Response to Negative Regarding Design Factor on AWWA C906 ballot,... Stephen Boros, Chairman, Hydrostatic Stress Board

advertisement

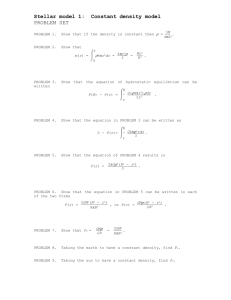

Response to Negative Regarding Design Factor on AWWA C906 ballot, item #9 Stephen Boros, Chairman, Hydrostatic Stress Board March 4, 2009 (Revised for by Committee Chair for Subcommittee use , June 2009) General Comment The comment submitted suggesting a design factor of 0.5 is confusing the design factor (DF) for thermoplastics in a piping application with an engineering safety factor (SF). They are very different concepts in this application and must be treated as such. There are many considerations that go into a design factor for thermoplastic pipe – not the least of which is recognition of the potential failure mode for each type of plastic. It is not the hoop stress from internal pressure that will determine the service life of a plastic pipe, but rather how the material responds to other induced stresses during service and the corresponding stress intensifications (point loading, fatigue, surge, etc...). Ductile materials will shed these stress concentrations by distributing the stress into the surrounding matrix, while more brittle materials will tend to be further affected and result in failure. Add to this the effects of fatigue and it is not a simple system. Due to these complex issues, the Hydrostatic Stress Board has been the source of the hydrostatic design stress (HDS) and the corresponding DF for thermoplastic materials for more than 40 years. The Hydrostatic Stress Board was initiated in 1958 to develop methodology for the determination of the long-term strength of thermoplastic materials (such as PVC and PE) intended for piping applications. It is made up of a cross section of knowledgeable experts from across the plastics industry. The application of the strength reduction factor (i.e. design factor in this case) to the HDB results is a maximum hydrostatic design stress (HDS) which takes into account that there will be additional stresses imposed on the pipe as well as how the material will respond to these conditions. (A list of HSB current members is shown at the end of this document). The Hydrostatic Stress Board, after studying the subject for several years set three additional performance criteria in order for a PE material to qualify for the higher 0.63 design factor. PE materials not meeting these requirements continue to utilize the 0.50 DF for determining the maximum design stress for water at 73°F. 1. A demonstration, in accordance with Plastics Pipe Institutes requirements, that in its stress-rupture evaluation a PE material shall continue to fail by the ductile mode through at least the 50-year intercept. This requirement ensures that the PE material continues to operate in the ductile state even after very prolonged periods of sustained stress. 2. The lower confidence limit (LCL) of the projected average value of the material’s long term hydrostatic strength cannot be less than 90% of the average value that is forecast by means of method ASTM D2837 (i.e. the LCL/LTHS ratio must be greater than 0.90) – A high ratio enhances the statistical reliability of the forecast of the long-term strength. It is also another indication of high resistance to failure by a brittle-like mechanism, a mechanism that leads to greater scatter in stress-rupture data. 3. The minimum failure time under ASTM test method F1473, a fracture mechanics based method that uses a combination of a significantly elevated test temperature and a very sharp notch that induces a high localized stress intensification in the test specimen, cannot be less than 500hrs – This time is about 5 times greater than the test time which based on a calibration of test results versus actual quality of field experience has been found to result in essential immunity to the effect of localized stress intensifications that occur under field conditions (by comparison, the previous edition of C906 required only 10 hours on this test). Additional background information on the development and evolution of the design factor is attached in a memo from Stan Mruk, past chair of the Hydrostatic Stress Board. A- Safety factor (SF) against failure due to over-pressurization exceeds two to one (2:1). All PE pipe conforming to the standard has a safety factor against burst from over pressurization that greatly exceeds 2 to 1. The importance of such a safety factor cannot be minimized as it gives protection to the pipeline operator against accidental temporary over-pressurization and surge pressures. The burst strength of PE pipe remains constant through out the life of the pipe, and should not be confused with the long-term strength as determined by the HDB. The attached report shows that PE pipes that have been under constant stress (i.e. pressurized) in excess of 100,000 hours at 60°C (more than 10 years) retain the same burst pressure as new pipe. (see attached reference paper by Sandstrum, et al ..). Taking into account the accelerating effects of the elevated temperature, this would be equivalent to more than 50 years at normal water service temperatures of 73°F. Therefore the safety factor against burst remains constant throughout the pipe’s life at greater than 2:1 even with the application of a 0.63 DF. B- Design factor increase based on improvements in PE materials. While long-term hydrostatic strength and burst strength are important in pipe design, it is not the limiting factor to PE pipe life. Most often the lifetime limiting mechanism in PE pipe is slow crack growth. In certain polyethylene pipe-grade materials, over long periods of time, microscopic cracks may develop, which then slowly grow into minute cracks (SCG). While not the end of the useful service life, this is typically considered failure of the pipe. Long term design involves estimating the time to failure under conditions that lead to slow crack growth (SCG) and applying a design factor, so as to lower the instigating stress well below the failure curve. The design factor for PE materials meeting the performance requirements in C906-07 continues to be limited to 0.5. The proposed changes to C906-07 provides for the introduction of newer and improved materials such as PE4710 and PE3710. These materials are considered 3rd and 4th generation improvements and have vastly improved slow crack growth resistance. One measure of slow crack growth resistance is test method ASTM F1473 referred to as the PENT test. PENT values for materials in C906-07 are required to equal or exceed 10 hours by cell class definition. The PE4710 and PE 3710 materials are required to equal or exceed 500 hours. Research indicates that this level of PENT performance moves the potential for brittle type failures to hundreds of years in service, essentially eliminating this as a potential failure mechanism. In addition to PENT the newer materials must also demonstrate a linear stress rupture curve to at least 50 years—that is, no downturn which might indicate a tendency toward slow crack growth. These additional requirements assure longevity, such that the occurrence of slow crack growth has been shifted out to hundreds of years and any additional stress from the application of the 0.63 DF will not result in a reduced operating safety of the system over the design life. C- Design factor change approved by HSB and by AWWA. As explained in the General Comments section above, the increase in design factor was determined and approved by the Hydrostatic Stress Board. The Hydrostatic Stress Board is a body within the Plastics Pipe Institute and has historically established the design factors for all thermoplastics materials including HDPE and PVC. Membership in the Hydrostatic Stress Board includes representatives from all thermoplastic materials industries including PVC, PE, PEX, CPVC, PA, and thermoplastic composites. The Hydrostatic Stress Board members develop polices on how to establish the long-term strength of thermoplastic compounds for piping applications and issue recommendations for the Hydrostatic Design Stress (HDS). The use of a higher Design factor for the improved PE materials has been accepted in Europe, Australia, and other parts of the world for years, the U.S. has been in the process of developing the appropriate protocols and standards since 2002. It might be noted that the most recent edition of AWWA C901 now contains the Design factor of 0.63 for these higher performing materials. This was approved and passed through AWWA last year. So, there is already precedent in AWWA to use the higher Design factor for the improved materials. The AWWA PE standards C901 and C906 need to be consistent as was done last year for PVC standards C900 and C905. D- Design factor is lower for natural gas applications. The commenter misinterpreted how PE pipe is utilized in natural gas distribution systems. The design factors for regulated natural gas distribution service are established by the Department of Transportation and published in the Title 49 Code of Federal Regulations, Part 192. The transportation of a fuel gas demands a higher degree of conservatism in design. The design factor for this application takes many factors into account, such as the potential for the formation of gas condensates and elevated temperatures, along with an additional factor of safety due to the serious consequences of a failure in a piping system conveying a compressed combustible gas – even a pinhole leak. While PE pipes have a more conservative design factor in these applications, the Federal Code no longer permits the use of PVC pipe for new gas pipeline construction. However, if it did the design factor for PVC would be no higher than 0.32 and possibly as low as 0.25, and gasket joints would not be allowed at all. As an additional point of information, the same PE materials that are being proposed for use with a Design factor of 0.63 for water, are also being proposed for an increased design factor by the Federal DOT from 0.32 to 0.40 (the same 25% increase in working stress). Because of the improved performance of these PE materials, this is not being considered a decrease in the ―safety‖ of these critical systems nor should it be for water. E- Design factor placed in body of standard. In response to received comments, the definition for the design factor has been placed in the body of the standard, as well as additional verbiage to show how the Hydrostatic Design Stress is calculated. It is further clarified that the DF of 0.63 does not apply to all PE materials, but only those that qualify for the enhanced performance properties as determined by the Hydrostatic Stress Board and published in TR-3. Previously approved PE materials will continue to have the HDS determined using the 0.50 DF. These materials are also listed in PPIs TR-4 publication. F- Summary The increase in Design factor from 0.5 to 0.63 is based on marked improvements in PE material’s long-term performance. The increase is consistent with changes approved by the Hydrostatic Stress Board and by AWWA in C901, as well as numerous other standards organization including ASTM, CSA, and ASME. The safety factor against burst continues to exceed two to one (2:1) . List of 2009 HSB members Pipe Suppliers 1 2 3 4 5 6 Richard Kolasa – PE Gary Runyan - PEX Peter Cook - PVC/Composite/PEX/CPVC Ron Bishop - PVC Keith Steinbruck – PVC Bob Walker – PVC Resin Suppliers 7 8 9 10 11 Andy Olah - PEX/CPVC Richard Guise - PVC Brian Cole – PE Nancy Conley – PE Bill Michie – PE Distributor/End User 12 13 Steve Sandstrum – ISCO Will Bezner - Complete Production HSB Consultants 14 15 16 17 Bob Ayres Michael Byrne Stan Mruk Frank Volgstadt Laboratories 18 19 Ken Oliphant Jarno Hassenin Certifying Bodies 20 21 Nasrin Kashefi – NSF Nils Holm– CSA Trade Associations 22 23 24 PPI Technical Director - Stephen Boros Uni-Bell PVC Pipe Assoc - TBD PPI Tech. Com. Chair- Adel Haddad