Manufacturing Planning and Control Systems D. Clay Whybark

advertisement

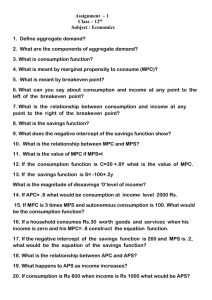

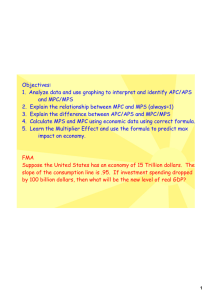

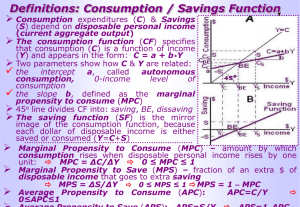

Manufacturing Planning and Control Systems Thomas E. Vollmann International Institute for Management Development William L. Berry The Ohio State University D. Clay Whybark University of North Carolina V liH Fourth Edition Ftanctfco, ^ ' -t Irwin/McGraw-HUI New York • St. Louis • San Francisco • Aucl<iand • Bogota Caracas • Lisbon • London • Madrid • Mexico City • Milan Montreal • New Delhi • San Juan • Singapore Sydney • Tokyo • Toronto Contents Chapter 1 Manufacturing Planning and Control Bucketless Systems Lot Sizing 31 2 Safety Stock and Safety Lead Time 32 Typical MPC Support Tasks 2 Low-Level Coding 33 Costs and Benefits of MPC Systems 2 Pegging 33 3 Firm Planned Orders 34 MPC System Activities 4 Service Parts 34 The System and the Framework 4 Planning Horizon 35 Matching the MPC System with the Needs of the Firm 6 Scheduled Receipts versus Planned Order Releases 35 An MPC Classification Schema 7 EVOLUTION OF THE MPC SYSTEM 9 THE MPC SYSTEM DEFINED AN MPC SYSTEM FRAMEWORK The Changing Competitive World 9 Reacting to the Changes 9 CONCLUDING PRINCIPLES 10 USING THE MRP SYSTEM Material Requirements Planning MATERIAL REQUIREMENTS PLANNING IN MANUFACTURING PLANNING AND CONTROL MRP and MRPII 13 14 16 36 The MRP Planner 36 Exception Codes 38 Bottom-Up Replanning 39 An MRP System Output 40 SYSTEM DYNAMICS Chapter 2 30 42 Transactions during a Period 42 Rescheduling 43 Complex Transaction Processing 44 Procedural Inadequacies 45 THE MRP DATA BASE The Item Master File 47 47 RECORD PROCESSING 17 The Subordinate Item Master File 47 p ; ^ The Basic MRP Record 17 The Bill of Material File 47 ] ^ 25 The Location File 48 29 The Calendar File 48 29 Open Order Files 48 Unking the MRP Records "^^^^^CHNICAL ISSUES Processing Frequency wll v%iii Other File Linkages MRP SYSTEM EXAMPLES Ethan Allen Furniture Company A Manual Application .me Jet Spray—An Integrated On-Line Example CONCLUDING PRINCIPLES Chapter 3 Justin-Time 48 48 49 MANAGERIAL IMPLICATIONS Information System Implications 109 Manufacturing Planning and Control 109 Scorekeeping no Pros and Cons 111 4 f\ 49 108 CONCLUDING PRINCIPLES 111 Chapter 4 120 52 Capacity Planning 68 CAPACITY PLANNING'S ROLE IN MPC SYSTEMS JIT IN MANUFACTURING PLANNING AND CONTROL 69 Major Elements of Just-in-Time 70 JIT's Impact on Manufacturing Planning and Control 71 The Hidden Factory 73 JIT Building Blocks in MPC 74 121 Hierarchy of Capacity Planning Decisions 121 Links to Other MPC System Modules 122 CAPACITY PLANNING AND CONTROL TECHNIQUES 124 78 Capacity Planning Using Overall Factors (CPOF) 124 Leveling the Production 78 Capacity Bills 126 Pull System Introduction 79 Resource Profiles 128 Product Design 83 Process Design 85 Capacity Requirements Planning (CRP) 135 Bill of Material Implications 87 Input/Output Control 137 89 The Capacity "Bath Tub" 140 A JIT EXAMPLE JIT APPLICATIONS Single-Card Kanban 89 Toyota 91 Hewlett-Packard 96 NONREPETITIVE JIT 99 A Service-Enhanced View of Manufacturing Flexible Systems Simplified Systems and Routine Execution 99 100 101 JIT IN PURCHASING The Basics Lessons 102 SOFTWARE HP JIT Software fiiJIT Using MRP Software 102 MANAGEMENT AND CAPACITY PLANNING 141 Capacity Planning in the MPC System 141 Choosing the Measure of Capacity 142 Choice of a Specific Technique 144 Using the Capacity Plan 145 DATA BASE REQUIREMENTS 146 Data Base Design Considerations EXAMPLES OF APPLICATIONS 146 147 105 Capacity Planning at Montell USA, Inc. 147 105 Capacity Planning at Twin Disc 148 105 Capacity Planning at Applicon 152 108 CONCLUDING PRINCIPLES 153 Cfmtmts Chapter 5 Production Activity Control A FRAMEWORK FOR PRODUCTION ACTIVITY CONTROL MPC System Linkages 165 166 167 The Linkages between MRP and PAC 167 Just-in-Time Impact on PAC 168 The Company Environment 169 PRODUCTION ACTIVITY CONTROL TECHNIQUES Basic Shop-Floor Control Concepts Gantt Charts 169 169 172 Priorrty Sequencing Rules 173 Finite Loading 174 Vendor Scheduling and Follow-Up 178 Lead Time Management 179 PRODUCTION ACTIVITY CONTROL EXAMPLES 180 MASTER PRODUCTION SCHEDULING TECHNIQUES The Time-Phased Record Rolling through Time Order Promising Consuming the Forecast Key Definitions 224 The Modular Bill of Material 225 The Planning Bill of Material 227 THE FINAL ASSEMBLY SCHEDULE Relation to the MPS 229 The Hill-Rom FAS THE MASTER PRODUCTION SCHEDULER The MPS as a Set of Firm Planned Orders 231 233 234 The Job 186 Vendor Scheduling at Steelcase 188 PAC Procurement Practices under "World Class" Manufacturing 188 THE PRODUCTION ACTIVITY CONTROL DATA BASE 191 The Ethan Allen Master Production Schedule Master Production Scheduling at Jet Spray MASTER PRODUCTION SCHEDULE STABILITY 238 238 242 244 192 Ethan Allen Stability 244 246 194 Freezing and Time Fencing MANAGING THE MPS THE MASTER PRODUCTION SCHEDULING ACTIVITY 217 222 The CAPOSS System at Swissair Master Production Scheduling 213 BILL OF MATERIAL STRUCTURING FOR THE MPS EXAMPLES Chapter 6 210 220 181 CONCLUDING PRINCIPLES 210 Mitel Corporation: Order Promising with ATP Critical Ratio Shop-Floor Control at Twin Disc Data Acquisition and Feedback \\x 205 206 The Anticipated Build Schedule 206 Linkages to Other Company Activities 207 The Business Environment for the MPS 208 247 The Overstated MPS 247 MPS Measures Monitoring the MPS at Ethan Allen 248 248 CONCLUDING PRINCIPLES 251 Chapter 7 269 Production Planning PRODUCTION PLANNING IN THE FIRM Sales and Operations Planning 270 270 f^-^ents Productfon Planning and Management Production Planning and MPC Systems Payoffs THE PRODUCTION-PLANNING PROCESS Routinizing Production and Game Planning The Basic Trade-Offs Evaluating Alternatives THE NEW MANAGEMENT OBLIGATIONS Top-Management Role 272 274 275 276 278 282 286 286 Functional Roles 287 Integrating Strategic Planning 288 Controlling the Production Plan 289 OPERATING PRODUCTION-PLANNING SYSTEMS Production Planning at Compugraphic Demand Management and Production Planning Demand Management and Master Production Scheduling Make to Demand Outbound Product Flow Data Capture Dealing with Day-to-Day Customer Orders Make-to-Order Demand Management MANAGING DEMAND Organizing for Demand Management Managing Service Levels 330 Using the System COMPANY EXAMPLES 335 Forecasting at Ross Laboratories Customer Order Promising at Kirk Motors, Ltd. Make-to-Order Products at Elliott Company, Division of Carrier Corporation Chapter 9 300 DEMAND MANAGEMENT IN MANUFACTURING PLANNING AND CONTROL SYSTEMS 325 290 Hill-Rom's Use of Planning Bills of Material Demand Management Make-to-Stock Demand Management Assemble-to-Order Demand Management CONCLUDING PRINCIPLES 293 Chapter 8 319 290 Mohawk's Integrated Planning Process CONCLUDING PRINCIPLES D^ 270 DEMAND MANAGEMENT TECHNIQUES Aggregating and Disaggregating Forecasts 302 312 313 314 314 316 318 318 319 Integrated MPC Systems MPC DESIGN OPTIONS Master Production Scheduling Options Detailed Material Planning Options Shop-Floor System Options CHOOSING THE OPTIONS Market Requirements The Manufacturing Task Manufacturing Process Design MPC System Design THE CHOICES IN PRACTICE Moog, Inc., Space Products Division Kawasaki, U.S.A. Applicon The Driver Is the Marketplace INTEGRATING MRP AND JIT The Need to Integrate 320 327 331 332 333 336 336 340 342 342 354 354 355 357 358 361 361 362 363 364 369 369 372 374 377 377 377 Contents Physical Changes That Support Integration AUDITING 378 XXI 424 Cross-Checking the Data Base 424 Reconciling Data Base Errors 425 The Just-in-Time Approach to Data Accuracy 425 A Detailed Checklist for the MRP-Based System 427 The Audit Process 428 Continual Improvement 430 CONCLUDING PRINCIPLES 430 400 Chapter 11 Advanced Concepts in Material Requirements Planning 439 Matching the Manufacturing Task to System Design 401 DETERMINING MANUFACTURING ORDER QUANTITIES 440 MPC Data Base Integrity 402 Economic Order Quantities (EDO) 441 Discipline to Use the Formal System 405 Periodic Order Quantities (POQ) 442 405 Part Period Balancing (PPB) 4^3 Top-Management Commitment 406 McLaren's Order Moment (MOM) 445 Waste or "Slack" Reduction 406 Wagner-Whitin Algorithm 447 Job Design 407 Simulation Experiments 447 Some Techniques for Integrating MRP and JIT Strategy for Combining MRP and JIT CONCLUDING PRINCIPLES Chapter 10 Implementation of MPC Systems INITIATING THE PROJECT 378 379 380 389 390 The Yardstick of Performance 390 The Company Environment 393 Justification 394 An Evolutionary Point of View 399 ESSENTIAL PREREQUISITES ORGANIZATIONAL ISSUES THE IMPLEMENTATION PROJECT TEAM 408 DETERMINING PURCHASE ORDER QUANTITIES 449 Project Team Structure 408 The Purchasing Discount Problem 449 The Primary Project Team 409 Look-Ahead Feature 453 Team Building 410 Performance Comparisons 453 EDUCATION 412 BUFFERING CONCEPTS 455 Education Levels and Requirements 413 Categories of Uncertainty 456 An Education Program 415 Safety Stock and Safety Lead Time 457 Problem Solving 416 Coping with Change 418 Safety Stock and Safety Lead Time Performance Comparisons 459 PROJECT MANAGEMENT 419 Other Buffering Mechanisms 461 Defining the Scope 419 Where to Start 420 Project Planning NERVOUSNESS 461 420 Sources of MRP System Nervousness 462 Project Control 421 Reducing MRP System Nervousness 462 When to Quit 423 OTHER ADVANCED MRP CONCEPTS 464 Timing Conventions Bucketless Systems Phantom Assemblies Scrap Allowances Automatic Updating CONCLUDING PRINCIPLES 464 465 465 466 467 467 Chapter 12 Advanced Concepts in Just-in-Time 480 A JIT RESEARCH FRAMEWORK 481 SCHEDULING Scheduling Mixed Model Assembly Lines under JIT Schedule Stability in Implementing JIT SUPPLIER MANAGEMENT 481 PRODUCTION FLOOR MANAGEMENT 497 Setup Time Reduction Determining the Optimal Number of Kanbans JIT PERFORMANCE AND OPERATING CONDITIONS Variability in Operating Conditions Lot Size Comparing MPC System Approaches CONCLUDING PRINCIPLES 498 Chapter 13 Advanced Concepts in Scheduling A SCHEDULING FRAMEWORK Performance Criteria Shop Structure Product Structure Work Center Capacities BASIC SCHEDULING RESEARCH C W Static Scheduling Approaches Dynamic Scheduling Approaches The One-Machine Case The Two-Machine Case [P® 484 488 489 502 507 507 509 511 515 524 525 525 526 527 528 528 529 529 530 531 Queuing Model Approaches Sequencing Rules Sequencing Research Results ADVANCED RESEARCH FINDINGS Due Date Setting Procedures Dynamic Due Dates Labor-Limited Systems Lessons for Practice 533 EMERGING ISSUES IN SCHEDULING Scheduling Cellular Manufacturing Systems Scheduling Manned Cellular Manufacturing Systems Scheduling FMS Systems 548 CONCLUDING PRINCIPLES 560 Chapter 14 Advanced Concepts in Master Production Scheduling 574 TWO-LEVEL MASTER PRODUCTION SCHEDULING Two-Level MPS Example Booking Customer Orders Managing with a Two-Level MPS TWO-LEVEL MPS AT MITEL CORPORATION MPS Planning MPS Detail ADDITIONAL TECHNIQUES Alternative ATP Explosion Conventions Consumption by Actual Orders Capacity Planning METHODS FOR CONSTRUCTING PLANNING BILLS OF MATERIAL The Matrix Bill of Material Approach Commonality and Bill of Material Depth Component Commonality Analysis System 533 535 537 537 540 544 546 548 549 553 575 575 577 578 579 579 581 582 582 584 586 587 588 588 591 Contents Material Handling Equipment Manufacturer Example CONCLUDING PRINCIPLES Chapter 15 Advanced Concepts in Production Planning MATHEMATICAL PROGRAMMING APPROACHES 591 595 612 613 The Basic Exponential Smoothing Model ENHANCING THE BASIC EXPONENTIAL SMOOTHING MODEL XXIll 657 660 Trend Enhancement 660 Seasonal Enhancement 662 Trend and Seasonal Enhancement Other Enhancements 665 666 Linear Programming 613 FOCUS FORECASTING 666 Mixed Integer Programming 615 COMPARISONS OF METHODS 667 OTHER APPROACHES 617 The Forecasting Competition 667 The Linear Decision Rule 617 The Focus Forecasting Comparison 668 The Management Coefficients Model 619 Search Decision Rules 620 USING THE FORECASTING SYSTEM 670 670 620 Incorporating External Information Getting Started The Disaggregation Problem 620 Demand Filter Monitoring 672 Hierarchical Production Planning 621 Tracking Signal Monitoring 673 Strategic Issues 674 DISAGGREGATION Disaggregation through Mathematical Programming 671 623 FORECASTING IN INDUSTRY 676 627 CONCLUDING PRINCIPLES 677 Owens-Corning Fiberglas: Anderson, South Carolina, Plant 627 Aggregate Production Planning 628 Disaggregating the Production Plan 631 Chapter 17 Independent Demand Inventory Management 688 COMPANY EXAMPLE APPLICATIONS POTENTIAL 633 Application of Modeling Techniques 634 Data Issues 634 The Future 635 CONCLUDING PRINCIPLES 636 Chapter 16 Short-Term Forecasting Systems 648 THE FORECASTING PROBLEM 649 Forecasting Perspectives 649 Forecast Evaluation BASIC FORECASTING TECHNIQUES Example Forecasting Situation Moving Averages O Jl D BASIC CONCEPTS Independent versus Dependent Demand Items Functions of Inventory 689 MANAGEMENT ISSUES Routine Inventory Decisions 692 Determining Inventory System Performance Timing the Implementation INVENTORY-RELATED COSTS 689 691 692 693 693 694 650 Order Preparation Costs 694 653 Inventory Carrying Costs Shortage and Customer Service Costs 694 653 656 695 \\1% t i ''il '^'^ 696 DRP and Demand Management 746 Example Cost Trade-Offs ECONOMIC ORDER QUANTITY MODEL 696 DRP and Master Production Scheduling 747 Solving the EDO Model QUANTITY DISCOUNT MODEL ORDER TIMING DECISIONS 699 Incremental Inventory Costs 698 DRP TECHNIQUES 748 The Basic DRP Record Time-Phased Order Point (TPOP) 748 Linking Several Warehouse Records 751 704 Managing Day-to-Day Variations from Plan 754 Continuous Distributions Probability of Stocking-Out Criterion 707 Safety Stock in DRP 758 708 MANAGEMENT ISSUES WITH DRP 761 Customer Service Criterion 710 Data Integrity and Completeness 761 Time Period Correction Factor 710 762 Forecast Error Distribution 712 Organizational Support Problem Solving Sources of Demand and Supply Uncertainty The Introduction of Safety Stock ORDER QUANTITY AND REORDER POINT INTERACTIONS 701 702 702 713 750 765 COMPANY EXAMPLE 768 CONCLUDING PRINCIPLES 773 Chapter 19 787 Service Levels and Order Quantities 714 Total Cost Criterion 717 Grid Search Procedure 718 The Iterative (Q, R) Procedure 719 The Standard for MPC Systems 788 720 Beyond the Schematic 789 MULTI-ITEM MANAGEMENT Single-Criterion ABC Analysis 720 Multiple-Criterion ABC Analysis 722 MULTIPLE ITEMS FROM A SINGLE SOURCE Methods Based on Individual Item Reorder Points Methods Based on Group Reorder Points A Group Service Level Method Simulation Experiments CONCLUDING PRINCIPLES Chapter 18 Distribution Requirements Planning DRP IN MANUFACTURING PLANNING AND CONTROL SYSTEMS DRP and the Marketplace 725 727 730 731 732 733 743 744 745 MPC Frontiers THE MPC SYSTEM SCHEMATIC OPTIMIZED PRODUCTION TECHNOLOGY (OPT) Basic Concepts of OPT OPT and the MPC Framework Philosophical Underpinnings Theory of Constraints Implementation Issues The Repetitive Lot Concept MPC FOR THE PROCESS INDUSTRIES (PRISM) Production Resources Production Models Transaction Processing Performance Measurement Implications for MPC Practice INTEGRATED SUPPLY CHAIN MANAGEMENT THE NEXT FRONTIER Supply Chain Complexity 788 789 790 795 796 798 798 799 802 803 804 804 805 807 807 808 Contents Best Practices 808 Implications for MPC Systems 810 CONCLUDING PRINCIPLES 812 Index 823 xxv