where is the Lagrange multiplier. They showed that for some n⬘, the solution

f n(l(n)) ⫽ 1/ does not exist for all n ⱖ n⬘. In those

instances, the optimal leadtime quote is l(n) ⫽ 0. This

implies that it is optimal (although unethical) to

quote leadtimes that are impossible to achieve (i.e.,

quote zero leadtimes) to customers that see n⬘ jobs or

more in the system.

3.1.2. Fill-Rate Constraint—Exponential Processing Times (Bounded). Realizing that quoting zero

leadtimes is not practical, we modify the LQP-F and

add another constraint requiring quoted leadtimes to

customers that see n jobs in the system to be at least

equal to the mean flow time for all customers that see

n jobs in the system. (Of course, we could set any

arbitrary lower limits on leadtime quotes, but we use

mean flow time as a representative and ‘‘fair’’ option.) The leadtime-quoting problem with a fill-rate

MANUFACTURING & SERVICE OPERATIONS MANAGEMENT

Vol. 3, No. 4, Fall 2001

constraint and bounds on the quotes (LQP-FB) can be

expressed as

min

冘 p(n)l(n)

(5)

n

冘 p(n)F [l(n)] ⱖ ␣,

s.t.

(6)

n

n

l(n) ⱖ (n)

∀ n.

(7)

The solution to the LQP-FB is very similar to that

of the LQP-F and results in l(n) such that f n(l(n)) ⫽

1/ or l(n) ⫽ (n) when f n(l(n)) ⫽ 1/ does not exist.

Note that the value of that solves this problem can

be different from the value of that solves the LQP-F.

For our purposes, is merely a control parameter that

can be adjusted to ensure the constraint is met.

3.1.3. Fill-Rate Constraint—Normal Processing

Times. The above solutions to the LQP are elegant

but may not perform well in realistic systems because

they were derived under restrictive M/M/1 assumptions. To be more general, we now consider the case

where processing times are i.i.d normal random variables. Under this assumption, constraint (4) of LQP-F

can be written as:

⫺ (n)

冘 p(n)⌽ [l(n)(n)

] ⱖ ␣.

⬁

(8)

n

Note that we use ⌽() to represent the cdf (pdf) of

the standard normal distribution.

We can write the Lagrangian of the LQP-F as

L⫽

⫺ (n)

冘 p(n)l(n) ⫺ [冘 p(n)⌽ [l(n)(n)

] ⱖ ␣].

⬁

⬁

n

n

(9)

Taking the partial of L with respect to l(n) we get the

following:

[

]

L

l(n) ⫺ (n) 1

⫽ p(n) ⫺ p(n)

⫽ 0.

l(n)

(n)

(n)

(10)

Solving for l(n), the leadtime quote, yields

冪

l(n) ⫽ (n) ⫹ (n) ⫺2 ln

[

]

兹2 2 (n)

.

(11)

For low fill-rate levels, the radical term in Equation

(11) is undefined (i.e., the value under the radical is

negative) for some values of n in certain systems. In

these instances, we choose to set l(n) equal to (n) so

325

HOPP AND STURGIS

A Simple, Robust Leadtime-Quoting Policy

that, as in the LQP-FB, the leadtime quote for a customer that sees n jobs in the system is quoted at least

the mean flow time.

3.2.

Leadtime Policies Subject to a Tardiness

Constraint (LQP-T)

The leadtime-quoting problem subject to a tardiness

constraint (LQP-T) can be formulated as

min

冘 p(n)l(n)

(12)

n

s.t.

冘 p(n)E{[FT (n) ⫺ l(n)] } ⱕ ,

⫹

where  is the target average relative-tardiness level

(i.e., ratio of tardiness to leadtime quote).

3.3.1. Relative Tardiness—Exponential Processing

Times. If we assume exponential processing times,

then the flow time of a job that sees n jobs in the

system is n-Erlang. Hence, the expected value in constraint (17) of LQP-RT can be written as

E

冦

冧 冕

[FT (n) ⫺ l(n)]⫹

⫽

l(n)

⬁

xn ⫺ l(n) e ⫺xn

·

dx

l(n)

(n ⫺ 1)! n

l(n)

(13)

⫽ e ⫺l(n)

n

where  is the target average tardiness level.

3.2.1. Tardiness Constraint—Exponential Processing Times. Spearman and Zhang (1999) showed that

the solution to the LQP-T with exponential processing times is to quote leadtimes such that

1

Fn [l(n)] ⫽ 1 ⫺ .

(14)

3.2.2. Tardiness Constraint—Normal Processing

Times. Hopp and Roof (2000) showed that the solution

to the LQP-T with i.i.d normal processing times is

l(n) ⫽ (n) ⫹ z␣(n)兹n

(15)

with ⫽ 1. Note that since the solution to the LQP-T

is to quote leadtimes such that the same fill rate is

experienced by each customer, ␣ represents that target fill rate. Hence, if flow times were independent

normal random variables, then ⫽ 1 would yield a

fill rate of ␣. To accommodate cases where the i.i.d

normal assumption is violated, we include as a control parameter.

3.3.

Leadtime Policies Subject to a RelativeTardiness Constraint (LQP-RT)

The leadtime-quoting problem subject to a relative

tardiness constraint (LQP-RT) can be formulated as

min

冘 p(n)l(n)

(16)

n

冘 p(n)E冦[FT (n)l(n)⫺ l(n)] 冧 ⱕ ,

⫹

s.t.

n

326

(17)

n

i⫺1

i⫽0

]

.

(19)

Substituting (19) into constraint (17), the Lagrangian

for LQP-RT can be written as

L⫽

冘 p(n)l(n)

n⫺i

⫺ 冦 冘 p(n)e

冘

[ i! l(n)

⬁

n⫽0

⬁

n

⫺l(n)

n⫽0

In other words, quote leadtimes such that the same

fill rate is experienced by any customer regardless of

the congestion level of the system.

n⫺i

冘

[ i! l(n)

(18)

i⫺1

i⫽0

]

冧

⫺ .

(20)

Taking the partial of L with respect to l(n) and setting

the result equal to zero yields the following:

冦 [ 冘 (i ⫺ 1)(ni! ⫺ i) l(n)

⫺e

冘 n ⫺i! 1 l(n) ]冧 ⫽ 0.

p(n) ⫺ p(n) e ⫺l(n)

n

(i⫺1)⫺1

i⫽0

n

⫺l(n)

i⫺1

i⫽0

(21)

Unfortunately, we cannot simplify this to get a

closed-form expression for l(n). However, we can rearrange (21) to get

l(n) ⫽ e ⫺l(n)

冦冘 n i!⫺ i l(n)

n

i⫽0

i⫺1

冧

[i ⫺ 1 ⫺ l(n)] .

(22)

It is a fairly simple task to solve Equation (22) numerically for l(n) given a value of (e.g., Goal Seek

in Excel can do it). To find a value of that achieves

the service constraint requires searching over ,

which is also straightforward.

3.3.2. Relative Tardiness—Normal Processing

Times. If we assume i.i.d normal processing times in

the LQP-RT, then flow times are nearly normal. The

distribution of the flow time of a job that sees n jobs

in the system is given by the convolution of n ⫺ 1

process times plus the remaining life of the job curMANUFACTURING & SERVICE OPERATIONS MANAGEMENT

Vol. 3, No. 4, Fall 2001

HOPP AND STURGIS

A Simple, Robust Leadtime-Quoting Policy

rently in process. If we approximate this remaining

life by a full regular process time, then the flow time

can be represented as a normal random variable

(FT (n) ⬃ N((n), 2(n))) and the expected value in

constraint (17) of LQP-RT can be written as

E

[

]

⫽

冕

冦

⬁

]冧

[

x n ⫺ l(n)

1

1 xn ⫺ (n)

·

exp ⫺

l(n)

2 (n)

兹2(n)

l(n)

(n)

兹2l(n)

⫹

冦

exp ⫺

[

2

冬

]冧

[

1 l(n) ⫺ (n)

2

(n)

⫺2ln

⫺l(n) 2 兹2 (n) ⫺ (n)

⫺

(n) 2

l(n) ⫹ (n)

⫻

2

] [

⫻

]

1 (n)

l(n) ⫺ (n)

⫺ 1 erfc

,

2 l(n)

兹2(n)

冘 (⫺1)

⬁

i

i⫽0

冭

2i

l(n) ⫺ (n)

(n)

[

(23)

]

i!

1/2

.

(26)

where erfc(·) is the complimentary error function.

Substituting (23) into Constraint (17), the Lagrangian

for LQP-RT can be written as

L⫽

l(n) ⫽ (n)

⫹ (n)

(FT (n) ⫺ l(n))⫹

l(n)

⫽

We can rearrange this to get the following expression for l(n):

冘 p(n)l(n)

Again, this is not a closed-form expression for l(n), so

we will have to use a numerical method to solve for

the optimal leadtime quotes as a function of n.

⬁

n

⫺

冦冘

⬁

n

[

p(n)

(n)

兹2l(n)

⫹

冦

exp ⫺

冢

]冧

[

1 l(n) ⫺ (n)

2

(n)

2

冣 冧

]

冣 冢

1 (n)

l(n) ⫺ (n)

⫺ 1 erfc

⫺ .

2 (n)

兹2(n)

(24)

Taking the partial of L with respect to l(n) and setting

the result equal to zero yields:

p(n) ⫺ p(n)

⫺

1

兹2

冦

exp ⫺

]冧

[

1 l(n) ⫺ (n)

2

(n)

⫻

[

⫹

⫺兹2

1 (n)

⫺1

2 (n)

兹(n)

⫻

2

]

l(n) ⫺ (n)

(n)

⫹

l(n)(n)

l(n) 2

[

][

]

[

l(n) ⫺ (n)

(n)

i!

] 冘 (1)

⬁

i

i⫽0

2i

⫽ 0.

MANUFACTURING & SERVICE OPERATIONS MANAGEMENT

Vol. 3, No. 4, Fall 2001

(25)

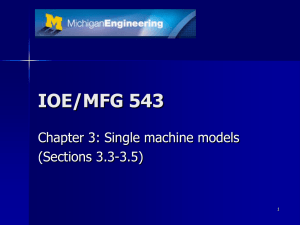

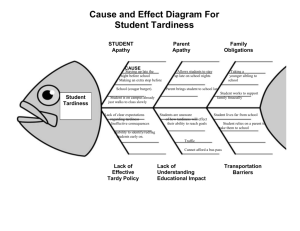

3.4. Characteristics of Safety Leadtimes

Each policy defined above provides an option for setting leadtime quotes as a function of work backlog

(n). To gain insight into the differences between these

policies and anticipate their robustness over various

performance measures, it is useful to separate the

leadtime for a job that sees n jobs in the system into

an estimate of mean flow time ((n)) plus a safety

leadtime (sl(n)):

l(n) ⫽ (n) ⫹ sl(n).

(27)

The key to the difference between leadtime policies

is the behavior of sl(n) as a function of n. We examined

this behavior for an M/M/1 system with a utilization

level of 0.90 and analytically solved for l(n) in the

above models (with the assumption that leadtimes are

bounded to be at least equal to the expected response

time) for the fill rate, tardiness, and relative-tardiness

constraints. We controlled l(n) so that average leadtime

was the same for each leadtime policy. We then computed the implied safety leadtime, sl(n), by subtracting

the mean flow time of jobs that see n jobs in the system, (n), from the leadtime quote, l(n). We graphed

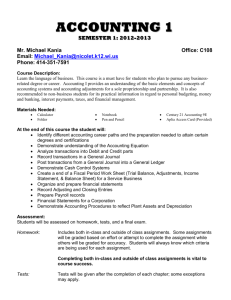

the results as a function of n in Figure 1.

It is clear from Figure 1 that the character of the

327

HOPP AND STURGIS

A Simple, Robust Leadtime-Quoting Policy

Figure 1

Safety Leadtimes as a Function of n for an M/M/1 System

safety leadtime varies greatly depending on the service constraint. Safety leadtime for the LQP-T, denoted as Tardy SLT, is an increasing function of n. Safety

leadtime for the LQP-FB, denoted Fill Rate SLT, is also

an increasing function of n but less so than the Tardy

SLT safety leadtimes. Safety leadtime for the LQP-RT,

denoted as Rel Tardy SLT, increases in n for small

values of n but decreases in n for large n. For small

values of n, Rel Tardy SLT is greater than Tardy SLT;

the reverse is true for large values of n. The reason

for this is that for smaller values of n, and hence

smaller leadtimes, it is imperative in the relative-tardiness constraint problem for jobs to be completed on

time because even a short delay has an enormous impact on relative tardiness. Consequently, unlike the

tardiness constraint problem where the likelihood of

a job finishing processing on or before the quoted

leadtime is the same regardless of n, the fill rate as a

function of n tends to decrease in n in the relativetardiness constraint problem.

Because the safety leadtimes are so different, we

328

would expect them to perform differently with respect

to the various measures of customer service. Moreover,

since Fill Rate SLT lies between Tardy SLT and Rel

Tardy SLT, we would expect the fill-rate leadtime policy to perform better in terms of average tardiness

than the relative-tardiness leadtime policy and better

in terms of average relative tardiness than the tardiness leadtime policy. That is, the fill-rate policy should

perform more robustly than the other two policies.

3.5. Constant Safety Leadtime Policy

Figure 1 also suggests that a simple leadtime policy

with safety leadtime that is constant across n might

be effective, since it would result in safety lead times

that lie in between the extremes of those implied by

the various policies. So, in addition to the policies derived above, we will investigate the following policy.

l(n) ⫽ (n) ⫹ ,

(28)

which we term the Constant SLT policy. Here, the

MANUFACTURING & SERVICE OPERATIONS MANAGEMENT

Vol. 3, No. 4, Fall 2001

HOPP AND STURGIS

A Simple, Robust Leadtime-Quoting Policy

Table 1

Summary of Leadtime Policies

LT Policy

Constraint

Leadtime Equation

冪

Fill Rate-Norm

Average Fill

Rate

Fill Rate-Exp

Average Fill

Rate

f n [l(n)] ⫽

Fill Rate-Exp

(bounded)

Average Fill

Rate

f n [l(n)] ⫽

Tardy-Norm

Average

Tardiness

Tardy-Exp

Average

Tardiness

Relative TardyNorm

l(n) ⫽ (n) ⫹ (n) ⫺2 ln

1

1

Flow Times

兹2 2 (n)

[

]

Normal Flow

Times

or l(n) ⫽ 0

Erlang Flow

Times

or l(n) ⫽ (n)

Erlang Flow

Times

l(n) ⫽ (n) ⫹ z␣ (n)兹n

Fn [l(n)] ⫽ 1 ⫺

Normal Flow

Times

Erlang Flow

Times

1

冑

Average Relative

Tardiness

l(n) ⫽ (n) ⫹ (n)

Average Relative

Tardiness

l(n) ⫽ e⫺l (n)

Constant

None

l(n) ⫽ (n) ⫹

(n) ⫺ (n)

⫺l(n) 2 兹2

⫺

(n) 2

l(n) ⫹ (n)

⫺2 ln

冦冘 (n ⫺i! i) l(n)

Relative TardyExp

n

i⫺1

⬁

i⫽0

[

冧

[i ⫺ 1 ⫺ l(n)]

i⫽1

control for ensuring the customer service constraint

is met, , is simply the safety leadtime.

Because of its simplicity, the Constant SLT policy is

prevalent in industry. Virtually all MRP systems include a mechanism for inflating leadtimes by a constant amount; this is the equivalent of using the Constant SLT policy for internal leadtime quotes. Some

service systems make use of this policy too. For example, during a recent trip to an amusement park,

one of the authors noted that the estimated wait times

posted at queues consistently exceeded actual waits

by five minutes, regardless of the length of the queue.

(Even empty queues had posted wait times of five

minutes.) Whatever safety leadtime mechanism the

park was using, the net effect was very close to that

of the Constant SLT policy.

3.6. Leadtime Policy Overview

We summarize all of the candidate leadtime policies

in Table 1. For each leadtime-quoting policy, this table

gives the definition of customer service used in the

constraint, the formula for quoting leadtimes, and the

key assumption about the distribution of the flow

MANUFACTURING & SERVICE OPERATIONS MANAGEMENT

Vol. 3, No. 4, Fall 2001

冘

2i

l(n) ⫺ (n)

(n)

(⫺1)i

i!

]

Normal Flow

Times

Erlang Flow

Times

No Flow Time

Assumption

times. We label each policy according to its constraint

and assumption from which the leadtime policy was

derived. For example, Fill Rate-Norm refers to the

leadtime policy derived when a fill-rate constraint

and normal flow times are used. We denote policies

with uppercase letters (i.e., Fill Rate-Norm) while

constraints are denoted by lowercase letters (i.e., fill

rate).

4. Numerical Analysis

To compare the performance of the various leadtime

policies, we tested each leadtime policy on a variety

of production systems. We adjusted the control parameter () so that average leadtime for all policies

was the same. We then compared their performance

in terms of average fill rate, average tardiness, and

average relative tardiness.

4.1. Simple Systems

We began by testing the policies in simple environments represented by the M/M/1 and M/G/1 (with

normal processing times) queues. Since the M/M/1

329

HOPP AND STURGIS

A Simple, Robust Leadtime-Quoting Policy

Table 2

Average Performance Measures for the M/M/1 System

Performance

Error Relative to ‘‘Best’’

Leadtime Policy

Fill Rate

Tardy

Rel Tardy

Fill Rate

Tardy

Rel Tardy

Max Error

Fill Rate-Norm

Fill Rate-Exp

Fill Rate-Exp (bounded)

Tardy-Norm

Tardy-Exp

Relative Tardy-Norm

Relative Tardy-Exp

Constant

‘‘Best’’ for Measure

89.53%

90.57%

89.71%

84.39%

90.30%

89.68%

89.94%

89.69%

90.57%

0.336

0.507

0.301

0.272

0.234

0.311

0.281

0.286

0.234

0.016

1.1%

0.0%

0.9%

6.8%

0.3%

1.0%

0.7%

1.0%

44%

117%

29%

16%

0%

33%

20%

22%

6%

44%

⬁

0.015

0.052

0.017

0.015

0.015

0.015

0.015

system was used to derive the ‘‘Exp’’ policies we

would expect them to perform best in terms of their

respective service measures. Similarly, since the M/

G/1 system was used to derive the ‘‘Norm’’ policies

we would expect them to perform well in this environment. (However, since we simplified the distribution of the remaining life, it is not as clear that the

‘‘Norm’’ policies should be optimal as it is for the

‘‘Exp’’ policies, which were derived without any simplifying approximations.)

4.1.1. M/M/1 System. We tested an M/M/1 system with processing rate of one job per hour with

average interarrival times of 1.1 hours. We simulated

the system until we observed 32,000 outputs and recorded the flow time for each job as well as the number of jobs in the system that the arriving job saw

(including itself). For each policy we adjusted the control parameter () to make the average leadtime equal

to 14.0 hours. Then we observed the performance of

each policy with respect to fill rate, tardiness, and

relative tardiness.

Table 2 summarizes the results of the performance

measures for each leadtime policy. As we anticipated,

the leadtime policies derived using the exponential

processing-time assumption outperform those policies based on the normal flow time assumption. Fill

Rate-Exp achieves the highest average service level

among all policies, Tardy-Exp achieves the lowest average tardiness among all policies, and Relative Tardy-Exp achieves the lowest average relative tardiness

among all policies.

330

⬁

1%

251%

13%

4%

0%

4%

⬁

29%

251%

13%

33%

20%

22%

Table 2 also compares the error of each policy relative to the ‘‘Best’’ leadtime policy for each performance measure. For example, the difference in average fill rate (as a percentage of the ‘‘Best’’ policy)

between Tardy-Norm and Fill Rate-Exp is 6.8%. This

implies that using the Tardy-Norm policy to quote

leadtimes would achieve a fill rate that is 6.8% lower

than the fill rate that would be achieved if we quoted

leadtimes based on the Fill Rate-Exp policy for the

same average leadtimes.

Finally, Table 2 reports the maximum relative error

for a given policy across all three performance measures. For example, the maximum error for the TardyNorm leadtime policy is 251%. This maximum error

gives an indication of the robustness of the policies

to the definition of customer service.

4.1.2. M/G/1 System. We tested an M/G/1 system

with normal processing times with a mean processing time of one hour and a standard deviation of 0.3

hours. We simulated 32,000 outputs with average interarrival times of 1.1 hours. We recorded the flow

time for each job as well as the number of jobs in the

system that the arriving job saw (including itself). For

each policy, we adjusted the control parameter () to

make the average leadtime equal to 7.5 hours. Again

we compared the policies in terms of fill rate, tardiness, and relative tardiness. Table 3 summarizes the

resulting performance measures for each policy, compares the relative error of each policy relative to the

‘‘Best’’ policy, and reports the maximum error across

all performance measures.

MANUFACTURING & SERVICE OPERATIONS MANAGEMENT

Vol. 3, No. 4, Fall 2001

HOPP AND STURGIS

A Simple, Robust Leadtime-Quoting Policy

Table 3

Average Performance Measures for the M/G/1 System

Performance

Error Relative to ‘‘Best’’

Leadtime Policy

Fill Rate

Tardy

Rel Tardy

Fill Rate

Tardy

Fill Rate-Norm

Fill Rate-Exp

Fill Rate-Exp (bounded)

Tardy-Norm

Tardy-Exp

Relative Tardy-Norm

Relative Tardy-Exp

Constant

‘‘Best’’ for Measure

92.84%

91.37%

79.41%

86.82%

87.30%

92.49%

85.07%

92.43%

92.84%

0.049

1.496

0.174

0.039

0.042

0.052

0.258

0.039

0.039

0.003

0.0%

1.6%

14.5%

6.5%

6.0%

0.4%

8.4%

0.4%

27%

3776%

351%

0%

9%

34%

569%

5%

⬁

0.016

0.014

0.020

0.003

0.016

0.003

0.003

From Table 3 we see that leadtime policies based

on the normal flow time assumptions outperform

leadtime policies based on the exponential processing-time assumption for the performance criteria

from which they were derived. For example Fill RateNorm outperformed Fill Rate-Exp (mean) and Fill

Rate-Exp with regard to average fill rate. Tardy-Norm

outperformed Tardy-Exp with regard to average tardiness. Relative Tardy-Norm outperformed Relative

Tardy-Exp with regard to average relative tardiness.

In general, leadtime policies based on exponential

processing times perform poorly in terms of robustness for a M/G/1 system with maximum errors at

373%, 485%, 569%, and ⬁. Finally, the clear winner

in terms of robustness is the Constant policy with a

maximum error of 5%.

4.2. Complex Systems

While very useful for deriving formulas and developing intuition, the M/M/1 and the M/G/1 systems

are not very representative of real-world production

environments. So to test our leadtime-quoting policies under more realistic conditions, we simulated

several more complex systems. Our analysis of such

systems indicated that policies based on the normal

flow time assumption always outperformed policies

based on the exponential processing-time assumption. Hence, from this point on we will limit our discussion to policies based on the normal flow time assumption plus the Constant SLT policy.

4.2.1. Four-Machine Normal System. To test a system with serial resources, we simulated four maMANUFACTURING & SERVICE OPERATIONS MANAGEMENT

Vol. 3, No. 4, Fall 2001

Rel Tardy

0%

Max Error

27%

⬁

⬁

373%

310%

485%

2%

359%

0%

373%

310%

485%

34%

569%

5%

chines in tandem with normally distributed processing times with a mean of one hour and a standard

deviation of 0.3 hours. We tested this system under

three different arrival rates that resulted in utilization

levels of 75%, 90%, and 95%. Jobs were processed in

order of arrival, and interarrival times were exponentially distributed with an average interarrival time of

1.325, 1.11, and 1.05 hours, respectively. We simulated for 32,000 outputs and recorded the flow time for

each job, as well as the number of jobs in the system

that the arriving job saw (including itself). For each

policy and each utilization level, we adjusted so that

the average leadtimes achieved three different levels

(low, medium, high). This in turn resulted in three

different service levels: ‘‘low’’ (75%), ‘‘medium’’

(90%), and ‘‘high’’ (95%). Hence, we analyzed the

performance of 4 leadtime-quoting policies under

nine different test conditions (three utilization levels

and three leadtime levels).

For these nine test conditions, we compared the

policies in terms of fill rate, tardiness, and relative

tardiness. We also compared the error of each policy

relative to the ‘‘Best’’ leadtime policy for each performance measure as we did for the M/M/1 and M/

G/1 systems.

The maximum errors across all performance measures for each policy at various leadtimes and utilization levels are listed in Table 4. For example, the

maximum error across all three performance measures for a utilization level of 75% is 1% when using

the Constant policy for low leadtimes. In other words,

331

HOPP AND STURGIS

A Simple, Robust Leadtime-Quoting Policy

Table 4

Maximum Percentage Error Across Performance Measures for Various Leadtime and Utilization Levels in the Four Machine Normal System

Utilization ⫽ 0.75

Leadtime Levels

Utilization ⫽ 0.90

Leadtime Levels

Utilization ⫽ 0.95

Leadtime Levels

Leadtime Policy

Low

Med

High

Low

Med

High

Low

Med

High

Max Error

over all Util

and LT Levels

Fill Rate-Norm

Tardy-Norm

Relative Tardy-Norm

Constant

12

18

22

1

9

53

178

0

0

97

7

5

25

38

35

1

11

106

34

0

0

156

20

3

31

46

36

1

11

134

70

0

0

293

50

18

31

293

70

18

the performance measures achieved from using the

Constant policy will be no more than 1% off from the

performance measures achieved by using the ‘‘Best’’

policy for the same average leadtime. By reporting

the maximum error for various leadtimes and utilization levels, Table 4 shows that errors tend to be

worse for high leadtime/utilization combinations.

However, the worst error we observe for the Constant

policy across all leadtimes and utilization levels is

18%.

Recall that we calculated the maximum error based

on performance measures that were estimated via

simulation. Consequently, it is not a given that the

‘‘Best’’ policy is statistically significantly better than

the other policies. Therefore, we performed a twosample t-test to determine which policies were significantly worse than the ‘‘Best’’ policy. We did this

by dividing the output into 40 batches and calculating

the average fill rate, average tardiness, and average

relative tardiness for each batch. We then compared

the average fill rate from the 40 batches of the ‘‘Best’’

leadtime policy with the average fill rate from the 40

batches of the other leadtime policies by calculating

the appropriate t-statistic. We performed the same

comparison on average tardiness and average relative

tardiness. Based on this statistic, Table 5 lists the leadtime policies that are significantly different from

(worse than) the ‘‘Best’’ policy. Table 5 also lists the

utilization level, leadtime level, the performance criteria, the ‘‘Best’’ policy, and the level of significance

for the four Machine Normal System.

The key conclusions from this analysis are:

(1) The Constant policy is never significantly different from the ‘‘Best’’ (in fact, it is the ‘‘Best’’ across

332

all utilization levels and all performance measures for

medium leadtime levels).

(2) The Constant policy has the smallest maximum

error, at 18%, across all performance measures, all

leadtime levels, and all utilization levels. The next

lowest, as shown in Table 4, is 31% for the Fill RateNorm policy. Thus, the Constant policy is the most

robust.

(3) The Tardy-Norm policy is the worst performer

in terms of average relative tardiness. This is not surprising considering the graph of safety leadtimes presented in Figure 1 where the Tardy and Relative Tardy policies represented the extremes. Because their

safety leadtimes are so qualitatively different, these

policies do not perform well for each other’s service

criterion.

4.2.2. DPRO System. Because the key source of variability in effective process times in many production

systems is machine failures, we simulated a serial line

with deterministic processing times but with random

outages. We designate this system ‘‘DPRO’’ (deterministic processing with random outages). The processing times were assumed deterministic with a duration of one hour. Machines 1, 3, and 4 were assumed

reliable. Machine 2 was subject to random failures

with mean time to failure (MTTF) and mean time to

repair (MTTR) exponentially distributed with means

of 40 and 4 hours, respectively. Jobs were processed

in order of their arrivals, and interarrival times were

also exponentially distributed with average interarrival times of 1.530 hours, 1.246 hours, and 1.173

hours, which yielded utilization rates of 75%, 90%,

and 95% on machine 2. We simulated the system for

32,000 outputs and recorded the flow time for each

MANUFACTURING & SERVICE OPERATIONS MANAGEMENT

Vol. 3, No. 4, Fall 2001

HOPP AND STURGIS

A Simple, Robust Leadtime-Quoting Policy

Table 5

Identification of Leadtime Policies Significantly Different from ‘‘Best’’ Policy for the Four NORM System

Utilization

Level

Leadtime

Level

low

low

fill rate

Constant

low

low

tardiness

Constant

low

low

relative tardiness

Fill Rate

low

medium

fill rate

Constant

low

medium

tardiness

Constant

low

low

low

low

medium

medium

medium

high

high

high

low

low

relative tardiness

fill rate

tardiness

relative tardiness

fill rate

tardiness

Constant

Fill Rate

Fill Rate

Fill Rate

Constant

Constant

medium

medium

medium

medium

medium

medium

medium

high

high

low

medium

medium

medium

high

high

high

low

low

relative tardiness

fill rate

tardiness

relative tardiness

fill rate

tardiness

relative tardiness

fill rate

tardiness

Fill Rate

Constant

Constant

Constant

Fill Rate

Fill Rate

Fill Rate

Fill Rate

Tardy

high

high

low

medium

relative tardiness

fill rate

Constant

Constant

high

high

medium

medium

tardiness

relative tardiness

Constant

Constant

high

high

high

high

high

high

fill rate

tardiness

relative tardiness

Fill Rate

Fill Rate

Fill Rate

Criterion

job, as well as the number of jobs in the system that

the arriving job saw (including itself). For each policy

and each utilization level, we adjusted so that the

average leadtimes achieved three different levels (low,

medium, high). This in turn resulted in three different service levels: ‘‘low’’ (75%), ‘‘medium’’ (90%), and

‘‘high’’ (95%). As a result, we analyzed the performance of four leadtime-quoting policies under nine

MANUFACTURING & SERVICE OPERATIONS MANAGEMENT

Vol. 3, No. 4, Fall 2001

Best Policy

LT Policies

Significantly

Different from

Best Policy

Significance

Level

Tardy

Rel Tardy

Fill Rate

Rel Tardy

Tardy

Rel Tardy

Tardy

Rel Tardy

Tardy

Rel Tardy

Tardy

Tardy

Tardy

Tardy

Tardy

Fill Rate

Rel Tardy

Tardy

Tardy

Rel Tardy

Tardy

Tardy

Tardy

Tardy

Tardy

Fill Rate

Rel Tardy

Tardy

Tardy

Rel Tardy

Rel Tardy

Tardy

Rel Tardy

Tardy

Tardy

Tardy

5.0%

15.0%

2.5%

0.5%

0.5%

15.0%

0.5%

15.0%

10.0%

5.0%

0.5%

0.5%

0.5%

0.5%

2.5%

10.0%

2.5%

0.5%

0.5%

15.0%

0.5%

0.5%

15.0%

0.5%

10.0%

10.0%

5.0%

0.5%

0.5%

10.0%

5.0%

0.5%

10.0%

0.5%

10.0%

0.5%

different test conditions (three utilization levels and

three leadtime levels).

As we did for the Four-Machine Normal System,

we compared the policies in terms of fill rate, tardiness, and relative tardiness for nine test conditions.

Again we compared the error of each policy relative

to the ‘‘Best’’ leadtime policy for each performance

measure. Table 6 summarizes the maximum error

333

HOPP AND STURGIS

A Simple, Robust Leadtime-Quoting Policy

Table 6

Maximum Percentage Error Across Performance Measures for Various Leadtime and Utilization Levels in the DPRO System

Utilization ⫽ 0.75

Leadtime Levels

Utilization ⫽ 0.90

Leadtime Levels

Utilization ⫽ 0.95

Leadtime Levels

Leadtime Policy

Low

Med

High

Low

Med

High

Low

Med

High

Max Error

over all Util

and LT Levels

Fill Rate-Norm

Tardy-Norm

Relative Tardy-Norm

Constant

0

0

0

0

17

8

12

7

0

25

0

4

0

0

0

0

14

29

17

9

1

60

1

10

2

6

2

4

11

69

25

6

6

136

17

17

17

136

35

17

across all performance measures for each policy at

three different leadtime levels for utilization levels of

75%, 90%, and 95%. Again, we see that the errors

tend to be larger for high leadtime/utilization combinations, although the maximum error we found

across all leadtimes and utilizations for the Constant

policy was 17%.

To test statistical significance of the performance of

each policy from the ‘‘Best’’ policy, we divided the

output into 40 batches and then compared the average fill rate of the 40 batches from each policy to the

average fill rate of the 40 batches from the ‘‘Best’’

leadtime policy using the two-sample t-test. We performed similar comparisons for average tardiness

and average relative tardiness. Table 7 gives the leadtime level, performance criteria, ‘‘Best’’ policy, and

the leadtime policies that are significantly different

from the ‘‘Best,’’ along with the significance level.

Note that to achieve ‘‘low’’ leadtime levels in the

DPRO system with utilization rates of 75% (low) and

90% (medium), each leadtime policy was reduced to

simply quoting the average mean flow time as a function of the number of jobs in the system. Adding any

slack leadtime to the leadtime quote would only increase the leadtime above the desired level. Thus, the

‘‘Best Policy’’ is not indicated for low leadtime levels

with low and medium utilization levels since all the

policies were reduced to the same policy of simply

quoting the mean leadtime.

The key conclusions from Tables 6 and 7 are:

(1) The Constant policy and the Fill-Rate policy are

the most robust policies with the lowest maximum

error of 17% across all performance measures, all

leadtime levels, and all utilization levels.

334

(2) The Constant policy never differs significantly

from the ‘‘Best’’ policy.

5. Conclusions

This paper describes several leadtime-quoting policies that address the problem of minimizing the average leadtime, subject to a constraint on customer

service. The policies for systems with exponential

flow times and service measured via fill rate and average tardiness are from the previous literature, while

the policies for systems with normal flow times and

any service definition, as well as policies for any system with service measured via relative tardiness, are

new to this paper. Because customer service can reasonably be defined as average fill rate, tardiness, or,

as we introduce in this paper, relative tardiness, and

because different customers care about different measures, a desirable feature of a leadtime-quoting policy

is that it perform robustly well across these service

measures, as well as across different production environments. However, because the safety leadtimes

resulting from the policies derived for specific definitions of customer service are very different, these

specialized policies do not necessarily perform robustly. Based on our analysis of different leadtimequoting methods for simple environments, we conjectured that a simple policy that quotes a constant

safety leadtime should be robust for complex systems. Our tests on several simulated production environments supported this conjecture. From Tables 2,

3, 4, and 6 we see that the maximum error across all

performance measures, all leadtime levels, and all

production systems is 31% for the Fill Rate-Norm polMANUFACTURING & SERVICE OPERATIONS MANAGEMENT

Vol. 3, No. 4, Fall 2001

HOPP AND STURGIS

A Simple, Robust Leadtime-Quoting Policy

Table 7

Identification of Leadtime Policies Significantly Different from ‘‘Best’’ Policy for the DPRO System

Utilization

Level

Leadtime

Level

Criterion

low

low

low

low

low

low

low

medium

fill rate

tardiness

relative tardiness

fill rate

—

—

—

Tardy

low

low

low

low

low

medium

medium

medium

medium

medium

medium

medium

medium

medium

high

high

high

high

high

high

high

medium

medium

high

high

high

low

low

low

medium

medium

medium

high

high

high

low

low

low

medium

medium

medium

high

tardiness

relative tardiness

fill rate

tardiness

relative tardiness

fill rate

tardiness

relative tardiness

fill rate

tardiness

relative tardiness

fill rate

tardiness

relative tardiness

fill rate

tardiness

relative tardiness

fill rate

tardiness

relative tardiness

fill rate

Tardy

Rel Tardy

Tardy

Rel Tardy

Fill Rate

—

—

—

Tardy

Tardy

Rel Tardy

Fill Rate

Fill Rate

Constant

Rel Tardy

Tardy

Rel Tardy

Constant

Tardy

Rel Tardy

Fill Rate

high

high

high

high

tardiness

relative tardiness

Fill Rate

Constant

icy, 293% for the Tardy-Norm policy, 70% for the Rel

Tardy-Norm policy, but only 18% for the Constant

policy.

Because it is so simple, the constant safety leadtime

policy is easily adapted to a broad range of manufacturing and service systems. Specifically, it may be

useful for establishing reasonable leadtimes within a

Capable to Promise (CTP) system. To strike a suitable

balance between leadtime and service, the single control parameter, (i.e., the safety leadtime), can be adjusted in real time using the control chart method

outlined by Hopp and Roof (2000). Hopp and Roof

give an efficient procedure for adjusting in the case

of a fill-rate constraint. In practical settings, however,

MANUFACTURING & SERVICE OPERATIONS MANAGEMENT

Vol. 3, No. 4, Fall 2001

Best Policy

LT Policies

Significantly

Different from

Best Policy

Significance

Level

—

—

—

Fill Rate

Rel Tardy

Fill Rate

—

—

—

Tardy

—

—

—

Rel Tardy

—

Tardy

Tardy

—

Tardy

—

—

—

—

—

Tardy

Tardy

Rel Tardy

—

Tardy

—

—

—

5.0%

10.0%

10.0%

—

—

—

0.5%

—

—

—

15.0%

—

5.0%

15.0%

—

0.5%

—

—

—

—

—

0.5%

5.0%

15.0%

—

0.5%

since leadtimes are generally quoted in increments of

days, it may be possible to simply use a step size of

one day. That is, increase (decrease) safety leadtime

whenever the current system’s service is statistically

higher (lower) than the target level. Further research

is needed to determine whether a more efficient stepsize procedure is possible and effective for the LQP,

subject to average tardiness and average relative tardiness constraints. Additional study is also needed to

investigate how well the Constant policy performs in

systems where simple leadtime-quoting mechanisms

can be used as building blocks for more sophisticated

CTP systems that consider multiple products, complex bills of material, and multiple customer classes.

335

HOPP AND STURGIS

A Simple, Robust Leadtime-Quoting Policy

References

Adam, N. R., J. W. M. Bertrand, D. C. Morehead, J. Surkis. 1993.

Due date assignment procedures with dynamically updated

coefficients for multi-level assembly job shops. Euro. J. Oper. Res.

68 212–227.

Bookbinder, James H., Afzal Ibn Noor. 1985. Setting job-shop due

dates with service-level constraints. J. Oper. Res. Society 36(11)

1017–1026.

Cheng, T. C. E., M. C. Gupta. 1989. Survey of scheduling research

involving due date determination decisions. Euro. J. Oper. Res.

38 156–166.

Dellaert, N. P. 1991. Due date setting and production control. Internat. J. Production Res. 23 56–67.

Duenyas, I. 1995. Single facility due date setting with multiple customer classes. Management Sci. 41(4) 608–619.

Enns, S. T. 1994. Job shop leadtime requirements under conditions

of controlled delivery performance. Euro. J. Oper. Res. 77 429–

439.

Fry, T. D., P. R. Philipoom, R. E. Markland. 1989. Due date assignment in a multistage job shop. IIE Trans. 21(2) 1453–1461.

Gordon, V. S., V. A. Strusevich. 1999. Earliness penalties on a machine subject to precedence constraints: SLK due date assignment. Computers and Oper. Res. 26 157–177.

Hopp, W. J., M. L. Roof. 2000. Quoting manufacturing due dates

subject to a service level constraint. IIE Trans. 32(9) 771–784.

Larson, R. J., M. L. Marx. 1986. An Introduction to Mathematical Statistics and Its Applications, 2nd ed. Prentice Hall, Englewood

Cliffs, NJ.

Lawrence, S. R. 1995. Estimating flow times and setting due dates

in complex production systems. IIE Trans. 27(5) 657–668.

Philipoom, P. R., L. P. Rees, L. Wiegmann. 1994. Using neural networks to determine internally-set due date assignments for

shop scheduling. Decision Sci. 25(5/6) 825–851.

Qi, X., F. S. Tu. 1998. Scheduling a single machine to minimize

earliness penalties subject to SLK due date determination

method. Euro. J. Oper. Res. 105 502–508.

Raman, N., F. B. Talbot. 1993. The job shop tardiness problem: A

decomposition approach. Euro. J. Oper. Res. 69 187–199.

Spearman, M. L., R. Q. Zhang. 1999. Optimal leadtimes. Management Sci. 45(2) 290–295.

Stalk, G., Jr., T. M. Hout. 1990. Competing Against Time: How TimeBased Competition Is Reshaping Global Markets. Free Press, New

York.

Udo, G. 1993. An investigation of due date assignment using workload information of a dynamic job shop. Internat. J. Production

Res. 29 89–101.

Wein, L. M. 1991. Due date setting and priority sequencing in a

multiclass M/G/1 queue. Management Sci. 37(7) 834–850.

Weng, Z. K. 1996. Manufacturing leadtimes, system utilization rates

and leadtime-related demand. Euro. J. Oper. Res. 89 259–268.

The consulting Senior Editor for this manuscript was Lawrence Wein. This manuscript was received on April 12, 1999, and was with the authors 641

days for 3 revisions. The average review cycle time was 71.3 days.

336

MANUFACTURING & SERVICE OPERATIONS MANAGEMENT

Vol. 3, No. 4, Fall 2001