A PRODUCT CLASSIFICATION AND PRODUCTION TRACEABILITY SYSTEM FOR WOMEN SILVER JEWELRY PRODUCTS

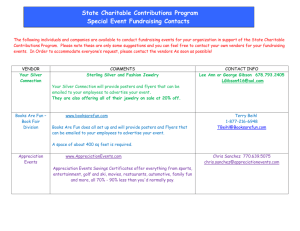

advertisement