CHARACTERISTICS OF TRANSFORMER PARAMETERS DURING

advertisement

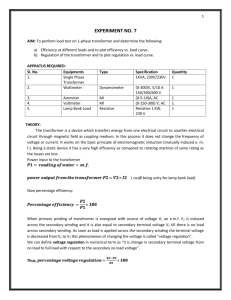

CHARACTERISTICS WINDING OF TRANSFORMER FAULTS PARAMETERS BASED ON EXPERIMENTAL Peter Palmer-Buckle Student Member, IEEE Karen L. Butler Member, IEEE DURING INTERNAL MEASUREMENTS N. D. R. Sarma Member, IEEE Power System Automation Laborato~ Department of Electrical Engineering Texas A&M Universi~ College Station, TX 77840-3128 This paper describes in detail, field experiments performed on a single-phase, distribution transformer to study the behavior of transformer terminal parameters during internal winding faults. A custom-built transformer provided with external taps was used for these tests. The taps were used to stage various internal winding faults in the transformer. Terminal values of voltages and currents were monitored and the results presented. A comparison of these results with simulation results is also presented. Abstract: Keywords: distribution transformers, windings, internal winding faults, fault detection, fault diagnosis, incipient faults. I. INTRODUCTION Internal winding faults comprise about seventy to eighty percent of modern transformer breakdown [1] and this is likely to increase since loading transformers to their optimum capacity is becoming normal practice. These winding faults are a result of the degradation of the transformer winding due to aging, high voltages, etc., which tend to cause a breakdown in the dielectric strength of the insulation. This breakdown either causes adjacent windings to short (turn-totum) or a winding to be shorted to ground (turn-to-earth). Several techniques have been developed for the detection and diagnosis of these faults with a large proportion using the gases dissolved in the transformer oil (dissolved gas analysis) [2, 3] or determination of the degree of polymerization [4] of paper insulation. Other parameters used are temperature, thermal and electrical stress of insulation, insulation aging and overloading incidents. This research investigates the viability of utilizing electrical parameters (mainly terminal voltages and currents) of a transformer in an on-line transformer incipient fault detection method. The magnetizing current in a normal transformer is about ten percent of the full load current. During internal winding faults, depending on the location of the fault, the magnetizing current increases rapidly, The distribution of transformer current subsequent to an internal electrical fault therefore differs entirely fi-om the distribution of normal load or no-load currents and is governed mainly by the internal reactance of the windings [5]. This paper presents results of experiments performed on a custom-built, 25kVA, 60Hz, 7200V1240VI120V, singlephase transformer connected to a 25kW load. To prevent damage to the transformer during faults due to high circulating currents, the experiments were performed at a low voltage level. The results presented in this paper are therefore at the reduced voltage level. Future work would be performed at the rated values. The transformer was provided with taps on both the primary and secondary windings which were used to stage the following cases of faults: 1. Turn-to-earth and turn-to-turn faults on the primary windings. 2. Turn-to-earth and turn-to-turn faults on the secondasy windings. A variac capable of supplying up to 140V was used to supply power to the primary side of the transformer and digital meters were used to monitor the terminal voltages and currents. The recorded values of voltages and currents were used to validate computer models compatible with the Alternative Transients Program (ATP) [6] to simulate internal winding faults of single-phase, distribution transformers. The models used were based on those developed for three-phase, power transformers by Bastard et al. [7]. II. COMPUTER SIMULATION MODELS In ATP, a single-phase, two-winding transformer shown as a T-circuit in fig. 1 is represented by 2X2 matrices of [R] and [L]. 0-7803-5515-6/99/$10.00 (c) 1999 IEEE ‘R]’E :1‘L]=[$l + 1, (1) ?1 where the Ri represents the winding resistance, Li, the winding inductance and A4~,the mutual inductance between windings i andj. Subscript ‘1’ refers to the primary winding and ’2’ the secondary winding. 11 R1 L, L2 + R, na, i= v, ‘b, ‘b — - nmi= 4’ J’ I R(?O o [R] = o 0 [L] = OR2 I La ~.b Mac M.2’ Mb. Lb Mb. Mb2 Mca Mcb L. Mc2 LM2. M2b M2c L2 III. FIELD TESTS A. EXPERIMENTAL SETUP The experimental setup (shown in figure 4) comprises mainly the transformer, primary and secondary panel boards and a variable resistive load bank. ‘R]=l’NIL]=E::~l ‘2) Figure (3) shows the case of a turn-to-tun fault on the primary. This divides the winding into three sub-coils and as by 4X4 matrices (3b) In both cases, the values in italics for the resistance matrices are computed using proportionality while those of the inductance matrices are computed using the rules of proportionality, leakage and consistency as outlined in [7]. “R2” and “L2” are given by BCTRAN. Fig. 2. SingIe-phase transformer with a turn-to-earth fault on primary. in (3a) and (3 b), it is represented — (3a) OORCO — BCTRAN, a supporting routine of ATP is used to derive a linear [R] and [L] representation for the single-phase, twowinding transformer using open-circuit and short-circuit test data at rated frequency. To model internal faults, the [R] and [L] matrices are revised where some of their elements are from the BCTRAN output and the other elements computed using mathematical equations modeling the faulted transformer as proposed by Bastard et al [7]. A turn-to-earth fault on the primary (originally having N1 turns with Nz turns on the secondary) divides the winding into two sub-coils as shown in figure (2). In this case the faulted transformer is represented by 3X3 matrices of [R] and [L] shown in (2). [R] and [L]. V2 0 OR bi)o V* Fig. 1. T-Circuit Representation of a Single-Phase, Two-Wkding Trrmsfonner. shown + Fig. 3. Single-phase transformer with a turn-to-turn fault on primary. 12 L. . L NJ T + v 12 —~ of Fig. 4. Experimental setup for the field tests 0-7803-5515-6/99/$10.00 (c) 1999 IEEE The transformer, shown in fig. 5, is custom-built based on the following specifications: Both panel boards (fig. 6) are made of G- 10 (epoxy), 0.5” thick. Copper strips bolted to the panel board at 1.0” separation are used as bus bars on the primary to facilitate ease in connections while on the secondary side, mechanical lugs are used due to the thickness of tihe cables. Instrument transformers on both the primary and the secondary sides reduce terminal voltages and currents to measurable levels. B. Fig. 5. Single-phase, two-winding transformer with taps ● . ● . . . . Power rating Rated primary voltage Rated seconda~ voltage Rated primary current Rated secondary current Primary turns Secondary turns 25kVA 7200V 1201240V 3.472A 208.4I1O4.4A 780 13/26 The transformer is provided with taps on both the primary and the secondary sides. There are 12 taps on the primary and 10 taps total on the secondary. These taps are external to the transformer as shown in figure (5). For ease of simulation of internal winding faults, these taps are connected to panel boards through cables. The cables used on the primary side are 15kV class capable of withstanding not more than 10Arms of current and the secondary side cables are of the 600V class. They can withstand up to 400Arms. REDUCED VOLTAGE TEST PROCEDURE The simulation revealed very high circulating currents in the shorted windings. Currently we are investigating ways of reducing these currents to levels that would not damage the windings of the transformer. The results presented in this paper therefore represent values obtained when the supplied voltage was far less than the rated on the primary. The primary was supplied using a single-phase variac capable of supplying up to 140V, 22A. The variac was connected to the primary panel board (fig. 7) and a resistive load of 2.3040hms connected to the secondary side. Digital meters were used to monitor primary and secondary voltages and currents as well as circulating currents during faults. To stage an internal fault, a tap is either connected to the ground (turn-to-earth fault) or to another tap (turn-to-turn fault). The voltage on the variac is varied sllowly till a voltage of about 10OV is reached. The primary voltage was limited to 100 V due to high circulating currents flowing through the shorted windings. This could damage the transformer. The maximum allowable current that could flow through the windings was calculated based on (4), supplied by the transformer manufacturer. The terminal voltages and currents as well as the circulating current were recorded. n “ “ = Load IL--+JJ , — Fig. 7. Setup for reduced voltage tests. The A ‘,s are ammeters, V’s are voltmeters, AC is a 120V, 60Hz mains, Vu is single-phase, 60Hz, 120V input, 140V maximum output, variac, HI and H2 represent terminals of the primary winding and XI and X.2 are the terminals of the secondary winding. Fig. 6. Primary and secondmy panei boards showing connectors. AT= K .12. T~in,. (Q/#) 0-7803-5515-6/99/$10.00 (c) 1999 IEEE (4) Table 2. Terminal values of turn-to-turn tkadtson secondary. where AT is the temperature rise in degrees Celsius, K = 0.343 is a constant, I is current in amps, T is time in minutes and Q/# is the ohms per pound of conductor. E Short Normal The maximum AT for the transformer was limited to 115°C. Knowing the ohm per pound of the conductor used (which is copper for the primary and aluminum for the secondary in this case) and the time, the maximum current was calculated. IV. RESULTS A. S16-17f Tables 1 and 2 give recorded values of voltages and currents for turn-to-turn faults on the primary and secondary respectively. Both tables show an increase in primary current as the number of turns shorted increase. The primary voltage was kept almost constant at 100V. The secondary voltage in Table 1 remained fairly constant as expected. Since the load was purely resistive and maintained at 2.304 ohms, the current flowing through the load was in direct proportion to the secondary voltage. In Table 2, the secondary voltage decreased as the number of shorted turns increased. This is because as more turns are shorted, few effectively remain in circuit. Tables 3 and 4 give results of turn-to-earth faults. Like in Tables 1 and 2, the primary current increases with increasing shorted turns in both cases. The secondary voltages in this case decrease with increasing shorted turns for turn-to-earth fault on both windings. All voltage and current values are rms. 99.8 3.165 0.14 1.37 s19-2of 2 99.8 3.166 0.12 1.28 s2-4f 3 100.2 2.987 0.41 1.32 S8-10f 3 100.2 3.021 0.39 1.37 slo-13f 4 100.0 2.682 0.68 1.21 S16-20f 4 100.1 2.390 1.11 1.04 5 99.9 2.333 0.92 0.97 S16-19f 5 100.4 2.665 0.82 1.34 S8-13f 6 100.0 2.076 1.20 0.91 S2-8f 7 100.0 1.933 1.30 0.86 s4-lof 7 100.1 1.931 1.32 0.91 s13-2of 8 100.3 1.622 1.54 0.65 s2-lof 9 100.0 1.450 1.55 0.58 s4-13f 10 100.4 1.190 1.75 0.59 s2-13f 12 100.4 0.970 1.88 0.36 E s13-17f FIELD TESTS 2 Table 3. Terminal values of turn-to-earth faults on primary. m= Short Number Primary Secondruy Pfimrrry Table 1, Terminal values of turn-to-turn faults on primary. Fault on primary Table 4. Terminal values of turn-to-earth faults on secondary. Secondary Short I Number I Primary I Secondwy I Primary Current Turns [ Voltage I Voltage I Current 1.49 100.OI 3.3091 0.03 I Normal I 01 P9-lof 21 99.8 3.326 0.38 1.46 P4-5f 100.2 3.316 0.51 1.46 P5-6f 28 25 100.C 3.320 0.53 1.53 P1-2f 41 100.C 3.234 0.78 1.49 P4-6f 5( 100.3 3.334 1.02 1.54 P6-7f 57 100.3 3.337 1.03 1.53 P5-7f 8$ 100.1 3.336 1.61 1.53 P4-7f 112 100.4 3.348 2.29 1.53 P4-8f 22L 100.2 3.467 5.34 1.61 E kRiiF=$=F=d Short B. Number Primary COMPARISON RESULTS Secondmy Primary BETWEEN FIELD AND SIMULATION Figures 8, 9 and 10 show a comparison between field and simulation results of secondary voltage, primary current and secondary current respectively. 0-7803-5515-6/99/$10.00 (c) 1999 IEEE for a turn-to-turn fault on the primary V. DISCUSSIONS AND CONCLUSION taps shorted IEiField ■ Simulation \ Fig. 8. Comparison between field and simulation results: secondmy voltage, turn-to-turn fault on primary. 5.0 g 4.0 : x ~2 ? 3.0 2.0 1.0 0.0 taps shorted H Field H Simulation Fig. 9. Comparison between field and simulation results: primary eurren~ turn-to-turn fault on primary. 2.00 1.80 1.60 1.40 1.20 1.00 0.80 0.60 0.40 0.20 0.00 Results of field experiments carried out on a custom-built transformer fitted with taps to simulate internal winding faults are presented. Comparisons between field and simulation results are also given. The terminal voltages and currents behaved as the simulation. The slight discrepancies could be due to the following factors: ● During the field experiments, it was not easy to get the exact primary voltage as used in the simulation. ● Leakage factors were assumed to be negligible in some cases while in others, they were assumed to be small. This was for ease in calculation of the inductance parameters using the method proposed in [7]. . The cables used in the field for (connection to the tap positions on the panel board were modeled as pure resistors. The primary current as stated earlier increased with increasing number of shorted turns. In the case of faults on the primary winding, as the shorted turns increase, the effective number of turns across the primary decrease. However, the primary voltage is maintained constant at 100V, This causes the magnetizing current and hence the primary current to increase rapidly [5]. For faults on the secondary side, the increase in primary current is not rapid. The increased primary current is due to the high circulating current in the shorted windings. This current flows in opposition to the normal flow of current in the winding. The effective flux which is dependent on the primary voltage is reduced. More current must therefore be drawn from the primary to bring the flux to the value proportional to the primary voltage. As expected, the secondary voltages were not significantly affected when the faults were on the primary winding. However, for faults on the secondary winding, the voltage decreased with increasing shorted turns, This is due to the decrease in effective number of turns across which the load is connected, The secondary current as stated earlier is in direct proportion to the secondary voltage in adlcases and hence has the characteristics of the secondary voltage. These experiments were performed to validate and if necessary fine-tune the models used in the simulations. From the results of the comparison plots, it can be concluded that the models agree well with the actual transformer under internal winding fault conditions. Future work would investigate the dependence of the voltages and currents on the fault position. VI. ACKNOWLEDGMENT taps shorted ❑ Field . The authors greatly acknowledge the National Science Foundation through grant ECS-9522208 for their support of this work. Simulation Fig. 10 Comparison of field and simulation results: secondary current, turnto-tum fault on primwy 0-7803-5515-6/99/$10.00 (c) 1999 IEEE VI. REFERENCES StigrmL A. C. Franklin, The .J&PTrarr<ormer Book, New York Toronto, John Wiley and Sons, 1973. [2] “IEEE Guide for the Interpretation of Gases Generated in OilImmersed Transformers”, LE.E.EStandardC57.104-1991, New York IEEE Press, 1992. [3] Stebbins, D. Randy., et al., “Dissolved Gas Analysis of Transformers Oil”, PanelSession, 1997 Winter Meeting, PES/IEEE, February 1997, [1] !&n, D. M., “Practical Life-Assessment Techniques for Aged Transformer Insulation”, IEEE Proceedings - A, Vol. 140, No.5 September, 1993, pp. 404-408. [5] E. Billig, “Electrical and Mechanical Effects of Internal Faults in Transformers”, The British Electrical and Allied Industries Research Association, Technical Report Q/T103, London, 1944. [6] Alternative Transients Program (ATP) Rule Book, Canadian/American EMTP Users Group, 1987-1995. [7] P. Bastard et al., “A Transformer Model for Winding Fault Studies”, IEEE Transactions on Power Delivery, Vol. 9, No.2 April 1994, pp. [4] 690-699. 0-7803-5515-6/99/$10.00 (c) 1999 IEEE