Bio-Decontamination with H2O2 – Vapor in Pharmaceutical Industry Bio-decontamination with H O

advertisement

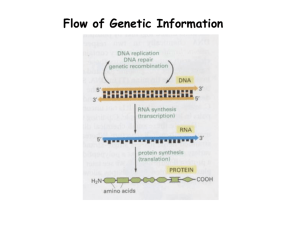

Bio-decontamination with H2O2 - Vapor Bio-Decontamination with H2O2 – Vapor in Pharmaceutical Industry Dr. Johannes Rauschnabel, Robert Bosch GmbH SBM Expert’s Congress 13th-14th of September, 2007 Packaging Technology 1 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Structure Î Introduction Î “VHP” for Isolators Î Results Î More Applications Î Summary Packaging Technology 2 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 1 Bio-decontamination with H2O2 - Vapor Structure Î Introduction z Chemistry / Biocidal Effect z Challenges z Regulatory Î “VHP” for Isolators Î Results Î More Applications Î Summary Packaging Technology 3 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Introduction Î Hydrogen Peroxide is an old sterilant – well established in food industry, where liquid H2O2 is applied for disinfection of packaging material and plastic bottles. Î H2O2 has a broad antimicrobial activity spectrum and shows low toxicity. Î Residues of hydrogen peroxide decompose into neutral species, which underlines the environmental friendliness of this agent: 2 H2O2 ' 2 H2O + O2 Î But: hydrogen peroxide can decompose with fast kinetics – under some circumstances it can explode at high concentrations. Î For complex geometries disinfection with liquid peroxide has limits. For this case H2O2 in the vapor state is widely used. Packaging Technology 4 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 2 Bio-decontamination with H2O2 - Vapor Chemistry / Biocidal Effect Î The hydrogen peroxide molecule has a unique geometry with a high energy angle, which makes splitting of O-O-bond easy: H2O2 ' 2 HO● 2 HO● ' H-O-H + ½O2 Î The decomposition can be catalyzed by metallic surfaces (Cu, Pb, Mg…) – which can be used to decompose after use. On the other side this makes the need for noble surfaces in the equipment to be disinfected. Packaging Technology 5 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Chemistry / Biocidal Effect Î The biocidal effect of hydrogen peroxide comes from the oxygen atom/radical, which is released under influence of the enzyme catalase at the microbiotic surface. The oxidative power of oxygen radicals cause irreversible damage to enzymic systems and DNA. Î A minimum of humditiy at the surface to be treated helps to promote this metabolismism – especially bacterial spores need a basic humidity to show any biochemical activity. Packaging Technology 6 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 3 Bio-decontamination with H2O2 - Vapor Structure Î Introduction z Chemistry / Biocidal Effect z Challenges z Regulatory Î “VHP” for Isolators Î Results Î More Applications Î Summary Packaging Technology 7 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Challenges Î Vaporized Hydrogen Peroxide is used to disinfect bottles and pharmaceutical equipment interior, such as isolators (mini-cleanrooms on top of machinery). Î Pioneer in that technique was AMSCO, later bought by Steris Co., with their VHP® technology back in the 80 ies. Î T [°C] Disadvantage of vaporizing H2O2 are the two physical states present in the system, when using diluted H2O2 for evaporation. This results in different concentrations and thereby in different inactivation efficacy. Gas + liquid Gas state 25 liquid state 2 35 79 Conc. H2O2 [%] Packaging Technology 8 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 4 Bio-decontamination with H2O2 - Vapor Challenges Î Slow evaporation of e.g. 35% H2O2 separates the both components (”destillation”) during transition into vapor. Condensation on the surfaces makes the next separation (“concentration change”). Î Sterilisation means absence of viable microbiotics. In complex geometries this is a challenge, because homogeneous inactivation is required. This can be questioned with vapor/liquid mixtures. Î H202 vapor is known as bio-decontaminating, not sterilizing surfaces – though 6 log inactivation can be achieved/proven. Packaging Technology 9 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Structure Î Introduction z Chemistry / Biocidal Effect z Challenges z Regulatory Î “VHP” for Isolators Î Results Î More Applications Î Summary Packaging Technology 10 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 5 Bio-decontamination with H2O2 - Vapor Regulatory Î In “Guidance for Industry: Sterile Drug Products Produced by Aseptic Processing — Current Good Manufacturing Practice” published by FDA in September 2004, within Appendix 1: Aseptic Processing Isolators the need for decontaminated surfaces is explained: “1. Surface Exposure Decontamination procedures should ensure full exposure of all isolator surfaces to the chemical agent. The capability of a decontaminant to penetrate obstructed or covered surfaces is limited….” Packaging Technology 11 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Regulatory Î Continuation “Aseptic Guidance”: “2. Efficacy The decontamination method should render the inner surfaces of the isolator free of viable microorganisms. Multiple available vaporized agents are suitable for achieving decontamination…. Cycles should be developed with an appropriate margin of extra kill to provide confidence in robustness of the decontamination processes. Normally, a four- to six-log reduction can be justified depending on the application.” “E. Filling Line Sterilization …Where decontamination methods are used to render certain product contact surfaces free of viable organisms, a minimum of a six-log reduction should be demonstrated using a suitable biological indicator.” Packaging Technology 12 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 6 Bio-decontamination with H2O2 - Vapor Regulatory Î Continuation “Aseptic Guidance”: “E. Filling Line Sterilization …Where decontamination methods are used to render certain product contact surfaces free of viable organisms, a minimum of a six-log reduction should be demonstrated using a suitable biological indicator.” Î In EC GUIDE to Good Manufacturing Practice, Annex 1 a list of sterilization techniques (heat, moist heat, radiation, ethylene oxide…) does not include hydrogen peroxide. The description of sterilization/decontamination of isolators does not specifically discuss issues coming from bio-decontamination instead sterilization. Packaging Technology 13 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Regulatory Î In EC GUIDE to Good Manufacturing Practice, Annex 1 a list of sterilization techniques (heat, moist heat, radiation, ethylene oxide…) does not include hydrogen peroxide. The description of sterilization/decontamination of isolators does not specifically discuss issues coming from bio-decontamination instead “sterilization”. Packaging Technology 14 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 7 Bio-decontamination with H2O2 - Vapor Regulatory Î PIC/S Recommendation “Isolators used for Aseptic Processing and Sterility Testing”; Chapter “An expansion of the detailed points to be considered for the implementation of the principles to isolators subjected to a sporicidal process” collects 14 points for the sporicidal process. Point 9.4.1 mentions H2O2 bio-decontamination: “…The agent selected for gas generation should be sporicidal. The agent used for gas generation or other means of application should be capable of rapidly killing bacterial endospores, fungal spores and vegetative microorganisms. … Peracetic acid, hydrogen peroxide and formaldehyde are used. …” Packaging Technology 15 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Structure Î Introduction Î “VHP” for Isolators Î Results Î More Applications Î Summary Packaging Technology 16 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 8 Bio-decontamination with H2O2 - Vapor “VHP” for Isolators Î Vaporized hydrogen peroxide is widely used to decontaminate the inside of pharmaceutical isolators. The good old pioneering days applied a mixture of steam and H2O2 to be on the safe side, but validation was a nightmare. Î Nowadays several H2O2 gas generators are on the market – different philosophy, but more or less reliable technology. Î Cycle development and validation has become a routine job. Packaging Technology 17 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor “VHP” for Isolators Î Isolator design principle Air Management System (HVAC) Unidirectional Air Flow Unit Aseptic Processing Chamber Packaging Technology 18 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 9 Bio-decontamination with H2O2 - Vapor “VHP” for Isolators Example (isolated vial/bottle fill line in Austria) Packaging Technology 19 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor “VHP” for Isolators Î Liquid H2O2 is dropped on a heated plate inside the filter level of an isolator. Recirculation and continous injection of peroxide goes to saturation of atmosphere including strong visible condensation Î H2O2 Closed loop system: Heat plate Filter Open loop system: Liquid hydrogen peroxide is evaporated outside of the isolator in a gas generator; which carries the vapor with air into the Isolator Dry air H2O2 isolator, where it is recirculated. Some o-l-systems perform “flash evaporation”. Packaging Technology 20 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 10 Bio-decontamination with H2O2 - Vapor “VHP” for Isolators Î Î H2O2 Closed loop system: Ò Simple air management Ò Vapor passes filters first Ô Incomplete evaporation Ô Limited injection rate Ô Saturation/condensation soon Open loop system: Ò Complete (“flash”) evaporation Ò Controlled atmosphere Ò Capability for high gas conc. Ô Air management more complex Ô More sophisticated generator H2O2 Packaging Technology 21 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor “VHP” for Isolators Preparation (Phase I) - Expanding gloves, load monitoring goods Conditioning (Phase II) - Injection of H2O2 with a high rate to achieve a high gas concentration H2O2-conc. - Preparation of isolator atmosphere - Preheating of peroxide duct work I+ II Biodecontamination (Phase III) - Injection with a lower rate to replace III IV Process time inactivated peroxide and keep level Aeration (Phase IV) - Removal of H2O2 from injection system Idealized process cycle - Removal of peroxide from all isolator surfaces including filters. Packaging Technology 22 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 11 Bio-decontamination with H2O2 - Vapor “VHP” for Isolators Î Bosch SafeVAP (open loop system) Features: z Venturi transport z 3-step evaporation z Inj.rates up to 80g / min z Controlled atmosphere SafeVAP = Safe Vacuum Assisted Peroxide Evaporation Packaging Technology 23 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor “VHP” for Isolators Î Description Compressed air HVAC Particle filter Blower Evaporator Filter Venturi Peroxide source (35%) Scale Air to isolator Isolator Exhaust air Peroxide duct HEPA H14 Aseptic Processing Chamber Packaging Technology 24 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 12 Bio-decontamination with H2O2 - Vapor “VHP” for Isolators Isolator vol. 8 m³ Description Cycle time 22 min Aeration 1,5 hours Peroxide: 310 g Inj. rate I: 25 g/min Inj. rate II: 9 g/min 800 H2O2 concentration [ppm] 700 600 500 25000 20000 15000 400 10000 300 200 5000 100 0 H2O concentration [ppm] Î 0 -100 5: :0 15 06 -5000 1: :1 15 04 :1 15 7: 02 : 15 1 :0 23 8: :2 15 59 4: :3 15 58 : 15 6 :5 40 : 15 4 :5 46 1 3 :5 52 5: Time Packaging Technology 25 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor “VHP” for Isolators Î Cycle Development for H2O2 biodecontamination include z OQ-studies z tests with chemical indicators (CI’s) z Î Tests with bio indicators (BI’s), which are stainless steel coupons inoculated with 6 log of the most resistant viable (spores of Geobacillus stearothermophilus). To ease handling (and to put an extra challenge on the biological test system), BI’s wrapped in Tyvek became industrial standard. Packaging Technology 26 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 13 Bio-decontamination with H2O2 - Vapor “VHP” for Isolators Air flow study Worst location CIs for H2O2 concentration Air velocity mapping D-value determination Evaluate aeration time Worst location BIs 3 times Safety Evaluation Worst location with triplicate BIs Critical design area Testing Complete Biological Verification Temperature mapping Physical System Evaluation Chemical System Evaluation Biological System Characterization and Optimization Packaging Technology 27 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Structure Î Introduction Î “VHP” for Isolators Î Results z Recent Studies z Results Î More Applications Î Summary Packaging Technology 28 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 14 Bio-decontamination with H2O2 - Vapor Recent Studies Î Many studies were performed at Bosch during the last 3 years (PhD thesis). Basis for these studies was a reference isolator equipped with the SafeVAP system and placed in the Bosch PharmaLab. Packaging Technology 29 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Recent Studies st an da r d co nt ro (E ls S (E -1) SF ( E G) SE (E P ) (E S-G S) (E 443 S 5 ( A - 43 ) lu 01 m in ) iu m (P ) O (E M) PD (P M) VD F (F ) P ( H M) ( P YP A- A ) 12 (P G F VC ) (C -T G R ( P - TI ) VC SS -S ) C H ) (P ( P EE C K- ) N (P at) ET ( P ( P PVC ) EE -U K (P - P ) E- VX U H ) M W (V ) M (T Q ) R FX ) D-Value in min 5 4,5 4 3,5 3 2,5 2 1,5 1 0,5 0 Material av er ag e Goal of this study was to learn the influence of different surfaces (material, finish) on inactivation efficacy of bioburden. Prestudy Mainstudy Poststudy Humidity Study Influence of relative humidity at different H2O2 gas concentration levels was studied and compared with dew point analysis. 2100 20000 1900 1700 15000 1500 1300 10000 1100 900 5000 700 Water concentration [ppm] Î D-Values of tested Materials in Pre-, Main- and Poststudy Material of Construction Study: Hydrogen peroxide concentration [ppm] Î 500 300 00:00 00:02 00:05 00:08 00:11 00:14 0 00:17 Duration of bio-decontamination phase [hh:mm] W ater concentration (humidity level W ater concentration (humidity level W ater concentration (humidity level W ater concentration (humidity level Hydrogen peroxide concentration 4) 3) 2) 1) Packaging Technology 30 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 15 Bio-decontamination with H2O2 - Vapor Structure Î Introduction Î “VHP” for Isolators Î Results z Recent Studies z Results Î More Applications Î Summary Packaging Technology 31 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Results Objective of material study: z z z Examine influence of different construction material surfaces on inactivation of spores Determine variable kill kinetics (D-Value) Test organism: spores of Geobacillus stearothermophilus ATCC 12980 with population of > 1*106 spores per BI. Exposure time [min] 0 5 10 15 20 25 Results + + + - - - + + - - - - + + - - - - Survival Fractio nal Killing Packaging Technology 32 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 16 Bio-decontamination with H2O2 - Vapor Results Results on some materials (50 different surfaces tested) 5 4,5 4 3,5 3 2,5 2 1,5 1 0,5 0 st a nd ar d co nt ro (E ls S (E -1) SF (E G) SE (E P ) (E S-G S) (E 443 S- 5 ) 4 (A l u 301 m in ) iu m (P ) O M (E ) PD (P M) VD F (F ) P (H M) (P YP A- A ) 1 (P 2G F VC ) (C -T G R ( P - TI ) VC SS -S ) C H ) (P (P EE C K- ) N (P at) ET ( P (P PVC ) EE -U K (P -P ) E- VX U H ) M W (V ) M (T Q) R FX ) D-Value in min D-Values of tested Materials in Pre-, Main- and Poststudy av er ag e Material Prestudy Mainstudy Poststudy * No reliable kill Packaging Technology 33 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Results Results on standard control (commercial Bio indicator made from SSL) 1,2 1100 1,0 1000 0,8 900 0,6 800 0,4 700 0,2 600 0,0 Average Concentration of H2O2 in ppm D-Value of Standard Contorls in min D-Values of Standard Controls and average Hydrogen Peroxide Concentration during the Cycles 500 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 Number of Cycle for Material Study D-Value Standard Controls Concentration of Hydrogen Peroxide Packaging Technology 34 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 17 Bio-decontamination with H2O2 - Vapor Results Summary of the study: z z z z z Most materials tested show good inactivation properties. Plastic/elastomeric materials have generally higher D-values compared with stainless steel and glass. Standard commercial available BI’s show a certain spread of D-values (0,2 min to 0,9 min – late positives included in the calculation), which represents microbiobolgical accuracy. A correlation between wetting properties, surface roughness and the entire D-values can be recognized. Critical materials of construction should either be replaced or need prolonging of the cycle time. Packaging Technology 35 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Results The results were recently published: PDA journal, Vol. 61, No. 4, July-August 2007 Packaging Technology 36 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 18 Bio-decontamination with H2O2 - Vapor Results Procedure for Humidity study: z z z z Separate evaporation of water and hydrogen peroxide (35%) Control of humidity level with NIR probe, dew point sensor and standard humidity sensor D - value determination of commercial BI’s (SSL) Investigation on inactivation in hindered surfaces with high aspect ratio 35% liq. H2O2 H2O Packaging Technology 37 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Results 2100 20000 1900 1700 15000 1500 1300 10000 1100 900 5000 700 Water concentration [ppm] Hydrogen peroxide concentration [ppm] Details: 500 300 00:00 00:02 00:05 00:08 00:11 00:14 0 00:17 Duration of bio-decontamination phase [hh:mm] Water concentration (humidity level 4) Water concentration (humidity level 3) Water concentration (humidity level 2) Water concentration (humidity level 1) Hydrogen peroxide concentration Packaging Technology 38 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 19 Bio-decontamination with H2O2 - Vapor Results 400 ppm: Water concentration [ppm] 25000 20000 15000 10000 5000 0 0 2 4 6 8 10 12 14 16 18 20 14 16 18 20 D-value [min] Packaging Technology 39 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Results 600 ppm Water concentration [ppm] 25000 20000 15000 10000 5000 0 0 2 4 6 8 10 12 D-value [min] Packaging Technology 40 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 20 Bio-decontamination with H2O2 - Vapor Results 800 ppm: 25000 Water concentration [ppm] 20000 15000 10000 5000 0 0,0 0,5 1,0 1,5 2,0 2,5 3,0 3,5 D-value [min] Packaging Technology 41 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Results Comparison Wrapped vs. Nude BI’s : 3,0 D-value [min] 2,5 2,0 1,5 1,0 0,5 0,0 Humidity level 1 Humidity level 2 Humidity level 3 Humidity level 4 Humidity level BIs wrapped in Tyvek unpacked BIs Packaging Technology 42 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 21 Bio-decontamination with H2O2 - Vapor Results Correlation of injected H2O2-amount during Cond.phase with D values (mean average) Mittelwert 800ppm 1. FL Mittelwert 800ppm 2. FL Mittelwert 800ppm 3. FL Mittelwert 800ppm 4.FL Mittelwert 600ppm 1. FL Mittelwert 600ppm 2. FL Mittelwert 600ppm 3. FL Mittelwert 600ppm 4. FL Mittelwert 400ppm 1. FL Mittelwert 400ppm 2. FL Mittelwert 400ppm 3. FL Mittelwert 400ppm 4. FL 14,00 D-Wert [min] 12,00 10,00 8,00 6,00 4,00 2,00 0,00 0 100 200 300 400 500 600 700 Injected H2O2 amount [g] Packaging Technology 43 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Results Summary: z z z z The higher the cgas phase concentration, the more independent is the inactivation effect from the humidity level. At lower concentrations the same kill as at higher concentration can be achieved with higher humidity (condensation) The faster the concentration rises during conditioning phase (flash evaporation), the less peroxide is needed to achieve a good kill. (Nano/micro) condensation occurs at all humidity levels. Visible concentration is not needed to get short inactivation times. Packaging Technology 44 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 22 Bio-decontamination with H2O2 - Vapor Structure Î Introduction Î “VHP” for Isolators Î Results Î More Applications Î Summary Packaging Technology 45 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor More Applications Î Vaporized H2O2 is applied with all kinds of isolators: fill/finish isolators, sterility testing isolators, hospital isolators… Î A new trend is fumigation of cleanrooms and animal testing facilities with hydrogen peroxide vapor. Î H2O2 in vapor state could potentially replace alcoholic spray&pray procedures in material transfer chambers and material locks for thermolabile products. Î Bio-decontamination of tubs with presterilized, nested syringes can also be performed with H2O2. Packaging Technology 46 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 23 Bio-decontamination with H2O2 - Vapor Structure Î Introduction Î “VHP” for Isolators Î Results Î More Applications Î Summary Packaging Technology 47 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. Bio-decontamination with H2O2 - Vapor Summary Î Hydrogen peroxide vapor is widely used in pharmaceutical industry. One major application is disinfection of isolator interior. Î Closed and open loop systems are established in the market, which are technically robust and validatable. Î Inactivation effect on bioburden differs depending on the material of construction (material and finish). Î Gas concentration and humidity effect dominate the kill efficacy: high gas concentrations through flash evaporation help to achieve efficient processes. Î New applications of H2O2 vapor include cleanroom fumigation and decontamination of thermolabile materials in transfer chambers, Packaging Technology 48 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 24 Bio-decontamination with H2O2 - Vapor Thank you for your attention ! johannes.rauschnabel@de.bosch.com Packaging Technology 49 PA-PH/EPP | 10/09/2007 | © Robert Bosch GmbH 2007. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. 25